Hydrogen isotope purification filter

A technology for purifying filters and hydrogen isotopes, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation. Efficiency and the effect of ensuring filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

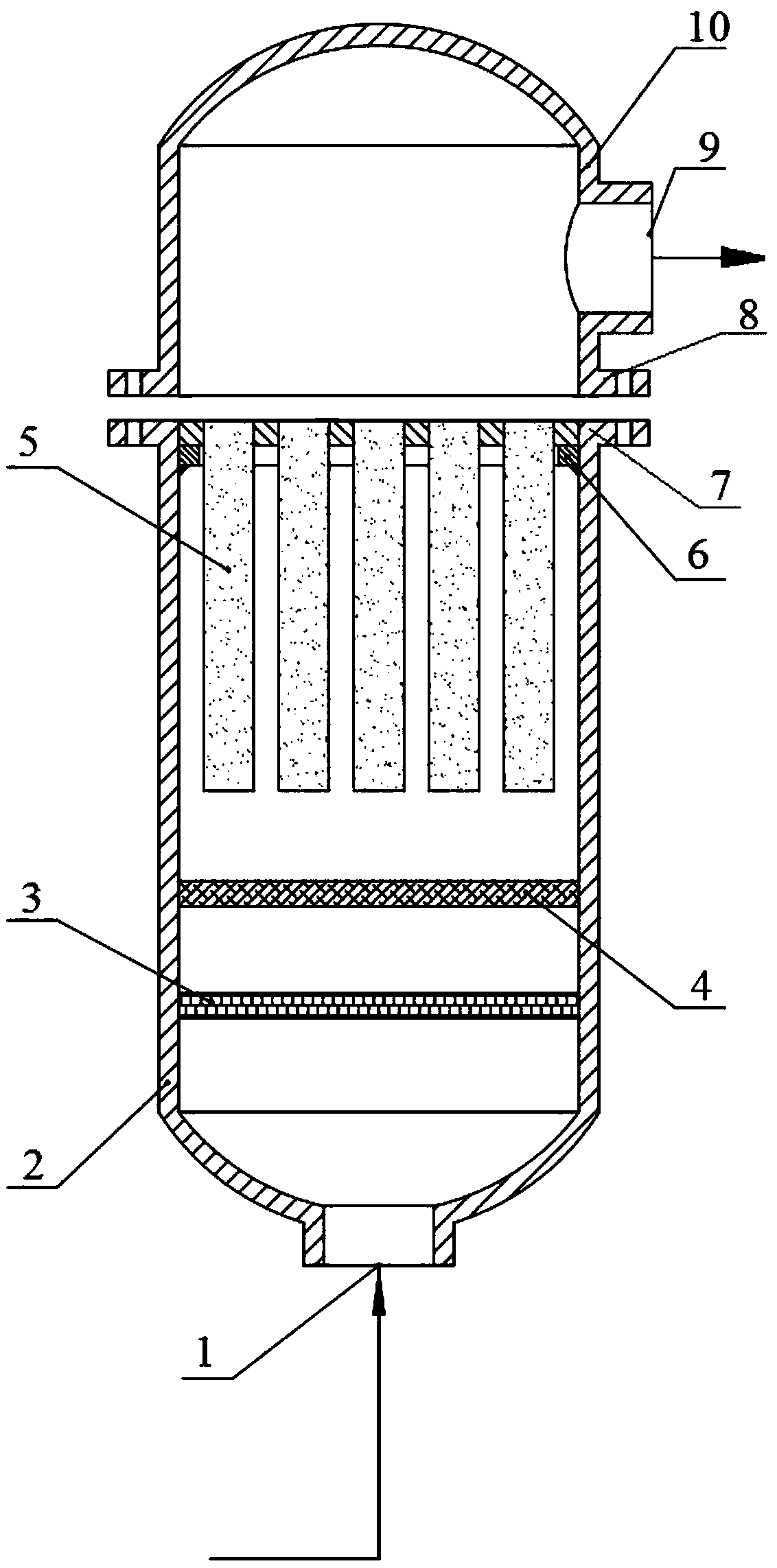

[0026] Such as figure 1 As shown, the hydrogen isotope purification filter of this embodiment is composed of an upper casing 10 and a lower casing 2, the lower end of the lower casing 2 is provided with an air inlet 1, and the lower casing 2 is provided with an air inlet along the air inlet The mouth 1 is provided with a coarse filter element 3 and a primary filter element 4 in parallel in turn, the upper end ring of the lower casing 2 is provided with a lower flange 7, and the upper wall of the lower casing 2 is provided with a The annular boss 6 is equipped with a secondary filter element 5 on the annular boss 6, the secondary filter element 5 is perpendicular to the primary filter element 4, and the upper end ring of the upper casing 10 is provided with a The upper flange 8 is fixedly connected by bolts between the lower flange 7 and the upper flange 8, and the side of the upper housing 10 is provided with an exhaust port 9; the filtration accuracy of the coarse filter elem...

Embodiment 2

[0028] Such as figure 1 As shown, the hydrogen isotope purification filter of this embodiment is composed of an upper casing 10 and a lower casing 2, the lower end of the lower casing 2 is provided with an air inlet 1, and the lower casing 2 is provided with an air inlet along the air inlet The mouth 1 is provided with a coarse filter element 3 and a primary filter element 4 in parallel in turn, the upper end ring of the lower casing 2 is provided with a lower flange 7, and the upper wall of the lower casing 2 is provided with a The annular boss 6 is equipped with a secondary filter element 5 on the annular boss 6, the secondary filter element 5 is perpendicular to the primary filter element 4, and the upper end ring of the upper casing 10 is provided with a The upper flange 8 is fixedly connected by bolts between the lower flange 7 and the upper flange 8, and the side of the upper housing 10 is provided with an exhaust port 9; the filtration accuracy of the coarse filter elem...

Embodiment 3

[0030] The difference between this example and Example 2 lies in that the mass content of Ag in the PdAg is 23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com