Preparation method of spherical CSNS-Amine nanostructure CO2 adsorbent

A nanostructure and adsorbent technology, which is applied in the field of amine grafting modified adsorbent preparation, can solve the problems of reduced adsorption capacity and poor cycle stability, and achieves the effect of high selectivity and improved cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

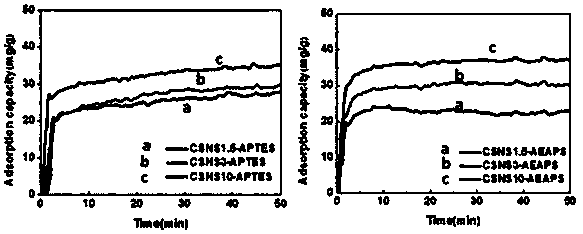

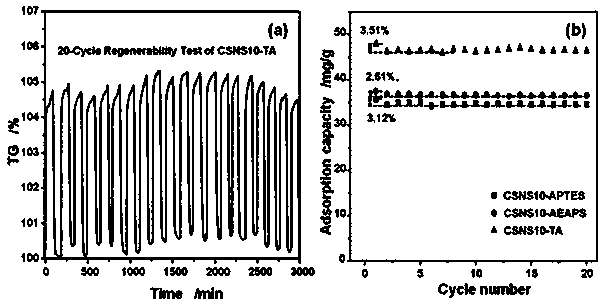

Embodiment 1

[0025] First, dissolve 5mL tetraethyl orthosilicate in a mixture of 20mL deionized water and 260mL absolute ethanol, then add 14mL ammonia water into the above mixture and mix evenly, and mechanically stir for 3 hours at room temperature; after the reaction is completed, put the milky white liquid in Centrifuge at 7000r / min for 2min; wash the obtained white gum with water and ethanol, and dry it at 60°C. Weigh 0.52g of colloidal sphere A and ultrasonically disperse it in 160mL of deionized water, and simultaneously add 2.8mmol of Cu(NO 3 ) 2 ・3H 2 O and 24 mL NH 3 ・H 2 O was dissolved in 240mL deionized water to form a blue cuproammonia solution; the colloidal ball emulsion and the cuproammonia solution uniformly dispersed by ultrasound were quickly poured into a round bottom flask with mechanical stirring, stirred for 10-20min, and then transferred to high pressure In the hydrothermal reaction kettle, the hydrothermal reaction was carried out at 140°C for 1.5h, and the bl...

Embodiment 2

[0027] This embodiment is to change the hydrothermal reaction time on the basis of embodiment 1.

[0028]First, dissolve 5mL tetraethyl orthosilicate in a mixture of 20mL deionized water and 260mL absolute ethanol, then add 14mL ammonia water into the above mixture and mix evenly, and mechanically stir for 3 hours at room temperature; after the reaction is completed, put the milky white liquid in Centrifuge at 7000r / min for 2min; wash the obtained white gum with water and ethanol, and dry it at 60°C. Weigh 0.52g of colloidal sphere A and ultrasonically disperse it in 160mL of deionized water, and simultaneously add 2.8mmol of Cu(NO 3 ) 2 ・3H 2 O and 24 mL NH 3 ・H 2 O was dissolved in 240mL deionized water to form a blue cuproammonia solution; the colloidal ball emulsion and the cuproammonia solution uniformly dispersed by ultrasound were quickly poured into a round bottom flask with mechanical stirring, stirred for 10-20min, and then transferred to high pressure In the hy...

Embodiment 3

[0030] In this example, on the basis of Example 1, the type of organic amine to be loaded is changed.

[0031] First, dissolve 5mL tetraethyl orthosilicate in a mixture of 20mL deionized water and 260mL absolute ethanol, then add 14mL ammonia water into the above mixture and mix evenly, and mechanically stir for 3 hours at room temperature; after the reaction is completed, put the milky white liquid in Centrifuge at 7000r / min for 2min; wash the obtained white gum with water and ethanol, and dry it at 60°C. Weigh 0.52g of colloidal spheres and ultrasonically disperse them in 160mL of deionized water, while 2.8mmol of Cu(NO 3 ) 2 ・3H 2 O and 24 mL NH 3 ・H 2 O was dissolved in 240mL deionized water to form a blue cuproammonia solution; the colloidal ball emulsion and the cuproammonia solution uniformly dispersed by ultrasound were quickly poured into a round bottom flask with mechanical stirring, stirred for 10-20min, and then transferred to high pressure In the hydrothermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com