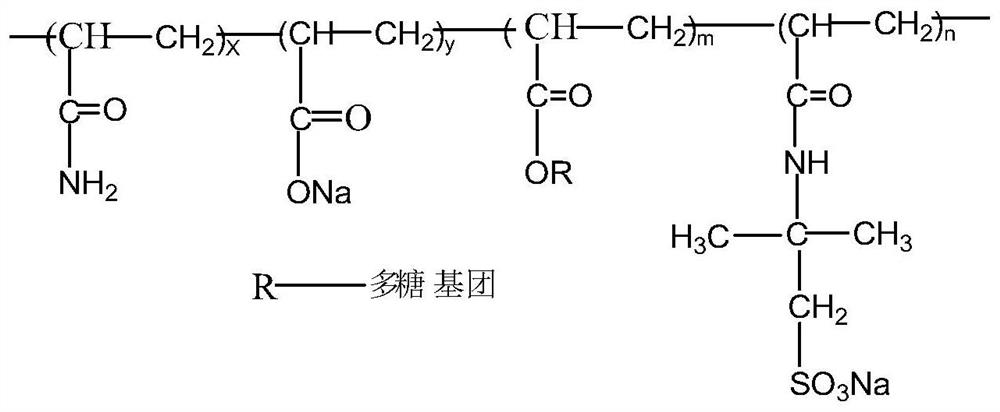

Polysaccharide modified salt-resistant resistance-reducing agent for shale gas fracturing fluid and preparation method thereof

A technology of drag reducing agent and polysaccharide, which is applied in the field of polysaccharide-modified anti-salt drag reducing agent for shale gas fracturing fluid and its preparation, which can solve the problem of solution viscosity drop, inability to meet salt resistance, polymer main chain breakage and degradation, etc. problems, to achieve the effect of increasing the solution viscosity, improving the comprehensive performance of temperature resistance and salt resistance, and obvious solution viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

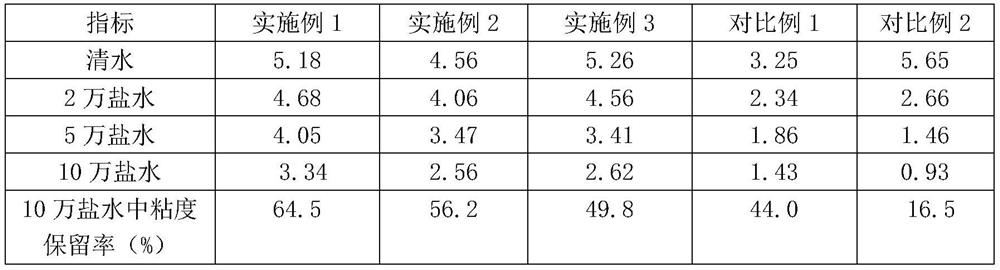

Examples

Embodiment 1

[0034] 1) Synthesis method of typical polymerizable modified polysaccharides:

[0035] Synthesis of chemical modification of xanthan gum: a large number of active hydroxyl groups on the outside of xanthan gum molecules react with maleic anhydride, and use the high activity of anhydride to undergo esterification reaction with hydroxyl groups, thereby introducing polymerizable double bonds and synthesizing modified xanthan gum. Raw gum MX (ie xanthan gum maleate (MA)).

[0036] Specific synthesis conditions: Dissolve 10.5g (0.11mol) of maleic anhydride in 100mL of tetrahydrofuran, add 20g (0.0214mol) of xanthan gum to swell for 1 hour; wherein, the molar ratio of xanthan gum to maleic acid is 1:5. Add 0.35g p-toluenesulfonic acid catalyst and 0.002g hydroquinone polymerization inhibitor, heat the system to 60°C, react at constant temperature for 24h, cool the reaction liquid to room temperature, and filter. The filter cake was washed successively with tetrahydrofuran (20mL×1), ...

Embodiment 2

[0040] 1) Synthesis of butyl glucoside maleate: add 102.85g n-butanol in a there-necked flask equipped with a thermometer, a stirrer and a nitrogen pipe, add 0.092g concentrated sulfuric acid dropwise under stirring, divide 5 Add 27.825g of glucose at a time, react at 105°C for 4.5h, use Fehling's reagent to detect the end point of the reaction, after the reaction, add 1mL of 2mol / L NaOH solution to neutralize the excess concentrated sulfuric acid, and distill off n-butanol under reduced pressure. Butyl glucoside is obtained. The obtained 0.15 mol of butyl glucoside was mixed with 29.4 g (0.3 mol) of maleic anhydride, 0.11 g of concentrated sulfuric acid was added, and the reaction was stirred at 60° C. for 3 h to obtain butyl glucoside maleate (BGMAH).

[0041] 2) Preparation of anti-salt drag reducing agent:

[0042] Add 60g solvent naphtha, 10.4g SPAN-80, 1.6g OP-10 to another three-necked flask, stir quickly to disperse into a uniform oil phase; accurately weigh 49g AM, 2...

Embodiment 3

[0044] 1) Synthesis of modified cyclodextrin (β-CD-A A): Weigh a certain amount of β-CD and 1,3-dicyclohexylcarbodiimide (DCC) condensing agent, dissolve in DMF, and heat at room temperature Add acrylic acid with the same molar ratio as DCC dropwise, and after adding dropwise for 30 minutes, continue to react at 80°C for 3 hours. After the reaction, remove the precipitated solid by vacuum filtration, and precipitate the crude product from the filtrate with acetone. Treatment, dissolving in distilled water and methanol, acetone precipitation and purification, vacuum drying to obtain acrylic acid β-cyclodextrin ester.

[0045] 2) Preparation of salt-resistant drag-reducing agent: synthesized according to the mass ratio of AM:AMPS:AA:modified cyclodextrin=10:1:2:0.6, the total mass fraction of the monomer is 30%, and the emulsifier adopts SPAN-80 and SMO-5 composite, the dosage is 4.5% of the total mass, kerosene is the reverse phase solvent, the addition is 20% of the total mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com