Preparation method of sensitive material with specificity to formaldehyde gas

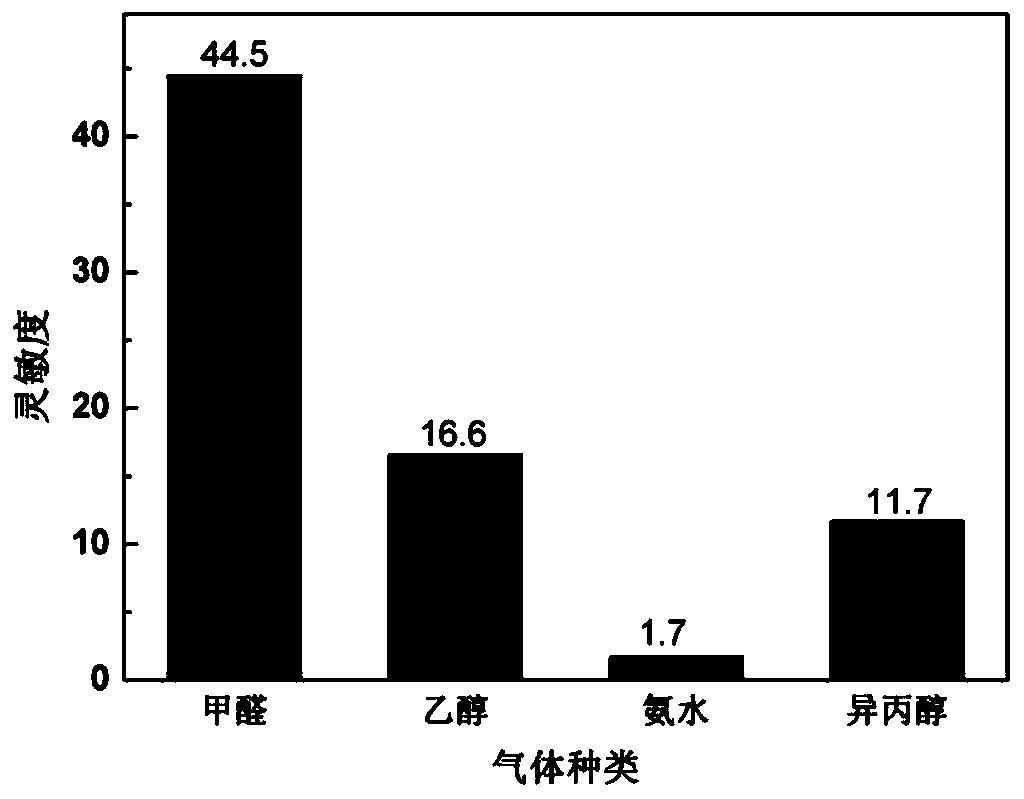

A formaldehyde gas and sensitive material technology, applied in the direction of analysis of materials, material resistance, material analysis through electromagnetic means, etc., can solve the problems of selectivity and anti-interference ability to be improved, and achieve the promotion of carrier separation and transfer, preparation Simple steps and high sensitivity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing a sensitive material specific to formaldehyde gas provided by the invention comprises the following steps:

[0023] 1) Weigh 30mg of graphene oxide, add it into 15mL of deionized water, and carry out ultrasonic dispersion, the ultrasonic power is 80-100W, and the time is 4h, to obtain GO suspension A;

[0024] 2) Mix 1mmol citric acid, 300mg glucose and 1-3mmol SnCl 2 2H 2 O was added to 15mL deionized water, and stirred vigorously on a magnetic stirrer until all soluble matter was dissolved to obtain solution B;

[0025] 3) Mix suspension A with solution B so that GO and SnCl 2 2H 2 The mass ratio of O is 1:5 to 1:25, and then urea and ammonia water are added in a certain proportion, so that the mass ratio of GO to urea is 1:100 to 1:300, that is, the mass of urea is 3-9g, so that urea The molar ratio to ammonia water is 3:1-1:3, that is, the volume of ammonia water is 0.7-17.3mL, and mixed solution C is obtained;

[0026] 4) Then transfer t...

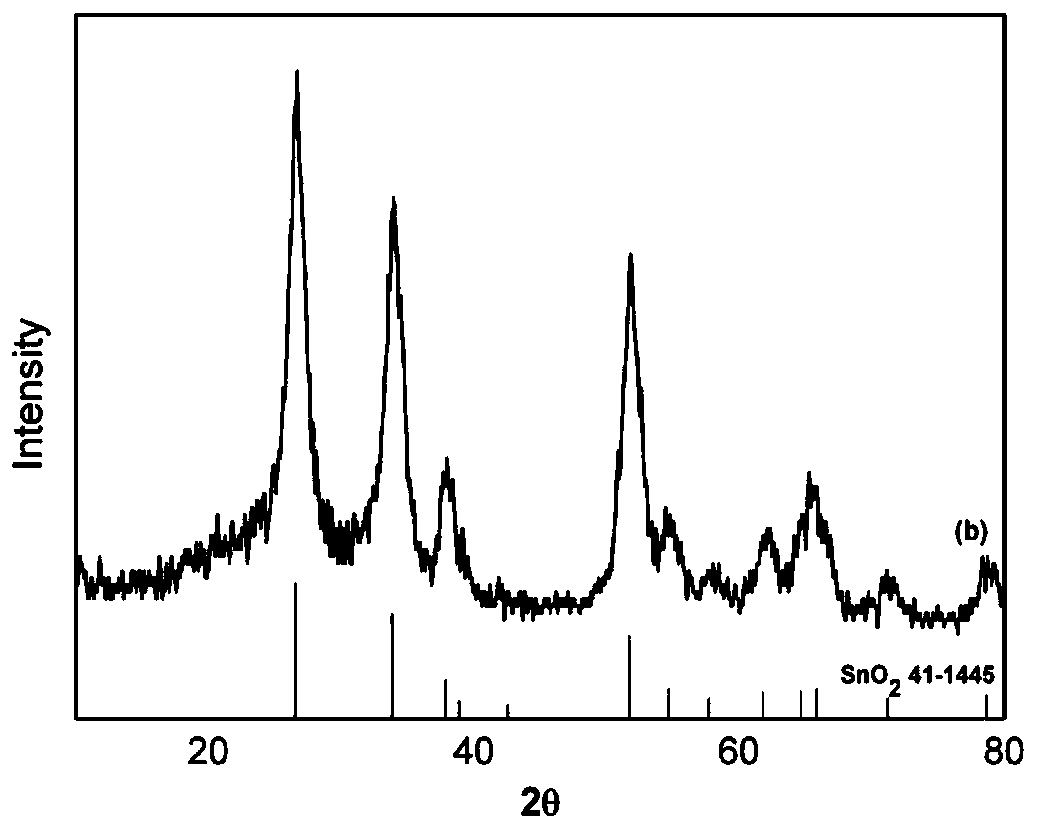

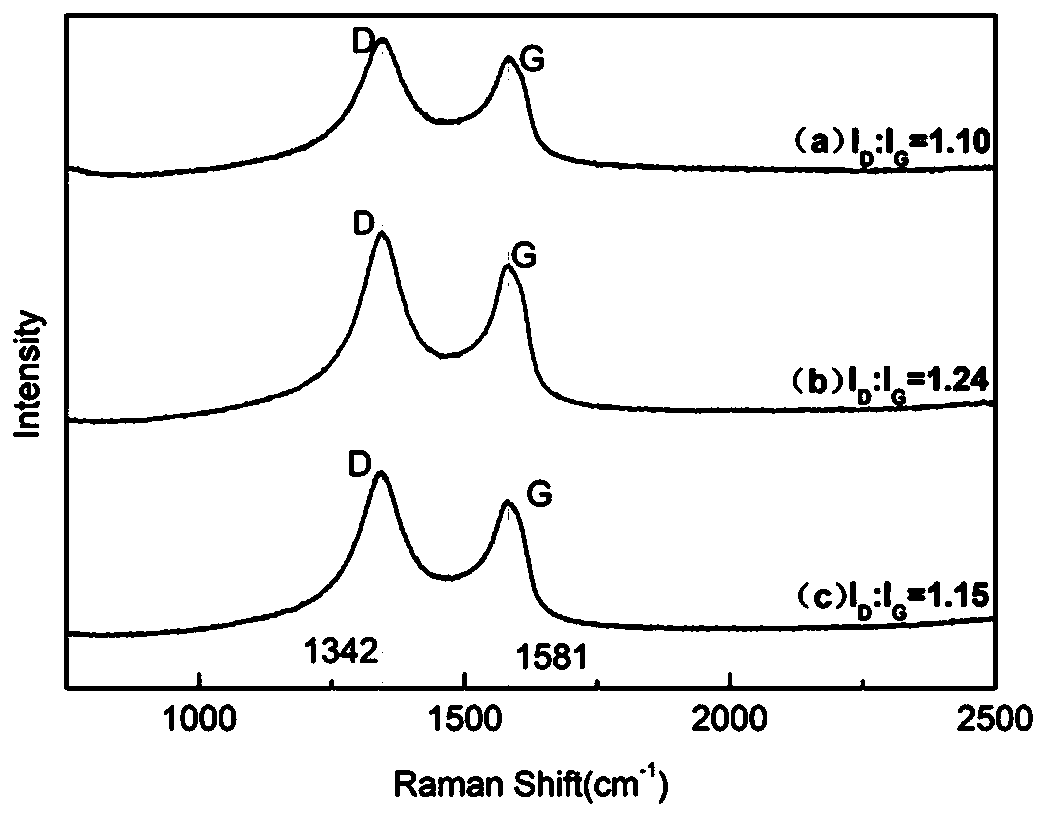

Embodiment 1

[0031] 1) Weigh 30mg of graphene oxide, add it into 15mL deionized water, and carry out ultrasonic dispersion, the ultrasonic power is 400W, and the time is 4h, to obtain GO suspension A;

[0032] 2) 1mmol of citric acid, 300mg of glucose and 2mmol of SnCl 2 2H 2 O was added to 15mL deionized water, and stirred vigorously on a magnetic stirrer until all soluble matter was dissolved to obtain solution B;

[0033] 3) Mix suspension A with solution B so that GO and SnCl 2 2H 2 The mass ratio of O is 1:15, then add urea and ammoniacal liquor, make the mass ratio of GO and urea in the solution be 1:100, promptly urea quality is 3g, and the molar ratio of ammoniacal liquor and urea is 3:1, promptly ammoniacal liquor volume is 0.7mL to obtain mixed solution C;

[0034] 4); Then transfer the solution C to the reaction kettle, install it in the microwave / ultraviolet / ultrasonic three-in-one reactor, and use the pressure control mode to carry out the microwave hydrothermal reaction, ...

Embodiment 2

[0037] 1) Weigh 30 mg of graphene oxide, add it into 15 mL of deionized water, and carry out ultrasonic dispersion, the ultrasonic power is 500W, and the time is 4h, to obtain GO suspension A;

[0038] 2) 1mmol of citric acid, 300mg of glucose and 1mmol of SnCl 2 2H 2 O was added to 15mL deionized water, and stirred vigorously on a magnetic stirrer until all soluble matter was dissolved to obtain solution B;

[0039] 3) Mix suspension A with solution B so that GO and SnCl 2 2H 2 The mass ratio of O is 1:7.5, then add urea and ammoniacal liquor, make the mass ratio of GO and urea in the solution be 1:200, promptly urea quality is 6g, and the molar ratio of ammoniacal liquor and urea is 1:1, promptly ammoniacal liquor volume is 3.9mL to obtain mixed solution C;

[0040] 4) Then transfer the solution C to the reaction kettle, install it in the microwave / ultraviolet / ultrasonic three-in-one reactor, and use the pressure control mode to carry out the microwave hydrothermal react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com