Patents

Literature

60results about How to "Not prone to chemical reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound active cosmetic collagen powder

The invention discloses a compound active cosmetic collagen powder, particularly discloses a synergetic oral compound active cosmetic collagen powder integrating various functions of remarkably resisting oxidation, whitening skin, moisturizing, dispelling wrinkles and freckles, delaying senescence and the like and belongs to the technical field of nutrient health-care foods. The compound active cosmetic collagen powder is characterized in that active polysaccharides, natural fruit powder and vitamin E are added based on cosmetic collagen and has the advantages of being reasonable in proportioning, strong in pertinence, remarkable in synergy effect, good in taste, convenient to eat, good in safety, free of toxic and side effects, simple in production process, easy to produce, filling market blank and extremely having market development potential.

Owner:北京姿美堂生物技术股份有限公司

Rare-earth butadiene rubber composite cable sheath material

InactiveCN104194083ALow costImprove aging resistanceInsulated cablesInsulated conductorsVulcanizationPolymer science

The invention discloses a rare-earth butadiene rubber composite cable sheath material, comprising the following raw materials in parts by weight: 80-100 parts of rare-earth butadiene rubber, 40-50 parts of butadiene styrene rubber, 1.8-2.3 parts of vulcanization system, 5-10 parts of organic montmorillonite, 20-30 parts of a lignin reinforcing agent, 30-40 parts of white carbon black, 20-30 parts of silane modified sepiolite, 2-3 parts of nano-zinc oxide, 1.5-1.8 parts of stearic acid, 1-2 parts of naphthenic oil, 40-50 parts of carbon black N330 and 5-6 parts of N-methylene carboxylic-2-benzothiazole sulfonamide. The rare-earth butadiene rubber composite cable sheath material has the advantages of low cost, good ageing resistance, excellent tensile strength and deflection resistance, good tear resistance, simple preparation process and convenience in practical operation.

Owner:ANHUI LAND GRP

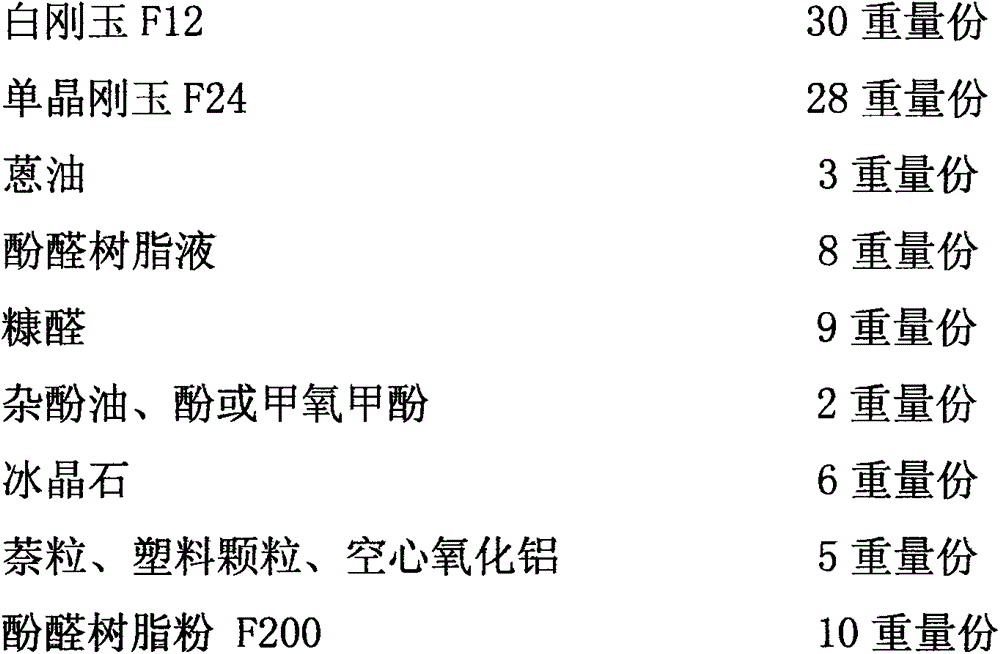

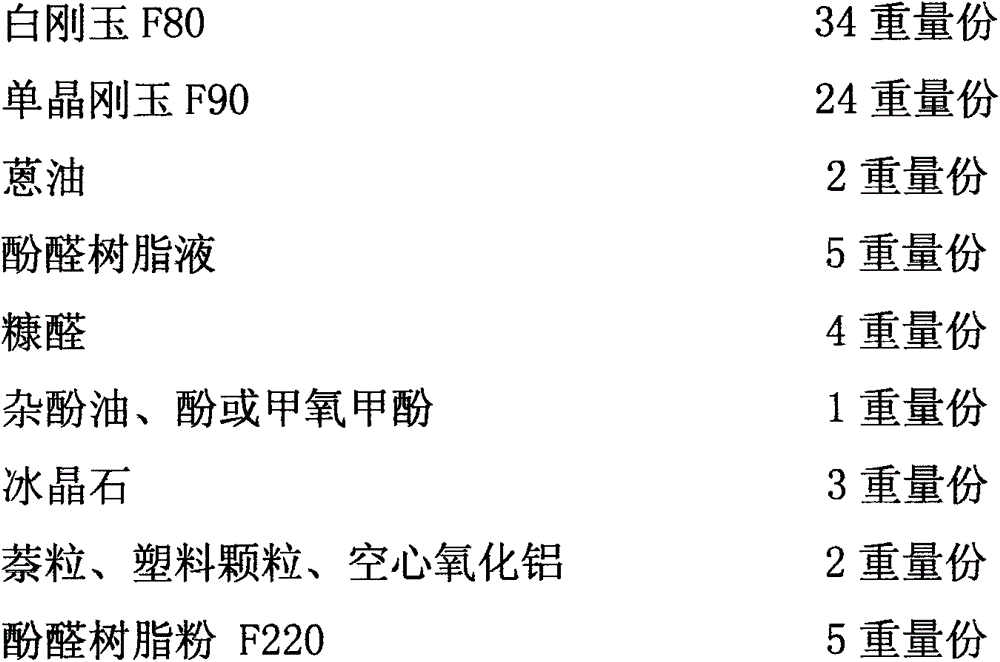

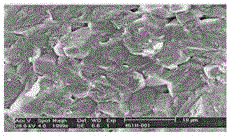

Resin grinding wheel preparation method

ActiveCN104128894AImprove production qualityGood chemical stabilityAbrasion apparatusGrinding devicesWettingPhenols

The invention provides a resin grinding wheel preparation method. A resin grinding wheel is prepared by combining multi-granularity white corundum, monocrystalline fused alumina, anthracene oil and phenolic resin liquid with furfural, kreosote, phenol or kreosol and cryolite, naphthalene grains, plastic particles and hollow alumina filling according to a certain weight ratio. By implementing the method, powder cannot be wrapped by wet materials in the process of mixing of materials, and influence on quality of a resin grinding wheel product due to the fact that the materials are not dispersed and cake is avoided. In addition, a certain weight part of silicon carbide is added in raw materials of mixed grinding materials, and grinding wheel cutting pieces different in performance can be acquired by controlling proportioning content of a silicon carbide grinding material, mixed white corundum and monocrystalline fused alumina and adjusting content of a wetting agent and phenolic resin powder within a certain range.

Owner:NINGBO DAHUA GRINDING WHEEL

Collagen nutrition powder for improving skin activity and whitening skin and preparation method thereof

The invention relates to collagen nutrition powder and a preparation method of the collagen nutrition powder, and in particular relates to collagen nutrition powder for improving skin activity and whitening skin and a preparation method of the collagen nutrition powder, belonging to the technical field of nutrient and heath care foods. The collagen nutrition powder is characterized by being added with ocean fish oligopeptide powder, algal polysaccharides, procyanidine, vitamin C and vitamin E based on collagen. The collagen nutrition powder disclosed by the invention has the advantages that the collagen nutrition powder is reasonably dosed, the components have an remarkable synergistic interaction effect, the skin activity can be remarkably improved and the skin can be whitened, and moreover, the collagen nutrition powder has good color and taste, and causes no harms or toxic and side effects to body after being normally eaten; and meanwhile, the production technique is safe and simple, and is strong in operability, therefore, good economic benefits are obtained, and remarkable social benefits are also obtained.

Owner:湖北诺思康医药科技有限公司

Protein solid drink suitable for diabetic patients

InactiveCN104544401AImprove balanceAvoid complicationsFood ingredient functionsFood preparationSucroseNutrition

The invention relates to a protein solid drink suitable for diabetic patients. The protein solid drink comprises the following raw materials in percentage by dry weight: 5-20% of erythritol, 10-25% of fructo-oligosaccharide, 2-15% of polydextrose, 5-25% of soy isolate protein, 5-15% of whey protein, 2-10% of soybean oligopeptides, 5-27% of maltodextrin, 2-10% of a Chinese wolfberry powder, 2-10% of a carrot powder and 2-8% of a green tea powder. The protein solid drink suitable for diabetic patients does not contain saccharose, thereby being low in heat quantity, good in mouth feel, rich in nutrients, having the efficacies of improving intestinal balance, strengthening nutrition, preventing occurrence of health complications of diabetic patients, boosting immunity of diabetic patients, and being a health drink suitable for diabetic patients.

Owner:BAOLINGBAO BIOLOGY

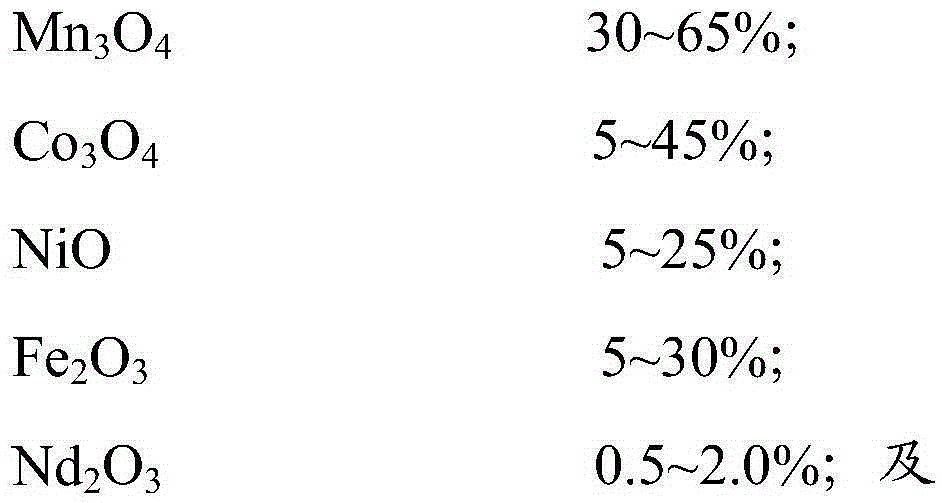

Negative temperature coefficient thermistor raw material composition and application thereof

The invention discloses a negative temperature coefficient thermistor raw material composition, a negative temperature coefficient thermosensitive composition, a preparation method of the negative temperature coefficient thermosensitive composition and a preparation method of a negative temperature coefficient thermistor chip. The negative temperature coefficient thermistor raw material composition is prepared from the following components in percentage by mass: 30 to 65 percent of Mn3O4, 5 to 45 percent of Co3O4, 5 to 25 percent of NiO, 5 to 30 percent of Fe2O3, 0.5 to 2.0 percent of Nd2O3 and 1 to 10 percent of Al(NO3)3.9H2O. Al<3+> is introduced into the negative temperature coefficient thermistor raw material composition in an aluminum nitrate form instead of an Al2O3 solid form; the aluminum nitrate is good in water solubility and is easily and uniformly distributed in the composition, so that the deviation between a resistance value and B value can be reduced, and electrical resistivity and B value precision are improved; in addition, by adding high-enthalpy rare earth oxide Nd2O3, the enthalpy of oxide is 1783KJ / mol, and the oxides do not easily generate chemical reaction at high temperature, so that the ageing influence caused by chemical changes is reduced, and further the electrical stability of the thermistor is improved.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Feature beautifying and skin nourishing nutrient composition

InactiveCN106360740AImprove beauty wrinkleImprove skin whiteningFood ingredient functionsWrinkle skinVitamin C

The present invention relates to a feature beautifying and skin nourishing nutrient composition and belongs to the technical field of nutritional and health-care food. The nutrient composition is characterized by adding a grape seed extract, a fructus hippophae extract, vitamin C and vitamin E on the basis of collagen peptides. Advantages are as follows: the collagen peptides are reasonable in proportions and each of the raw materials has obvious synergistic effects, so that the nutrient composition has the feature beautifying effects of removing wrinkles and whitening skin, and moisturizing skin. Besides, the collagen peptides are good in color and luster, and mouthfeel, and do not bring harmful, toxic and side effects to the body in a normal consumption. At the same time, the production technology is safe and simple, and high in operability, can achieve good economic benefits, and also has significant social benefits.

Owner:安徽旺润生物科技有限公司

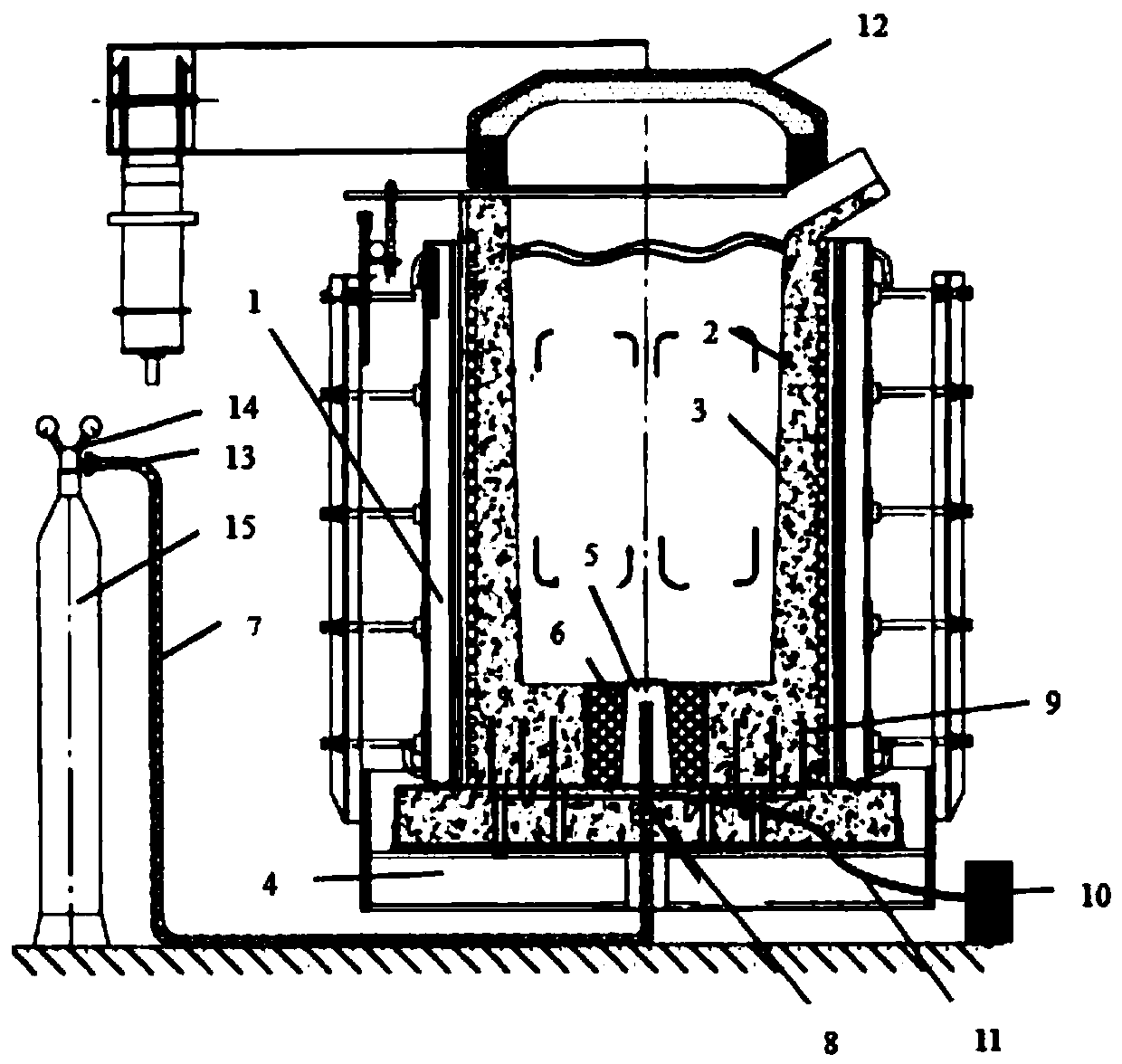

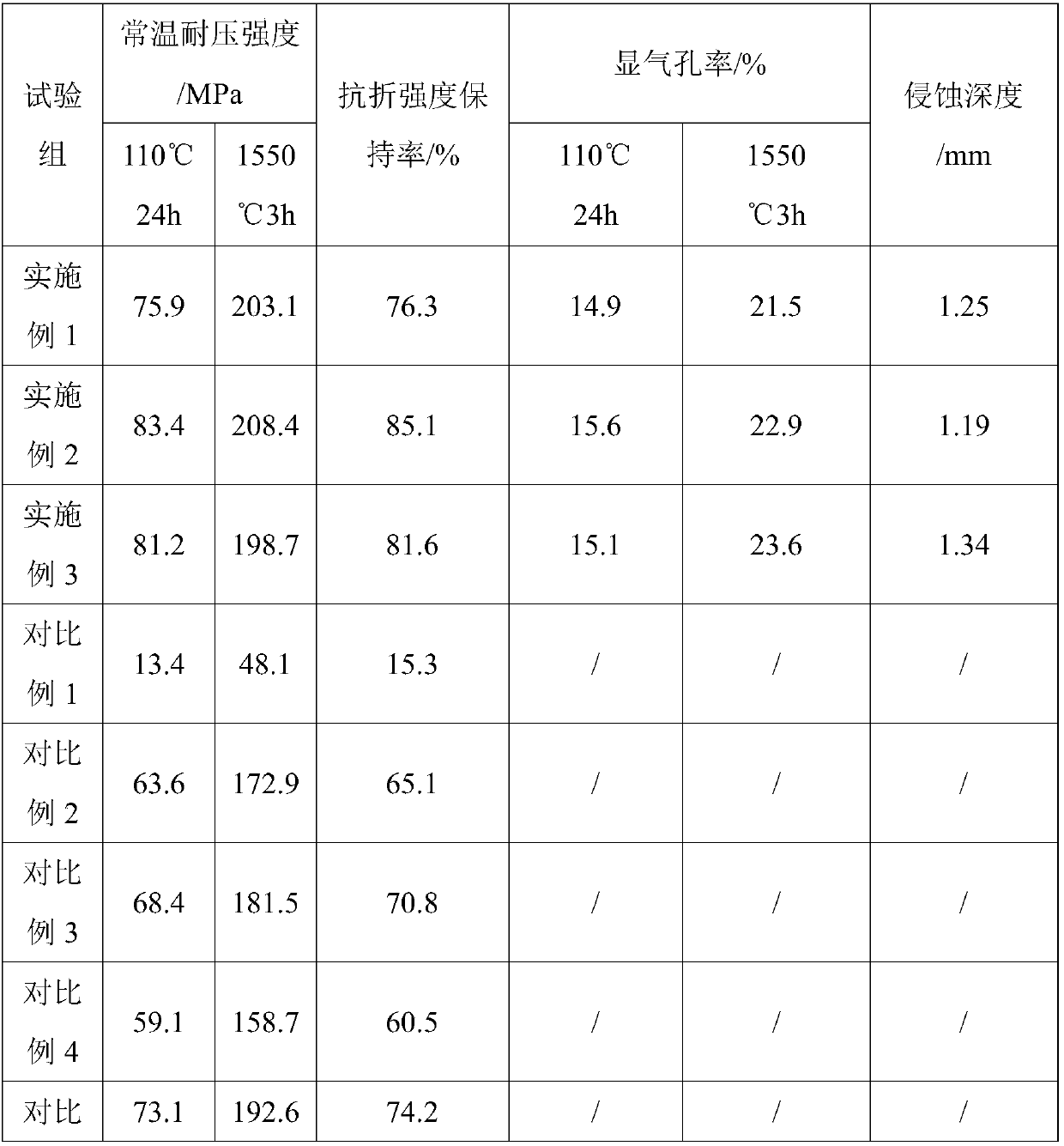

Ladle bottom argon blowing air brick for smelting high-purity high manganese steel

The invention discloses ladle bottom argon blowing air brick for smelting high-purity high manganese steel. The air brick is prepared from the following materials: forsterite sand, fused magnesia, corundum, sodium silicate, sodium permanganate, an explosion-proof admixture, a polycarboxylate dispersion water reducing agent and water. Uniformly-distributed tiny pores can be formed in the air brickdisclosed by the invention, and the permeation volume is 1.5 times or more than 1.5 times of the permeation volumes of slit and diffuse air bricks; argon is permeated in molten steel through the plurality of pores, so that the purification rate of the molten steel is obviously increased, and the contents of oxygen and hydrogen in the molten steel are reduced; the problems that a small number of straight thick holes are caused by slag-clearing iron oxygen burning, the argon intensively passes through the molten steel and quickly escapes from the liquid level and the like are solved; the purification rate of the molten steel is obviously increased.

Owner:广西长城机械股份有限公司

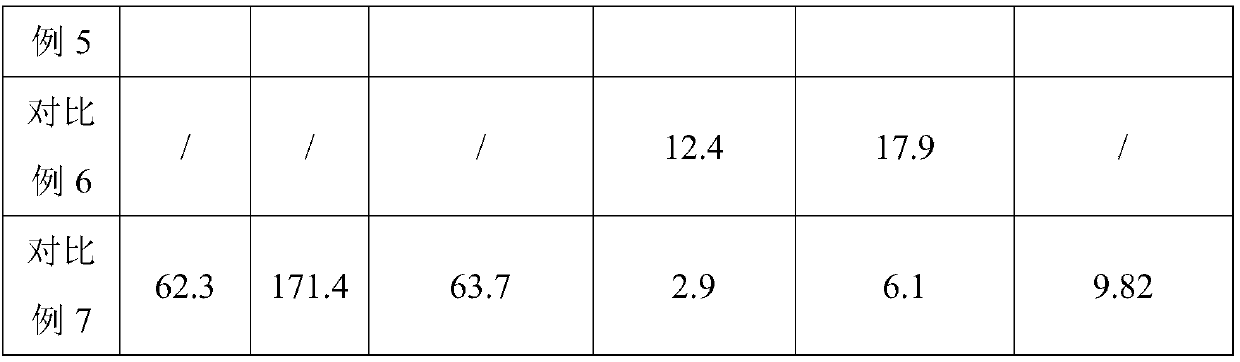

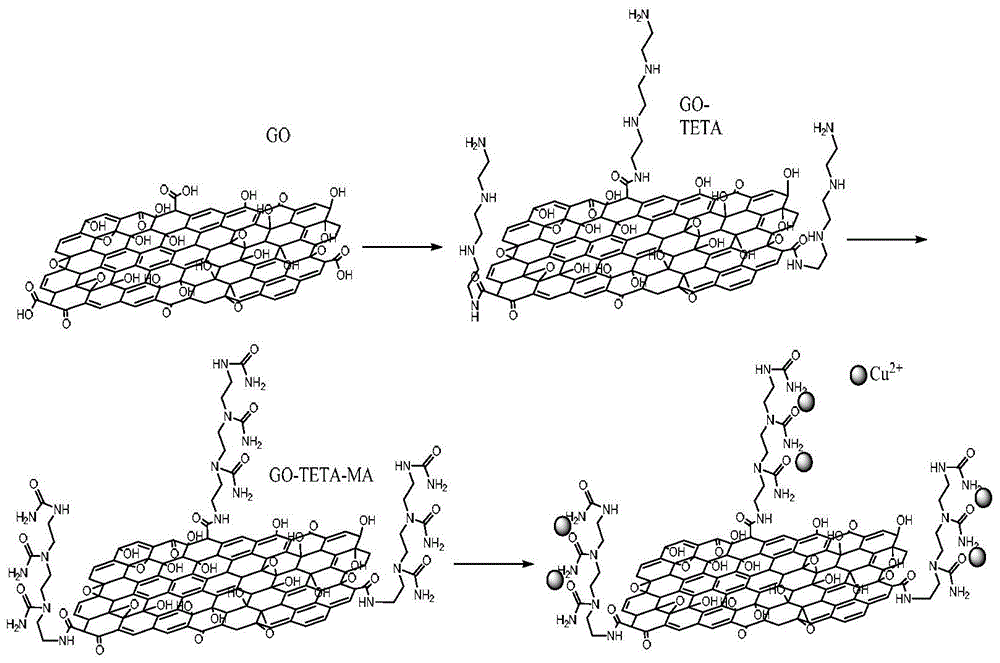

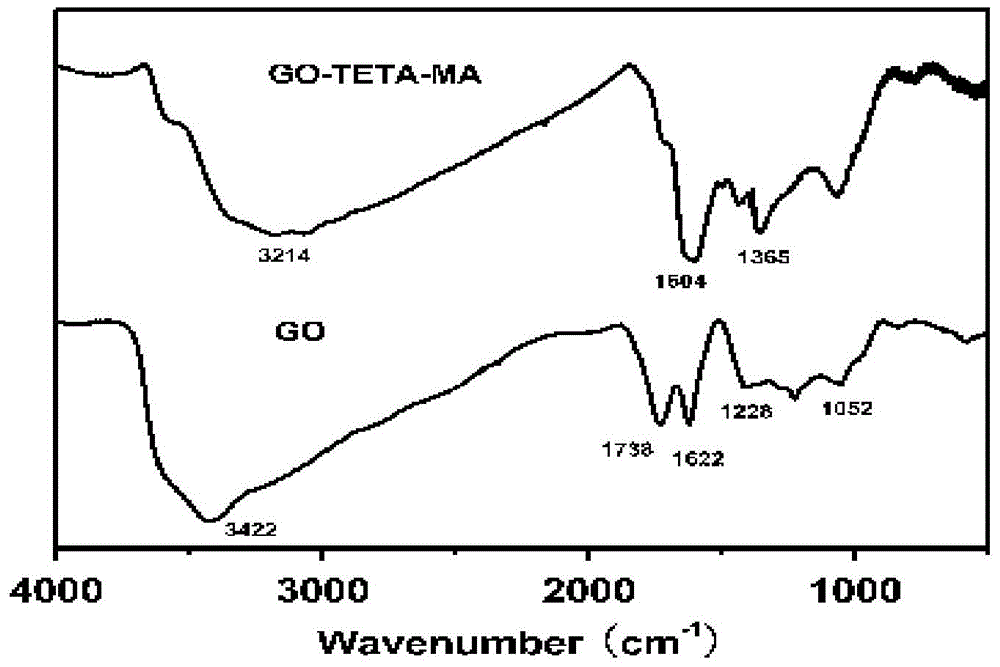

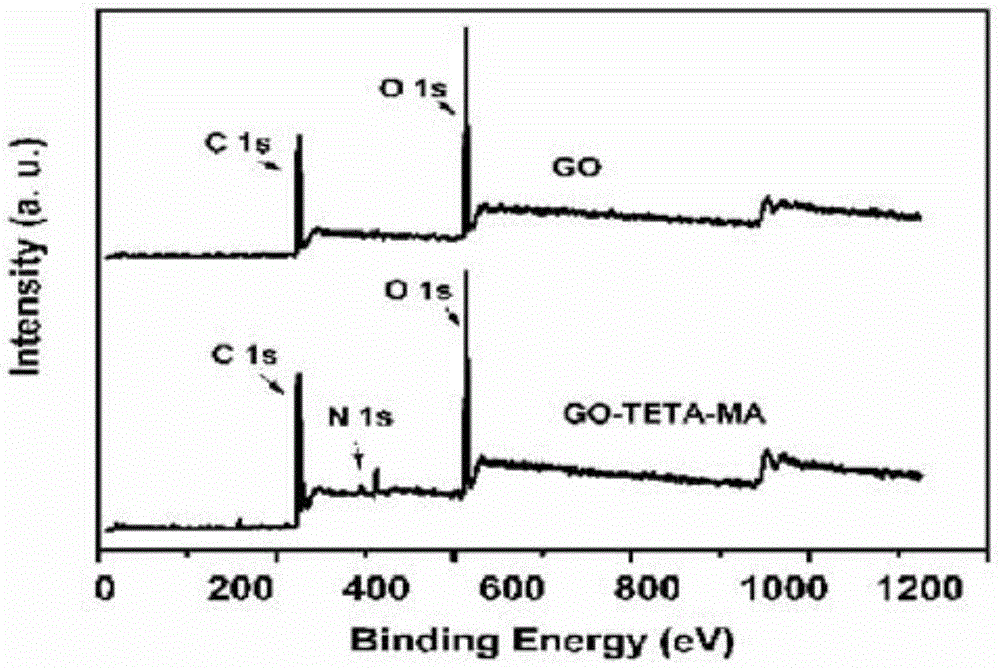

Preparation method of graphene oxide adsorption material adsorbing copper ions

The invention relates to a preparation method of a graphene oxide adsorption material adsorbing copper ions, and particularly relates to a preparation method of a graphene oxide adsorption material. The invention aims to solve the problem of low adsorption capacity of modified graphene oxide for copper ions. According to the preparation method, water is used as a solvent, and graphene oxide is grafted with triethylene tetramine and then is modified with potassium cyanate, so as to obtain a solid copper ion adsorption material with multiple adsorption sites. The material prepared by using the preparation method has a good adsorption effect on copper ions and can reach the hygienic standard of domestic drinking water after adsorption, the adsorbent is stable in properties and is not influenced by acid and alkaline, and the situations of secondary pollution and the like cannot occur; the synthetic method is simple and is suitable for industrial production. The preparation method is used in the field of treating heavy metal pollutants in water.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

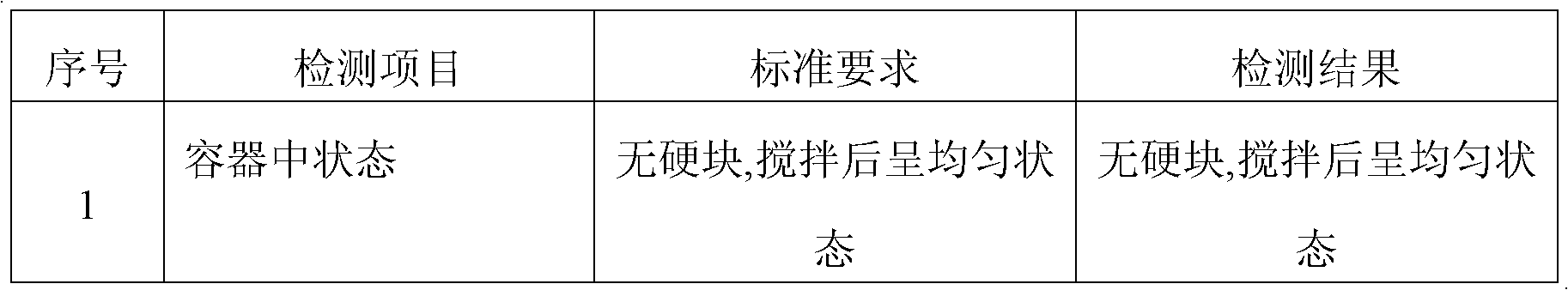

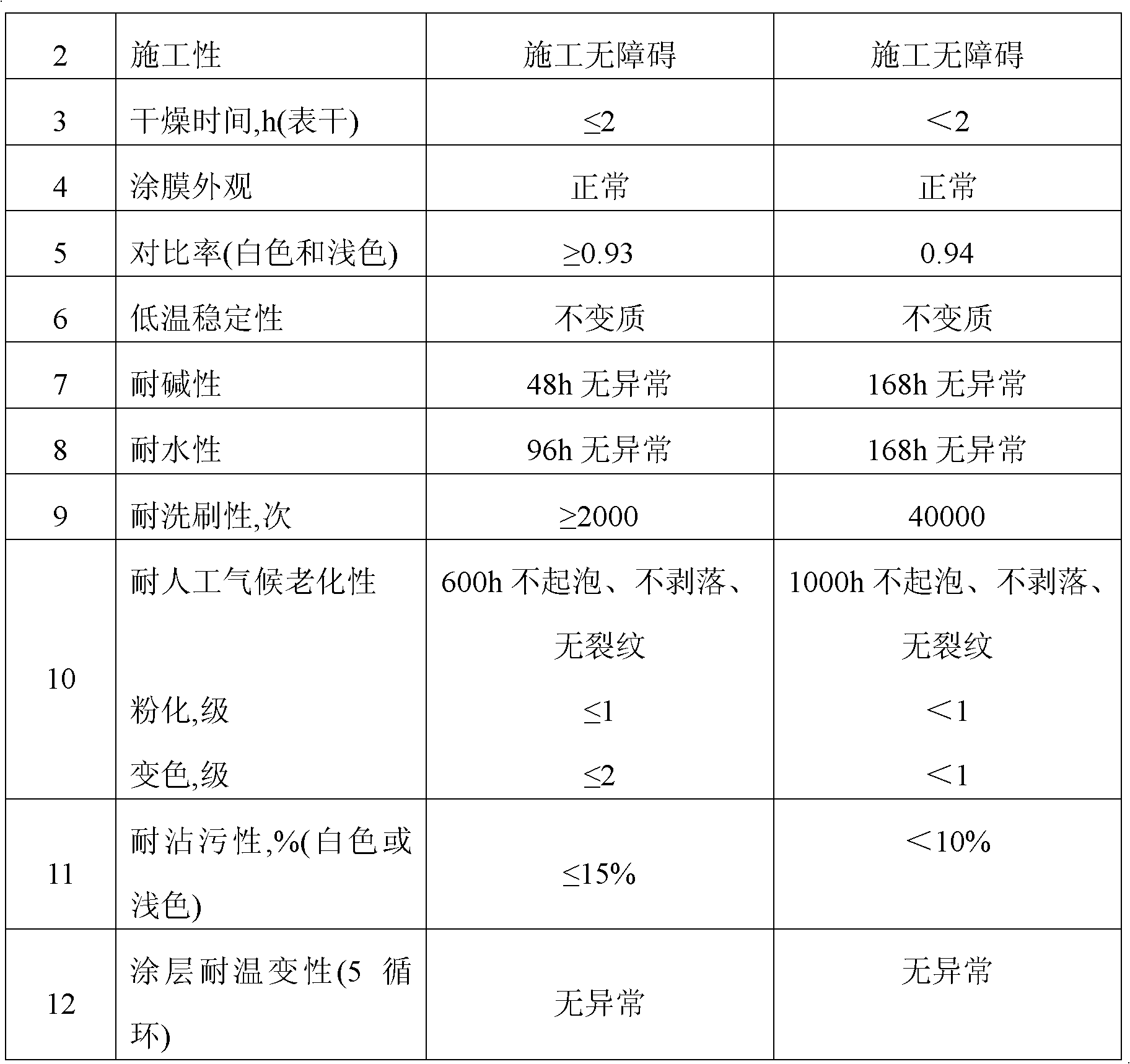

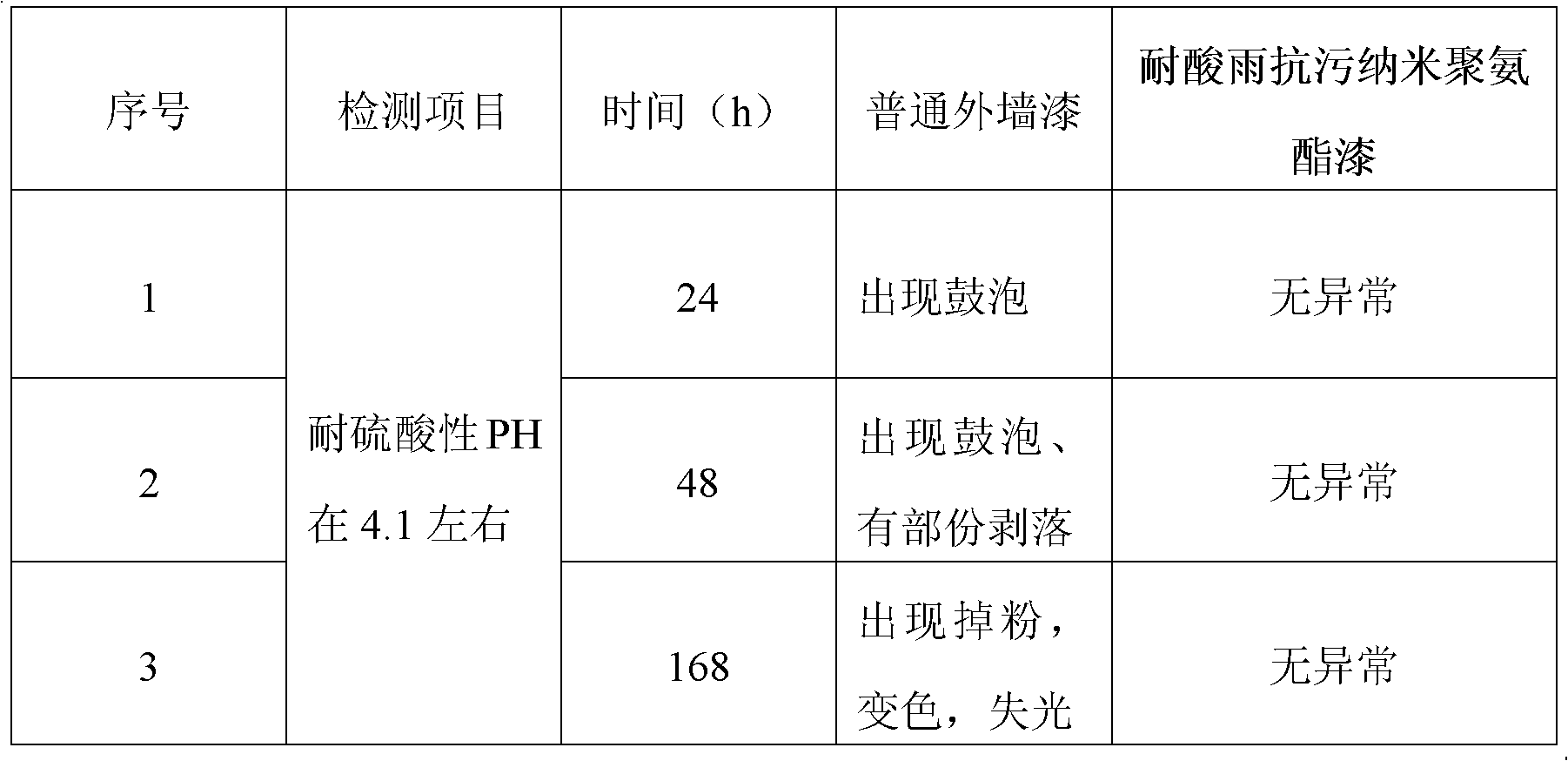

Acid rain-resistant antifouling aqueous nanometer polyurethane exterior wall finish

InactiveCN102504685AHigh strengthImprove the finishAntifouling/underwater paintsPaints with biocidesRutileAntiseptic

The invention discloses an acid rain-resistant antifouling aqueous nanometer polyurethane exterior wall finish. The finish is obtained by mixing a primary finish, a curing agent and water according to a weight ratio of 10:1:1, wherein the primary comprises water, a dispersant, a wetting agent, a defoamer, propylene glycol, rutile titanium dioxide, a nanomaterial with the particle size of equal to or less than 20nm, a chemical inert filler, an antiseptic, a mildew inhibitor, a pH conditioning agent, a film forming assistant, an aqueous polyurethane resin containing -OH, and a thickening agent; and the curing agent comprises polyisocyanate containing -NCO, and PMA (polymethyl acrylate). The exterior wall finish of the invention has the advantages of acid rain resistance and good antifouling performance.

Owner:肇庆千江高新材料科技股份公司

Novel PVC (polyvinyl chloride) inorganic pigment paste and preparation method thereof

The invention discloses novel PVC (polyvinyl chloride) inorganic pigment paste and a preparation method thereof. The PVC inorganic pigment paste comprises 125-130 parts of an inorganic pigment, 80 parts of epoxidized soybean oil, 20-25 parts of dioctyl terephthalate, 20-25 parts of chlorinated n-alkane, 5-7 parts of PVC resin, 1.2-1.5 parts of a toner, 1.2-1.5 parts of a dispersing agent, 0.8-1 part of a dispersing aid and 169.5-175 parts of heavy calcium carbonate; then the PVC inorganic pigment paste is obtained through steps of mixing, heating, stirring and grinding. The PVC inorganic pigment paste is brighter in luster, free of layering and low-temperature-resistant, cannot crystallize easily, and has characteristics of capability of increasing the luster, resisting settling and resisting freezing.

Owner:福建宝利特新材料科技有限公司

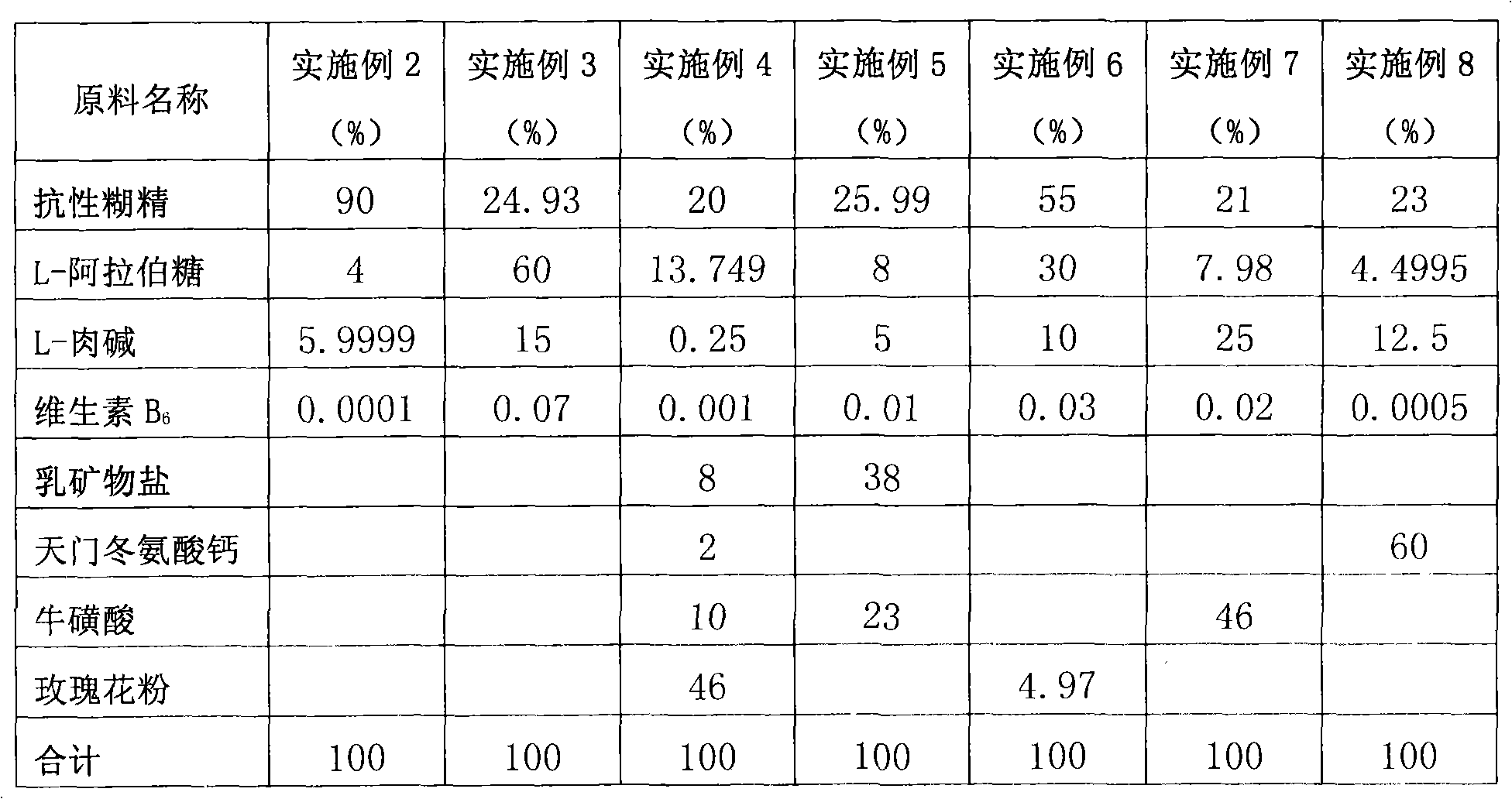

Rapidly beautifying and weight losing nourishment and preparation method thereof

ActiveCN102613461ANot easy to chemical reactionRelieve physical fatigueFood preparationNutrientSide effect

The invention discloses a rapidly beautifying and weight losing nourishment and a preparation method thereof, which belong to the technical field of nutritious and healthcare foods. The rapidly beautifying and weight losing nourishment is obtained by selectively adding one or more of a milk mineral, calcium aspartate, taurine and rose powder on the basis of scientific combination of resistant dextrin, L-arabinose, L-carnitine and vitamin B6. The rapidly beautifying and weight losing nourishment disclosed by the invention has the following advantages that: various raw materials are organicallyblended so that the nourishment is strongly targeted; the obese individuals can rapidly obtain weight losing effects; the nourishment has the advantages of contribution to long-term consolidation of the weight losing effect, no rebound, no influence on absorption of proteins and other nutrient substances, obvious synergetic effects, better mouth feel, convenience for eating, good safety, no toxicand side effect, simple production process, easiness for production and greater market development potential; market vacancy is filled.

Owner:李卫平

Preparation method of chemical material slurry plunger pump with composite coating, and product thereof

ActiveCN111826602AImprove corrosion resistanceReduce stress shockMolten spray coatingPolishing machinesOrganic solventSand blasting

The invention relates to the technical field of a plunger pump, and particularly relates to a preparation method of a chemical material slurry plunger pump with composite coating, and a product thereof. The preparation method comprises the following preparation steps: performing undercutting for a part where coating of a plunger base body is, thereby reserving 0.25-0.35mm coating thickness, chamfering 40-50 degrees for a connection part between a coating edge and the base body; executing organic solvent degreasing and baking for the base body; then, performing sand blasting, using a clamp forprotecting a non-coating area; preheating the base body to 90-110 DEG C, spraying a nickel chrome bottom layer coating, wherein spraying current is 350-450A, voltage is 35-40V, and coating thickness is 0.08-0.12mm; spraying a chromic oxide coating, wherein spraying current is 500-600A, voltage is 40-50V, and coating thickness is 0.2-0.4mm; performing vacuum impregnation hole sealing, wherein impregnation time is 10-20 minutes, heating curing is executed after surface drying, and curing time is 1.5-2.5 hours; and using a grinding machine to perform grinding processing for the plunger, wherein grinding processing comprises three working procedures including coarse grinding, fine grinding and polishing. The chemical material slurry plunger pump with composite coating, prepared by the method of the invention has high corrosion resistance and abrasion resistance.

Owner:德清创智科技股份有限公司

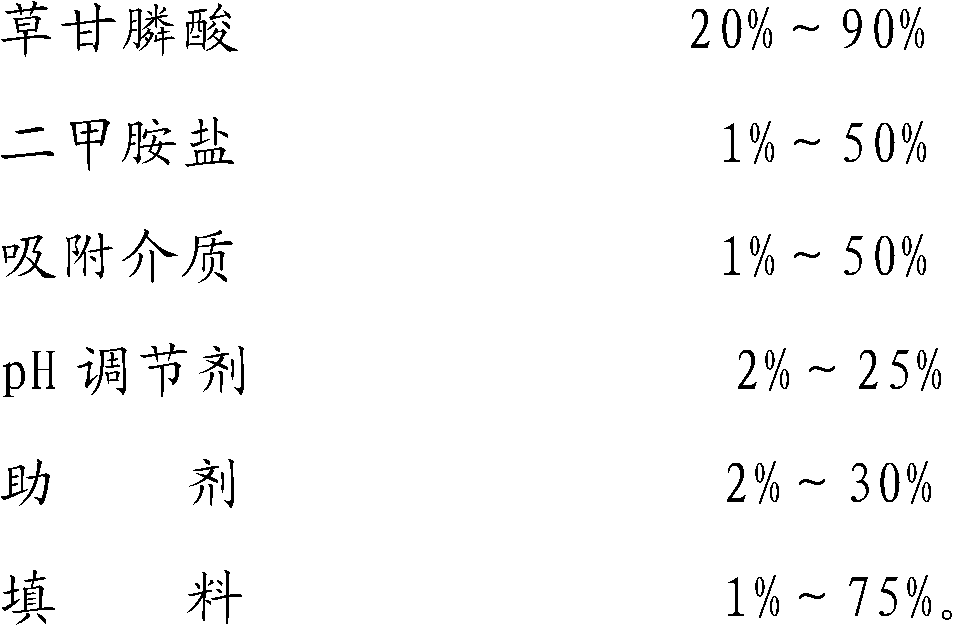

Solid herbicide composition

InactiveCN102870803ANot prone to chemical reactionsBiocideAnimal repellantsBiotechnologyResource consumption

The invention discloses a solid herbicide composition, comprising the following components of, by weight, 20%-90% of glyphosate acid, 1%-50% of a dimethylamine salt, a pH conditioning agent and 2%-30% of an auxiliary agent. The solid herbicide composition decreases the synthetic process for the raw material of a glyphosate dimethylamine salt, reduces resource consumption energy consumption, and is helpful to realize low-carbon economy. The method has relatively large competitive advantage by greatly reducing the cost of the final glyphosate dimethylamine salt.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

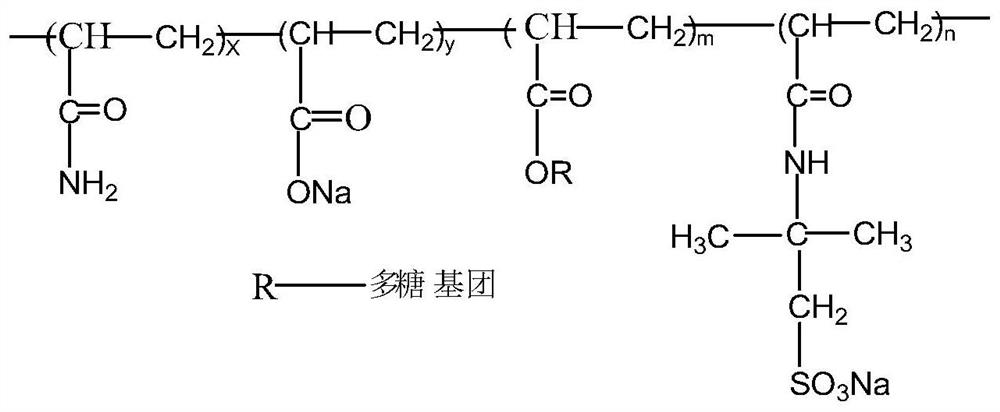

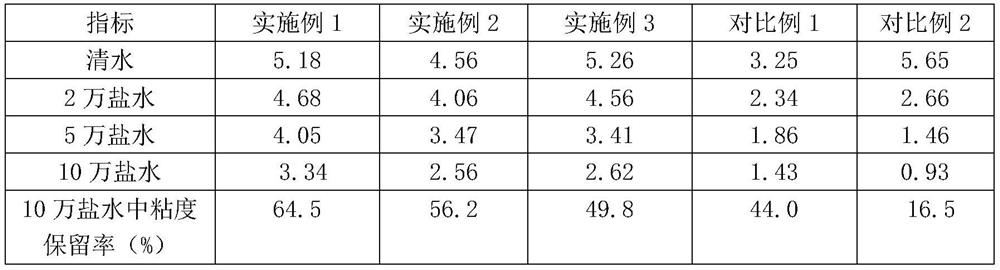

Polysaccharide modified salt-resistant resistance-reducing agent for shale gas fracturing fluid and preparation method thereof

ActiveCN112898488AHigh viscosityGood temperature and salt resistanceDrilling compositionDouble bondHydrolysis

The invention relates to preparation of a resistance-reducing agent, in particular to a polysaccharide modified salt-resistant resistance-reducing agent for shale gas fracturing fluid and a preparation method thereof. The salt-resistant resistance-reducing agent is a copolymer with a viscosity-average molecular weight of 7000000-18000000, wherein the monomer in the copolymer structure comprises the following components in parts by weight: 45-89 parts of acrylamide, 5-20 parts of hydrolyzed acrylamide or acrylic acid, 1-5 parts of modified polysaccharide and 5-30 parts of unit B. According to the invention, a novel polymerizable salt-resistant monomer is formed by carrying out structural modification on several biological polysaccharides and introducing double-bond groups, and is copolymerized with acrylamide and other monomers according to a certain proportion to form a polymer, wherein the polymer is high in molecular weight and more stable, and has the excellent performance of the biological polysaccharides and the acrylamide, so that a novel salt-resistant and high-temperature-resistant polyacrylamide copolymer is formed, and is particularly suitable for a high-salinity water fracturing process.

Owner:SHENYANG RES INST OF CHEM IND

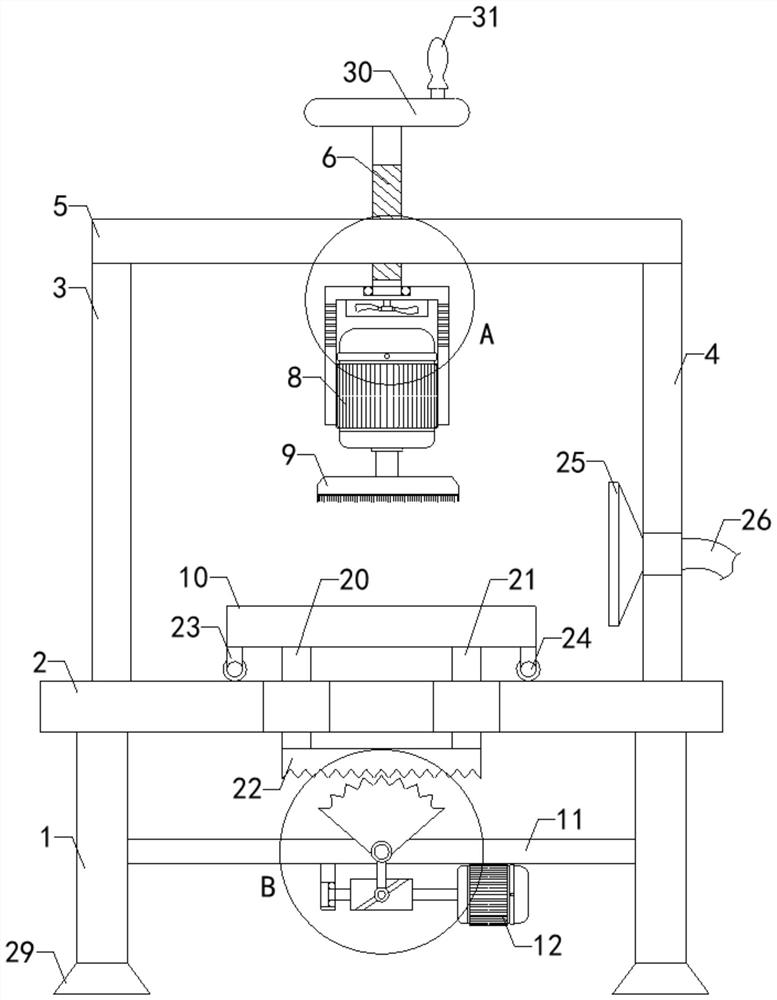

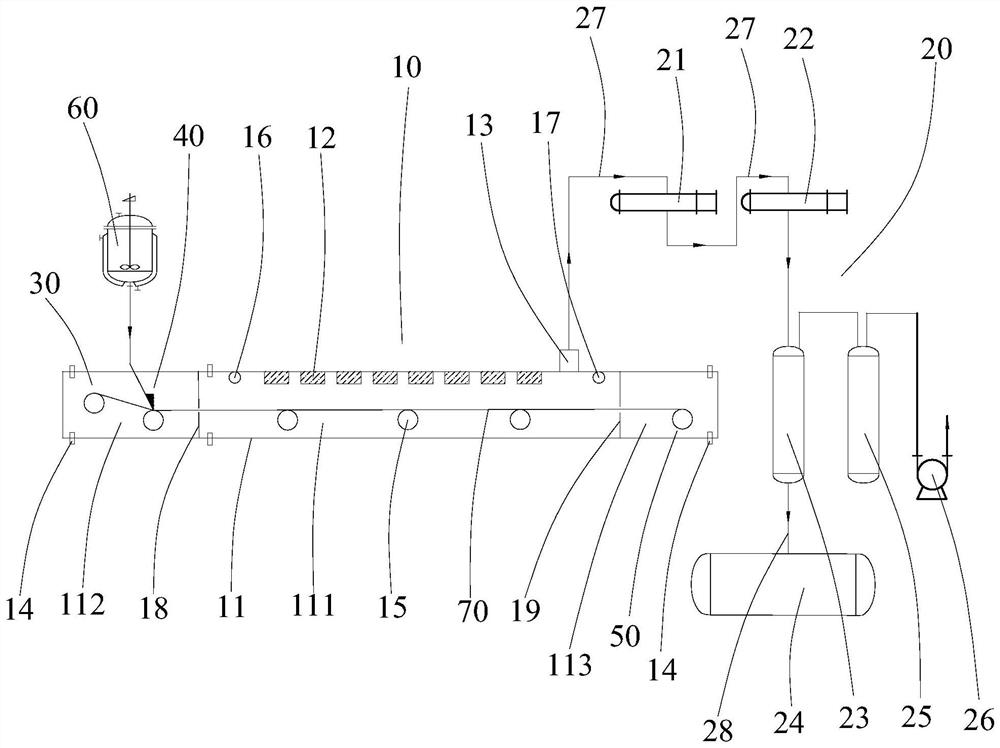

Lithium battery pole piece/diaphragm coating equipment and process

ActiveCN113751283AReduce the temperatureNot easy to crack and deformFinal product manufactureDispersed particle separationChemistryVapor–liquid separator

The invention discloses lithium battery pole piece / diaphragm coating equipment which comprises a coating machine body and a tail gas treatment mechanism, the coating machine body is provided with a closed high-pressure-resistant cavity, and an unwinding mechanism, a coating mechanism and a winding mechanism are sequentially arranged in the cavity. A heating device for heating a coating in a radiation mode is arranged between the coating mechanism and the winding mechanism, the tail gas treatment mechanism comprises a first-stage condenser, a second-stage condenser, a gas-liquid separator, a vacuum buffer tank and a vacuum pump which are sequentially connected through vacuum pipes, and the gas-liquid separator is connected with a recovered solvent storage tank through a liquid separation pipe; a tail gas extraction opening communicated with the cavity is formed in the coating machine body and is connected with the first-stage condenser through a vacuum pipe; the invention also discloses a lithium battery pole piece / diaphragm coating process. The process comprises the following steps of S1, nitrogen charging, S2, coating, and S3, tail gas treatment; and energy consumption can be reduced, enterprise cost can be reduced, and solvent recovery rate and product quality can be improved.

Owner:东莞市鹏锦机械科技有限公司

Composite milk mineral table salt

ActiveCN102551029ADoes not affect appearanceDoes not affect the tasteFood preparationPotassiumChloride

The invention discloses a composite milk mineral table salt and in particular relates to a composite milk mineral table salt which integrates the functions of supplementing calcium, reducing pressure, lowering blood lipid and sugar levels, relieving fatigue and improving immunity. The table salt is characterized in that milk minerals, potassium chloride and taurine are added to the table salt. The invention has the advantages that: the table salt has a reasonable formula, a target-oriented effect and a significant synergistic effect, fills in the blank in the market, is palatable and convenient to serve, has no toxic or adverse effect, has a simple production process, is easy to produce, and has a potential in market development.

Owner:李卫平

Seasoning material with health-care functions

InactiveCN106418412AWith health functionReasonable formulaFood ingredient functionsActive componentSalt content

The present invention provides a seasoning material with health-care functions. The seasoning material is prepared from purely natural raw materials, low in salt content, rich in flavoring components, free of artificial food additives, and rich in active components with health-care and nutritional functions, can play the effects of improving immunity and lowering blood pressure, and is originally ecological and health-care.

Owner:邓志程

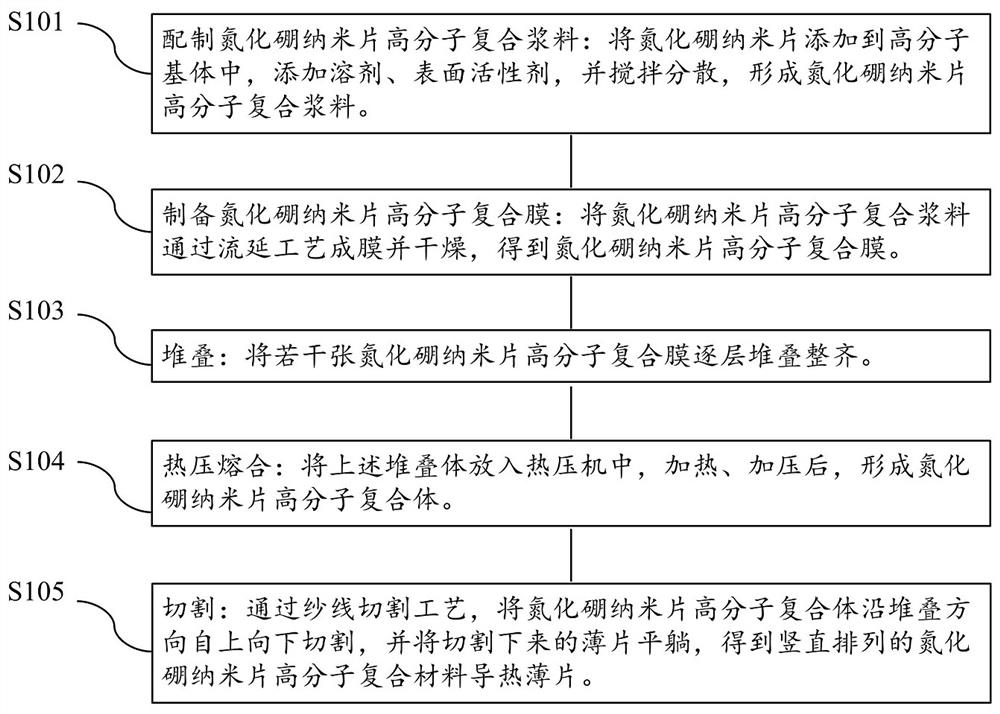

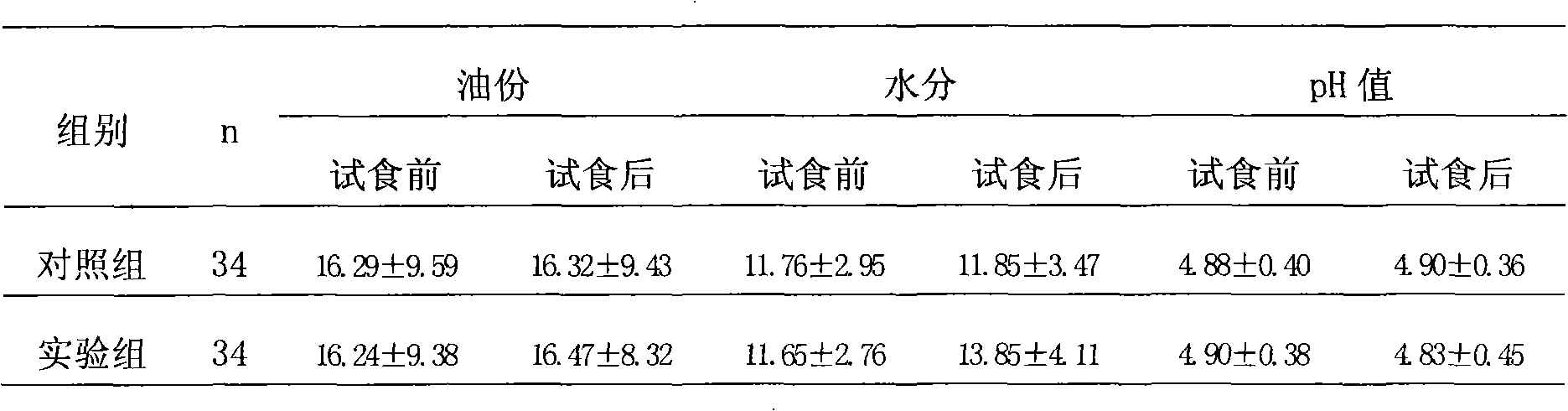

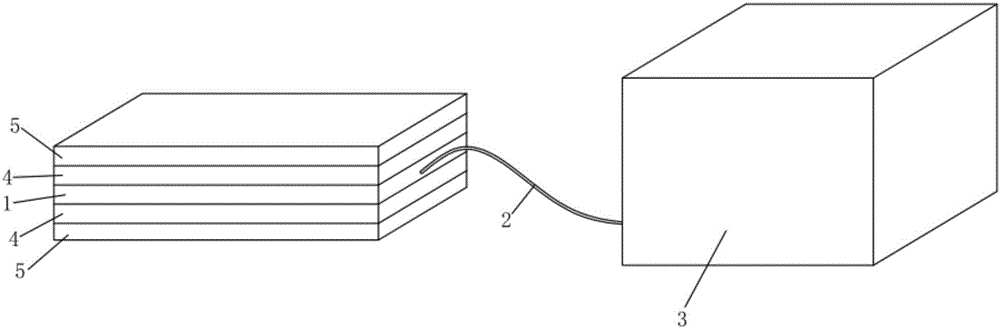

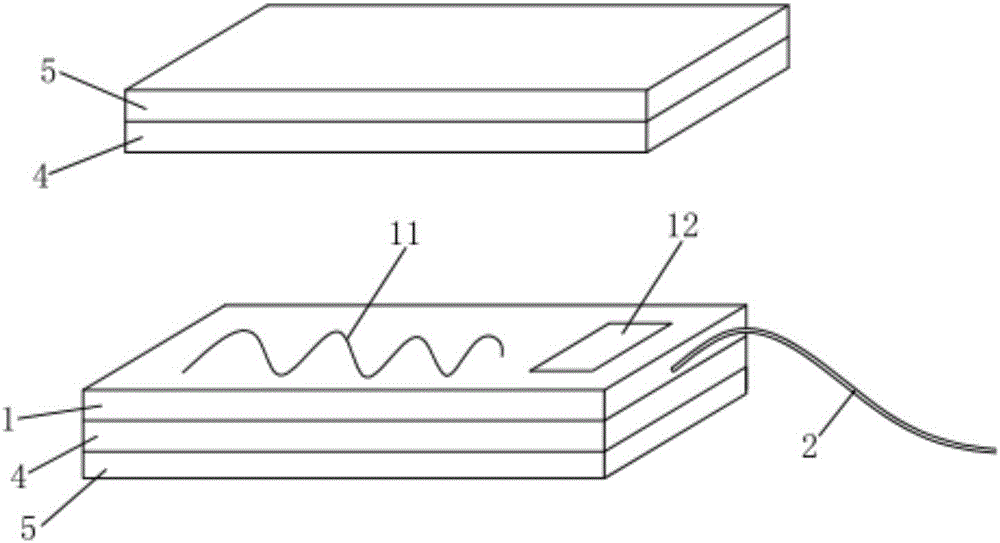

Vertically-arranged boron nitride nanosheet polymer composite material heat-conducting sheet and preparation method thereof

InactiveCN113524741AOvercoming the Problem of Polymer CompoundingEasy to prepareFlat articlesYarnBoron nitride

The invention provides a vertically arranged boron nitride nanosheet polymer composite material heat-conducting sheet and a preparation method thereof. A composite material takes a boron nitride nanosheet with a sheet structure as a filler, the filler is added into a polymer matrix, and a horizontally arranged boron nitride nanosheet polymer composite film is formed through stirring and casting processes, and stacking, hot-pressing fusion and yarn cutting processes are performed on the boron nitride nanosheet polymer composite film to prepare the vertically arranged boron nitride nanosheet polymer composite material heat-conducting sheet. Boron nitride nanosheets are vertically arranged in the polymer matrix, so that the interface thermal resistance is reduced, the heat conductivity coefficient of the material is improved, the composite material heat-conducting sheet with the thickness of 0.05-0.40 mm can be obtained through the yarn cutting process, the thermal resistance is smaller, and heat transfer is facilitated. The method is simple, reliable and high in operability, and can be applied to preparation of polymer composite materials of boron nitride nanosheets and various systems. The boron nitride nanosheet composite material heat-conducting sheet prepared by the method provided by the invention can be widely applied to heat management of electronic products.

Owner:HARBIN INST OF TECH AT WEIHAI

Young vitamin system pre-mixing material and preparation method thereof

InactiveCN101455275APromote absorptionStable absorptionAnimal feeding stuffAccessory food factorsFood additiveSide effect

The present invention relates to a nutrient and defence element premix and preparation method thereof, more specifically to a composite food nutrition intensifying agent, pertaining to the field of food additives and nutrition intensifying technology. The product formula of the invention is composed by the ferralia, zinc agent, copper agent, taurine, niacin, stabilizing agent and carrier. The invention has positive effects of reasonable formula, synergy, good mobility, long shelf-life, non-electrostatic adsorption, non-toxic side effects, safety and stability, and easy achievement of implement the automation packaging of products, and the like; but also has advantages of easy intensifying and addition process, streamline procurement procedures, storage convenience, reduced waste, etc., thereby providing facilitation guarantee for large-scale industrial production.

Owner:BEIJING T&X BIOTECH

Functional collagen nourishment

The invention discloses functional collagen nourishment, and particularly relates to efficacy-enhancement oral functional collagen nourishment integrated with various healthcare functions of remarkably improving face skin moisture, removing freckle and beautifying, strengthening body immune and repair abilities, improving sleeping and the like. The functional collagen nourishment is characterizedin that lactoferrin, alpha-lactalbumin and L-arabinose are added in collagen. The functional collagen nourishment has the advantages that the functional collagen nourishment is reasonable in proportioning, high in pertinence, remarkable in synergistic effect, good in taste, convenient to eat, fine in safety, free of toxic and side effects, simple in production process and easy in production, fills gaps of markets, and has quite a high market development potential.

Owner:BEIJING SANLIYUAN FOOD TRADING

Raw material bag applied to food processing machine

PendingCN109259068AThick and smooth tasteProne to delaminationFood ingredient functionsPsyllium HuskFood processing

The invention relates to a raw material bag applied to a food processing machine. The food processing machine is used for mixing the raw material bag and water and crushing into slurry at a crushing rotating speed of 5000 to 30000r / min; the raw material bag is prepared from 40 to 50 percent of oat, 10 to 25 percent of soybeans, 1 to 20 percent of quinoa and 0.5 to 5 percent of psyllium husk, wherein the soybeans are baked whole beans; the quinoa is in a puffed popcorn form. The food processing machine is used for crushing the raw materials; a manufactured beverage cannot be delaminated; the instant eating is realized; various nutrition elements beneficial to the health are provided; meanwhile, loss and nutrition risk caused by the raw material crushing in advance can be reduced.

Owner:JOYOUNG CO LTD

Raw material bag applied to food processing machine

The invention relates to a raw material bag applied to a food processing machine. The food processing machine is used for mixing the raw material bag and water and crushing into slurry at the crushingrotating speed of 5000 to 30000 r / min, wherein the raw material bag comprises 40 to 60 percent of oat, 10 to 25 percent of soybeans, 5 to 15 percent of dried apples and 17 to 35 percent of mixed nuts; the soybeans are baked whole beans; the dried apples are subjected to low-temperature drying; the mixed nuts are subjected to microwave treatment. The food processing machine is used for crushing the raw material bag; a manufactured beverage cannot generate delamination; instant eating and instant use are realized; various nutrition elements benefiting intelligence and tonifying the brain can beprovided; meanwhile, the loss and nutrition risk caused by the raw material crushing in advance can be reduced.

Owner:JOYOUNG CO LTD

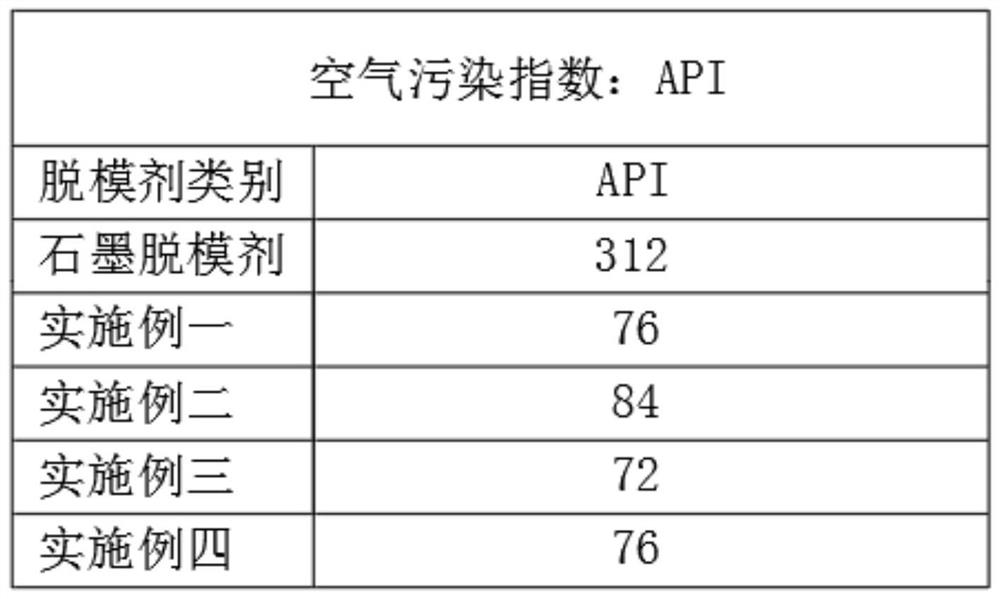

Novel releasing agent

InactiveCN106906037AExtended service lifeImprove casting qualityLubricant compositionChemical reactionHeat resistance

The invention discloses a novel releasing agent. The novel releasing agent is prepared from the following raw materials and formulation components in parts by weight: 70 to 95 parts of aquadag, 2 to 3 parts of edible salt, 7 to 8 parts of an emulsifying agent, 1 to 5 parts of polyacrylamide, 1 to 2 parts of a defoamer, 1 to 7 parts of organic silicon resin and 20 to 30 parts of deionized water. The novel releasing agent disclosed by the invention has good heat insulation and heat control effects; the service life of a mold can be prolonged, and the casting quality can be improved; the novel releasing agent has good lubricating property, releasing property, chemical stability and high-temperature adhesiveness, is unlikely to produce a chemical reaction, is easy for coating, has extremely high heat resistance, is unlikely to age the coating, is unlikely to freeze and solidify at too low temperature, and is low in cost.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

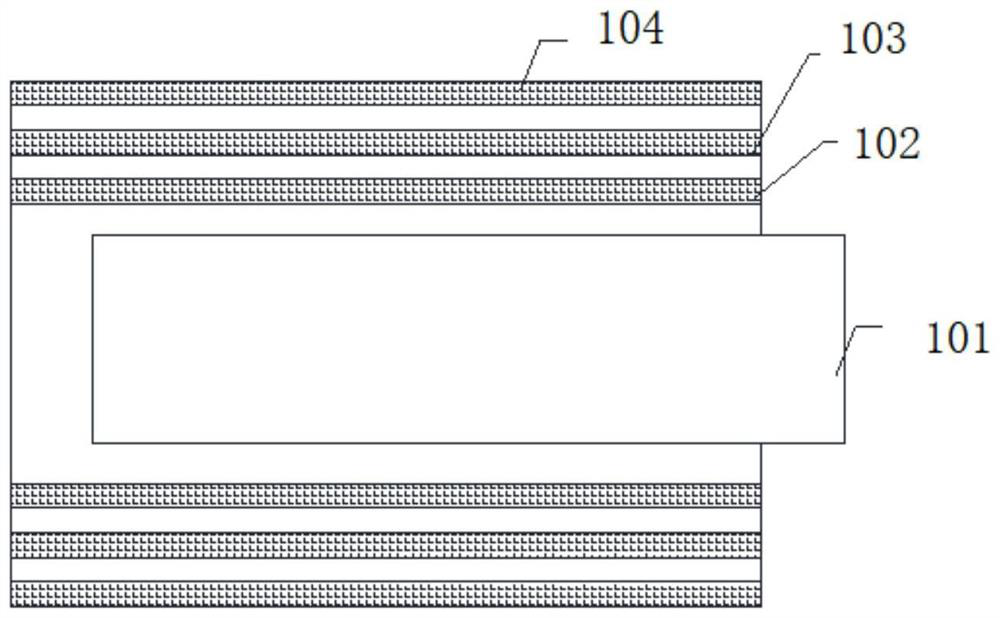

Device for heating to stop corrosion and application method of device

PendingCN106851870ALow production costLess power consumptionHeater elementsCoupling device detailsElectric heatingCorrosion

The invention provides a device for heating to stop corrosion. The device comprises a first flame-retarding cotton layer located in the middle, wherein the first flame-retarding cotton layer is provided with an electric heating wire and a temperature control switch; the electric heating wire is connected with the temperature control switch through an electric wire; the temperature control switch is connected with a switching switch through an electric wire; a second flame-retarding cotton layer is arranged outside the first flame-retarding cotton layer; an insulating leather or PVC (Polyvinyl Chloride) layer is further arranged outside the second flame-retarding cotton layer; the first flame-retarding cotton layer, the second flame-retarding cotton layer and the insulating leather or PVC layer are connected in a seam connection manner. The device provided by the invention has the beneficial effects that the structure is simple and water steam cannot be condensed into water on a metal surface of a protected part or daily electric appliance through a heating form when an electric appliance works or stops working, so that the metal of the part or the daily electric appliance is protected, and chemical reaction is not easy to occur, and furthermore, the service life of the part or the daily electric appliance is prolonged.

Owner:朱夕青

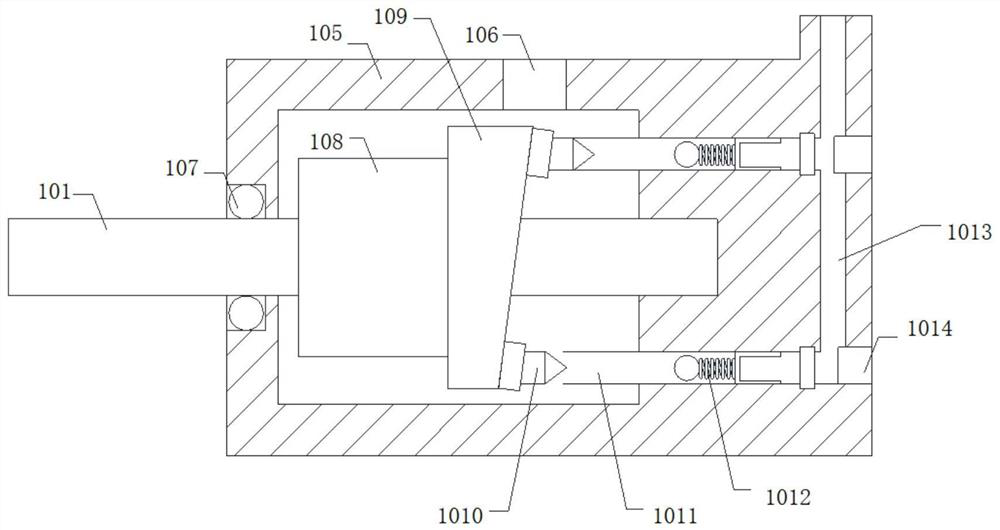

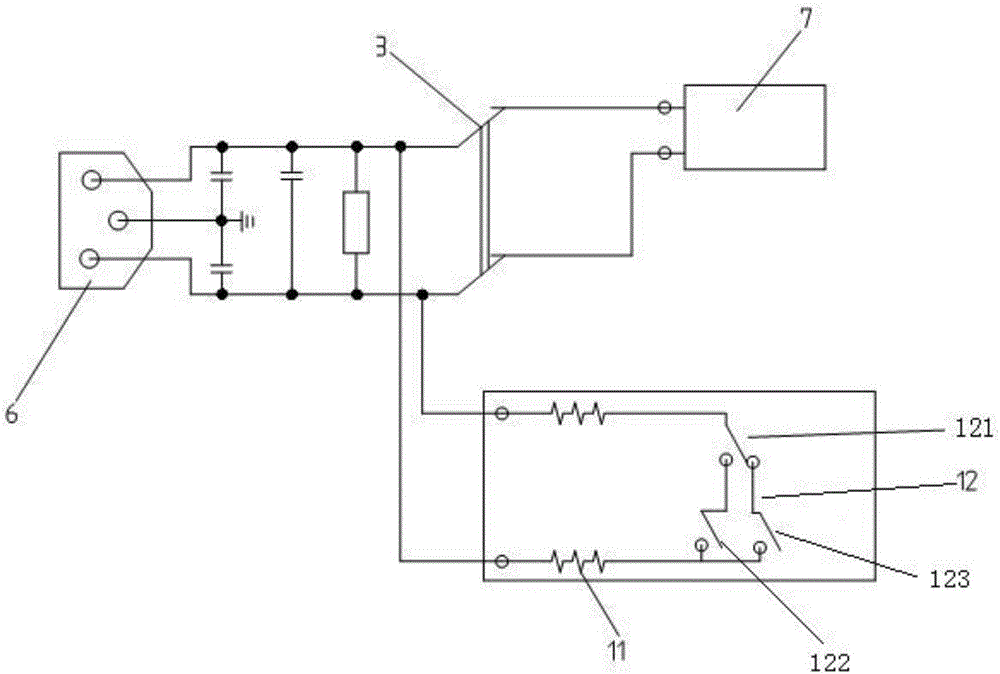

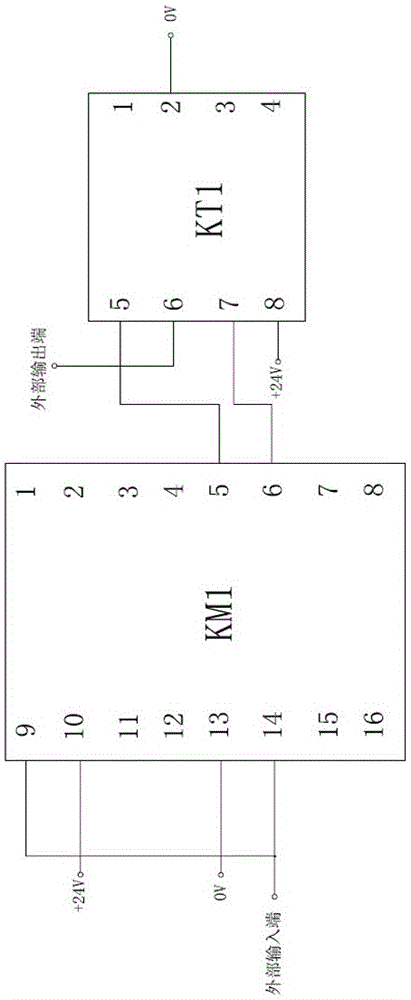

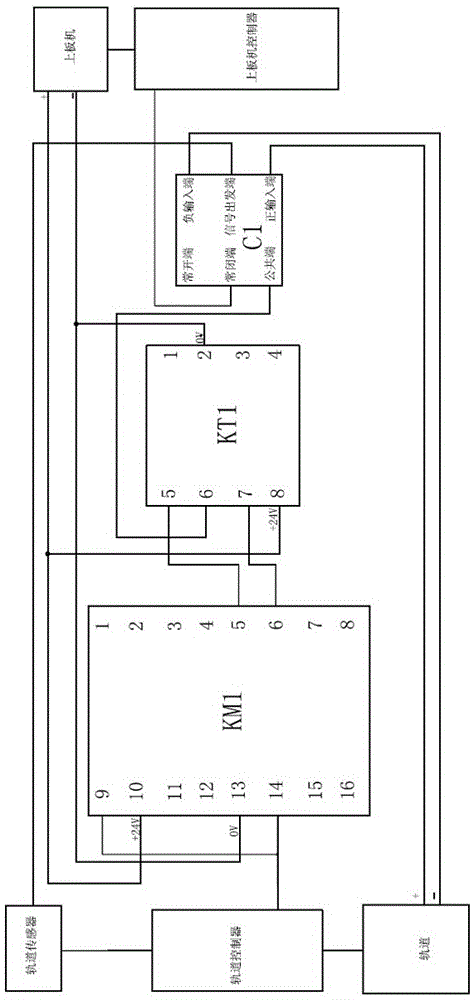

SMT production rhythm control system and self-locking time-delay loop thereof

ActiveCN105676828APrevent signal transmission errorsGuaranteed real-time transmissionTotal factory controlProgramme total factory controlTime delaysControl system

The invention provides an SMT (Surface Mount Technology) production rhythm control system, which controls substrate entering time, unifies step time, and thereby reduces the exposure time of solder paste or elements, decreases solder paste oxidation, and improves an SMT production yield rate. The system comprises a loader controller, a track controller and a track sensor which are in electric control connection; the track controller induces non-existence of a substrate on an induction track through the track sensor, and then issues a signal for requiring a substrate to the loader controller. The system also comprises a relay KM1 which is in electric control connection with the track controller, and intercepts the signal for requiring a substrate issued by the track controller to trigger the relay KM1; and a time relay KT1 which is in electric control connection with the relay KM1, wherein the relay KM1 triggers the time relay KT1, and forms a self-locking time-delay loop with the time relay KT1, and the time relay KT1 delays sending the signal for requiring a substrate.

Owner:RF360 TECH (WUXI) CO LTD

Aluminum alloy forging release agent

ActiveCN113372987ASolving Corrosion ProblemsStable chemical propertiesLubricant compositionCellulosePolyvinyl alcohol

The invention discloses an aluminum alloy forging release agent. The release agent comprises, by weight, 2-5% of an isobutene and maleic anhydride copolymer, 1-2.5% of sodium hydroxide, 2-5% of polyvinyl alcohol, 0.1-1% of polyacrylamide, 0.5-2% of sodium carboxymethyl cellulose, 3-5% of sodium polyphosphate, 2-5% of borax, 1-2% of sodium benzoate, 0.5-1% of siloxane ketone, and the balance of deionized water. Under the action of siloxane ketone and polyvinyl alcohol, the isobutene and maleic anhydride copolymer, polyacrylamide, sodium carboxymethyl cellulose, sodium polyphosphate, borax and sodium benzoate form a surface layer with good lubricity and demolding property at high temperature, and the surface layer is non-stick to a mold, so that the production efficiency of demolding operation is improved; most importantly, under high-temperature forging, due to the water retention characteristic, particles in the components are not prone to drying to generate dust, the problem that a traditional forging release agent seriously pollutes the environment is solved, and due to the fact that graphite is not contained, stains, pits and corrosion cannot be generated on forgings, and cleaning after forging is more convenient.

Owner:西安思凯石化科技有限公司

Fructus phyllanthi polyphenol product

InactiveCN107411086AReasonable formulaImprove absorption rateProtein composition from fishInorganic compound food ingredientsMedicineAdditive ingredient

The present invention provides a fructus phyllanthi polyphenol product. The fructus phyllanthi polyphenol product is rich in active ingredients and collagen. By combining each of components, the fructus phyllanthi polyphenol product is improved in skin whitening effects, at the same time improves human body environment and an absorption rate of each of the components in human body, thus reaches effects of improving skin vitality and whitening skin, and has an effect of improving immunity.

Owner:惠州嘉联生物科技开发有限公司

Raw material bag applied to food processing machine

The invention relates to a raw material bag applied to a food processing machine. The food processing machine is used for mixing the raw material bag and water and crushing into slurry at the crushingrotating speed of 5000 to 30000 r / min, wherein the raw material bag comprises 40 to 50 percent of oat, 10 to 30 percent of red date slices, 5 to 25 percent of soybeans, 5 to 10 percent of dried apples and 0.5 to 5 percent of ginger granules. The red date slices are shaped like a round slice sheet with the specification being 1 to 2cm; the soybeans are baked whole beans; the dried apples are subjected to low-temperature drying; the specification of the ginger granules is 1 to 2mm. Compared wit the prior art, the raw material bag has the advantages that the food processing machine is used for crushing the raw material bag; a manufactured beverage cannot generate delamination; instant eating and instant use are realized; various nutrition elements benefiting qi and tonifying blood can be provided; meanwhile, the loss and nutrition risk caused by the raw material crushing in advance can be reduced.

Owner:JOYOUNG CO LTD

Nutritious skin whitening healthcare product

InactiveCN106620658AReasonable formulaChemical reaction synergyPeptide/protein ingredientsHydroxy compound active ingredientsCitrate sodiumAbsorption rate

The invention provides a nutritious skin whitening healthcare product. The nutritious skin whitening healthcare product comprises, by weight, 40-50 parts of active components A, 1-3 parts of potassium chloride, 5-8 parts of xylitol, 2-4 parts of sodium citrate, 10-30 parts of collagen, 11-15 parts of active components B, 9-13 parts of active components C, 2-6 parts of sodium bicarbonate, 0.3-0.5 part of honey, 3-5 parts of glucan and 32-65 parts of water. The nutritious skin whitening healthcare product has the advantages that the nutritious skin whitening healthcare product contains abundant active ingredients and the collagen, various components are matched with one another, accordingly, skin whitening effects of the nutritious skin whitening healthcare product can be improved, and human body environments can be improved; the absorption rates of the various components in human bodies can be increased, accordingly, effects of improving the skin vitality and whitening skins can be realized, and the nutritious skin whitening healthcare product has a function of enhancing the immunity.

Owner:邓志程

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com