Preparation method and application of polymer-based composite membrane

A polymer, composite membrane technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., to achieve the effects of easy conditions, excellent gas separation performance, and mild conditions

Pending Publication Date: 2022-06-10

NINGBO ELECTRIC POWER DESIGN INST +1

View PDF19 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The secondary growth method needs to introduce a seed crystal on the carrier, and then put the carrier into the reaction solution to form a secondary growth film through the induction of the seed crystal, but the seed crystal is difficult to prepare, and the binding force between the seed crystal and the carrier still exists. big problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

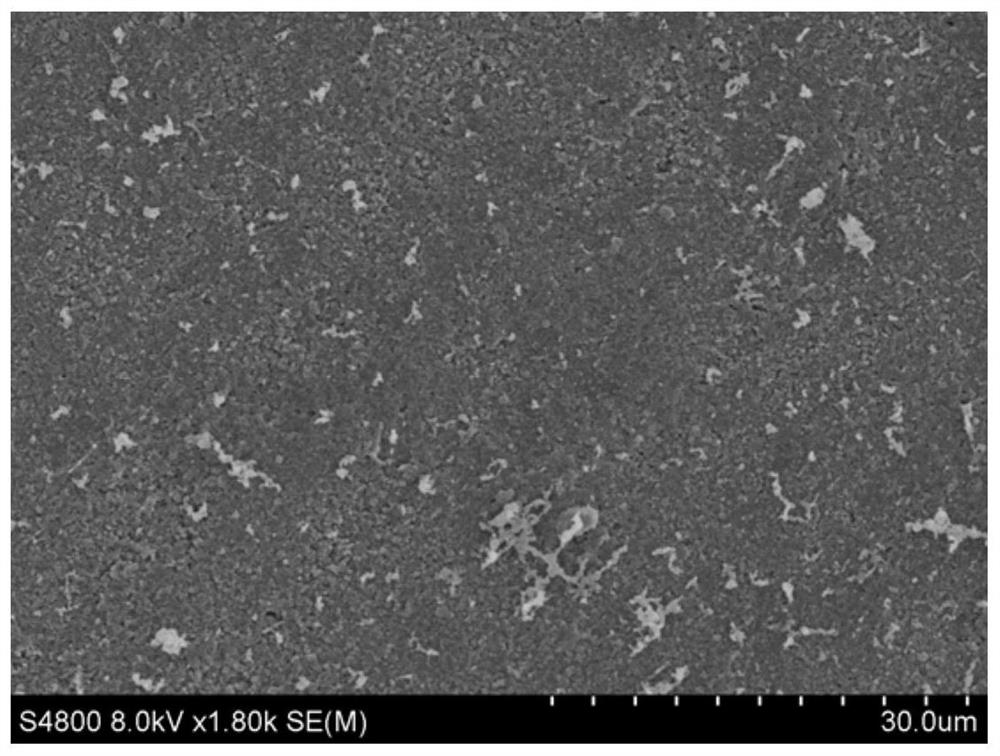

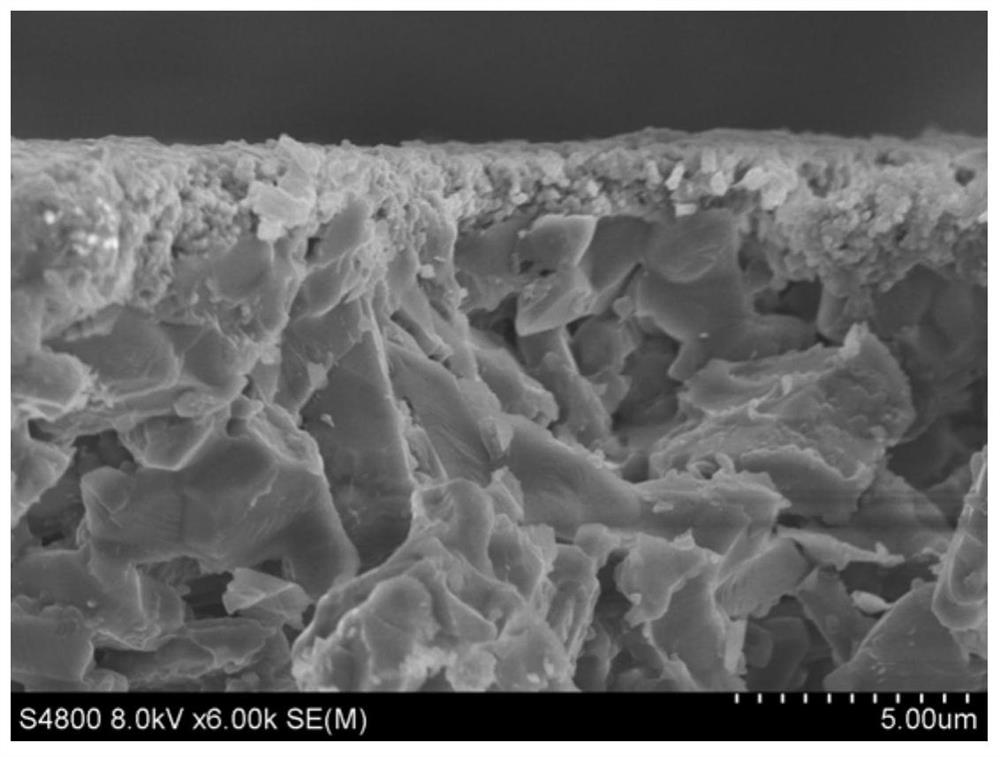

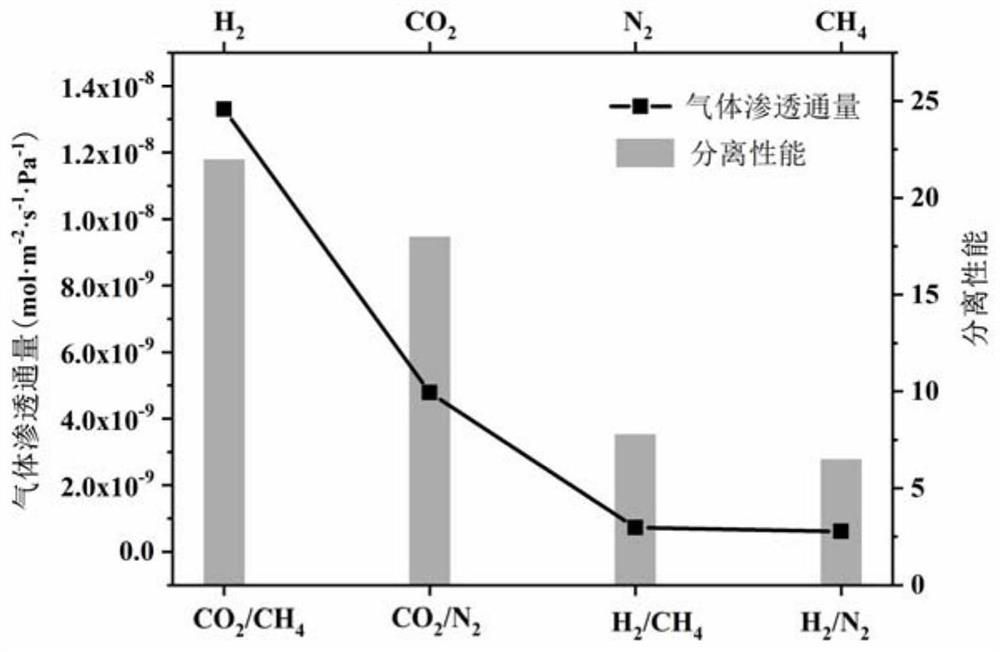

The invention discloses a preparation method and application of a polymer-based composite tube membrane, compared with a traditional method, the composite membrane prepared by the method has the advantages that the thickness of a polymer matrix membrane is greatly reduced, and meanwhile, a metal framework material grows in a limited range in a polymer; the size of the metal organic framework material is controlled, the defect that the metal organic framework material is easy to fall off on the carrier is overcome, and a continuous and compact metal organic framework-high-molecular polymer selective separation layer is formed on the surface of the tubular carrier. According to the composite separation membrane, by reducing the thickness of the membrane and introducing the metal organic framework material, the gas flux of the high-molecular polymer membrane is improved, the molecular screening capacity is high, the gas permeation flux is high, and the composite separation membrane has a good application prospect in the chemical field needing gas separation and purification.

Description

technical field [0001] The invention relates to the field of separation membranes, in particular to a preparation method for constructing a hybrid composite membrane based on a polymer, mainly in the preparation of a composite tubular membrane based on a polymer matrix and its application in gas separation. Background technique [0002] Gas separation membrane is a rapidly developing emerging field. Different from traditional separation methods, membrane separation of gas is to use the different gas permeation rates when different gas components pass through the membrane to separate one or several components from the mixture. purpose of coming out. Membrane separation technology has many advantages, including low cost, low energy consumption, simple operation, etc. Therefore, membrane separation of gas as a new unit component has attracted much attention and favor in the chemical industry. At present, gas membrane separation has been applied in oxygen-enrichment and nitroge...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D67/00B01D69/04B01D69/12B01D71/06B01D71/42B01D71/60B01D71/64B01D53/22

CPCB01D69/12B01D71/06B01D71/64B01D71/42B01D71/60B01D67/0002B01D69/04B01D53/228Y02C20/40

Inventor 严浩军舒恺马益平姚艳张帅高飞翎严倚天胡华杰赵鲁臻方瑞君赵亚云林贻超张秋菊陈亮

Owner NINGBO ELECTRIC POWER DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com