Lantern-ring bulk packing

A technology of bulk packing and collars, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as heat transfer, low mass transfer efficiency, low strength, small specific surface area, etc. , to achieve good gas-liquid distribution, increased carrying capacity, and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

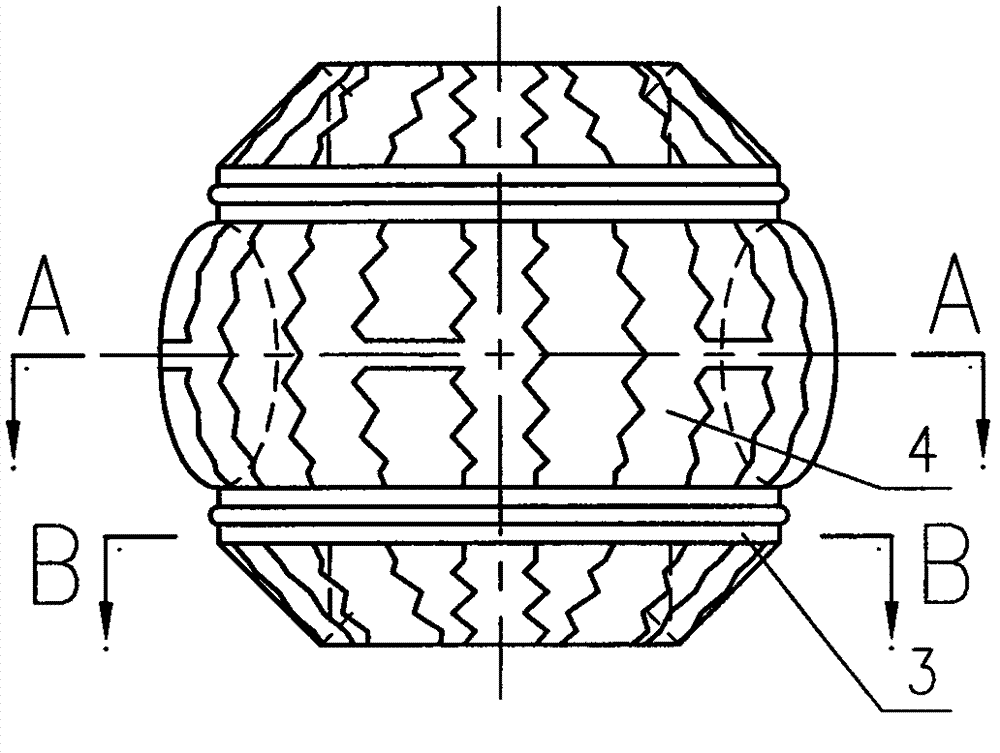

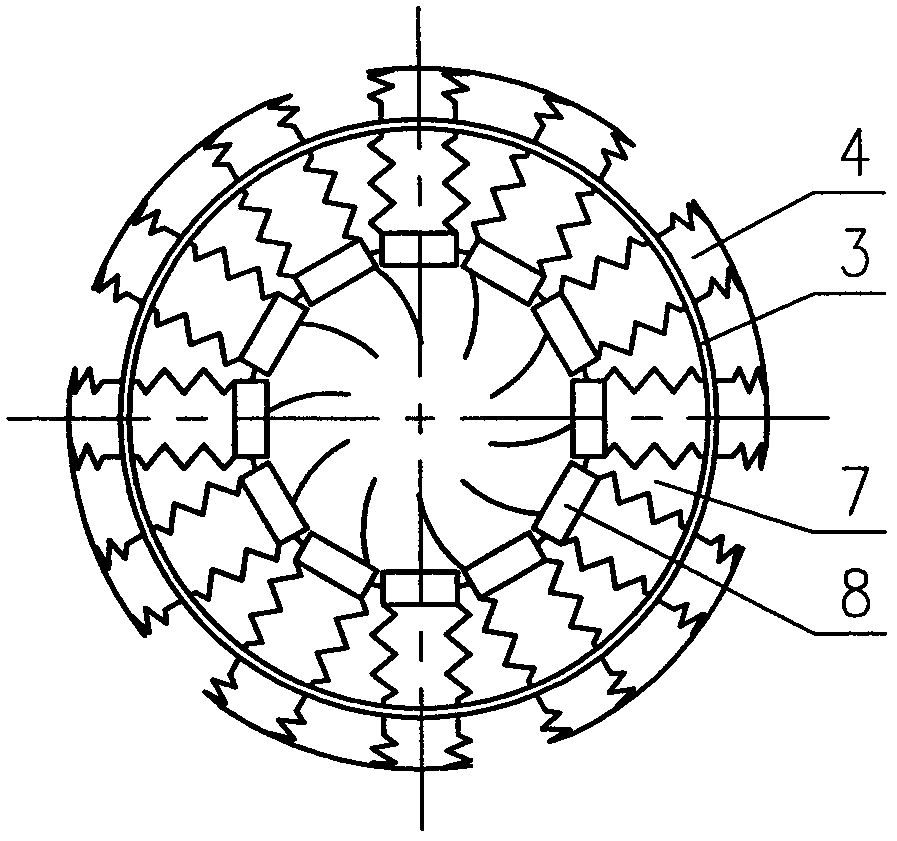

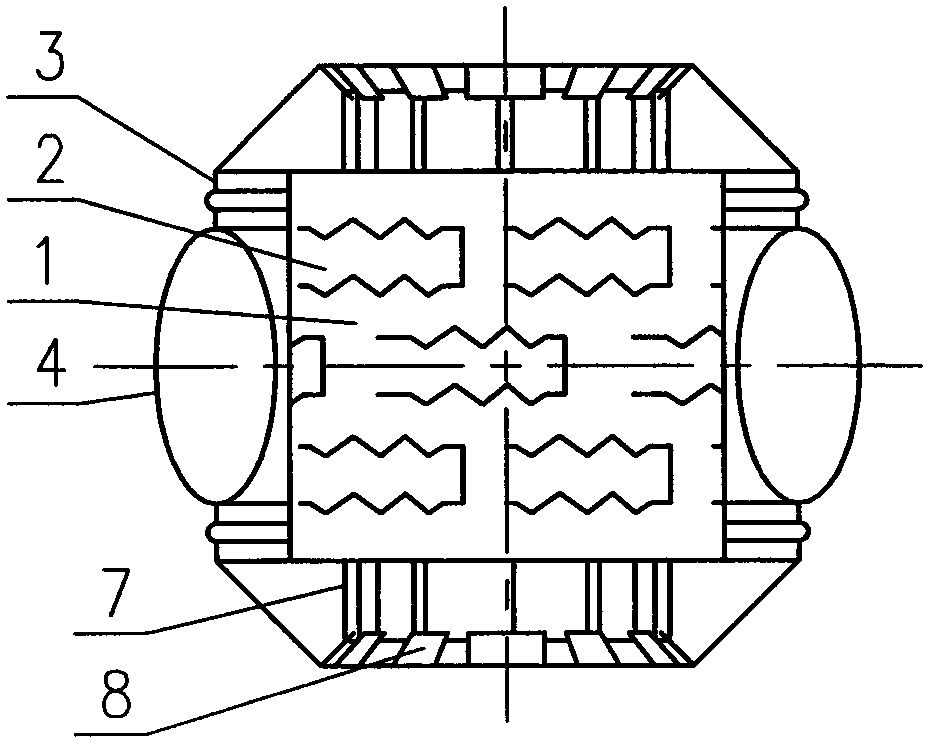

[0033] The present invention is mainly composed of an outer ring surface and an inner ring surface, and the inner ring surface is sleeved at the center of the outer ring surface. Each inner ring surface has a long cylindrical surface [1], on which there are 1 to 5 rows of holes, the number of holes in each row is 2 to 9, two adjacent rows of holes are arranged in a staggered manner, and each hole is provided with a The inner meander piece [2] with a curved central axis of the long cylindrical surface [1] is provided with teeth on the two long sides of the hole and the inner meander piece [2]. Each outer ring surface has two coaxial oblate cylindrical surfaces [3], and the middle part of each oblate cylindrical surface [3] is provided with a pressing edge. Between the two oblate cylindrical surfaces [3], an elliptical N H-shaped external connecting pieces [4], N long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com