Preparation method of PAA/AgNPs composite flexible ammonia gas sensor

A kind of ammonia sensor, a flexible technology, applied in the direction of instruments, scientific instruments, metal processing equipment, etc., can solve the problems of expensive conductive organic matter, material toxicity, etc., and achieve industrial production, low production cost, and large-scale manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

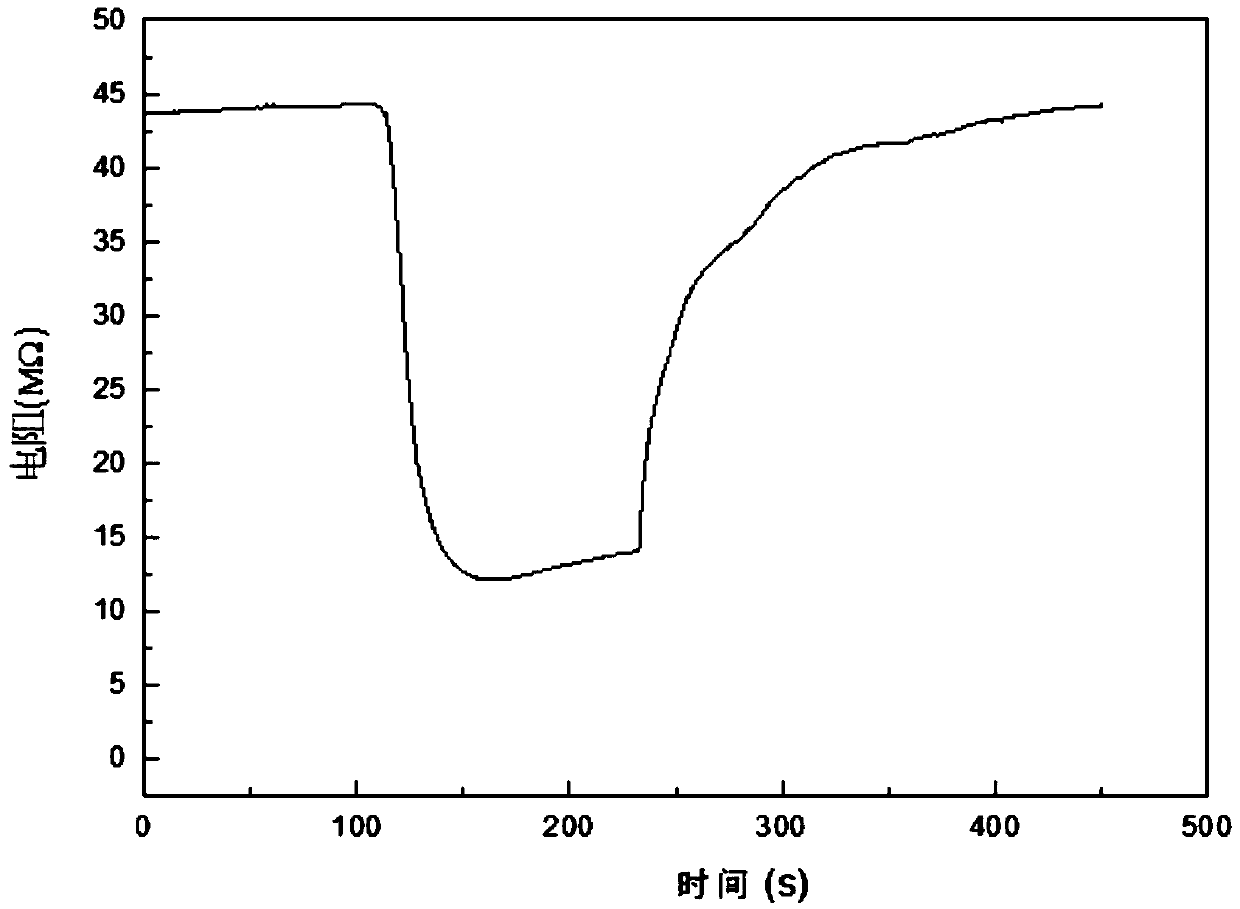

Image

Examples

Embodiment 1

[0024] The preparation method of the PAA / AgNPs composite flexible ammonia sensor of embodiment 1 comprises the following steps:

[0025] (1) Prepare the polyimide flexible substrate, ultrasonically clean the flexible substrate with ethanol and acetone for 10 minutes, and then heat-treat at 80°C for 20 minutes;

[0026] (2) Inkjet printing silver conductive ink on a flexible substrate, and then heat treatment at 100°C for 10 minutes to prepare a silver interdigitated electrode layer on a flexible substrate;

[0027] (3) Weigh 3g of polyacrylic acid with a molecular weight of 5000 and 40g of diethanolamine into 50mL of deionized water, stir magnetically for 2 hours to obtain solution A; weigh 15g of silver nitrate into 20mL of deionized water, and ultrasonically shake for 5 minutes, then Slowly add dropwise into the stirring solution A to obtain solution B, then react at 30°C for 17 hours, and then react at 70°C for 6 hours to obtain solution C; then add 200mL of ethanol to solu...

Embodiment 2

[0031] The polyacrylic acid / silver particle composite material of embodiment 2 is the preparation method of the flexible ammonia sensor of base, comprises the following steps:

[0032] (1) Prepare a polyethylene terephthalate flexible substrate, ultrasonically clean the flexible substrate with ethanol and acetone for 10 minutes, and then heat-treat at 80°C for 10 minutes;

[0033] (2) Inkjet printing silver conductive ink on a flexible substrate, and then heat treatment at 100°C for 10 minutes to prepare a silver interdigitated electrode layer on a flexible substrate;

[0034] (3) Weigh 1g of polyacrylic acid with a molecular weight of 5000 and 8g of monoethanolamine into 50mL of deionized water, stir magnetically for 1 hour to obtain solution A; weigh 6g of silver acetate into 10mL of deionized water, and ultrasonically shake for 5 minutes, then Slowly add dropwise to the stirring solution A to obtain solution B, then react at 40°C for 10 hours to obtain solution C; then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com