Round spherical combined packing

A technology of combined fillers and composite fillers, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as heat transfer, low mass transfer efficiency, small specific surface area, poor carrying capacity, etc. problems, to achieve the effect of good gas-liquid distribution, large specific surface area, and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

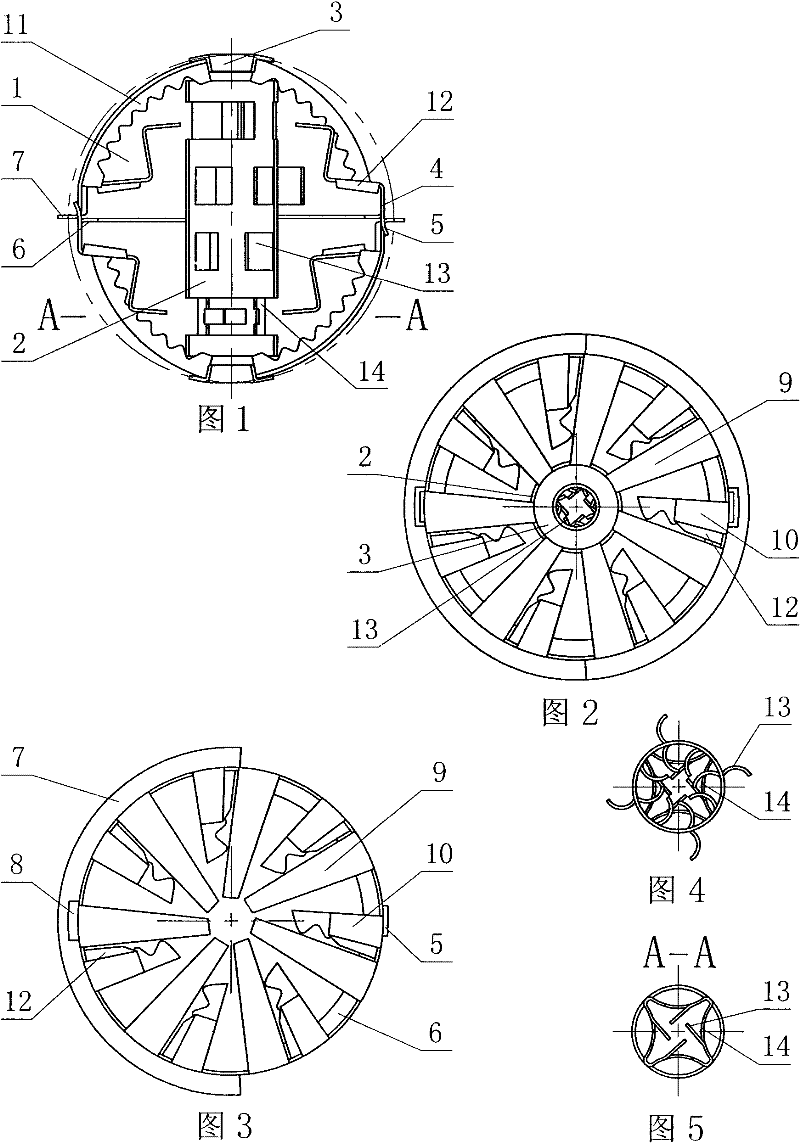

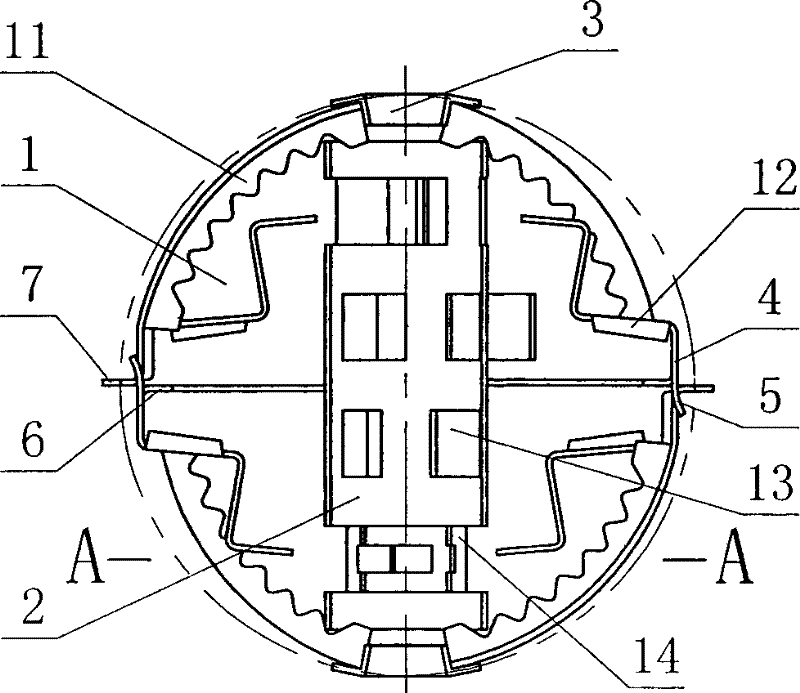

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] The present invention is mainly composed of two hemispherical packing sheets [1] and a long ring packing [2]. ] is contained in the whole spherical joint packing composed of two hemispherical packing sheets [1]. An overall spherical joint packing composed of two hemispherical packing sheets [1] spliced oppositely is used together with the long ring packing [2], and can also be used separately. A top ring [3] can be arranged at the top center of each hemispherical packing sheet [1], or there can be no top ring [3]. The shape of the top ring [3] is a hollow body of revolution, and its end Can be provided with teeth, also can not be provided with teeth, and top ring [3] can be bonded with adhesive, or be fixed on the hemispherical packing sheet [1] with welding process. The hemispherical packing sheet [1] has a cylindrical base surface [4], and the cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com