Device for treating organic smelly waste gas by utilizing coupled dielectric barrier discharge plasma

A dielectric barrier discharge and plasma technology is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., to achieve the effects of saving equipment investment costs, eliminating secondary pollution, and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

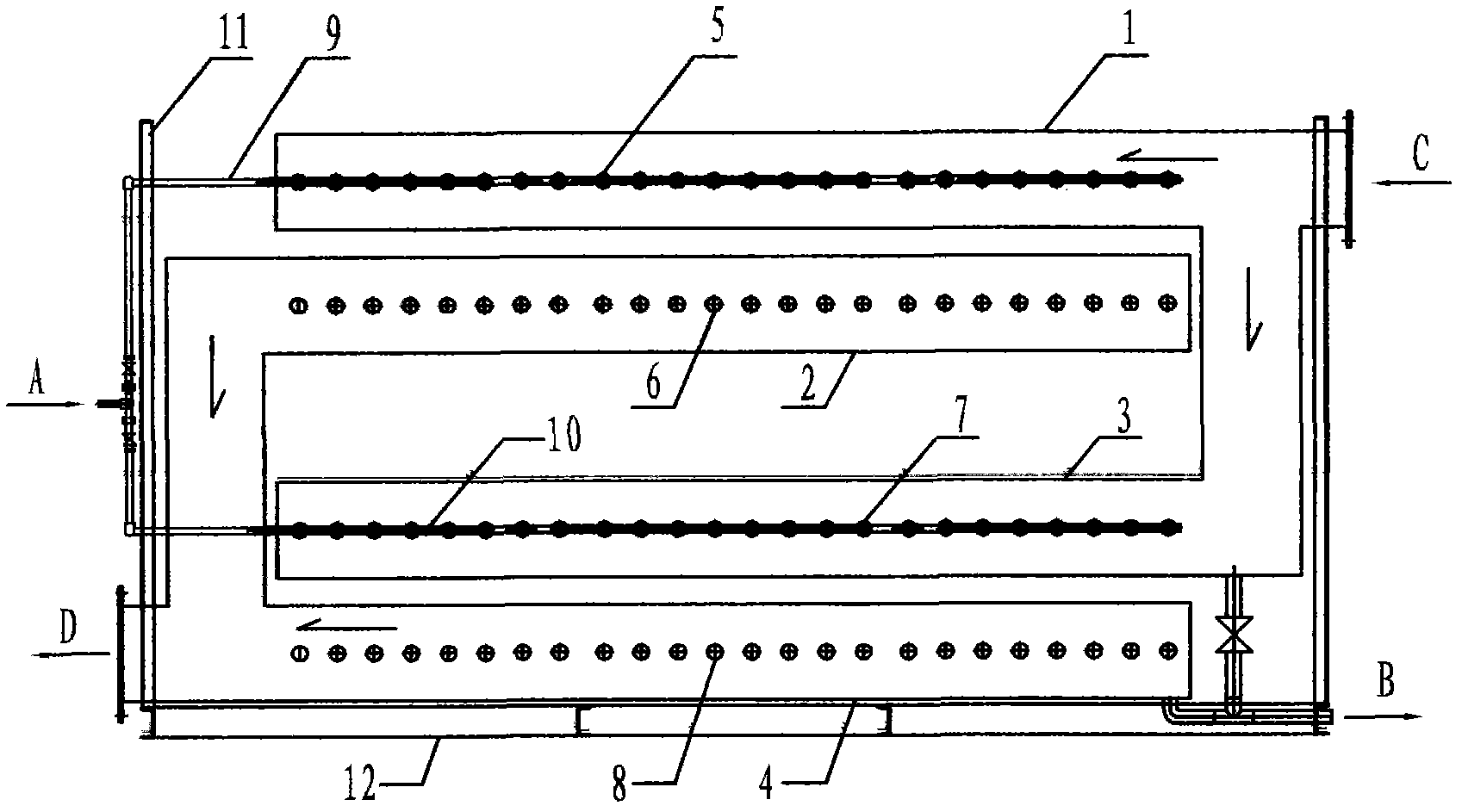

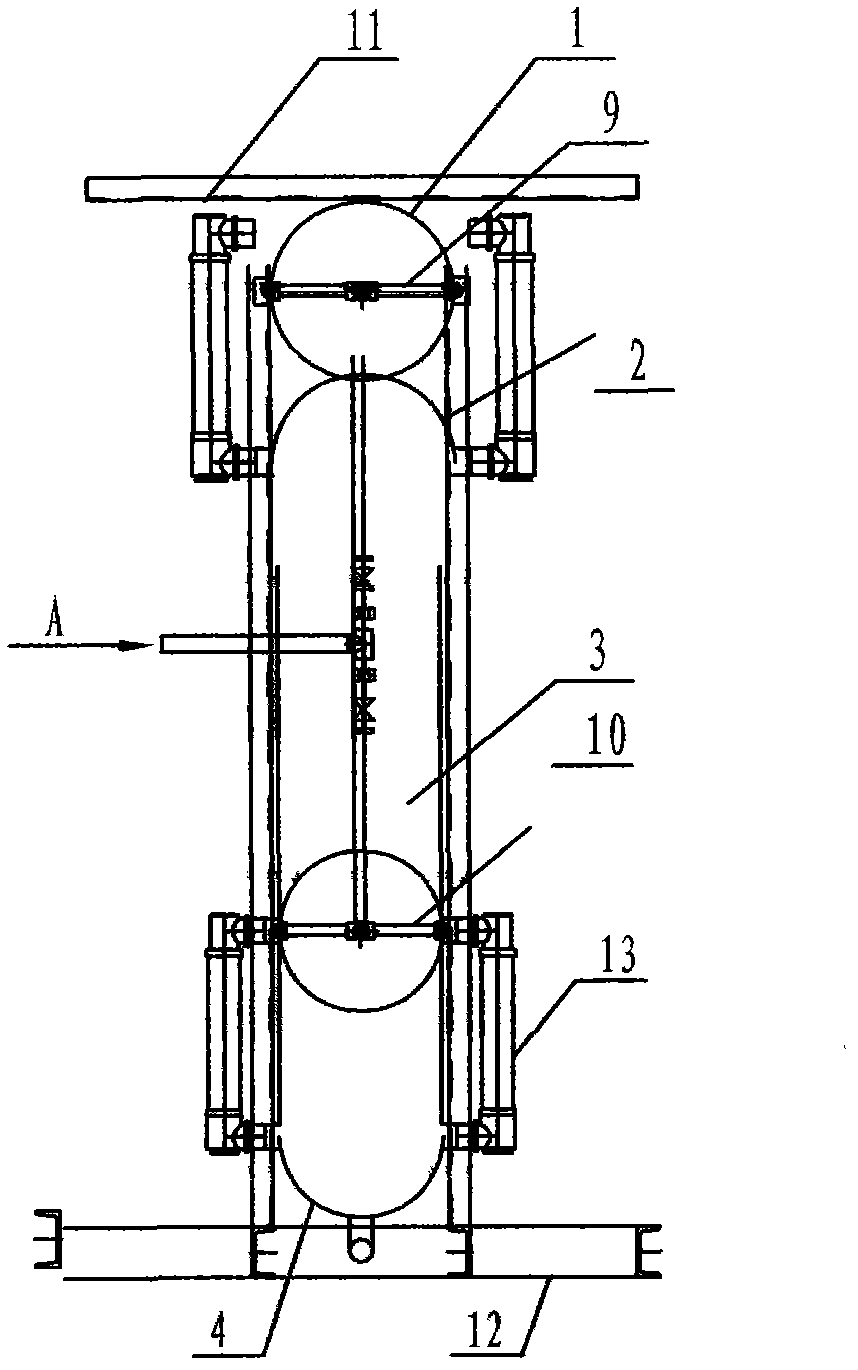

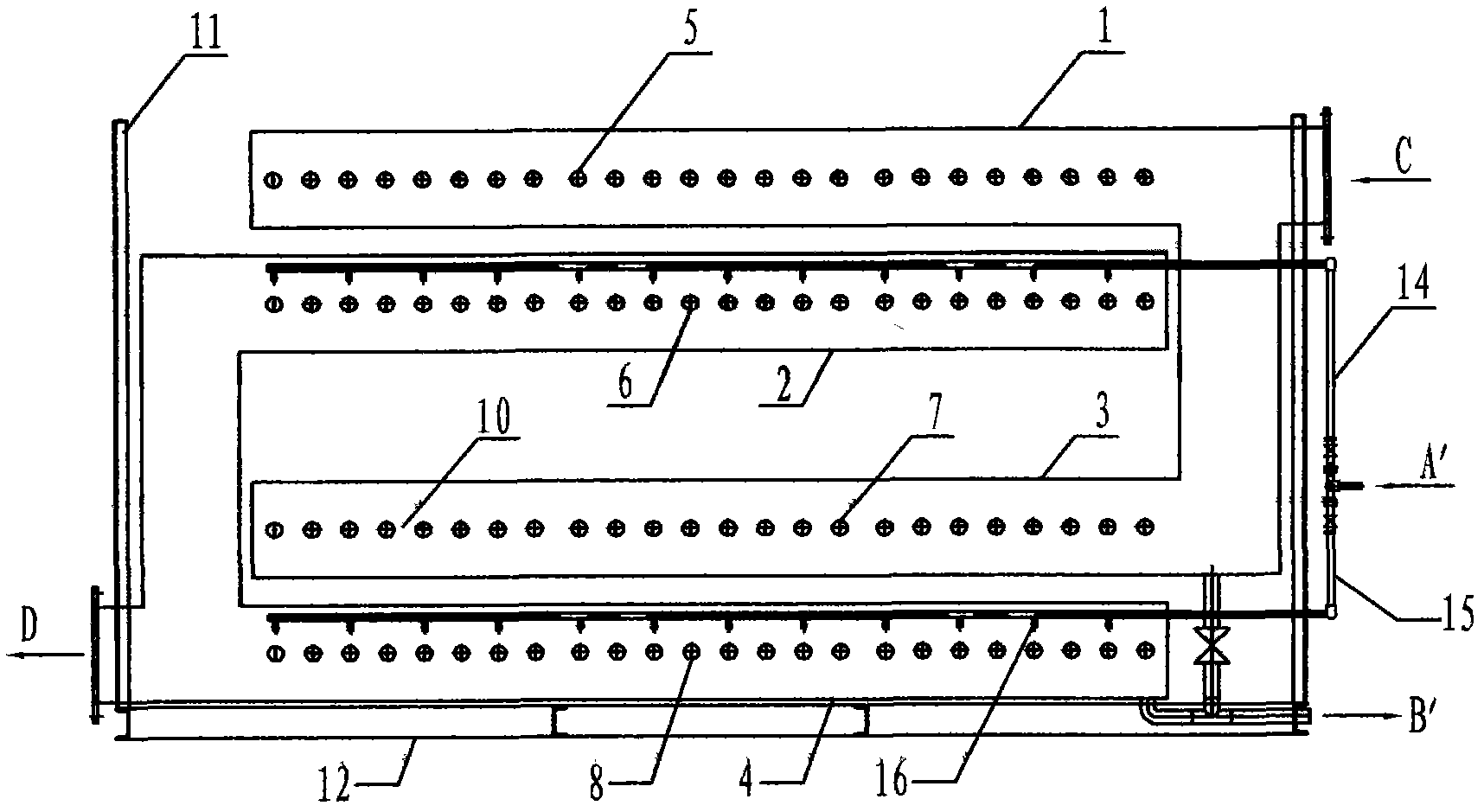

[0028] Examples Select toluene, a representative organic pollutant, as the treatment object to illustrate the implementation and treatment effect of the sleeve-type DBD plasma-coupled discharge tube flushing system and the outlet air collection pipe spray system.

[0029] Under the action of induced draft fan, the concentration is 850mg / m 3 The toluene-containing organic odor gas enters the coupled dielectric barrier discharge plasma reaction device. The gas treated by the plasma reactor is dewatered by the water eliminator and then discharged from the chimney. It is sampled and analyzed at 1m from the outlet of the induced draft fan. The accuracy of each sampling is fixed, and the sampling starts after the reactor runs stably for 30 minutes.

[0030] Coupled DBD plasma reactor: 1 set, processing capacity 3000m 3 / h.

[0031] The number of discharge tubes assembled is 96 pieces.

[0032] Use 1% lye as discharge tube flushing solution.

[0033] The sprinkler system uses H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com