Preparation method for acetone gas sensor

An acetone gas sensor and sensor technology, which is applied to the preparation of gas sensors and the field of preparation of acetone gas sensors, can solve the problems of high working temperature and high power consumption, and achieve fast response recovery time and good gas sensor selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Embodiment A kind of preparation method of acetone gas sensor

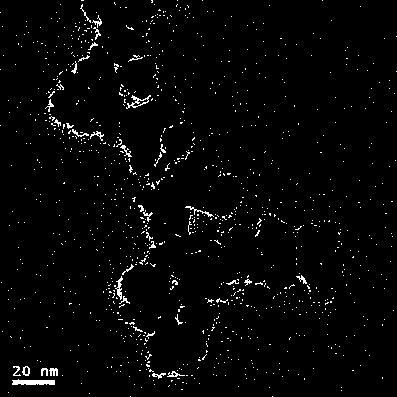

[0023] The acetone gas sensor adopts a side-heating device structure, with an alumina ceramic tube as a carrier, a platinum wire as a noble metal electrode lead, and an alumina ceramic tube as a sensitive element tube, which is coated with tin dioxide and polypyrrole hybrid. Material.

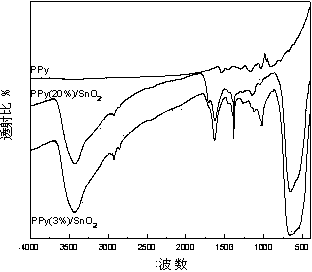

[0024] 1. Synthesis of tin dioxide and polypyrrole hybrid materials

[0025] 1. Synthesis method one

[0026] Take 50ml of distilled water and adjust its H with hydrochloric acid + The concentration is about 1mol / L, add 1mg of pyrrole, and ultrasonically disperse the solution for 30min. Another 95 mg of tin dioxide was added. After the mixture was stirred and ultrasonicated for 30 minutes, it was transferred to a reaction kettle, and 2.42 mg of ferric chloride was added. Place the reaction kettle in an oven at 140°C for 8 hours of hydrothermal reaction. After the reaction is complete, take out the reaction kettle and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com