Negative temperature coefficient thermistor raw material composition and application thereof

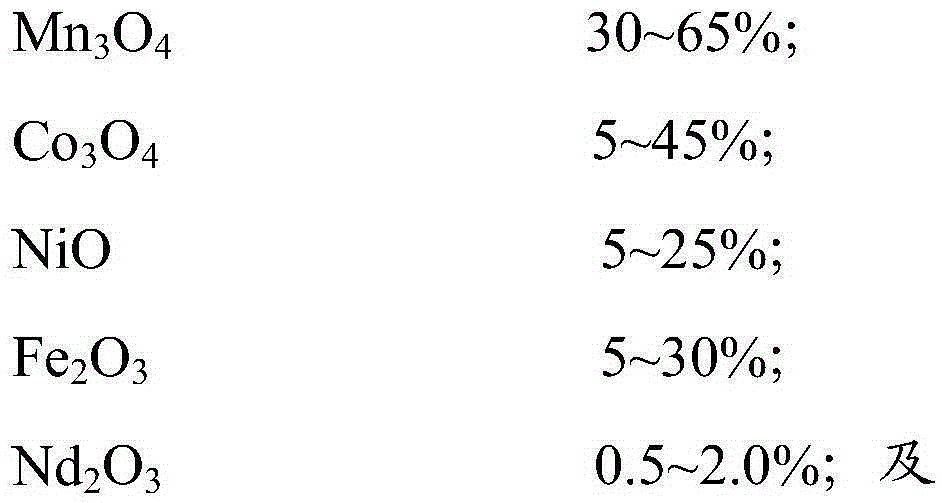

A technology of negative temperature coefficient and thermosensitive composition, which is applied in the field of negative temperature coefficient thermistor raw material composition, which can solve the problems of poor electrical stability, difficulty in uniform distribution, and poor concentration of electrical performance parameters of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the negative temperature coefficient thermosensitive composition of one embodiment, comprises the following steps:

[0032] Step S110, adding the above-mentioned negative temperature coefficient thermistor raw material composition into deionized water, performing wet grinding, and then drying to obtain a mixed powder.

[0033] Preferably, the mass ratio of the added deionized water to the negative temperature coefficient thermistor raw material composition is 2:1˜3:1.

[0034] Preferably, the wet grinding is carried out using a polyurethane ball mill tank, and the ball milling medium is zirconium balls. Further preferably, the diameter of the zirconium balls is 5-7.5 mm, and the mass ratio of the zirconium balls to the negative temperature coefficient thermistor raw material composition is 2:1-3:1. Further preferably, the grinding speed is 400-500 r / min.

[0035] Preferably, the wet grinding time is 4-6 hours.

[0036] Preferably, the drying...

Embodiment 1

[0060] NTC thermistor raw materials, containing the following components: Mn 3 o 4 260g, Co 3 o 4 20g, NiO20g, Fe 2 o 3 88g, Nd 2 o 3 8g, Al(NO 3 ) 3 9H 2 O4g.

[0061] Implementation process: Accurately weigh each raw material according to the above formula components, with a total weight of 400g, pour it into a polyurethane ball mill tank equipped with 800gΦ7.5mm zirconium balls, add 800g of deionized water, seal it and wet mill it on a planetary ball mill for 4 hours , with a speed of 500r / mm, pour the ground material into a stainless steel plate, put it in an oven at 150°C and bake for 2 hours, pre-burn the dried powder in a muffle furnace at 1000°C for 1 hour, and then put the pre-fired powder Wet mill on a planetary ball mill for 4 hours and dry in an oven at 150°C for 2 hours, pass the dried powder through a 80-mesh sieve, add 60g of PVA solution with a mass concentration of 4%, and put it in a 150°C oven after mixing evenly. Bake in an oven for 10 minutes, a...

Embodiment 2

[0064] NTC thermistor raw materials, containing the following components: Mn 3 o 4 120g, Co 3 o 4 180g, NiO20g, Fe 2 o 3 36g, Nd 2 o 3 4g, Al(NO 3 ) 3 .9H 2 O40g.

[0065] Implementation process: Accurately weigh each raw material according to the above formula components, with a total weight of 400g, pour it into a polyurethane ball mill tank equipped with 1200gΦ5mm zirconium balls, add 1200g of deionized water, seal it, and wet mill it on a planetary ball mill for 6h, at a speed of 400r / mm, pour the ground material into a stainless steel plate, put it in a 100°C oven and bake for 3 hours, pre-burn the dried powder in a 900°C muffle furnace for 2 hours, and put the pre-fired powder on the planetary Wet mill on a type ball mill for 6 hours and dry in an oven at 100°C for 3 hours. Pass the dried powder through an 80-mesh sieve, add 40g of PVA solution with a mass concentration of 7%, and put it into an oven at 100°C after mixing evenly. Bake for 20 minutes, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com