Nitrogen dioxide gas sensor based on SnSe2/SnO2 heterojunction as well as preparation process and application thereof

A gas sensor, nitrogen dioxide technology, applied in the field of nanomaterials, can solve the problems of increasing energy consumption, unsatisfactory gas characteristics, shortening service life, etc., to promote oxygen adsorption, improve gas sensing performance, slow down material aging and damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

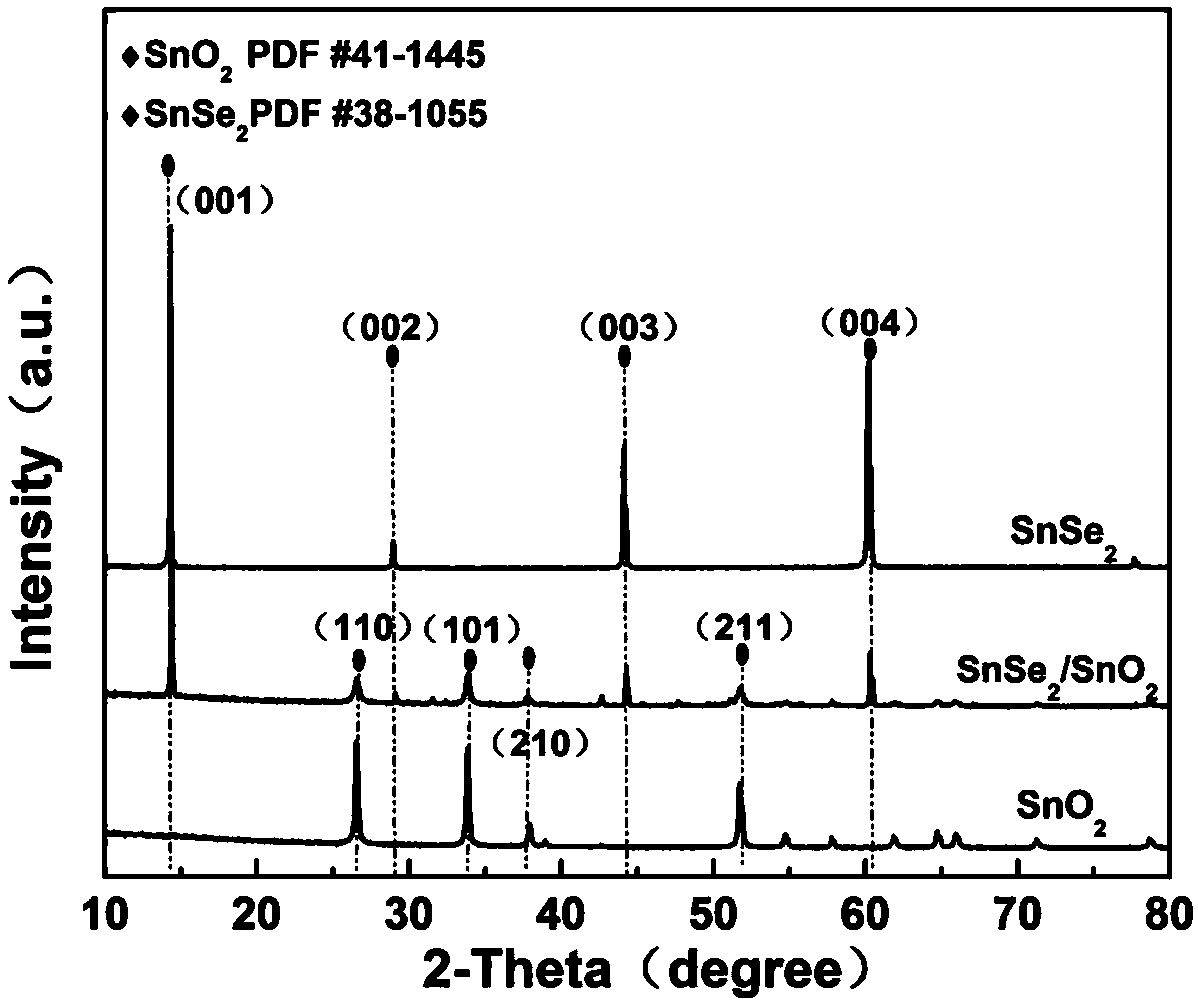

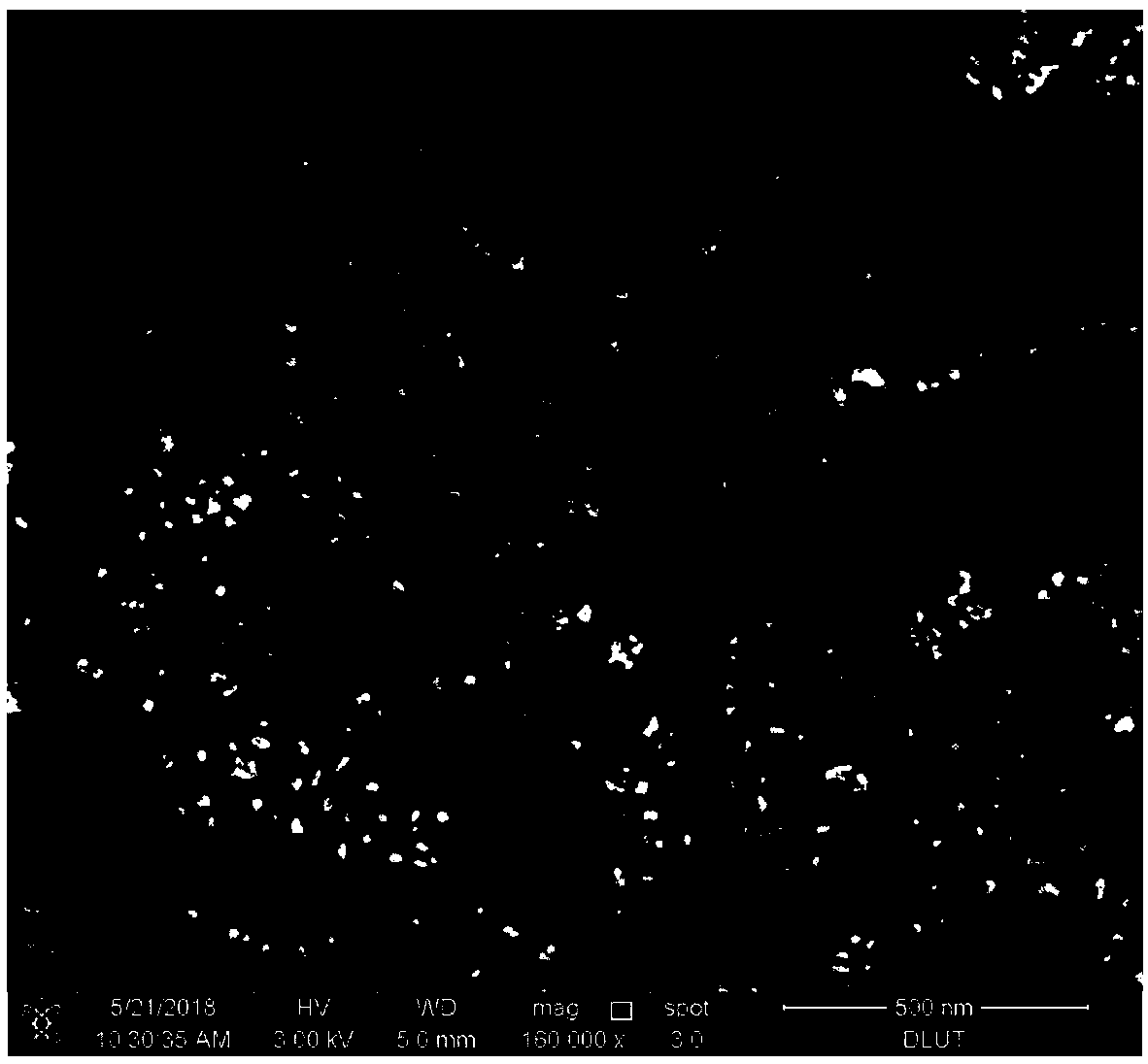

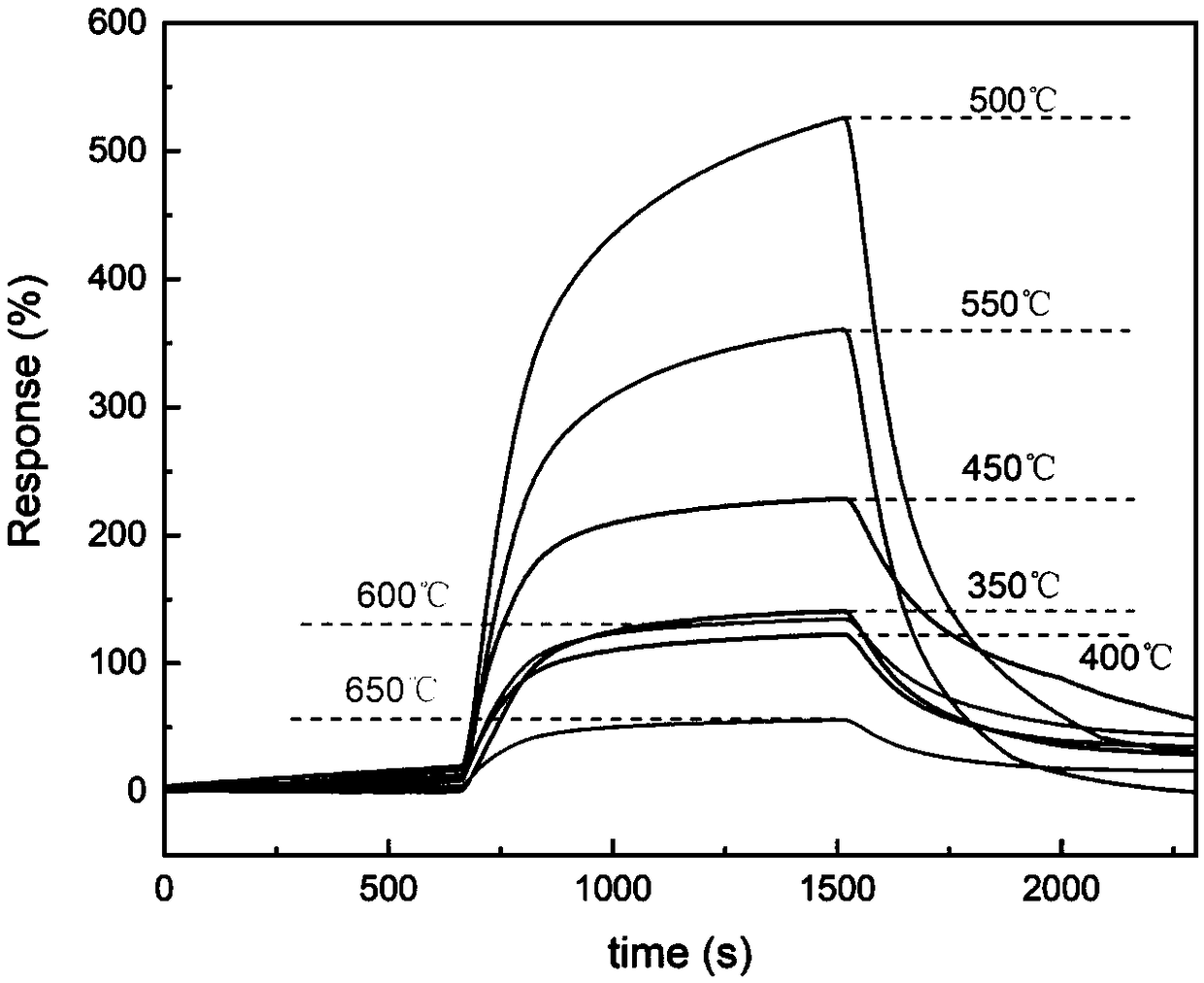

[0032] A SnSe-based 2 / SnO 2 The heterojunction nitrogen dioxide gas sensor is composed of a gas-sensing material and a heating substrate, and the gas-sensing material is coated on the surface of the substrate with a coating thickness of 100 μm. The gas-sensing material is composed of tin diselenide and tin dioxide heterojunction composite nanomaterials formed by calcining at 500° C. for 1 hour. The preparation method comprises the following steps:

[0033] Step 1, preparation of tin diselenide dispersion: put 5mg-10mg of tin diselenide into a mortar, grind for 15 minutes, then disperse the ground tin diselenide powder into 4mg-5mg of deionized water, and ultrasonicate for 1min Treat it into a dispersion liquid of 8 mg / ml-10 mg / ml with an ultrasonic power of 240W-260W, then take the dispersion liquid and apply it to the surface of the substrate, and place it in a drying oven at 60°C for 5 hours to dry.

[0034] Step 2, preparation of tin diselenide and tin dioxide heterojun...

Embodiment 2

[0038] A SnSe-based 2 / SnO 2 The heterojunction nitrogen dioxide gas sensor is composed of a gas-sensing material and a heating substrate, and the gas-sensing material is coated on the surface of the substrate with a coating thickness of 100 μm. The gas-sensing material is composed of tin diselenide and tin dioxide heterojunction composite nanomaterials formed by calcining at 550° C. for 1 hour. The preparation method comprises the following steps:

[0039] Step 1, preparation of tin diselenide dispersion: put 5mg-10mg of tin diselenide into a mortar, grind for 15 minutes, then disperse the ground tin diselenide powder into 4mg-5mg of deionized water, and ultrasonicate for 1min Treat it into a dispersion of 8 mg / ml-10 mg / ml with an ultrasonic power of 240W-260W, then take the dispersion and coat the surface of the substrate, and place it in a drying oven at 60°C for 5 hours.

[0040]Step 2, preparation of tin diselenide and tin dioxide heterojunction: Take out the substrate...

Embodiment 3

[0042] A SnSe-based 2 / SnO 2 The heterojunction nitrogen dioxide gas sensor is composed of a gas-sensing material and a heating substrate, and the gas-sensing material is coated on the surface of the substrate with a coating thickness of 100 μm. The gas-sensing material is composed of tin diselenide and tin dioxide heterojunction composite nanomaterials formed by calcining at 500° C. for 0.5 h. The preparation method comprises the following steps:

[0043] Step 1, preparation of tin diselenide dispersion: put 5mg-10mg of tin diselenide into a mortar, grind for 15 minutes, then disperse the ground tin diselenide powder into 4mg-5mg of deionized water, and ultrasonicate for 1min Treat it into a dispersion of 8 mg / ml-10 mg / ml with an ultrasonic power of 240W-260W, then take the dispersion and coat the surface of the substrate, and place it in a drying oven at 60°C for 5 hours.

[0044] Step 2, preparation of tin diselenide and tin dioxide heterojunction: Take out the substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com