Windowing type corrugated packing sheet

A corrugated packing sheet and corrugated packing technology are applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., and can solve the problems of interpenetration, biting, uneven gas-liquid distribution, and transmission of corrugated packing sheets. Heat, low mass transfer efficiency and other problems, to achieve the effect of easy processing and production, good gas-liquid distribution effect, and increased production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

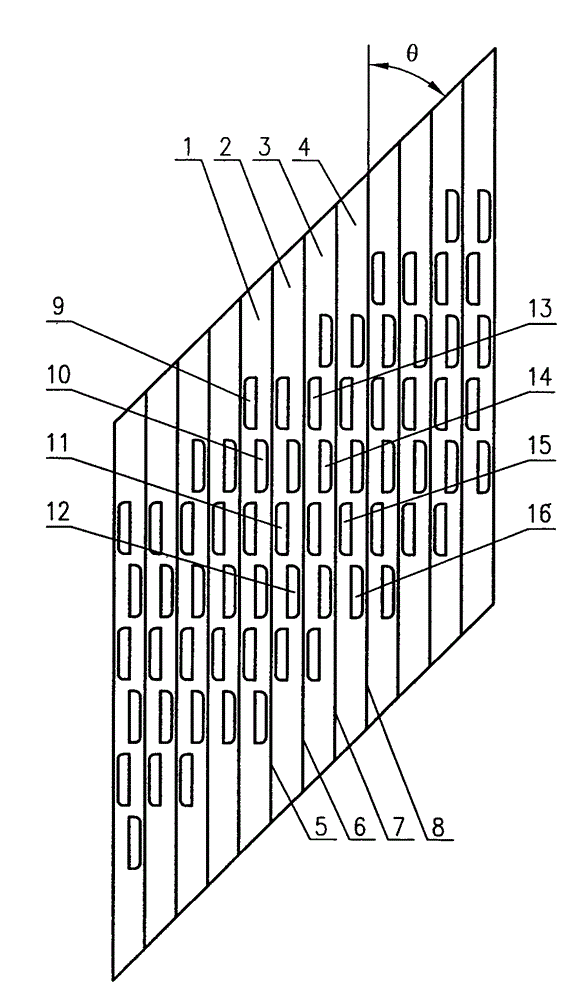

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

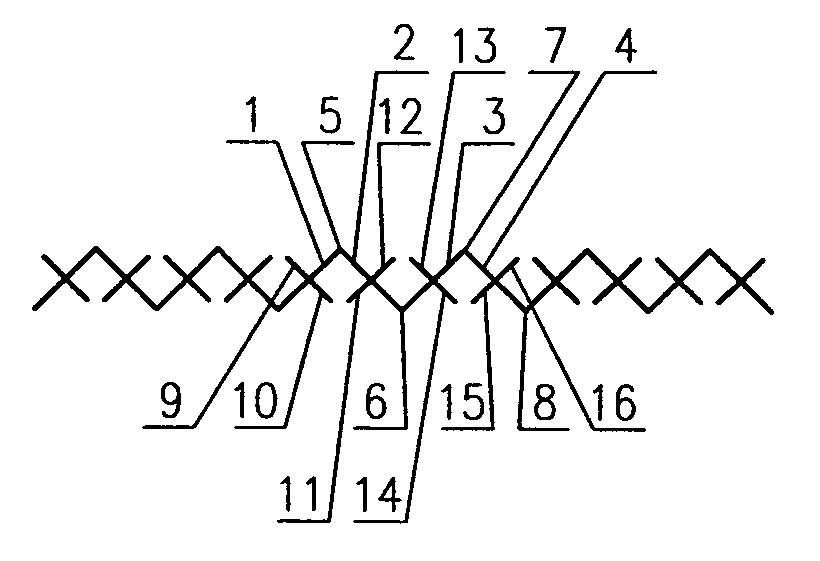

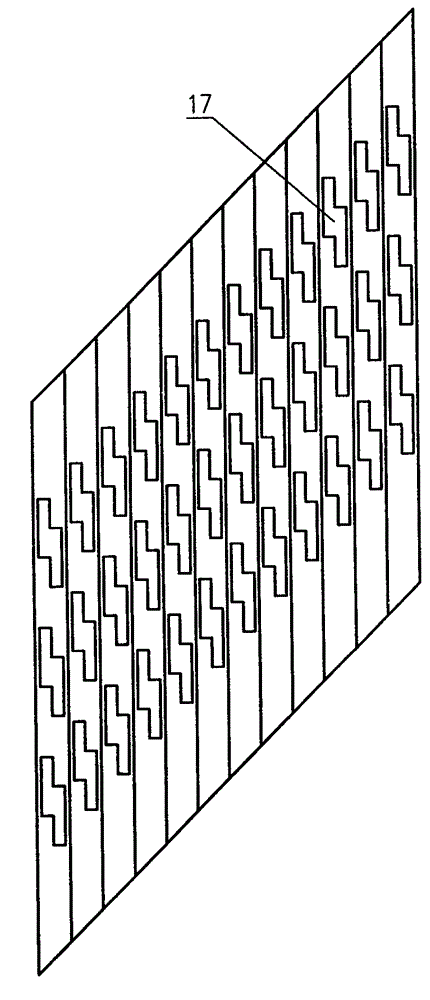

[0018] The present invention is mainly composed of a plurality of window-type corrugated packing units that circulate continuously. The left and right packing corrugations of each window-type corrugated packing unit are composed of four strip-shaped packing surfaces: left I packing surface [1], Left II packing surface [2], right III packing surface [3] and right IV packing surface [4], each two adjacent strip packing surfaces in the four strip packing surfaces intersect to form four ridges: left I packing Surface [1] intersects with left II filler surface [2] to form upper left ridgeline [5]; left II filler surface [2] intersects with right III filler surface [3] to form lower middle ridgeline [6]; right III filler Surface [3] intersects with right IV packing surface [4] to form upper right ridge line [7]; right IV packing surface [4] intersects with left I packing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com