A method for hydrogenation and upgrading of high-aromatic diesel oil

A technology for hydrogenation and upgrading of diesel oil, which is applied in the fields of hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of low dearomatization rate and unsatisfactory cetane number directly, and achieves simple and good process flow. Hydrogenation effect, the effect of accelerating the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

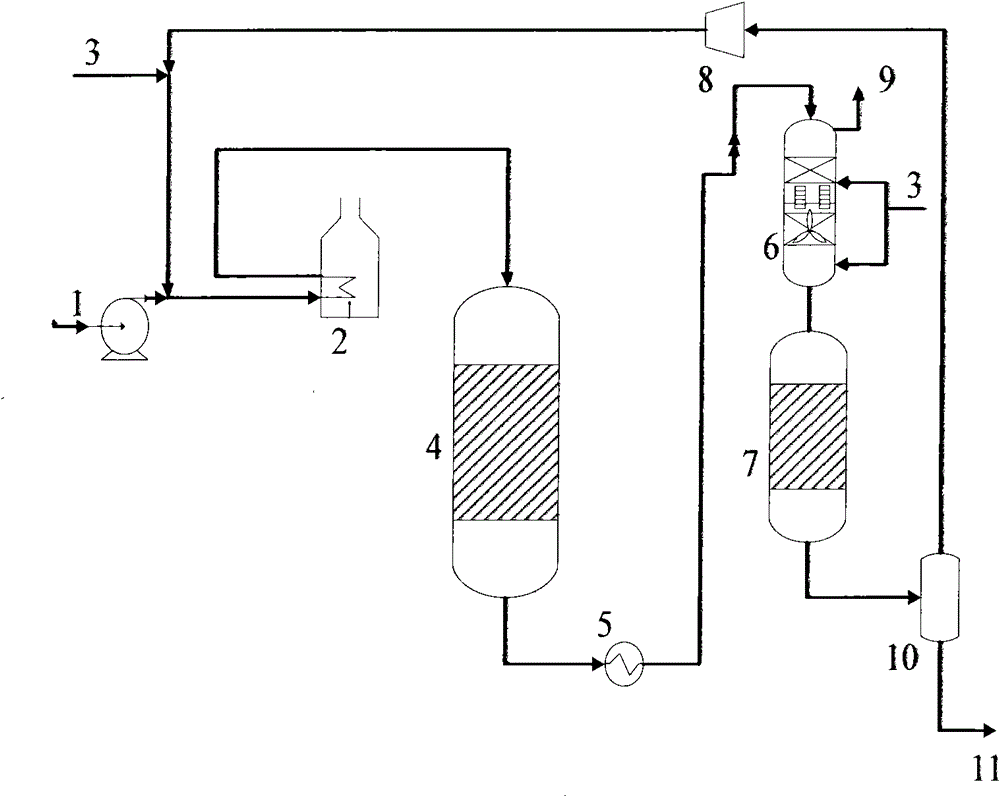

Method used

Image

Examples

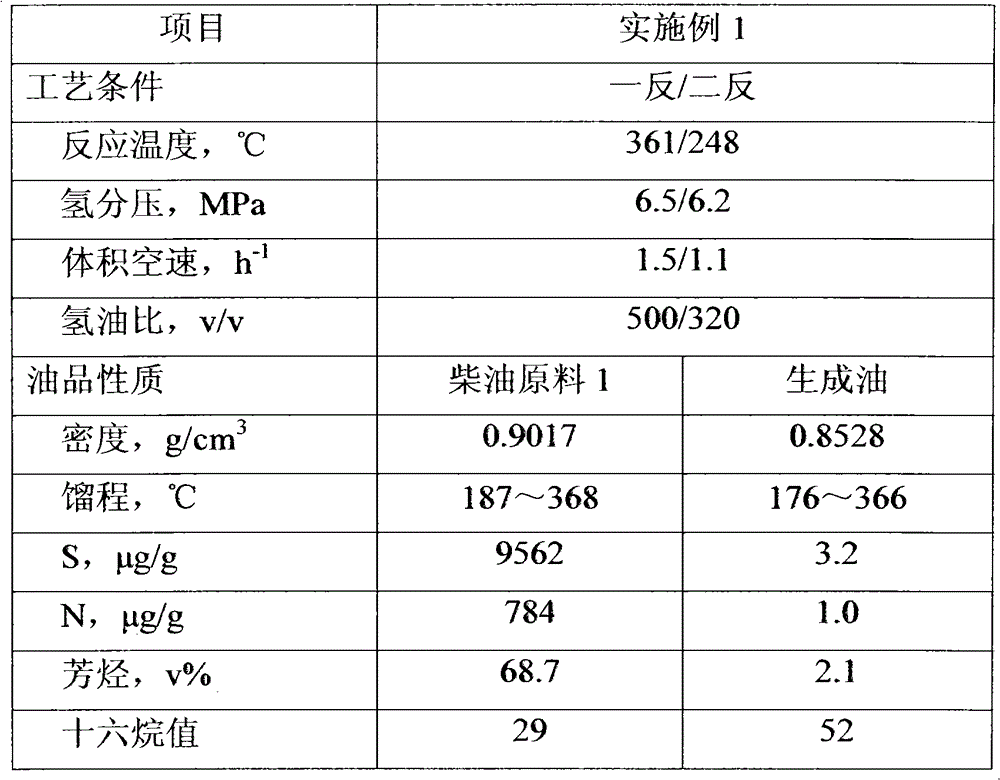

Embodiment 1

[0032] Diesel feedstock 1 enters the first hydrogenation reactor, the reaction conditions are: hydrogen partial pressure 6.5MPa, volume space velocity 1.5h -1 , The reaction temperature is 361°C, the volume ratio of hydrogen to oil is 500:1; the effluent enters the second hydrogenation reactor after passing through the gas stripping hydrogen mixer, and the reaction conditions are: hydrogen partial pressure 6.2MPa, volume space velocity 1.1h -1 , The reaction temperature is 248°C, and the volume ratio of hydrogen to oil is 320:1. The raw material oil properties and product properties are listed in Table 2.

[0033] It can be seen from Table 2 that the sulfur content of diesel products can be reduced to less than 10 μg / g, the aromatics content is greatly reduced, and the cetane number is increased by more than 20 units, directly meeting the requirements of the national standard clean diesel oil.

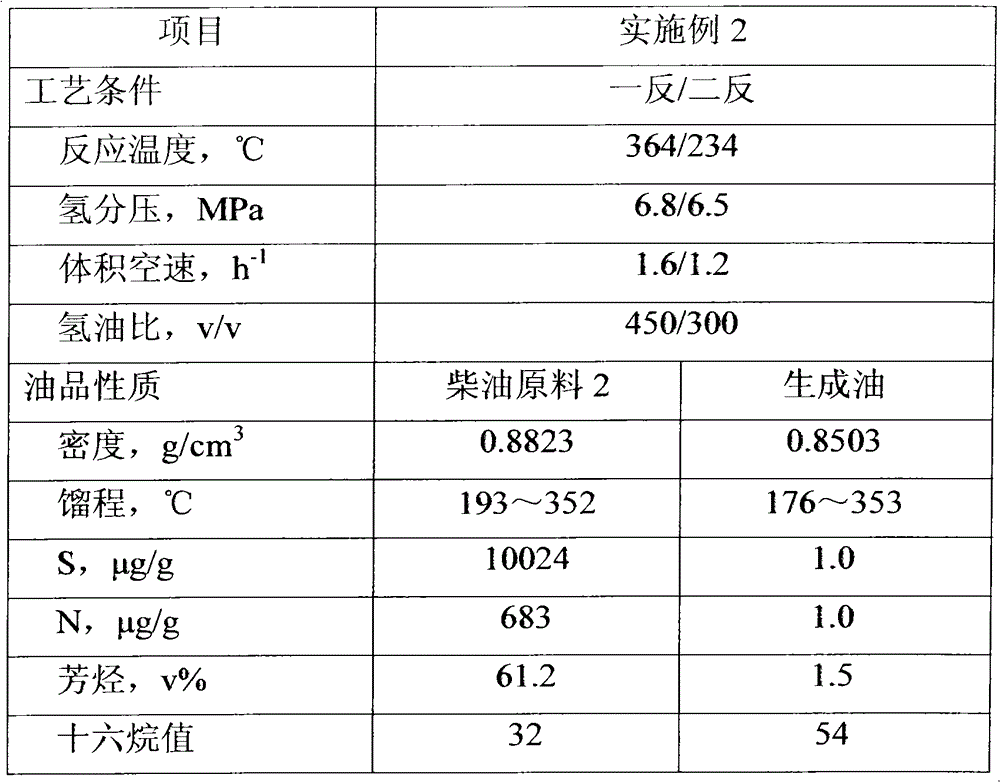

Embodiment 2

[0035] Diesel feedstock 2 enters the first hydrogenation reactor, the reaction conditions are: hydrogen partial pressure 6.8MPa, volume space velocity 1.6h -1 , The reaction temperature is 364°C, the volume ratio of hydrogen to oil is 450:1; the effluent enters the second hydrogenation reactor after passing through the gas stripping hydrogen mixer, and the reaction conditions are: hydrogen partial pressure 6.5MPa, volume space velocity 1.2h -1 , The reaction temperature is 234° C., and the volume ratio of hydrogen to oil is 300:1. The raw material oil properties and product properties are listed in Table 3.

[0036] It can be seen from Table 3 that the sulfur content of diesel products can be reduced to less than 10 μg / g, the aromatics content is greatly reduced, and the cetane number is increased by more than 20 units, which directly meets the requirements of the national standard clean diesel oil.

Embodiment 3

[0038] Diesel raw material 3 enters the first hydrogenation reactor, and the reaction conditions are: hydrogen partial pressure 6.6MPa, volume space velocity 1.3h -1 , The reaction temperature is 368°C, the volume ratio of hydrogen to oil is 550:1; the effluent enters the second hydrogenation reactor after passing through the gas stripping hydrogen mixer, and the reaction conditions are: hydrogen partial pressure 6.4MPa, volume space velocity 1.0h -1 , The reaction temperature is 257°C, and the volume ratio of hydrogen to oil is 340:1. The raw material oil properties and product properties are listed in Table 4.

[0039] It can be seen from Table 4 that the sulfur content of diesel products can be reduced to less than 10 μg / g by using this technology, the aromatics content is greatly reduced, and the cetane number is increased by more than 20 units, directly meeting the requirements of the national standard for clean diesel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com