Assembly of top-emission OLED (Organic Light-Emitting Diode) device and top-emission OLED device

A top-emission and module technology, applied in the field of top-emission OLED components and top-emission OLED devices, can solve the problems of low refractive index matching, sensitivity, and unfavorable light escape of the thin-film packaging layer, so as to achieve tight arrangement and increase transmittance , the effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] Take the preparation process of ZnO as an example: use diethyl zinc and water as the precursors of zinc and oxygen respectively, and pass them into the reactor in turn to form a ZnO film. In each reaction cycle, the exposure time of the precursor was 60 s, and the reaction environment was N 2 , temperature 130°.

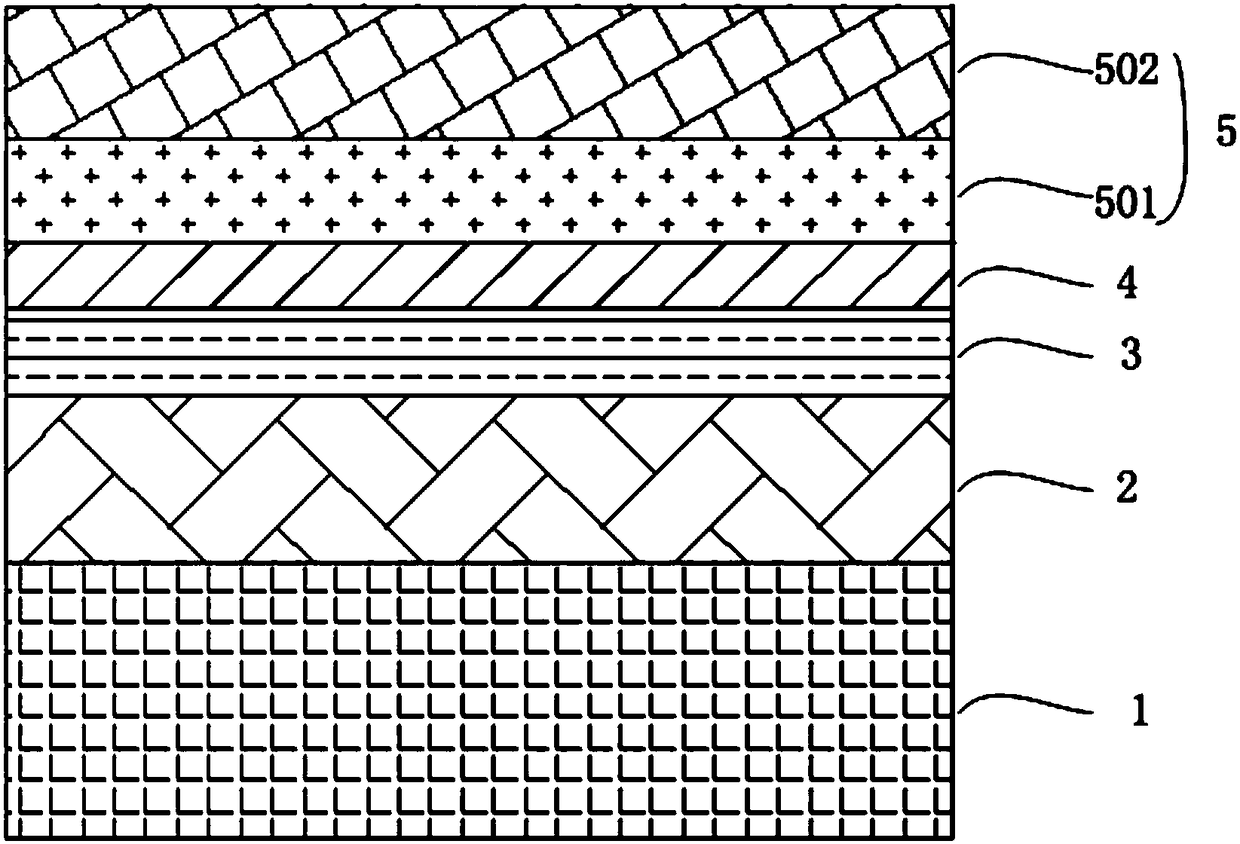

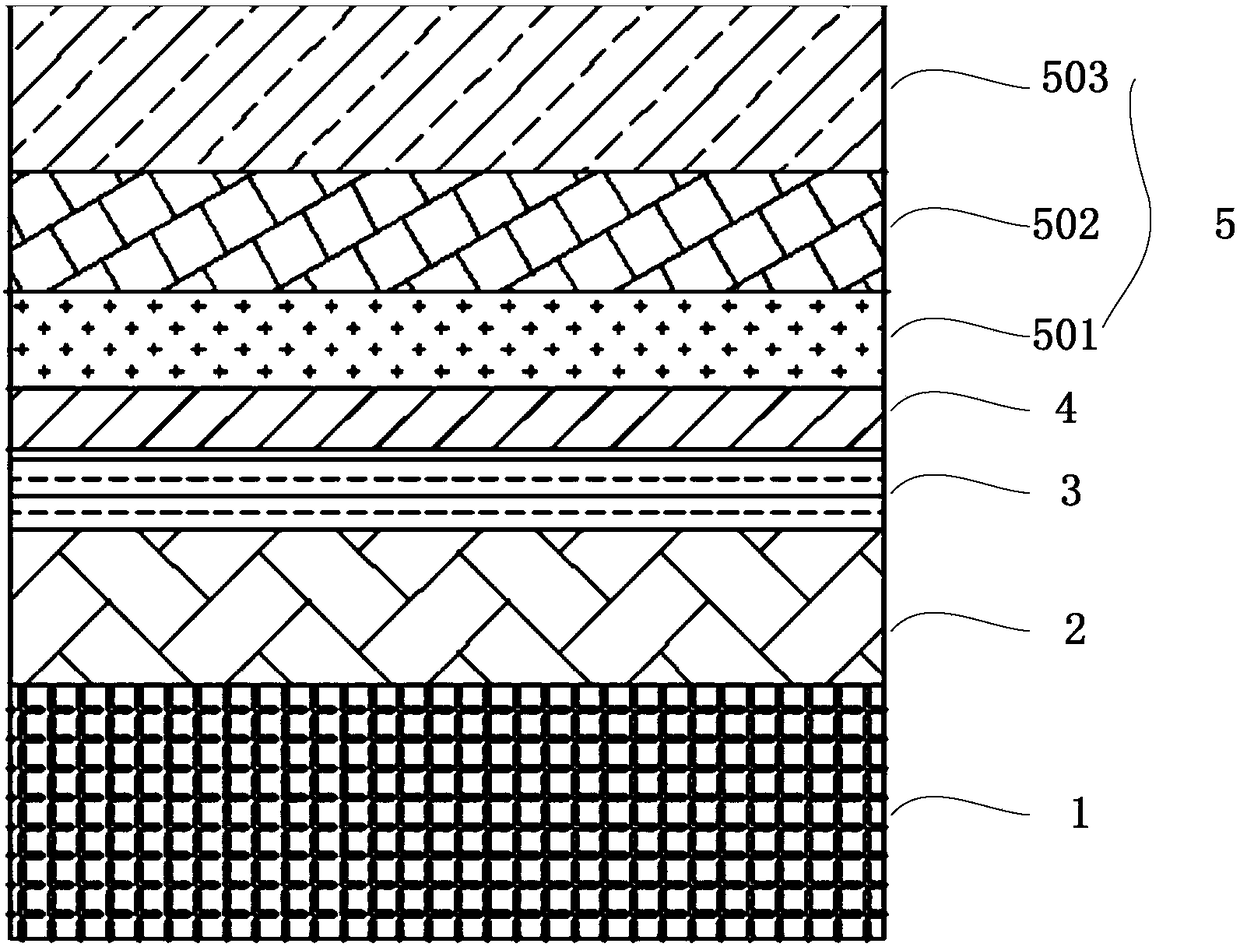

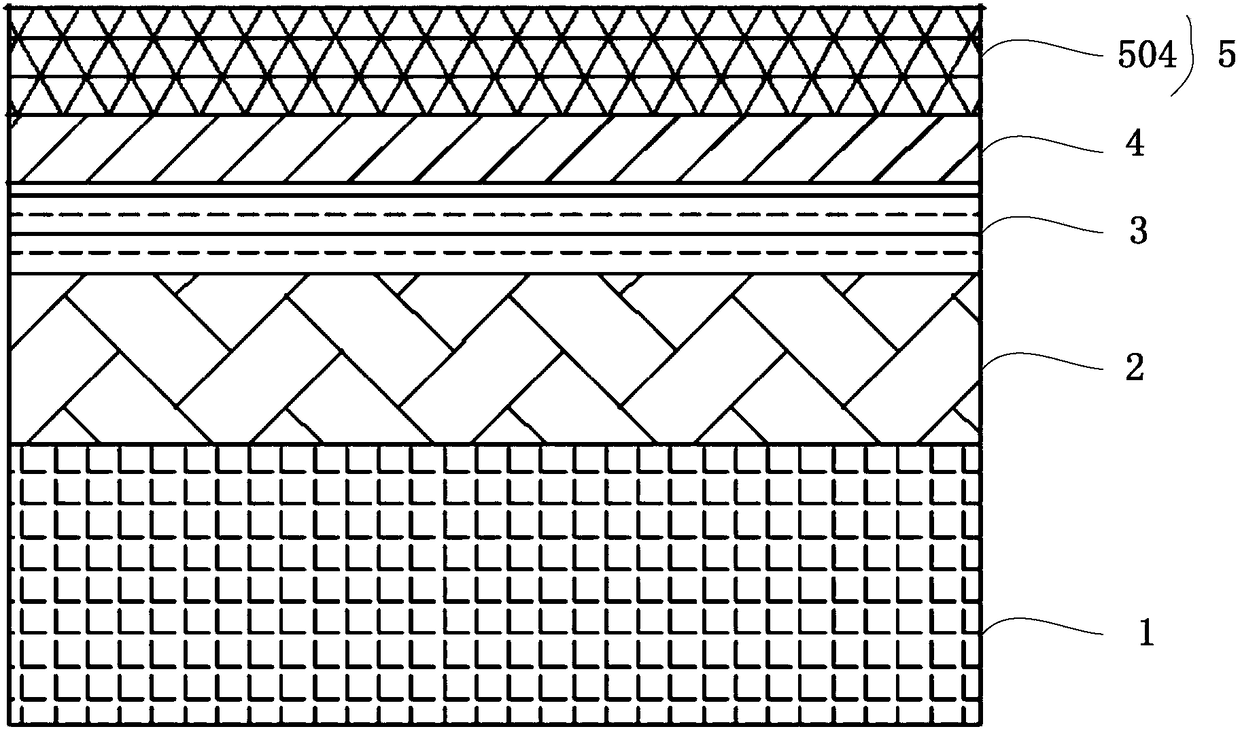

[0070] Furthermore, in the embodiment of the first aspect of the present invention, the material of the first organic encapsulation layer can be epoxy resin; the refractive index of the first organic encapsulation layer is smaller than the refractive index of the light extraction layer, forming a refraction gradient, reducing light total reflection. Further, the thickness of the first organic encapsulation layer may be 1-8 μm, and its refractive index is about 1.56.

[0071] In addition, the material of the first inorganic encapsulation layer can be silicon oxide, silicon nitride or silicon oxynitride, and the refractive index of the first inorganic encapsul...

Embodiment 1

[0094] Put the substrate into acetone, ethanol and deionized water for ten minutes, and then place it in an oven to dry;

[0095] The cleaned substrate is placed in a vacuum chamber, and an anode is formed on the substrate by magnetron sputtering, and the anode is an indium tin oxide / silver / indium tin oxide (ITO / Ag / ITO) film layer;

[0096] Put the prepared substrate into a vacuum evaporation chamber, keep the vacuum at 10-5Pa, use a heating source to heat and sublimate the material, and form a light-emitting layer (hole injection layer / hole injection layer) on the anode by evaporation. transport layer / luminescent layer / electron transport layer / electron injection layer);

[0097]Afterwards, a cathode is formed on the luminescent layer by vacuum evaporation, the thickness of the cathode is 14nm, and the material is a magnesium-silver alloy (the mass ratio of magnesium to silver is 2:8 or 9:1);

[0098] Deposit a light extraction layer on the cathode by atomic layer deposition ...

Embodiment 2

[0103] The difference between embodiment 2 and embodiment 1 lies in the addition of a second organic encapsulation layer. A second organic encapsulation layer with corrugated polymer was formed by layer-by-layer self-assembled polystyrene on the first inorganic encapsulation layer by spin coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com