Spherical composite packing

A combined filler and spherical technology, applied in chemical/physical/physical chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of heat transfer, low mass transfer efficiency, small specific surface area, poor bearing capacity, etc. , to achieve the effect of good gas-liquid distribution, large specific surface area and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

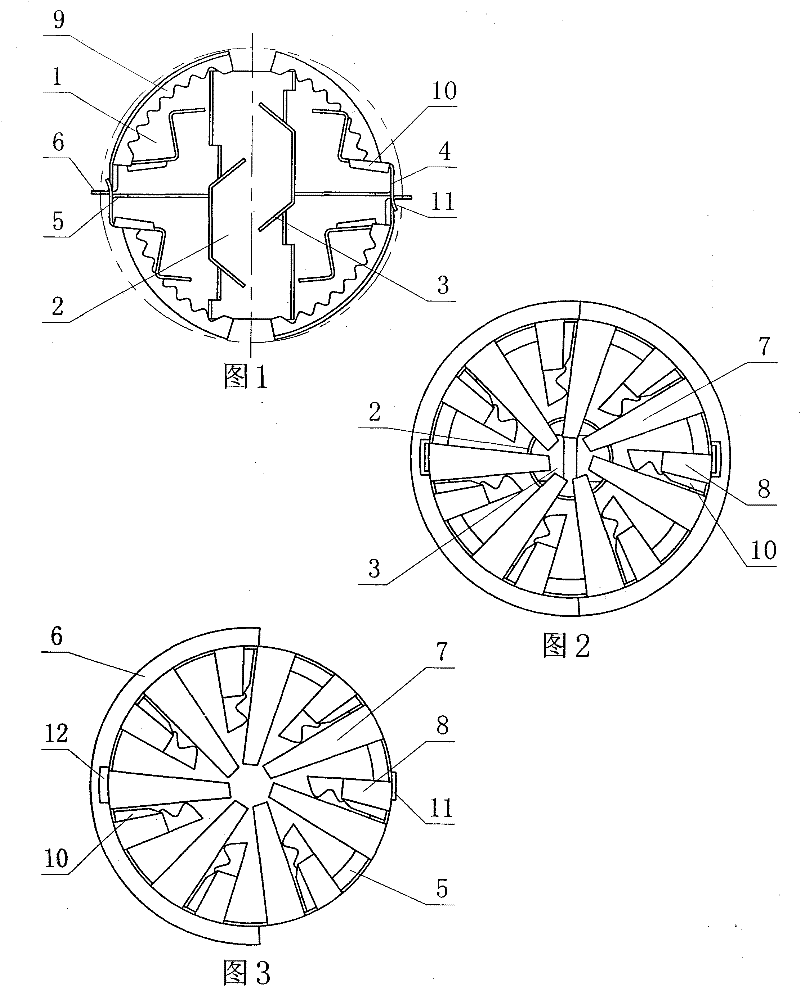

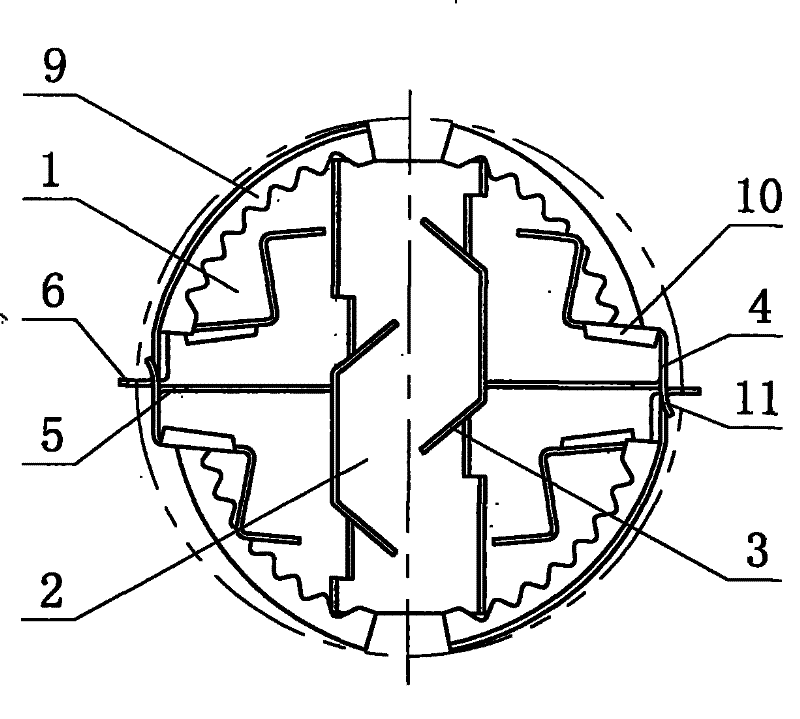

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] The present invention is mainly composed of two hemispherical shells [1] and a cylindrical tube [2]. The two hemispherical shells [1] are relatively spliced and fixed into a spherical whole, and a cylindrical tube [2] is contained in the two hemispherical shells [ 1] Among them. There are 1 to 8 inverting sheets [3] distributed on the cylindrical tube [2]. The hemispherical shell [1] has a cylindrical base surface [4], and there are 1 to 5 inner flanges [5] and 1 to 5 outer flanges [ 6]. The other end of the cylindrical base surface [4] is extended with 3 to 10 petal-shaped outer spherical surfaces [7] evenly distributed and inner folded surfaces [8] distributed alternately with the petal-shaped outer spherical surfaces [7] and having the same number. The petal-shaped outer spherical surface [7] is provided with a tooth-shaped inner flange [9] parallel to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com