Patents

Literature

63results about How to "Not easy to chemical reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

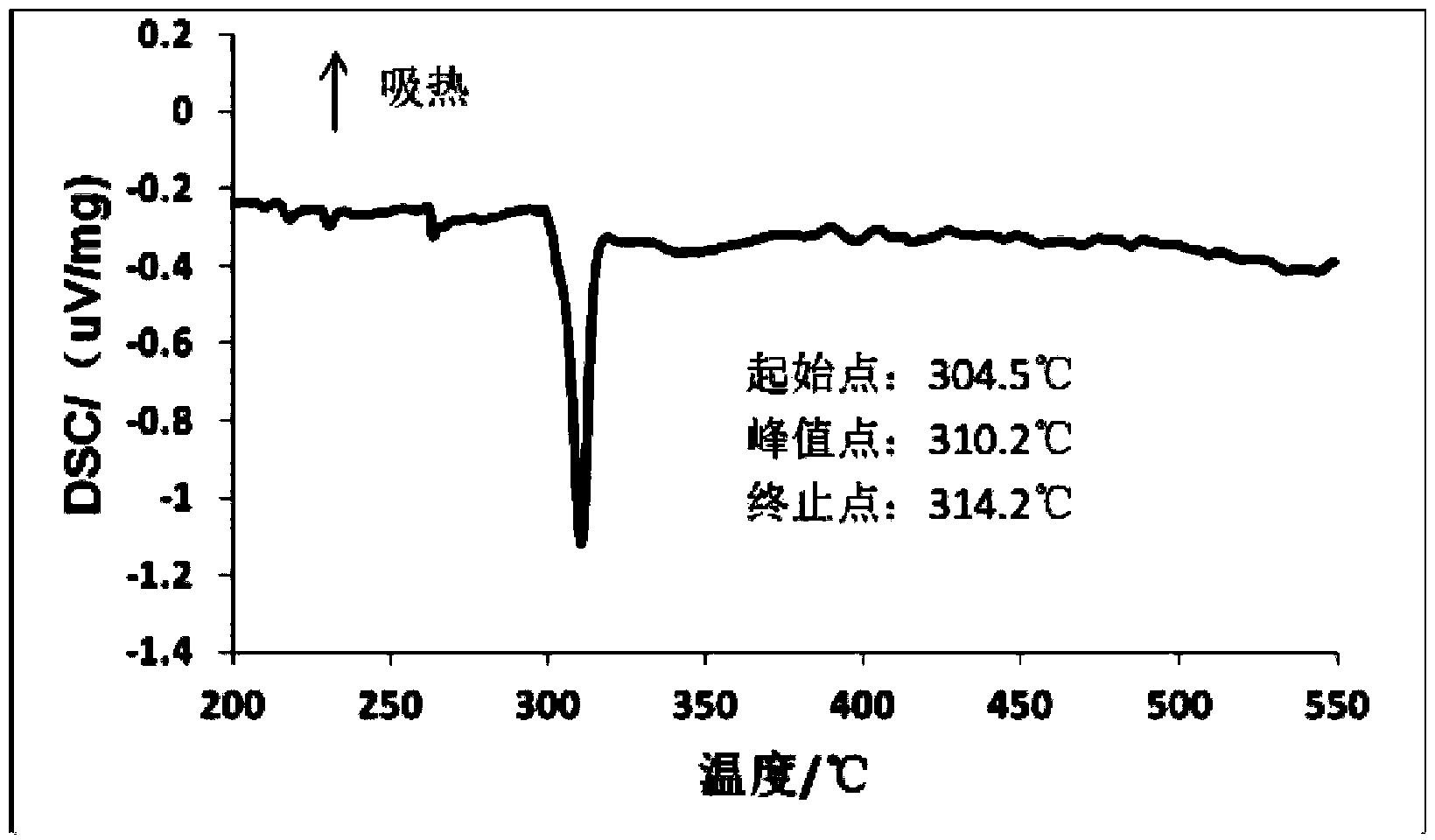

Gas hydrate generation accelerant and preparation method thereof

ActiveCN103663451AEnhance heat and mass transferShorten the timeCarbon compoundsGeneration processLiquid water

The invention belongs to the field of gas hydrate production and utilization and in particular relates to an accelerant capable of reinforcing gas hydrate generation and a preparation method thereof. The hydrate generation accelerant is a mixed water solution formed by compounding nano dispersed particles with a surfactant and dissolving the compound in water, wherein nano graphite powder is adopted as the nano dispersed particles; SDBS (sodium dodecylbenzenesulfonate) is adopted as the surfactant; based on the total amount of the mixed water solution, the mass fraction of the nano graphite powder is 0.05-1.5%, the mass fraction of SDBS is 0.02-0.08% and the balance is water. The accelerant has the obvious advantages that the mass and heat transfer processes of the hydrate can be greatly reinforced, the overall time of hydrate generation can be shortened and the synthetic efficiency of the hydrate can be improved by adopting the accelerant to reinforce the hydrate generation process; the graphite nano-particles can flow out along with liquid water and can be reused, thus saving the cost.

Owner:溧阳常大技术转移中心有限公司

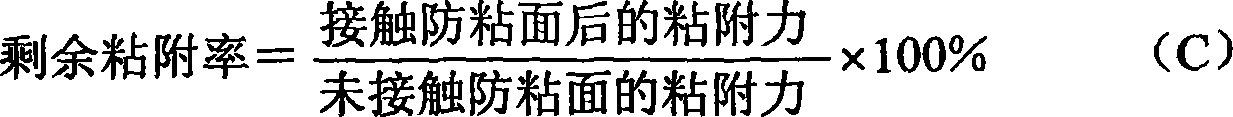

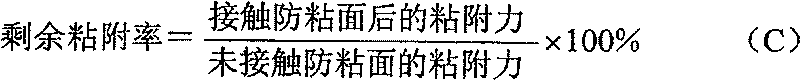

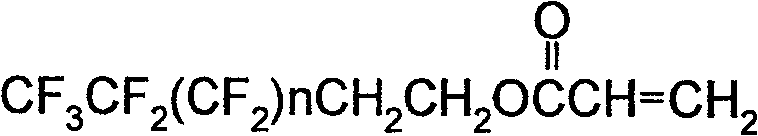

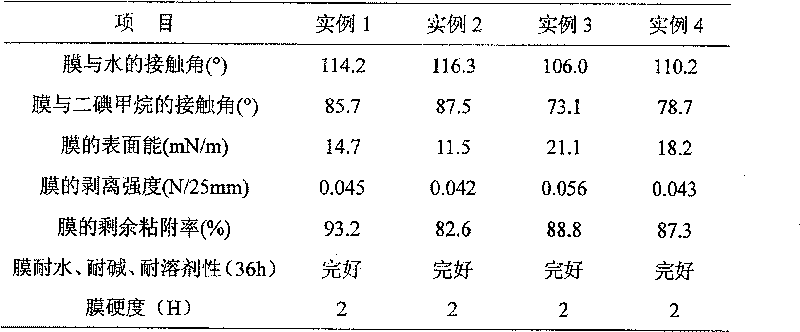

Production of fluoride acrylic-resin multipolymer anti-adhesive agent

Production of fluoride acrylate multi-polymer adhesion preventive agent is carried out by adding into solvent, non-fluoride monomer and fluoride monomer under existence of inert gas, raising temperature to 40-95degree, dissolving for monomers, dripping into initiator solution for 2-10hrs, heating to 60-110degree, reacting for 1-5hrs, and cooling to room temperature to obtain the final product. It has excellent water-proof and anti-solvent performances and alkali resistance and low stripping property.

Owner:SOUTHEAST UNIV

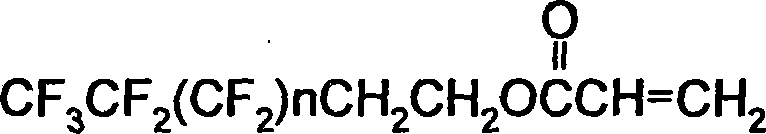

Submerged arc furnace body and constructing method thereof

The invention provides a submerged arc furnace body. The submerged arc furnace body comprises a furnace bottom and a furnace wall which is connected with the furnace bottom; the furnace bottom comprises an asbestos board layer, a refractory grain layer, a refractory brick layer, a ramming material layer and a refractory material layer, wherein the asbestos board layer is laid on a furnace bottom steel plate; the refractory grain layer is paved on the asbestos board layer; the refractory brick layer is constructed on the refractory grain layer, and comprises refractory bricks and refractory clays filled among the refractory bricks; the ramming material layer is paved on the refractory brick layer; and the refractory material layer is constructed on the ramming material layer. The invention further provides a constructing method for the submerged arc furnace body. Ramming materials are used to replace carbon bricks to construct the submerged arc surface body, the ramming materials can form a firm integrated sintering layer under the high-temperature sintering condition, so that the sintering layer has no seam and does not easily generate cracks in a smelting process while alternatively acted by cold and heat, thus molten iron can be prevented from eroding and burning through the furnace bottom, the service life of the submerged arc furnace is prolonged, the cost of metal melting is reduced, and the safety of the submerged arc furnace body is increased.

Owner:李成武

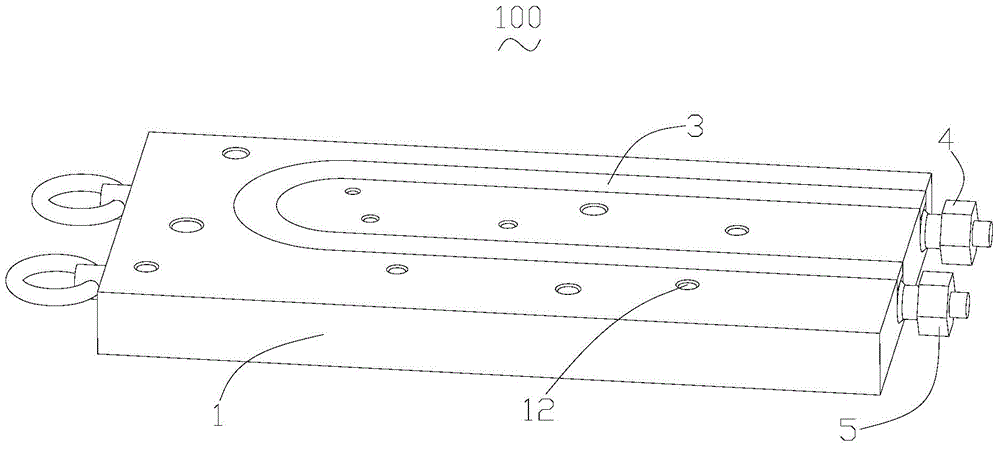

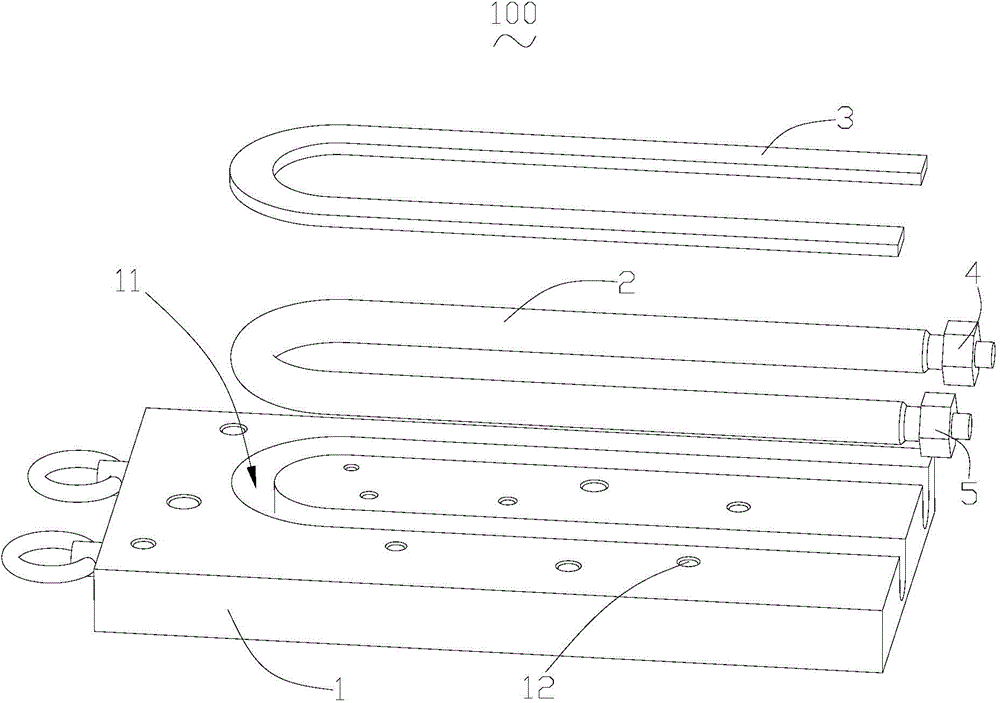

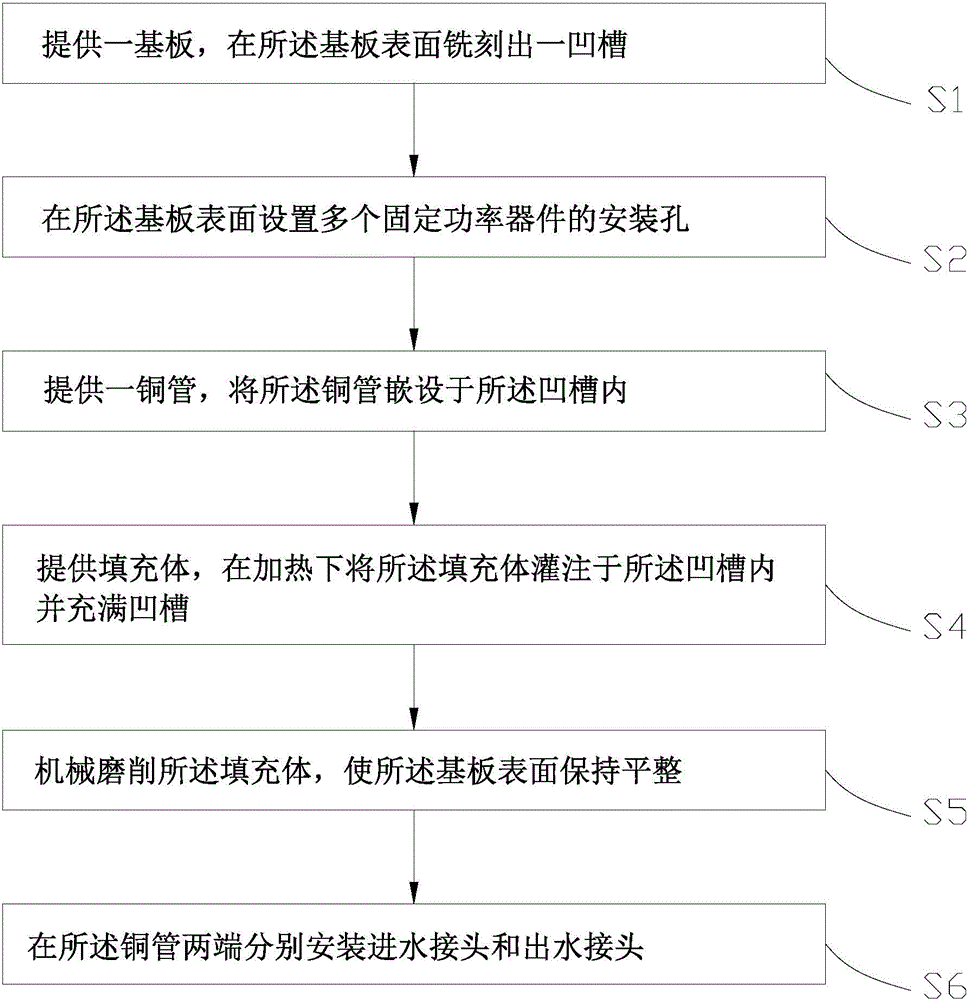

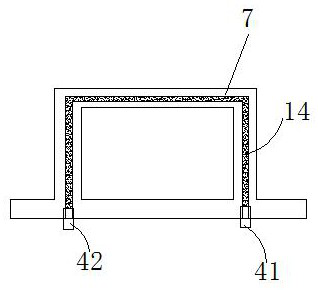

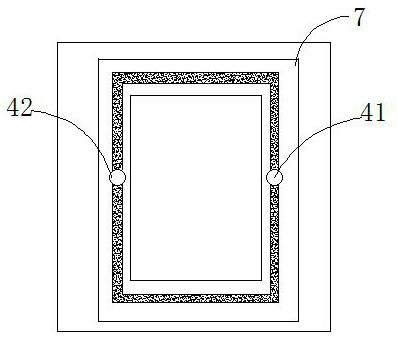

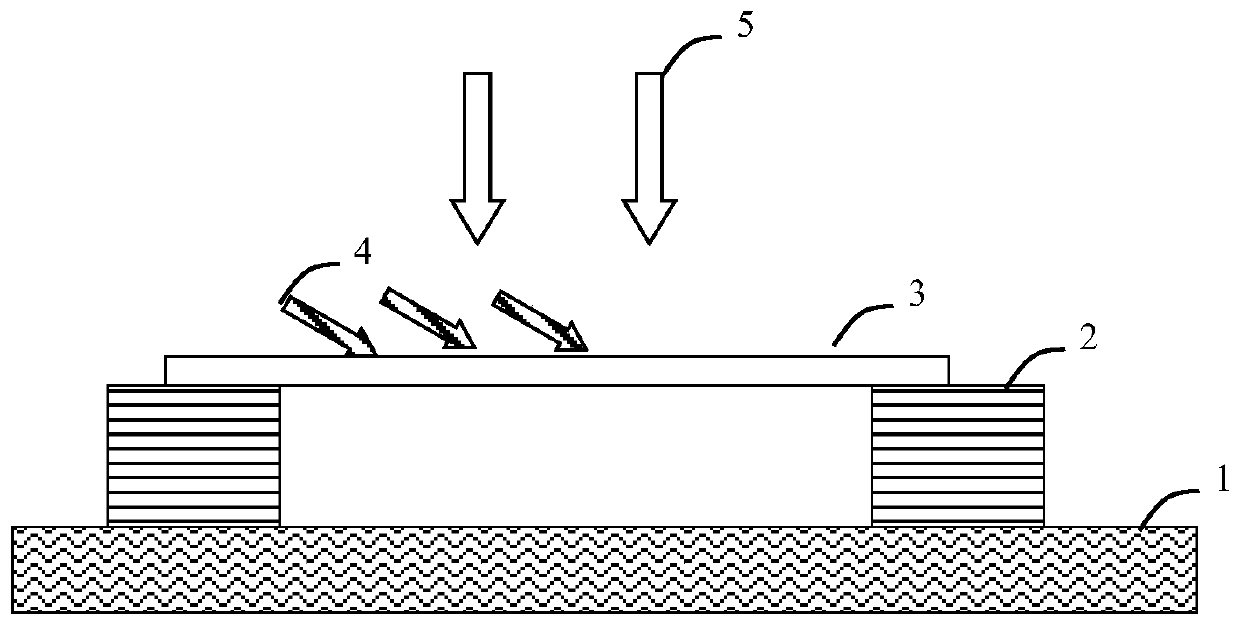

Method for preparing water cooling plate

ActiveCN104486938AImprove reliabilityNot easy to chemical reactionCooling/ventilation/heating modificationsChemical reactionCooling effect

The invention provides a method for preparing a water cooling plate. The method comprises the steps that a substrate is provided, and a groove is milled in the surface of the substrate; a copper tube is provided, and the copper tube is embedded in the groove; a filling body is provided, the filling body is poured into the groove under a heating condition, and the groove is full of the filling body; the filling body is mechanically ground, and the surface of the substrate is kept flat; a water inlet joint and a water outlet joint are mounted at the two ends of the copper tube respectively. According to the method for preparing the water cooling plate, the copper tube is embedded in the substrate to be used as a cooling liquid channel, and the copper tube can not be likely to be in chemical reaction with cooling liquid, so that substances with the very low thermal conductivity are prevented from being accumulated on the wall face of a pipeline, the heat exchange between the cooling plate and the cooling liquid is guaranteed, the good cooling effect can be kept for a long time, the reliability of the water cooling plate is improved, the filling body is poured in the groove, the copper tube can be fixed, and the flatness of the surface of the substrate can also be guaranteed.

Owner:DONGGUAN WERY DOOD CIRCUIT BOARD EQUIP

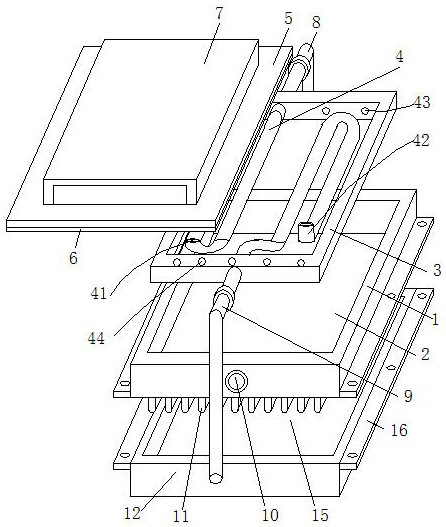

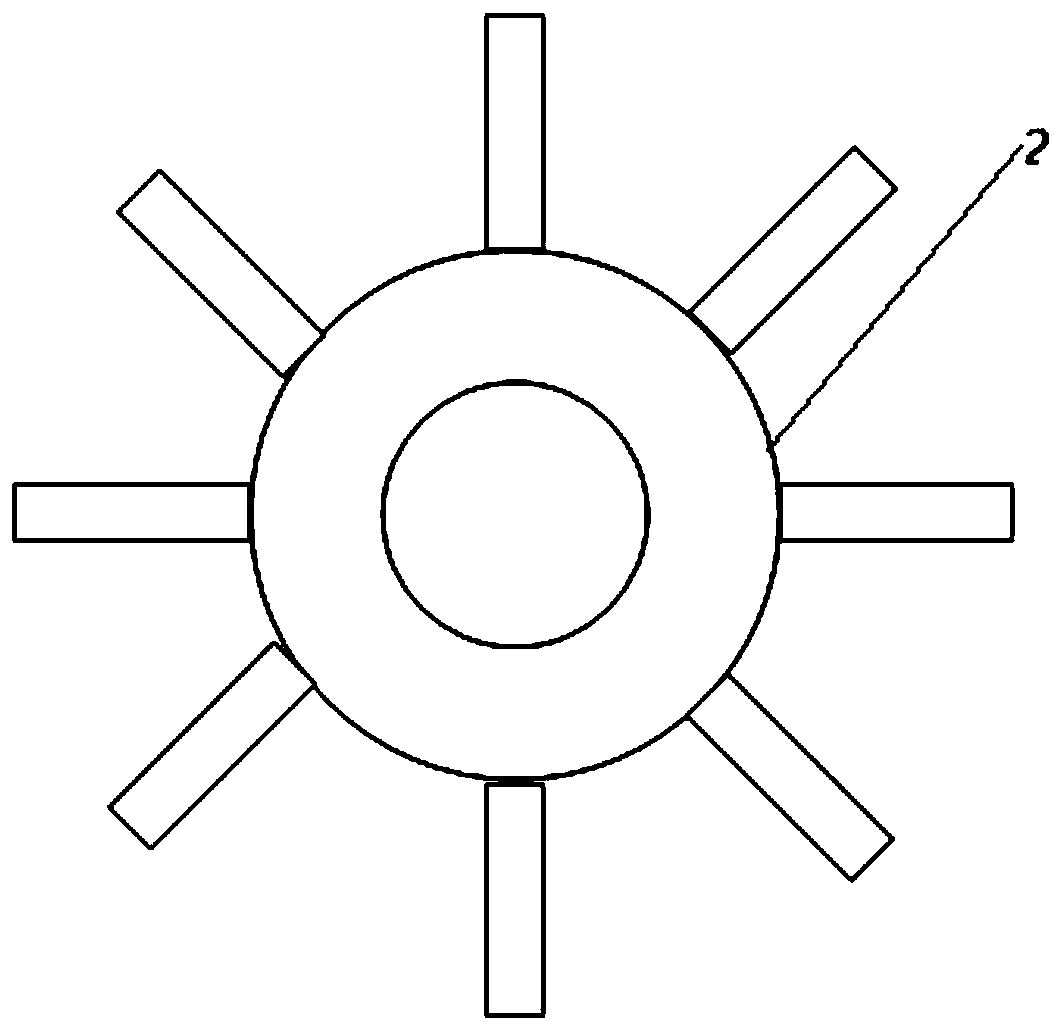

Automobile circuit board heat dissipation device

InactiveCN112004379AHeat dissipation fastImprove cooling effectCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersThermodynamicsThermal adhesive

The invention relates to the technical field of circuit boards, and particularly relates to an automobile circuit board heat dissipation device. The heat dissipation device comprises a liquid coolingplate, a heat dissipation groove, a loop pipe frame, a branch pipe, a heat conduction seat, a heat conduction adhesive layer, a circuit board protection shell, an input pipe, a return pipe, a heat dissipation assembly and a protection shell, wherein the heat dissipation groove is formed in the liquid cooling plate; the loop pipe frame is located in the heat dissipation groove; the branch pipe is fixedly installed on the loop pipe frame; the branch pipe is communicated with the loop pipe frame; the heat conduction seat is fixedly connected with the top of the liquid cooling plate; the bottom ofthe heat conduction seat is fixedly connected with the heat conduction adhesive layer through a heat conduction adhesive; the circuit board protection shell is fixedly installed on the top of the heat conduction seat; and the circuit board is placed and installed in the circuit board protection shell. The purpose of rapid heat dissipation of the circuit board is achieved, impact resistance protection of the circuit board can be achieved, the heat dissipation efficiency is improved, and meanwhile, the size of the heat dissipation assembly is reduced.

Owner:MAANSHAN JULI SCI & TECH

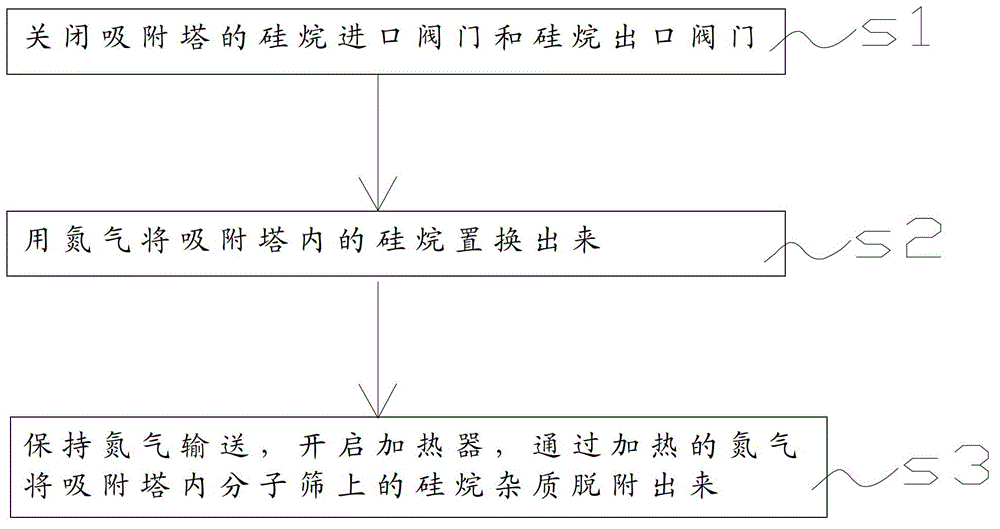

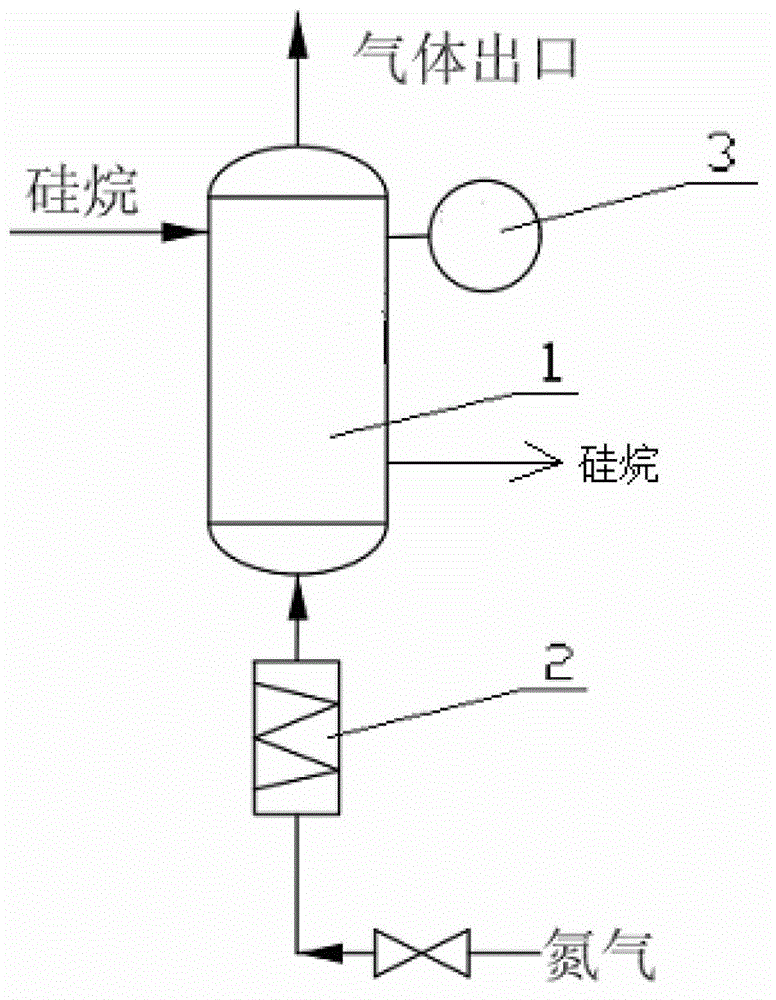

Molecular sieve regeneration method and equipment

InactiveCN102716731ALow costSimple recycling processDispersed particle separationCombustible gas purificationMolecular sieveSilanes

The invention discloses a molecular sieve regeneration method, which is applicable to a silane purification process. The molecular sieve regeneration method comprises the following steps of: closing a silane inlet valve and a silane outlet valve of an adsorption tower (1); displacing silane in the adsorption tower (1) by nitrogen; and starting a heater (2) when maintaining nitrogen transmission, and desorbing silane impurities on a molecular sieve in the adsorption tower (1) by heated nitrogen. According to the design of the regeneration method disclosed by the invention, on one hand, the regeneration process can be simplified, and nitrogen impurities are avoided, on the other hand, the safety is guaranteed, and the regeneration cost is reduced. In addition, the invention also discloses molecular sieve regeneration equipment.

Owner:FINE SILICON

Assembly of top-emission OLED (Organic Light-Emitting Diode) device and top-emission OLED device

ActiveCN108630822AHigh refractive indexChemically stableSolid-state devicesSemiconductor/solid-state device manufacturingWater vaporRefractive index

The invention discloses an assembly of a top-emission OLED (Organic Light-Emitting Diode). The assembly of the top-emission OLED device comprises an anode, a light emitting layer arranged on the anode, a cathode arranged on the light emitting layer, a light extraction layer arranged on the cathode and a packaging layer arranged on the light extraction layer, wherein the light extraction layer is made of a metal oxide, and the packaging layer comprises a first organic packaging layer arranged on the light extraction layer and a first inorganic packaging layer arranged on the first organic packaging layer. The light extraction layer of the assembly of the top-emission OLED device uses the metal oxide which is stable in chemical property and high in refractive index, thereby not only playinga role of isolating water vapor and oxygen to a certain extent for the cathode, the light emitting layer and the anode below, but also improving the transmittance of light through the matching of thelight extraction layer and the packaging layer with the refractive index.

Owner:BOE TECH GRP CO LTD

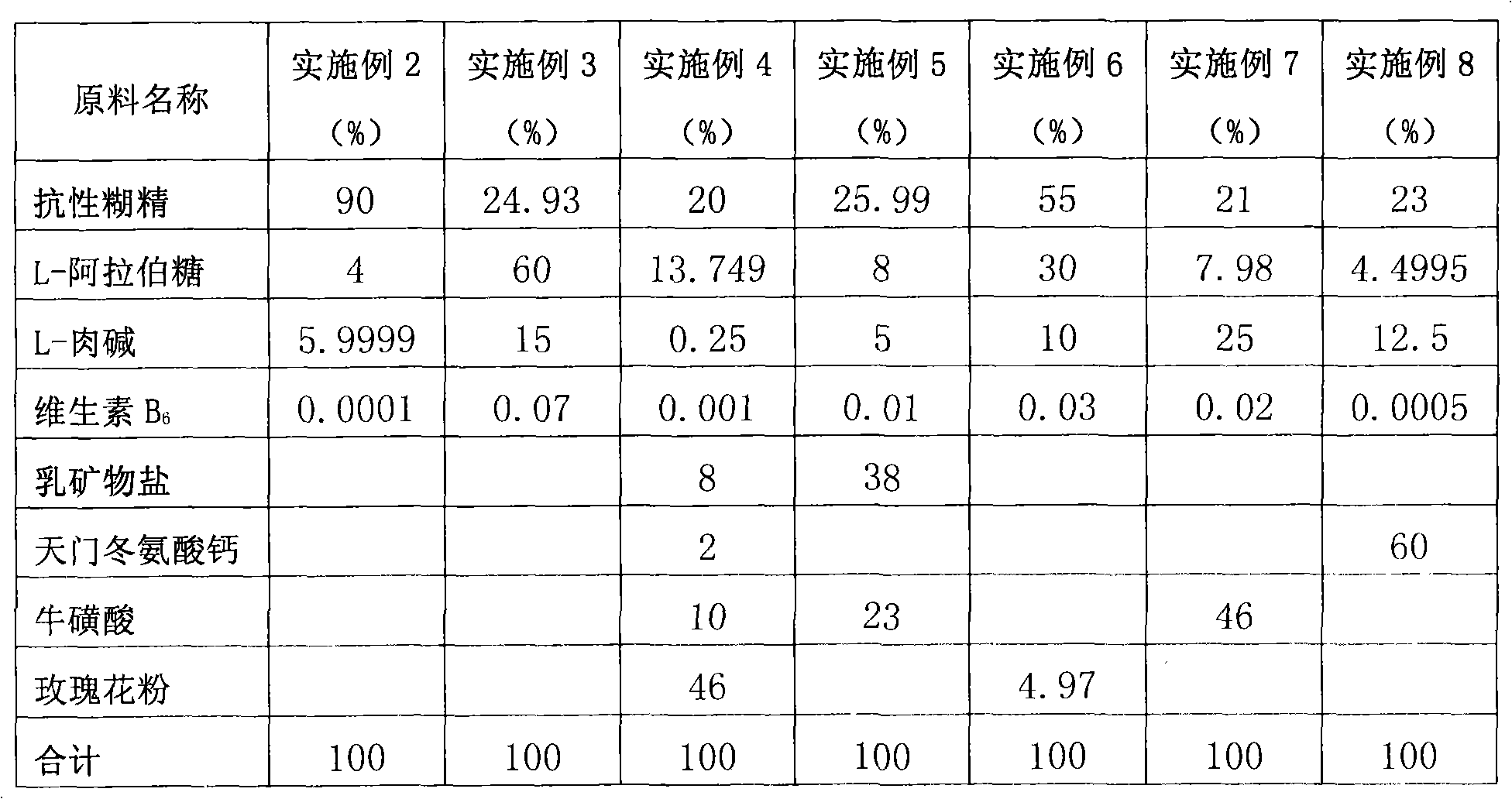

Rapidly beautifying and weight losing nourishment and preparation method thereof

ActiveCN102613461ANot easy to chemical reactionRelieve physical fatigueFood preparationNutrientSide effect

The invention discloses a rapidly beautifying and weight losing nourishment and a preparation method thereof, which belong to the technical field of nutritious and healthcare foods. The rapidly beautifying and weight losing nourishment is obtained by selectively adding one or more of a milk mineral, calcium aspartate, taurine and rose powder on the basis of scientific combination of resistant dextrin, L-arabinose, L-carnitine and vitamin B6. The rapidly beautifying and weight losing nourishment disclosed by the invention has the following advantages that: various raw materials are organicallyblended so that the nourishment is strongly targeted; the obese individuals can rapidly obtain weight losing effects; the nourishment has the advantages of contribution to long-term consolidation of the weight losing effect, no rebound, no influence on absorption of proteins and other nutrient substances, obvious synergetic effects, better mouth feel, convenience for eating, good safety, no toxicand side effect, simple production process, easiness for production and greater market development potential; market vacancy is filled.

Owner:李卫平

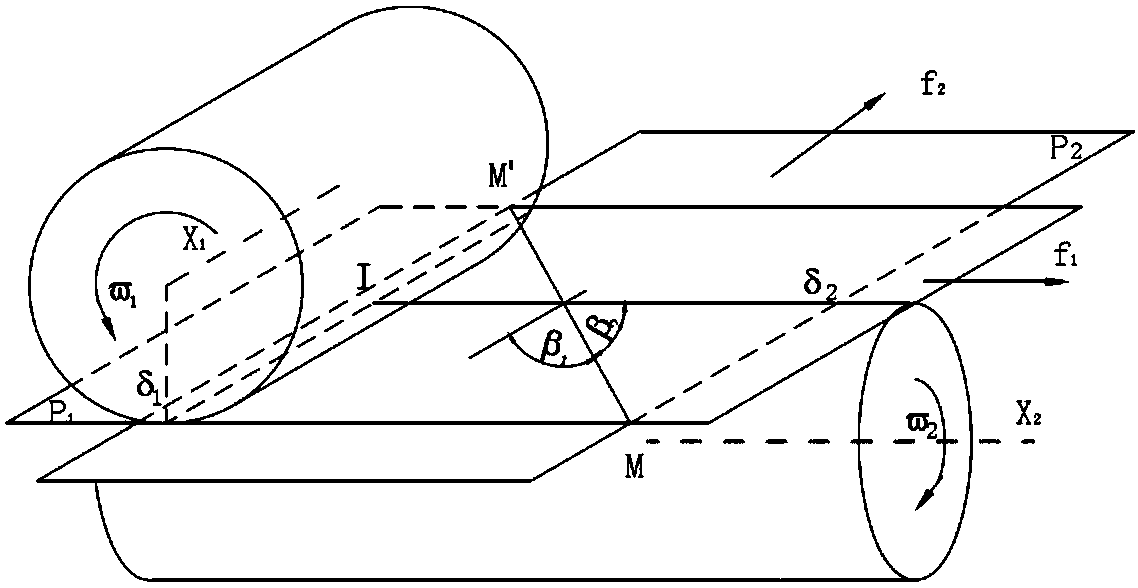

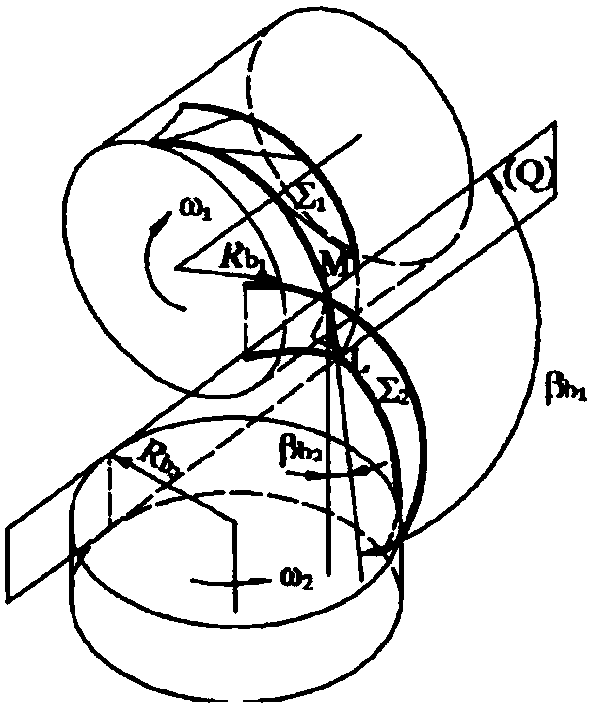

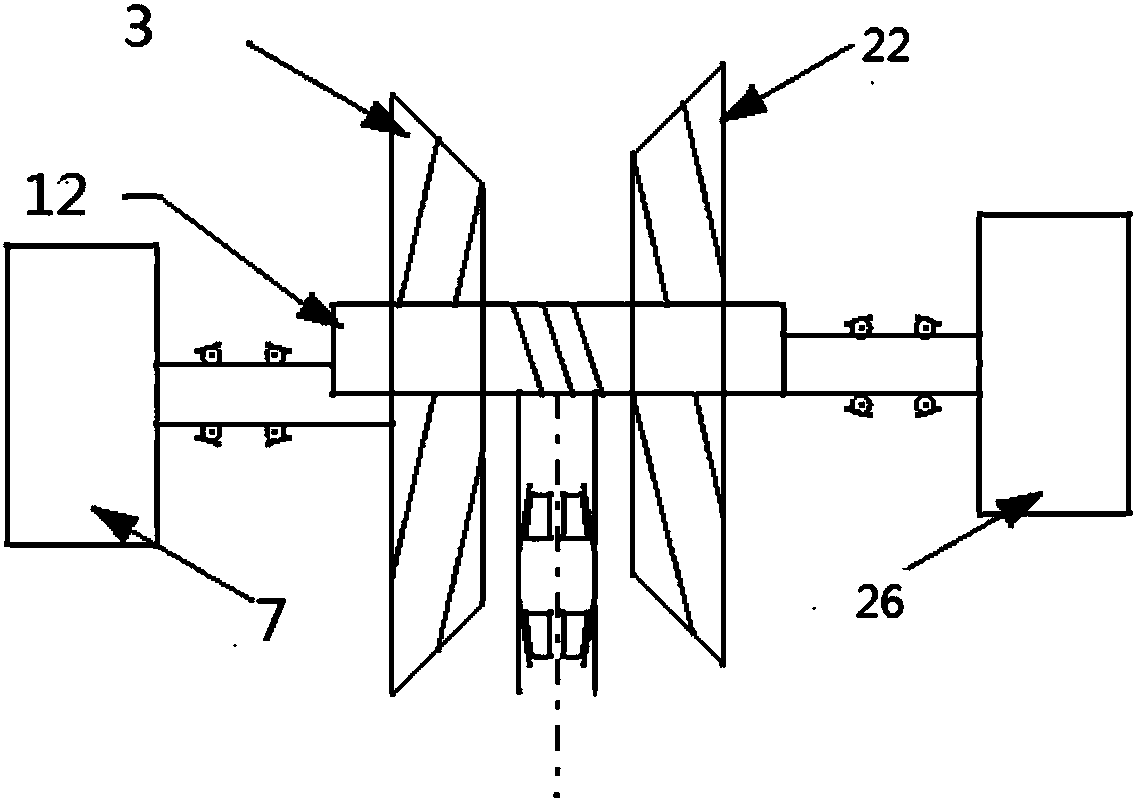

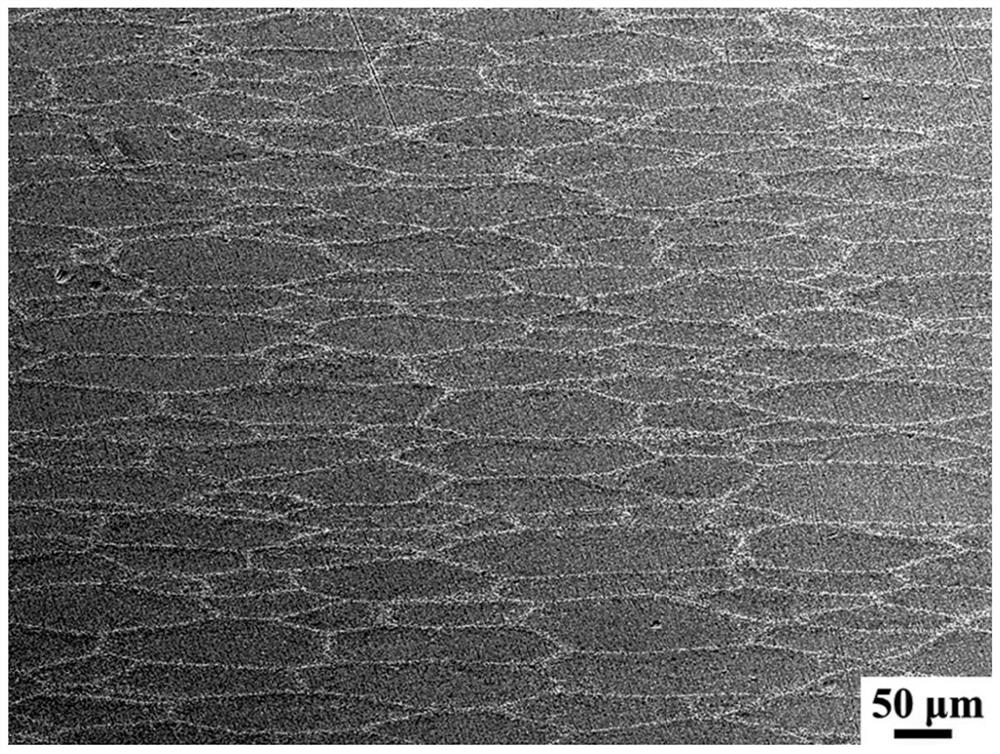

Gear honing machine tool without axial feed and gear honing method

The invention discloses a gear honing machine tool without axial feed and a gear honing method. A left tooth face honing wheel is fixedly connected with a thread at the tail end of a left tooth face honing wheel transmission shaft through a cone hole of the left tooth face honing wheel by means of a first fastening nut; a right tooth face honing wheel is fixedly connected with a thread at the tailend of a right tooth face honing wheel transmission shaft through a cone hole of the right tooth face honing wheel by means of a second fastening nut; a machined gear is placed parallel to a work table, and two cooling hoses are placed close to a grinding area. The left tooth face honing wheel and the right tooth face honing wheel are meshed with the machined helical gear, and the honing qualityand the honing allowance of the honing wheels for the machined helical gear are controlled by adjusting the rotating speed of two servo motors and the relative phase angle phi of the two servo motors.The gear honing machine tool is a special machine tool for finish machining of cylindrical hardened helical gears produced in batches or in large quantities. Compared with other similar machine tools, the gear honing machine tool has the advantages of simple mechanism, convenient operation, and low cost of manufacturing and later maintenance.

Owner:JILIN UNIV

Anion interior-wall putty powder

The invention relates to an anion interior-wall putty powder which comprises the following raw materials, by weight, 15-28 parts of white cement, 5-16 parts of sepiolite powder, 10-30 parts of Portland cement, 1-2 parts of carboxymethyl cellulose, 5-8 parts of japonica rice gel powder, 4-8 parts of heavy calcium carbonate powder, 0.5-2 parts of marble powder and 3-9 parts of a tourmalinite powder anion additive. In comparison with the prior art, the silicate foam cement powder is added in the invention, and the silicate foam cement powder has hygroscopicity so as to help the anion interior-wall putty powder to be combined with a finish and to be polished. As the tourmalinite powder anion additive is added in the putty powder, the putty powder can generate aero-anion to purify the ambient air and promote human health. Thus, the putty powder is suitable for wall priming.

Owner:广西兴安县桂兴矿粉厂

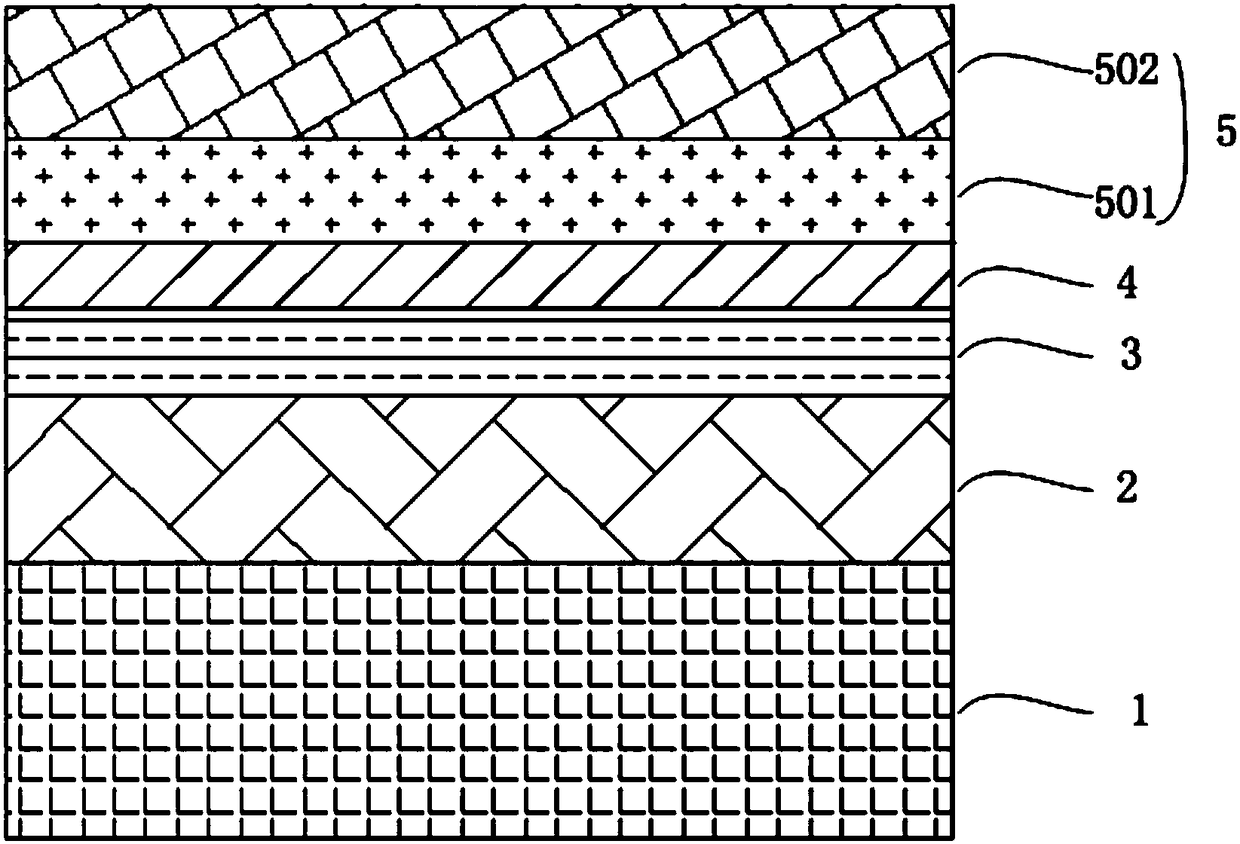

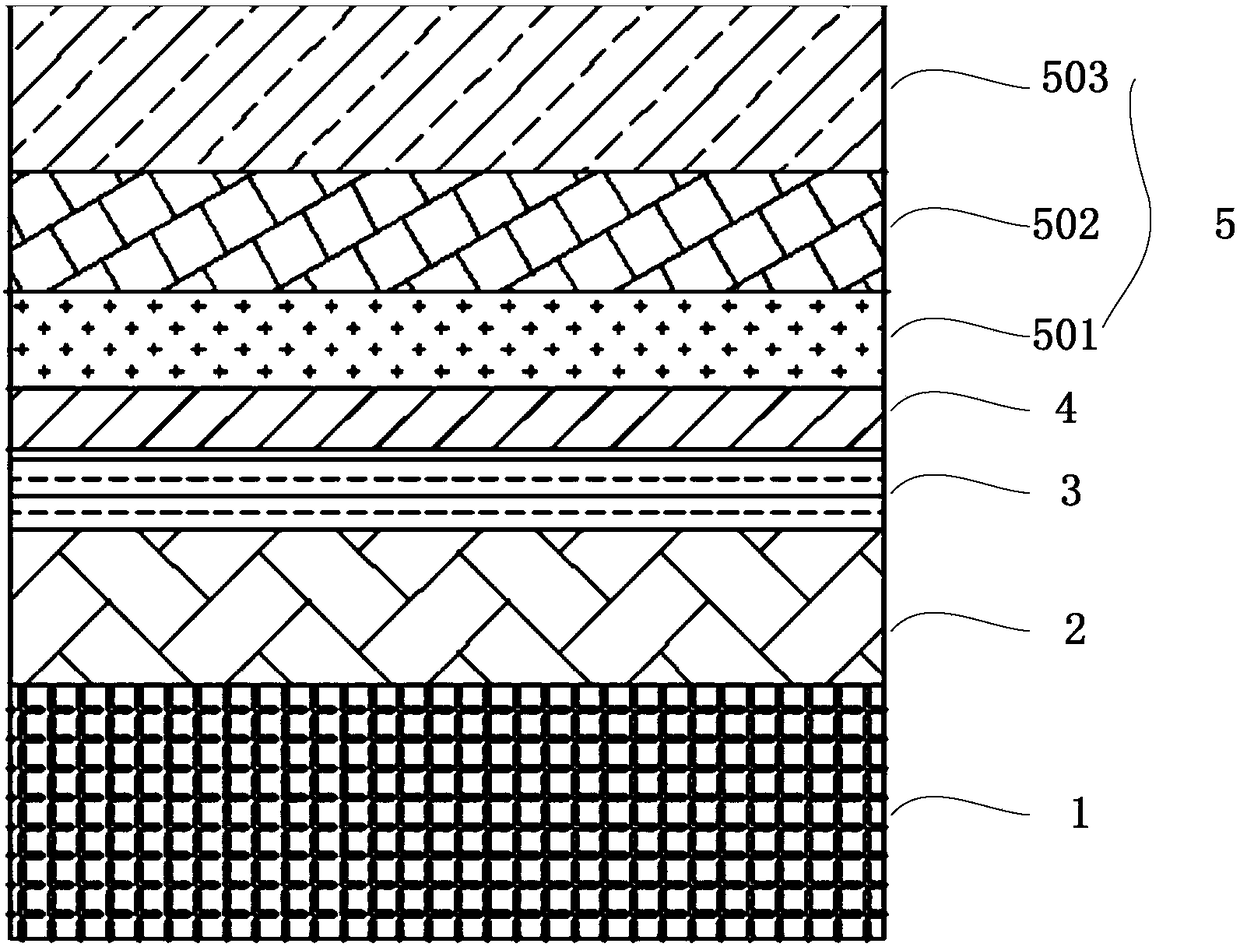

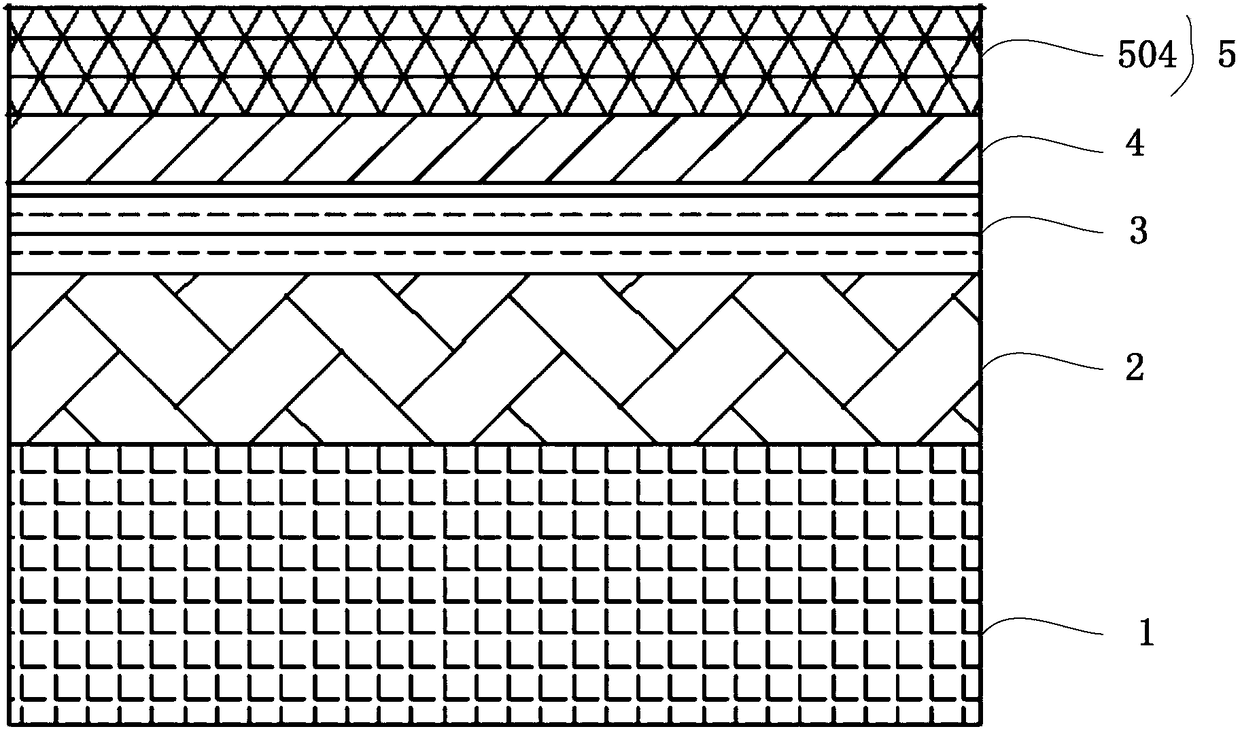

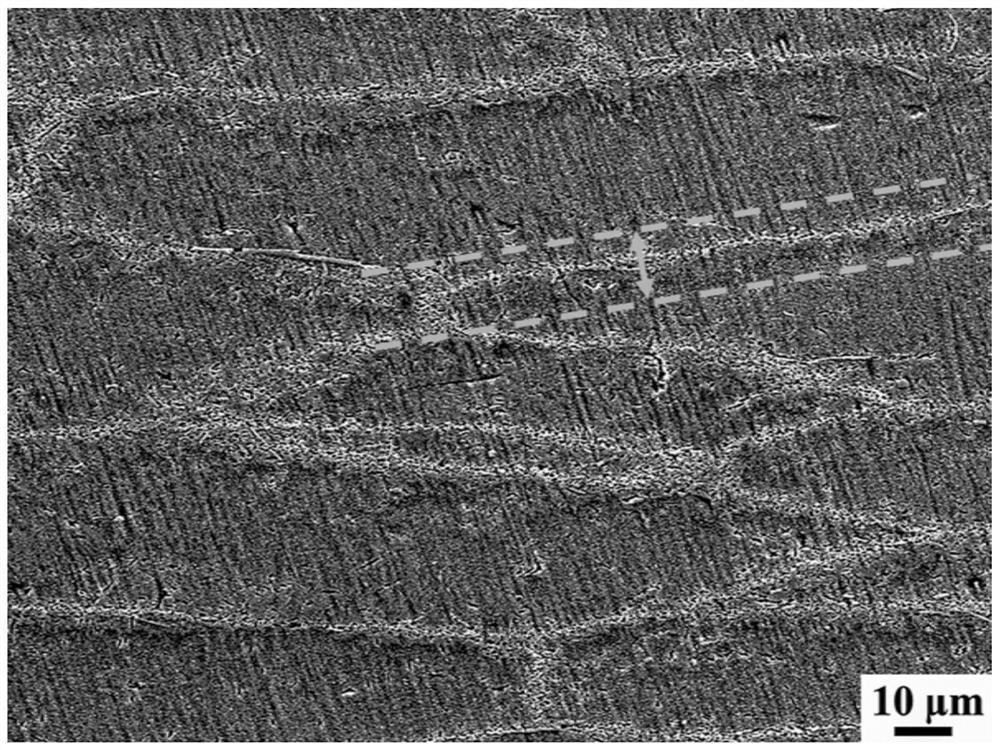

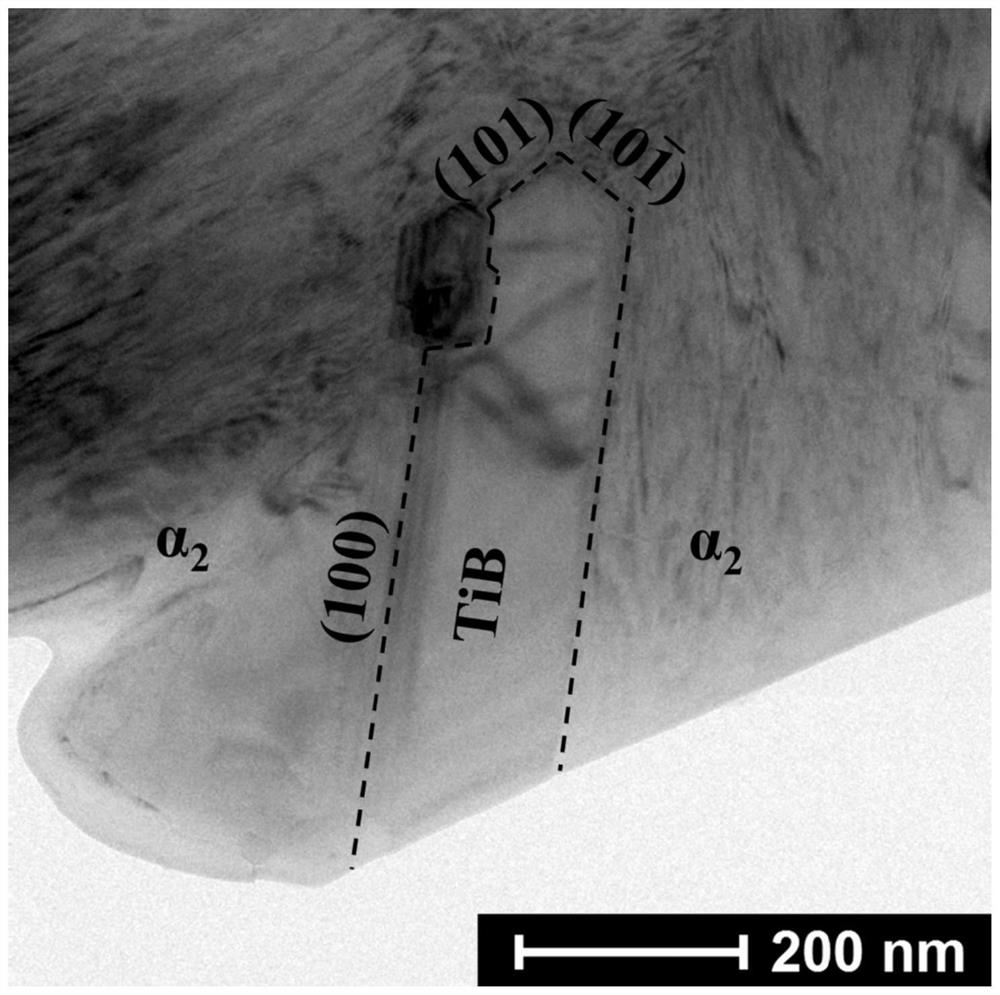

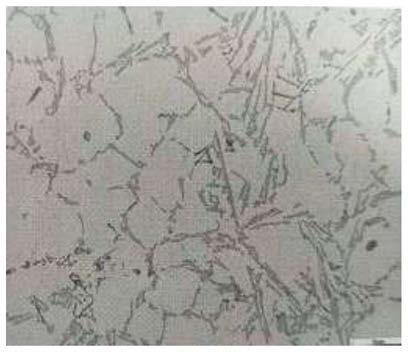

Method for preparing Ti2AlNb-based composite material of imitated shell laminated structure by combining powder metallurgy and forging

The invention discloses a method for preparing a Ti2AlNb-based composite material of an imitated shell laminated structure by combining powder metallurgy and forging, and relates to methods for preparing the Ti2AlNb-based composite material. The method aims to solve the problems of low preparation efficiency, difficult control of structure uniformity, high impurity element content of the preparedmaterial and weak interface bonding strength of a reinforcement body and a matrix of the existing Ti2AlNb-based composite material of the imitated shell structure. The method comprises the steps thatLaB6 powder, TiB2 powder and spherical Ti2AlNb alloy powder are weighed; ball milling is performed to obtain Ti2AlNb alloy powder coated and embedded with borides; the composite material is sintered;then one-way upsetting is performed; and a sheath is removed. Through the method, preparation efficiency is high, the prepared composite material is low in impurity content, and the interface bondingstrength of the reinforcement body and the matrix is high. The method is suitable for preparing the Ti2AlNb-based composite material of the imitated shell laminated structure.

Owner:HARBIN INST OF TECH

High-temperature-resistant heat-preservation dry powder functional film

InactiveCN112251052AImprove high temperature resistanceImprove insulation effectFireproof paintsAnti-corrosive paintsFiberPhosphate

The invention provides a high-temperature-resistant heat-preservation dry powder functional film, which comprises the following components in percentage by mass: 10%-15% of aluminum dihydrogen phosphate powder, 15%-20% of soluble sodium silicate, 3%-5% of silicon tripolyphosphate, 5%-10% of zirconium dioxide, 5%-8% of titanium dioxide, 3%-5% of zinc oxide, 15%-20% of expanded vermiculite, 10%-15%of the volcanic ash, 5%-10% of hollow ceramic microbeads, 3%-5% of fumed silica, and 5%-10% of aluminum oxide short fibers. The preparation method comprises the steps of uniformly stirring the materials, adding water, stirring to form a daub mixture, and coating an object with the daub mixture to obtain the functional film. The film has excellent high temperature resistance, heat preservation, waterproofness and corrosion resistance, is not easy to chemically react with external factors, and is harmless to human bodies.

Owner:上海载坤环保新材料科技有限公司

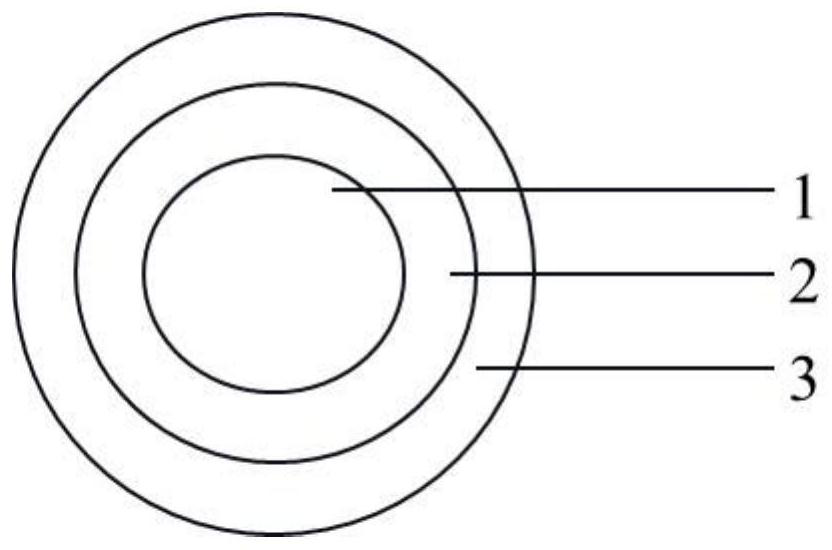

Low-platinum core-shell catalyst, preparation method thereof and fuel cell

The invention provides a low-platinum core-shell catalyst. The low-platinum core-shell catalyst comprises a composite body consisting of an inner core, a middle layer and a shell, wherein the inner core is coated with the middle layer; the shell is coated with the middle layer; the particle size of the complex is 3-6 nm. The low-platinum core-shell catalyst forms a multilayer core-shell structure of 'core-middle layer-shell', and the particle size of the complex is further controlled to be 3-6nm, so the size of the low-platinum core-shell catalyst is moderate, and the highest catalytic activity and the best catalytic effect of the catalyst with the structure are ensured.

Owner:EVERGRANDE NEW ENERGY TECH SHENZHEN CO LTD

Concrete anti-carbonization environment-friendly coating and construction method

InactiveCN111925675AIrreversibleImprove water resistanceCovering/liningsCement mixing apparatusSlagCarbonization

The invention relates to a concrete anti-carbonization environment-friendly coating and a construction method thereof. The coating comprises the following components in parts by weight: 2-10 parts ofsilica sol; 20-80 parts of steel slag powder; 15-40 parts of a water-based fluorine-containing acrylic polymer emulsion; 15 to 30 parts of heavy calcium carbonate powder; 0.5 to 3 parts of meerschaumpowder; 0.1 to 0.5 part of nano silicon carbide whisker; 0.1 to 2.5 parts of a water reducing agent; 2-8 parts of silica fume; 20 to 60 parts of cement; and 25-80 parts of water. Through the characteristic effects and the mutual synergistic effect of the components in the formula, the concrete anti-carbonization environment-friendly coating is good in anti-carbonization effect and good in performance of multiple properties, and can be widely applied to construction of various concrete base surfaces to form an anti-carbonization environment-friendly coating.

Owner:江西奇信集团股份有限公司

Preparation method of paint applied to internal surface of oil tank

ActiveCN104059436AImprove corrosion resistanceImprove high temperature resistanceAnti-corrosive paintsWater basedChemical reaction

The invention relates to a preparation method of a paint applied to the internal surface of an oil tank. The paint is composed of the following components in percentage by weight: 10-25 wt% of curing agent, 10-25 wt% of methyl cellulose, 15-65 wt% of silica sol, 20-45 wt% of corrosion-resistant water-based pigment and filler paste, 20-80 wt% of ammonium polyphosphate, 20-55 wt% of microparticle silicic acid, 20-40 wt% of drying agent, 50-80 wt% of solvent, 20-60 wt% of preservative, 10-30 wt% of defoamer, 2-10 wt% of water-based assistant and 30-60 wt% of deionized water. The paint has the advantages of favorable corrosion resistance, high temperature resistance, favorable oxidation resistance, favorable scrub resistance and the like, has an antiseptic effect inside the oil tank, and can not easily generate chemical reaction with the liquid (gasoline) in the oil tank; the construction technique is implemented by pouring the paint into the oil tank, uniformly shaking and pouring out, and thus, is simple; the paint can be closely combined with the base material immediately, and can not easily shed; and the method has the advantages of simple preparation process and low cost, and can easily implement industrialized mass production.

Owner:ハンツォウトップリフトマシーナリーカンパニーリミテッド

High-temperature heat transfer medium and preparation method thereof

InactiveCN104388059AImprove heat transfer coefficientReduce steam pressureEnergy inputHeat-exchange elementsSteam pressureCombustion

The invention provides a high-temperature heat transfer medium and a preparation method thereof. The high-temperature heat transfer medium is prepared by uniformly mixing the following components in parts by weight: 3-25 parts of NaBr, 4-25 parts of Ca(Br)2, 25-67 parts of KBr and 16-50 parts of LiBr. The high-temperature heat transfer medium provided by the invention is high in heat transfer coefficient, low in steam pressure and good in heat stability and safety performance at high temperature; and the high-temperature heat transfer medium does not easily generate chemical reaction with metal materials such as stainless steel within the using temperature range, and the condition that non-combustion or explosion and other violent accidents happen because of chemical reaction between the high-temperature heat transfer medium and most of fluid does not easily happen too, so that the requirement of solar heat power generation for heat transfer or the requirement of the medium and a high-temperature heat pipe for the performance of the heat transfer medium can be met.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

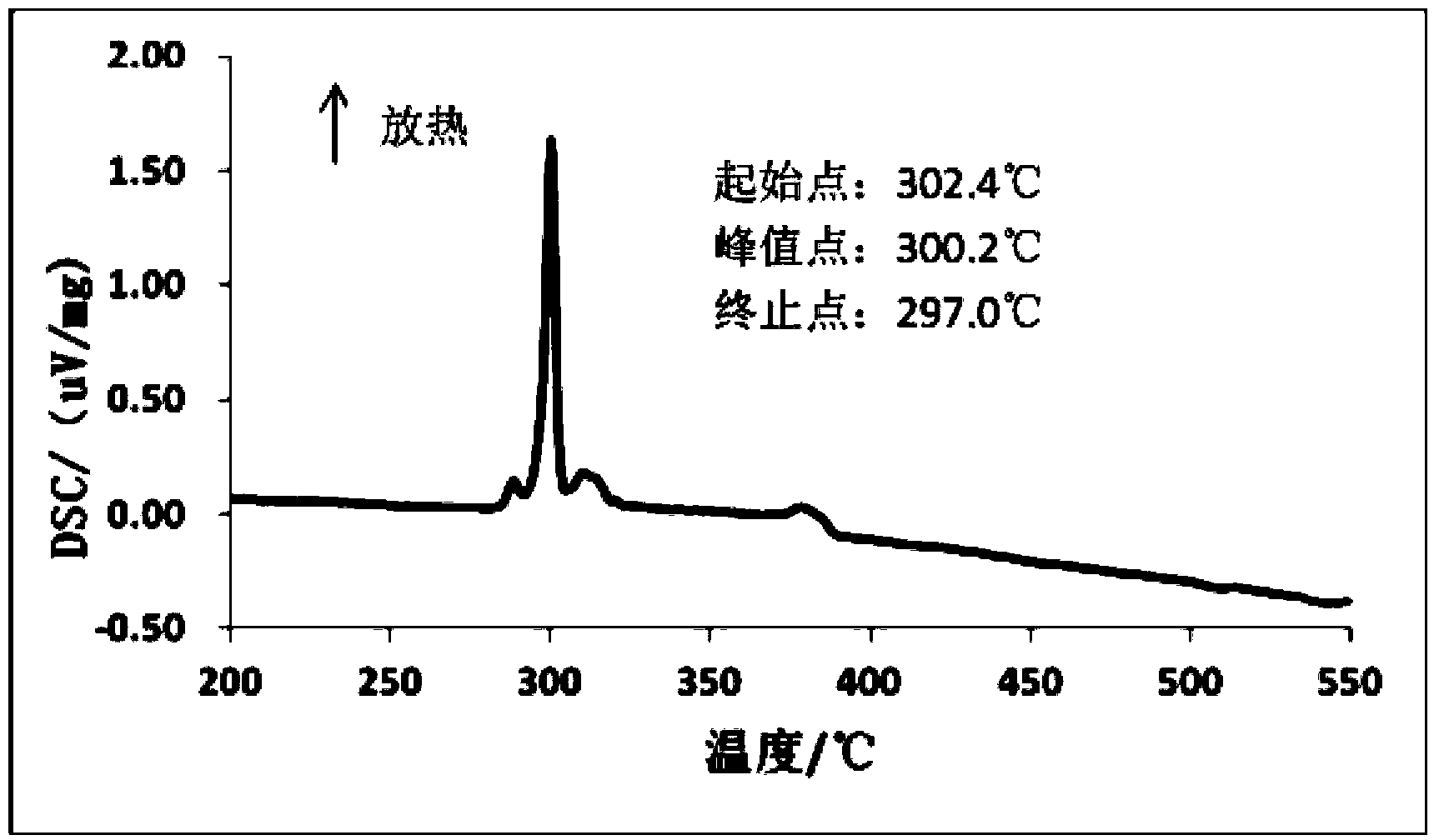

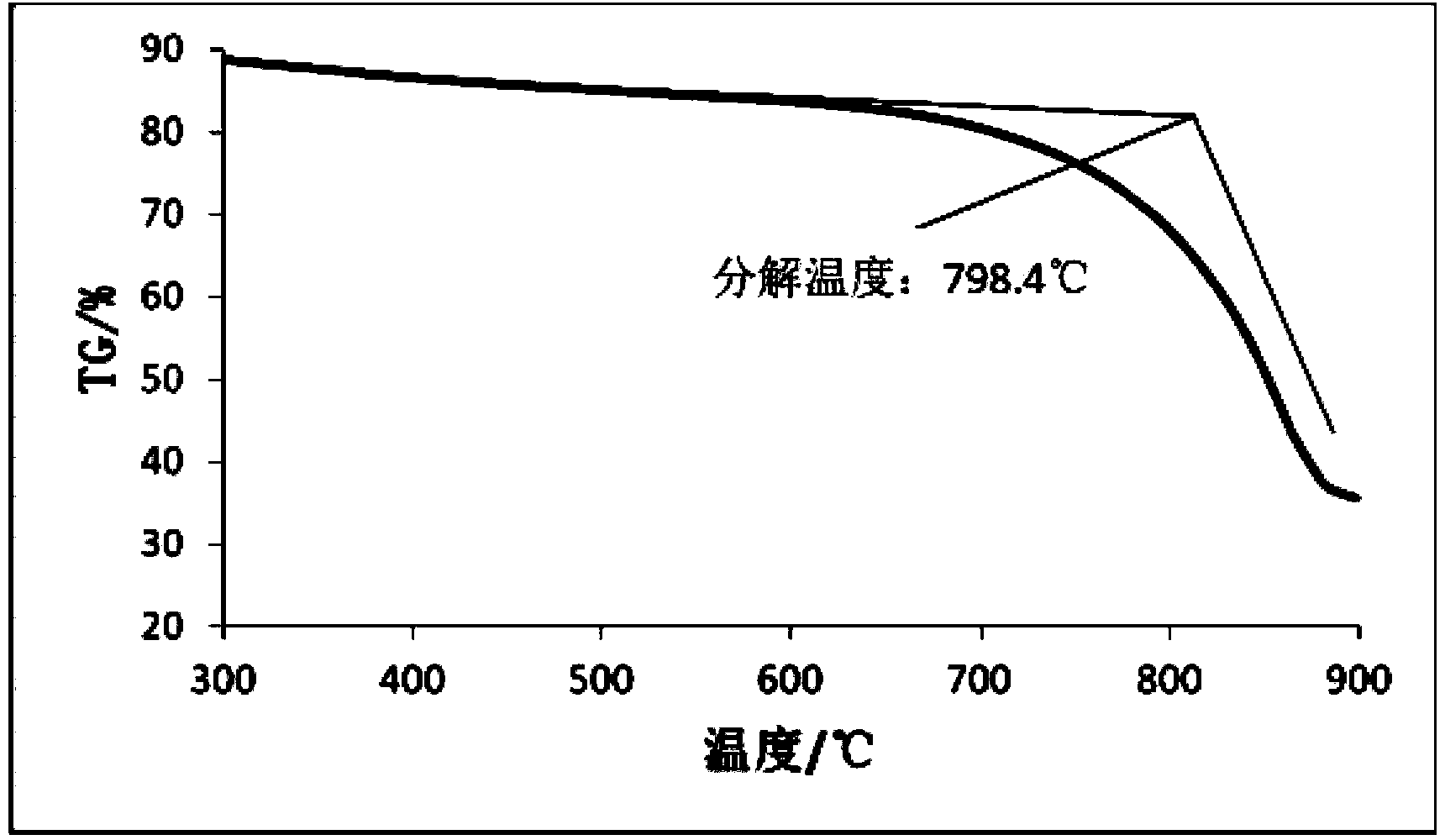

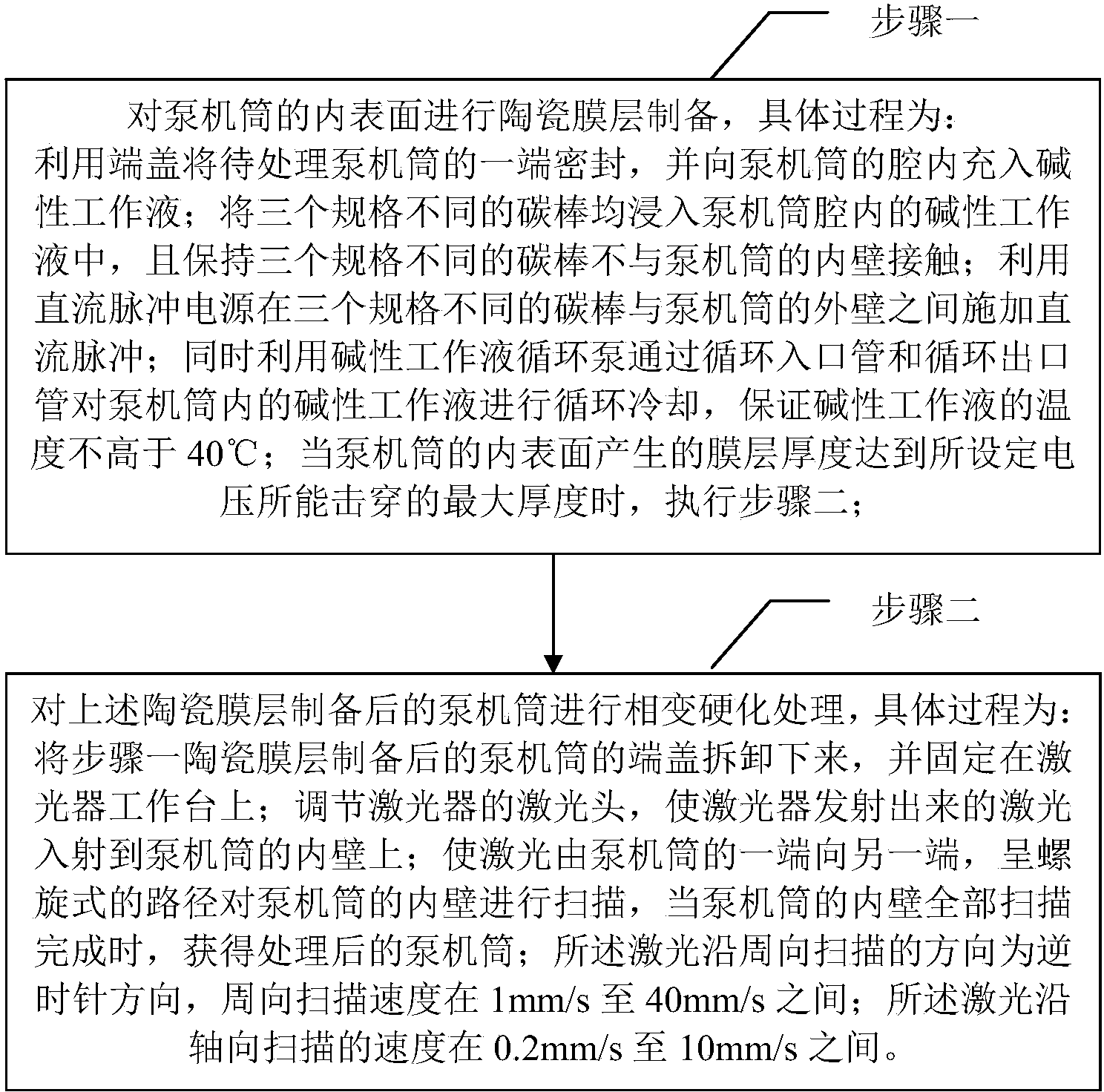

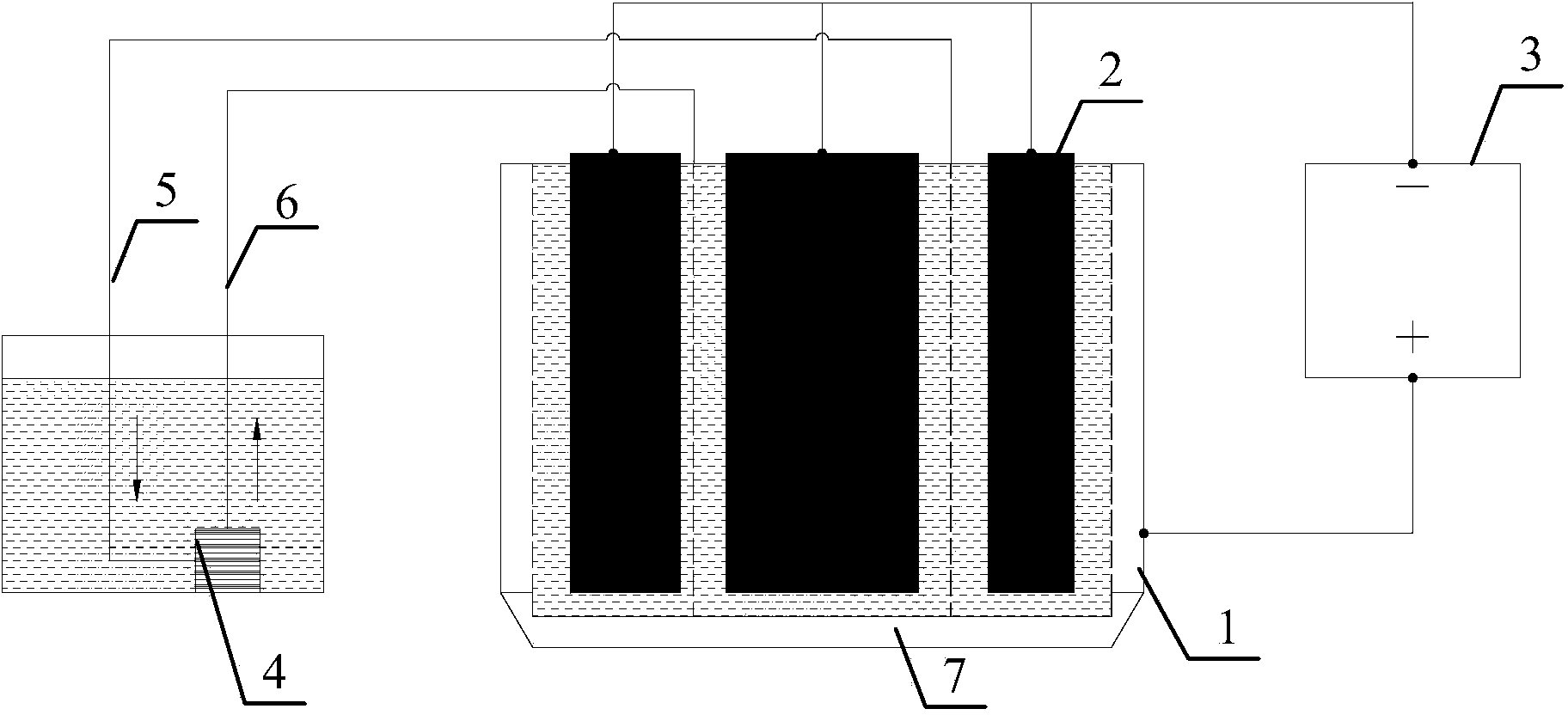

Three-screw pump machine barrel and ceramic treatment method of inner surface of three-screw pump machine barrel

ActiveCN103775333AHigh precisionImprove wear resistanceAnodisationMachines/enginesElectrochemical responseChemical reaction

The invention relates to a three-screw pump machine barrel and a ceramic treatment method of an inner surface of the three-screw pump machine barrel, and belongs to the technical field of material surface modification. The three-screw pump machine barrel can be used for solving the problems that the existing three-screw pump rubber bushing has high temperature sensitivity, is easy to age and has aeolotropy. The three-screw pump machine barrel is characterized in that a ceramic membrane is plated on the inner wall of the three-screw pump machine barrel, the ceramic membrane is more than 800HV in hardness and more than 50mu m in thickness, and the ceramic membrane has the characteristics of high precision, high abrasion resistance, no sensitivity to temperature change and difficulty in chemical reaction with acid-base media. The ceramic treatment method of the inner surface of the three-screw pump machine barrel comprises the following steps: firstly electrifying the pump machine barrel filled with an alkaline working solution by use of a pulsed power supply, so as to generate a Al2O3 film on the inner wall of the pump machine barrel by virtue of the electrochemical reaction, and scanning the surface of the generated film by use of a laser so as to enable the surface of the film to be flattened. The method is suitable for ceramic treatment of the surface of the pump machine barrel.

Owner:HARBIN INST OF TECH

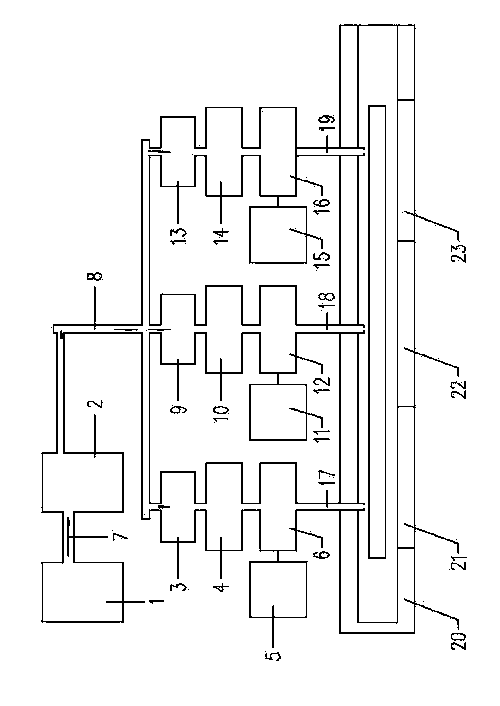

Welding method based on quartz tuning fork crystal three-temperature-area nitrogen blowing

InactiveCN103560765ANo pollution in the processNot easy to chemical reactionImpedence networksChemical reactionEngineering

The invention relates to the field of welding, in particular to a welding method based on quartz tuning fork crystal three-temperature-area nitrogen blowing. The welding method is characterized in that a nitrogen making machine is connected with one end of a drying machine through a pipeline, and the other end of the drying machine is respectively connected with a flow-limiting valve A, a flow-limiting valve B and a flow-limiting valve C through pipelines; the flow-limiting valve A is connected with a drying temperature area through a filter A, a heating wire A and a drying temperature area pipeline, and the other end of the heating wire A is connected with an adjustable converter A; the flow-limiting valve B is connected with a preheating temperature area through a filter B, a heating wire B and a preheating temperature area pipeline, and the other end of the heating wire B is connected with an adjustable converter B; the flow-limiting valve C is connected with a high temperature area through a filter C, a heating wire C and a high temperature pipeline, and the other end of the heating wire C is connected with an adjustable converter C; the drying temperature area, the preheating temperature area and the high temperature are provided with product track grooves. By the adoption of the technical scheme, due to the fact that chemical reactions among nitrogen molecules, tuning fork pieces and tuning fork base metal components do not easily occur at a high temperature, an oxidation process and dust pollution do not exist, and quality of products can be stable.

Owner:HUBEI TKD ELECTRONICS TECH

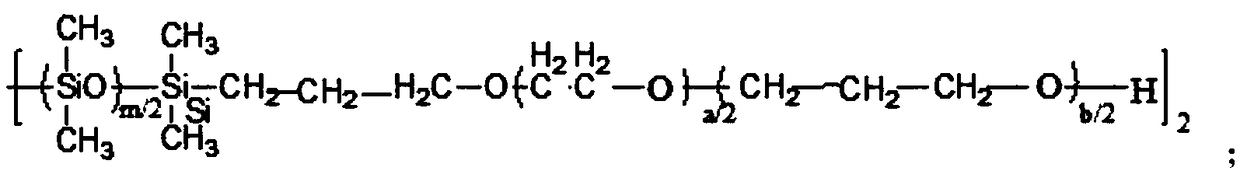

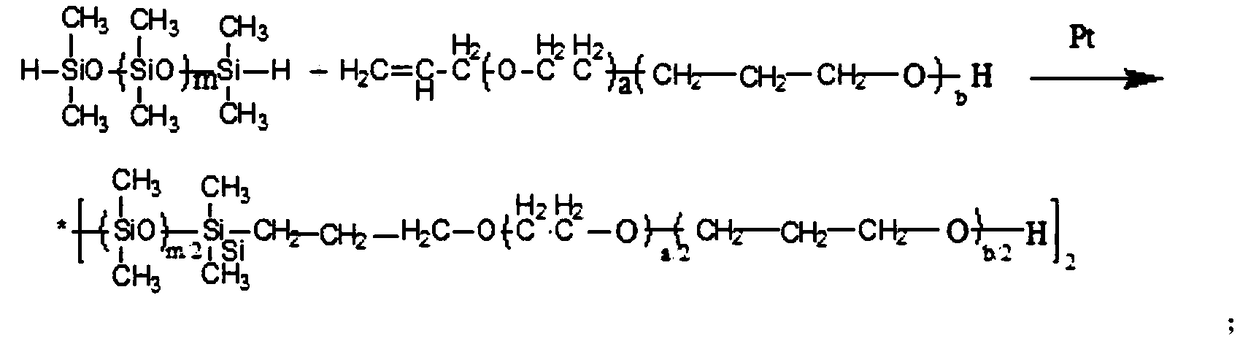

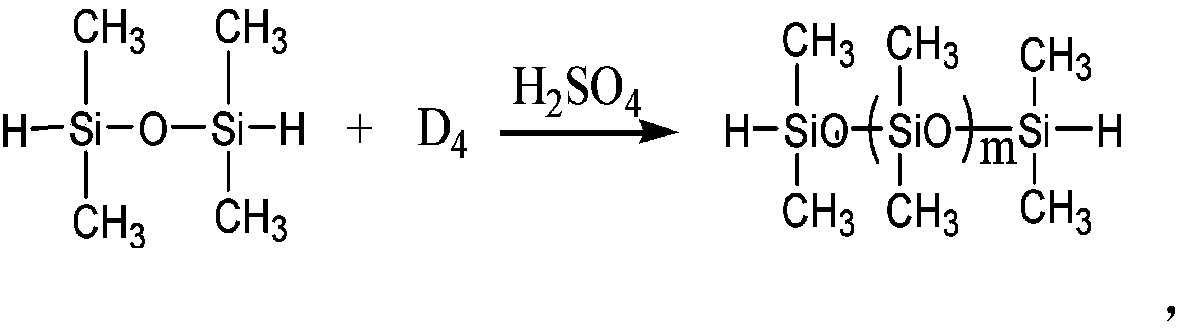

Preparation method of double-rotor type organosilicone defoaming agent

InactiveCN108786190AReduce surface tensionReduce manufacturing costFoam dispersion/preventionEmulsionDefoaming Agents

The invention discloses a preparation method of a double-rotor type organosilicone defoaming agent. The double-rotor type organosilicone defoaming agent is mainly of a double hydroxyl-terminated structure, and has the advantages that the convenience is realized in industrial defoaming, the stability and dispersivity of an emulsion are improved, the storage time is guaranteed, and the defoaming efficiency is greatly improved; the preparation technology is simple and convenient, and the raw materials are easy to obtain.

Owner:南通斯恩特纺织科技有限公司

Improved preparation method of paint applied to internal surface of oil tank

ActiveCN104073034AGood corrosion resistanceSimple construction processAnti-corrosive paintsSolventAmmonium polyphosphate

The invention relates to an improved preparation method of a paint applied to the internal surface of an oil tank. The paint is composed of the following components in percentage by weight: 10-25 wt% of curing agent, 10-25 wt% of methyl cellulose, 15-65 wt% of silica sol, 20-45 wt% of corrosion-resistant water-based pigment and filler paste, 20-80 wt% of ammonium polyphosphate, 20-55 wt% of microparticle silicic acid, 20-40 wt% of drying agent, 50-80 wt% of solvent, 20-60 wt% of preservative, 10-30 wt% of defoamer, 2-10 wt% of water-based assistant, 30-60 wt% of deionized water, 4-10 wt% of polyoxyethylene enzyme, 10-25 wt% of barium sulfate and 1-10 wt% of hydrogenated castor oil. The paint has the advantages of favorable corrosion resistance, high temperature resistance, favorable oxidation resistance, favorable scrub resistance and the like, has an antiseptic effect inside the oil tank, and can not easily generate chemical reaction with the liquid (turpentine, methanol and the like) in the oil tank; the construction technique is implemented by pouring the paint into the oil tank, uniformly shaking and pouring out, and thus, is simple; the paint can be closely combined with the base material immediately, and can not easily shed; and the method has the advantages of simple preparation process and low cost, and can easily implement industrialized mass production.

Owner:ハンツォウトップリフトマシーナリーカンパニーリミテッド

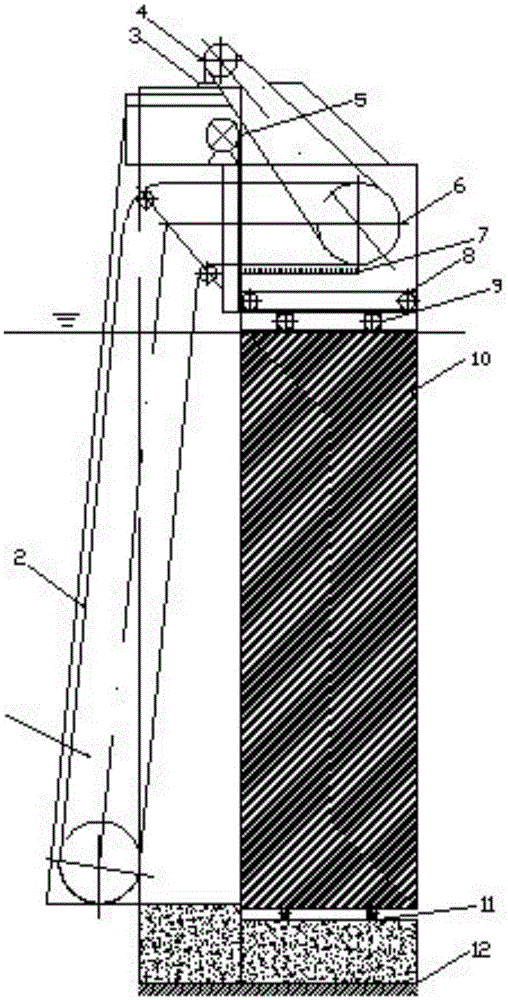

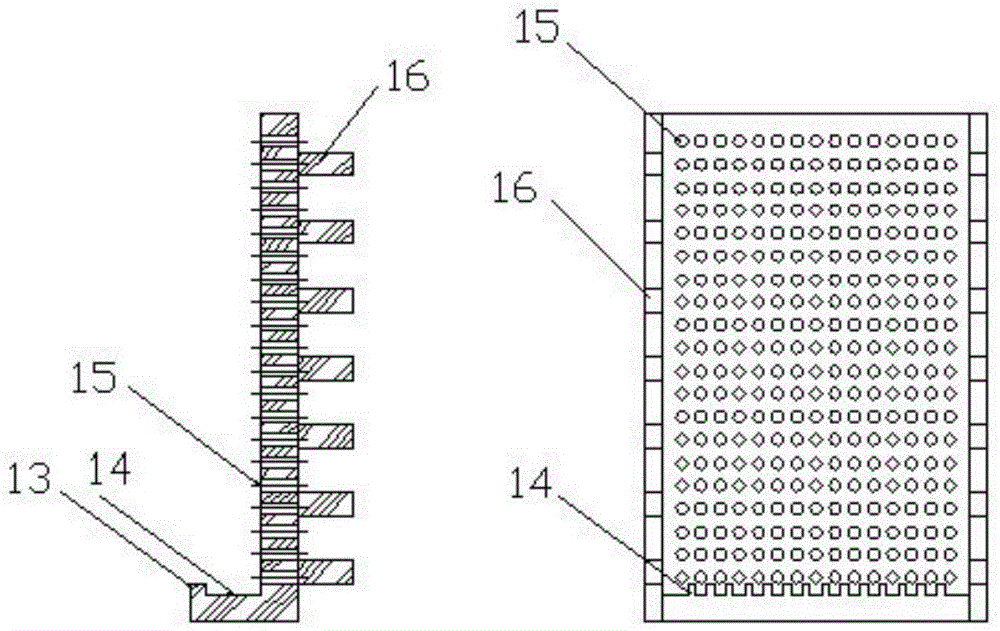

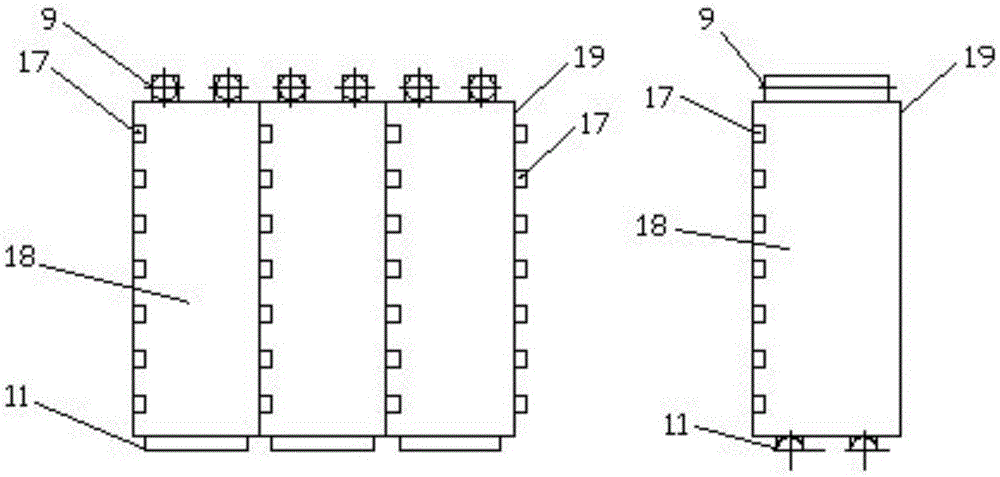

Vertical immersed type in situ water quality purification curtain screen

InactiveCN105585157AImprove water purification abilityEasy to operateWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentSupporting systemWater quality

The invention provides a vertical immersed type in situ water quality purification curtain screen and belongs to the field of water treatment equipment. The vertical immersed type in situ water quality purification curtain screen is mainly characterized in that the curtain screen is mainly composed of a grid system, a curtain screen purification unit, a motor transmission system and a supporting system; the grid unit is composed of grids constituted by mesh holes, grid teeth, grid tooth front hooks and side end hinge hanging teeth; the curtain screen purification unit is composed of screen door purification modules constituted by water quality purification multifunctional curtain production screen cores, side end movable hinges and peripheral screen frames; the motor transmission screen can drive the grid unit to move vertically and can drive the curtain screen purification unit to move in the horizontal direction; the work mode of the curtain screen is that the curtain screen is vertically immersed in raw water to be treated; the curtain screen has the function of in situ water quality purification. The vertical immersed type in situ water quality purification curtain screen has the advantages of being wide in application range, good in water quality purification effect, easy to operate and maintain, stable in performance after long-term operation and environmentally friendly.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

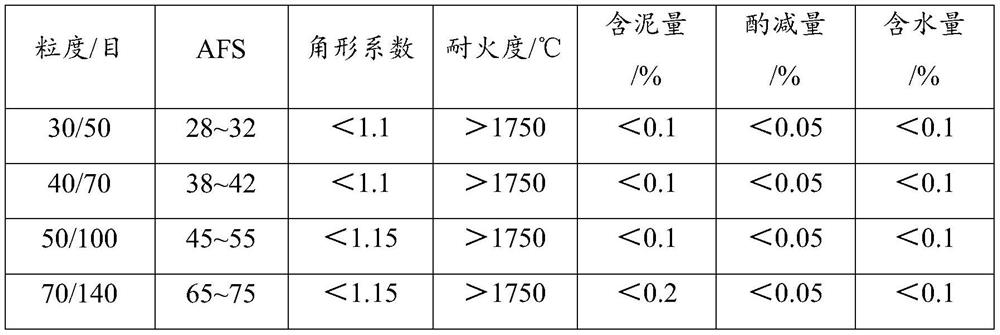

Forsterite spherical sand and preparation method and application thereof

PendingCN112250435AWide variety of sourcesSimple production processFoundry mouldsFoundry coresThermal dilatationChemical reaction

The invention provides forsterite spherical sand and a preparation method and application thereof, magnesite and quartz sand are used as main raw materials, and the forsterite spherical sand is obtained by crushing, pulverizing, mixing, granulating, drying, screening and sintering. The forsterite spherical sand has the advantages of being low in angular coefficient, round in grain shape, compact in surface, free of holes, high in sand core strength, low in thermal expansion coefficient, alkaline in chemical property and the like, the forsterite spherical sand and MnO2 in high manganese steel molten metal are not prone to chemical reaction, meanwhile, the repeated utilization rate of theforsterite spherical sand is high, the casting requirement can be met, the using amount of a casting binder can be reduced, the casting cost is reduced, and meanwhile, the emission of casting industrial waste gas is effectively reduced.

Owner:ZHANGWU COUNTY LIAN XIN FOUNDRY SILICON SAND

Modified investment casting shell manufacturing method

InactiveCN103056298ASmall and uniform coefficient of thermal expansionNot easy to chemical reactionFoundry mouldsFoundry coresChemical reactionSurface layer

The invention discloses a modified investment casting shell manufacturing method. A shell is obtained through steps of cleaning the surface of a mold set, coating, stuccoing, hardening and air drying, wherein the steps of coating, stuccoing, hardening and air drying are repeated 8 times, zircon sand with the granularity group of 15 is used as surface layer sand in the first stuccoing and the second stuccoing, silica sand with the granularity group of 30 is used in the third stuccoing and the fourth stuccoing, silica sand with the granularity group of 60 is used from the fifth stuccoing to the eighth stuccoing, and a water dissolving method using water at 90DEG C is adopted for dewaxing. According to the modified investment casting shell manufacturing method, the zircon sand with the granularity group of 15 is used as the surface layer sand, the thermal expansion coefficient of the zircon sand is low and uniform, and the zircon sand is difficult to chemically react with iron oxide and accordingly has a good sand burning resisting function, quality of the shell is improved, and the zircon sand is high in price, the silica sand is used from the third stuccoing to the eighth stuccoing, so that production cost is reduced on the premise of obtaining a high quality casting.

Owner:QINGDAO SANHESHAN CASTING GROUP

Novel silicon wafer wax-polishing method

InactiveCN104526538AAdd wax removal methodNot easy to chemical reactionLapping machinesWork carriersChemical reactionCleansing Agents

The invention provides a novel silicon wafer wax-polishing method which is improved on the basis of an original polishing method and added with a ceramic disc wax-removal cleaning method which can be used for better cleaning a ceramic disc in a wax-polishing process. The novel silicon wafer wax-polishing method employs a hairbrush and a wax-removal agent spraying device, wherein the hairbrush has higher elasticity and is not likely to deform. When brushing the surface of the ceramic disc, the hairbrush can cut residual wax print into countless fine wax strips, so that the novel silicon wafer wax-polishing method increases the contact area between residual wax and a chemical cleaning agent and enables the chemical reaction between the residual wax and the chemical cleaning agent to be more complete, and meanwhile the formed countless fine wax strip are more easily shaken off by ultrasonic waves of a follow-up cleaning machine. Meanwhile, the novel silicon wafer wax-polishing method employs a wax-removal agent recovery device, so that a wax-removal agent can be used repeatedly, and the cost is reduced. The novel silicon wafer wax-polishing method is simple in structure, convenient to operate and remarkable in cleaning effect.

Owner:TIANJIN ZHONGHUAN ADVANCED MATERIAL TECH

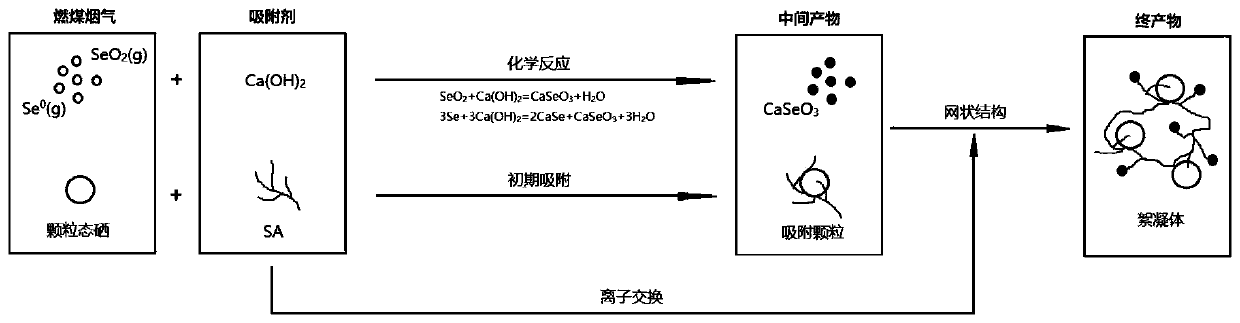

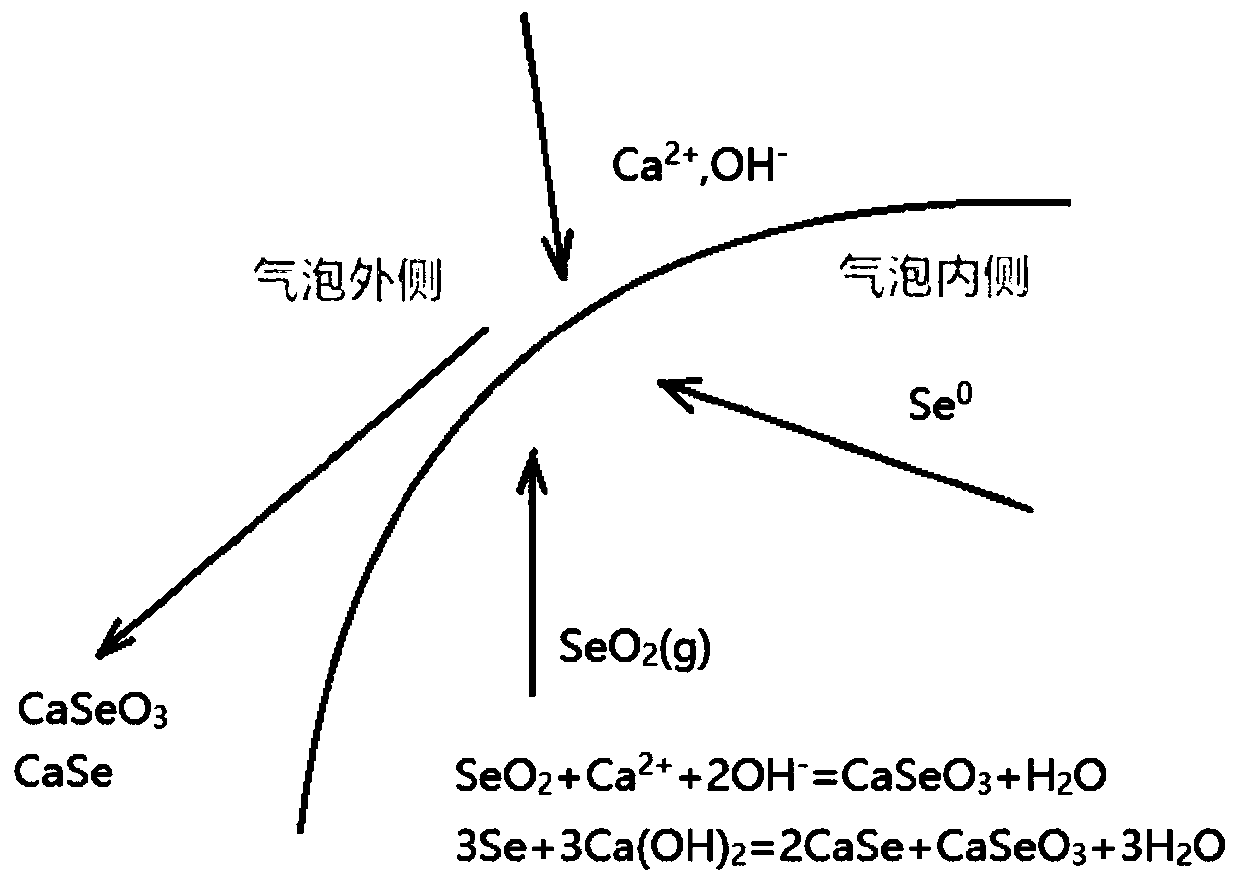

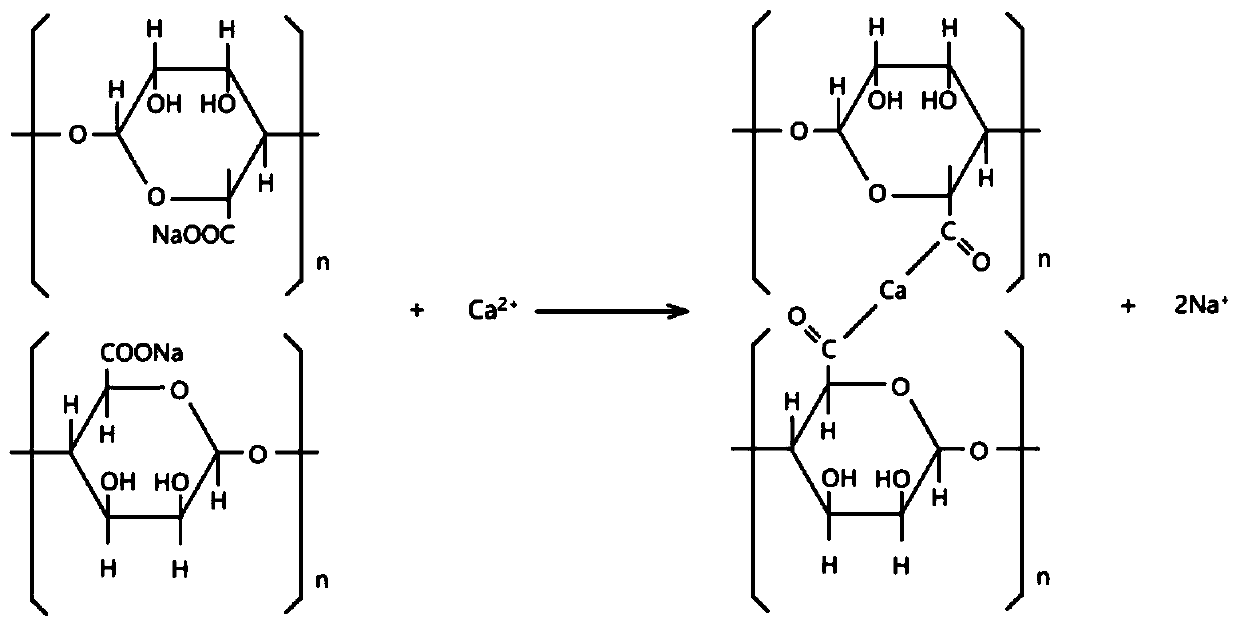

Basic group adsorbent for capturing selenium in coal-fired flue gas and preparation method of basic group adsorbent

InactiveCN110882619AGood dispersionImprove stabilityGas treatmentDispersed particle separationChemistryCalcium hydroxide

The invention belongs to the technical field of energy and environment correlation, and discloses a basic group adsorbent for capturing selenium in coal-fired flue gas and a preparation method of thebasic group adsorbent, wherein the basic group adsorbent is a mixed solution; raw materials of the basic group adsorbent comprise calcium hydroxide powder and polymer sodium alginate powder, and the mass ratio of the calcium hydroxide powder to the polymer sodium alginate powder is 0.1-0.5; calcium hydroxide in the basic group adsorbent and acidic gas-phase SeO2 in the coal-fired flue gas are subjected to a chemical reaction to generate CaSeO3; sodium alginate in the mixed solution has a polyanion property, and is subjected to a particle exchange reaction with divalent cations in the mixed solution, a sodium alginate alpha-L-guluronic acid unit is accumulated to form a cross-linked network structure, the cross-linked network structure captures and intercepts granular selenium to form flocculate, the formed flocculate is dispersed in the mixed solution, and thus separation of selenium and flue gas is completed. According to the invention, the efficiency and applicability are improved, and the cost is low.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of gas hydrate formation accelerator and preparation method thereof

ActiveCN103663451BEnhance heat and mass transferShorten the timeCarbon compoundsGeneration processLiquid water

The invention belongs to the field of gas hydrate production and utilization and in particular relates to an accelerant capable of reinforcing gas hydrate generation and a preparation method thereof. The hydrate generation accelerant is a mixed water solution formed by compounding nano dispersed particles with a surfactant and dissolving the compound in water, wherein nano graphite powder is adopted as the nano dispersed particles; SDBS (sodium dodecylbenzenesulfonate) is adopted as the surfactant; based on the total amount of the mixed water solution, the mass fraction of the nano graphite powder is 0.05-1.5%, the mass fraction of SDBS is 0.02-0.08% and the balance is water. The accelerant has the obvious advantages that the mass and heat transfer processes of the hydrate can be greatly reinforced, the overall time of hydrate generation can be shortened and the synthetic efficiency of the hydrate can be improved by adopting the accelerant to reinforce the hydrate generation process; the graphite nano-particles can flow out along with liquid water and can be reused, thus saving the cost.

Owner:溧阳常大技术转移中心有限公司

Preparation method and application of biosynthesized composite organic trace elements

PendingCN108991228AHigh in nutrientsGood physical conditions for growthFood processingFood preservationCompound organicTrace element

The invention discloses a preparation method and an application of biosynthesized composite organic trace elements. The method comprises the following steps: (1) separately preparing every single bacterial liquid; (2) preparing a mixed bacterial liquid from all the bacterial liquids prepared in step (1); (3) adding a composite inorganic trace element material to a carrier material to prepare a fermentation substrate; (4) mixing the mixed bacterial liquid with the fermentation substrate to obtain a material to be fermented; and (5) performing sealing fermentation on the material to be fermentedto obtain the composite organic trace element material. An application method of the prepared composite organic trace element material is characterized in that 2.5-5 wt% of the composite organic trace element material is added into a conventional diet feed free from trace elements in order to prepare a compound feed. The composite organic trace elements prepared in the invention can improve the absorption and utilization ratio of trace elements, reduce the addition amount of trace elements in the feed, reduce the pollution of the emission of trace elements to soil, improve the production performance of animas and reduce the breeding cost.

Owner:湖北华大瑞尔科技有限公司

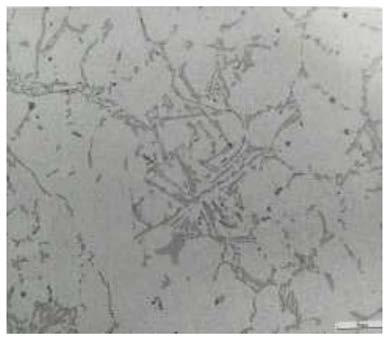

Casting method of metal alloy casting

InactiveCN110340297AReduced activityAvoid pinhole defectsFoundry mouldsFoundry coresChemical reactionInvestment casting

The invention provides a casting method of a metal alloy casting. The casting method comprises the following steps that a corresponding mould shell is prepared according to the shape of the metal alloy casting, a corresponding alloy raw material is prepared according to the material of the metal alloy casting, the alloy raw material is smelted to prepare alloy metal liquid, a proper amount of grain refiner is added into the alloy metal liquid, a mould material is obtained after uniform mixing, the mould material is poured into the mould shell through an investment casting process, and the metal alloy casting is obtained. Preferably, the composition of the grain refiner is aluminum titanium boron. By adopting the technical scheme, the aluminum titanium boron is used as the grain refiner toreplace an aluminum strontium modifier commonly used in the prior art, the elements such as aluminum, titanium and boron in the aluminum titanium boron grain refiner are lower in activity so as not likely to chemically react with other elements in the alloy raw material, so that the grains can be more fully refined, corresponding pinhole defects generated in the casting forming process of the casting can be avoided, and the forming quality, the mechanical property and the mechanical property of the finished casting are improved.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

Acousto-optic modulator

ActiveCN111240056AReduce thicknessRealize sound and light controlNon-linear opticsUltravioletAcousto-optics

The invention discloses an acousto-optic modulator. The modulator comprises a base; a vertical cylindrical lubricating layer is fixedly arranged on the base; the lubricating layer is hollow, the baseseals and covers an opening in the bottom end of the lubricating layer, a two-dimensional material is arranged on the upper surface of the lubricating layer, the two-dimensional material seals and covers an opening in the top end of the lubricating layer, and the base, the lubricating layer and the two-dimensional material form a closed gas cavity. The beneficial effects of the invention are that:when sound waves are transmitted to the structure, the acoustic pressure enables the two-dimensional material to slide on the lubricating layer and changes the distance between the two-dimensional material and the conductive base so as to achieve acousto-optic regulation and control, the acousto-optic modulator is wide in working frequency band, acoustic signals from infrasonic waves to ultrasonic waves with the frequency of 10 GHz can be converted into optical signals within the ultraviolet-to-infrared spectral range, and the response speed is high.

Owner:GUIZHOU MINZU UNIV

Production of fluoride acrylic-resin multipolymer anti-adhesive agent

Production of fluoride acrylate multi-polymer adhesion preventive agent is carried out by adding into solvent, non-fluoride monomer and fluoride monomer under existence of inert gas, raising temperature to 40-95degree, dissolving for monomers, dripping into initiator solution for 2-10hrs, heating to 60-110degree, reacting for 1-5hrs, and cooling to room temperature to obtain the final product. Ithas excellent water-proof and anti-solvent performances and alkali resistance and low stripping property.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com