Preparation method of double-rotor type organosilicone defoaming agent

A silicone defoamer, Gemini-type technology, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve problems such as poor defoaming speed, temperature sensitivity, etc., achieve small surface tension, overcome extreme Poor performance, improved stability and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

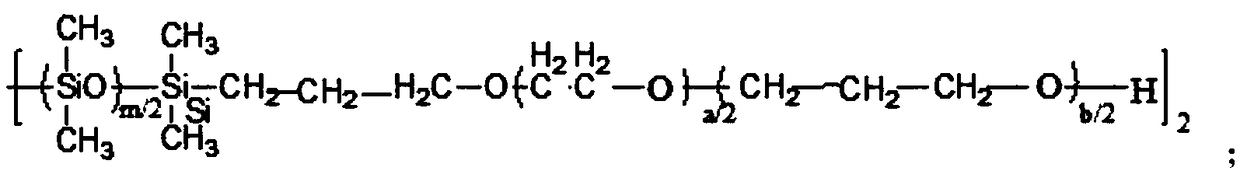

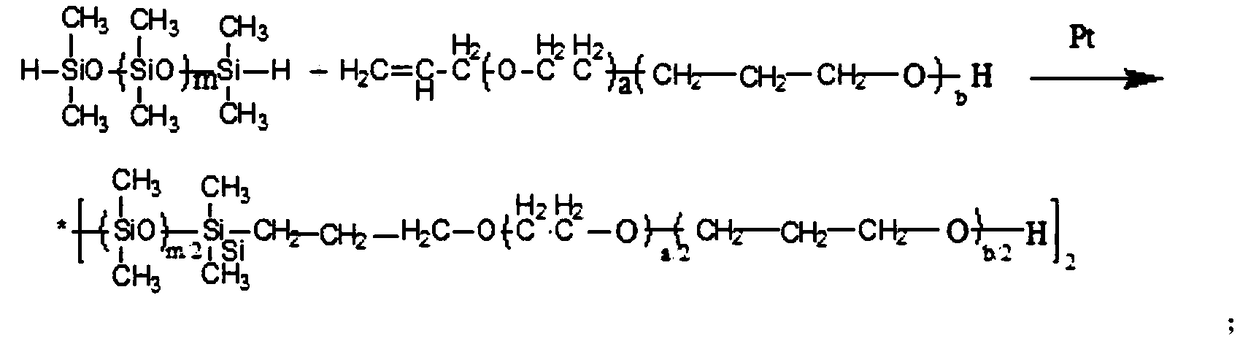

[0025] The present invention provides a kind of preparation method of gemini type organosilicon defoamer, it comprises the steps:

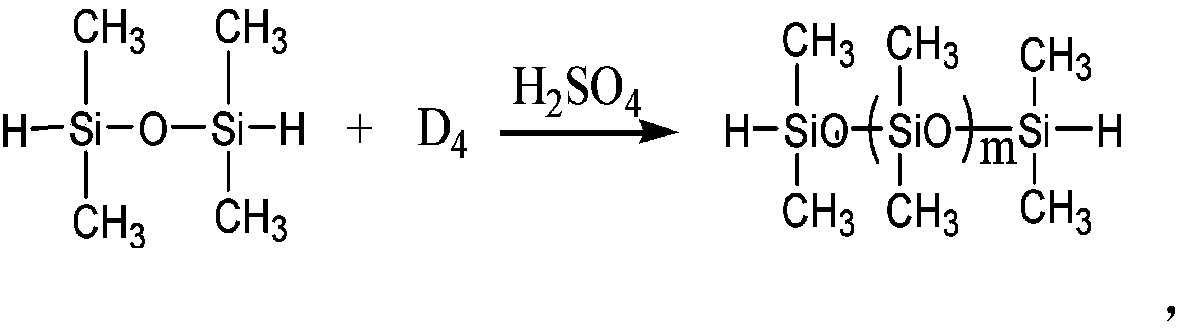

[0026] 1. Preparation process of hydrogen-terminated silicone oil:

[0027] The raw material of the hydrogen-terminated silicone oil includes 1 part by weight of a hydrogen-terminated double-header, 3 parts by weight of a molecular chain extender, and 0.1 part by weight of an acid catalyst; wherein, the hydrogen-terminated double The head-sealing agent is 1,1,3,3-tetramethyldisiloxane, the molecular chain extender is octamethylcyclotetrasiloxane (D4), and the acid catalyst is concentrated sulfuric acid catalyst;

[0028] The preparation method of the hydrogen-terminated silicone oil comprises the following steps: adding octamethylcyclotetrasiloxane (D4), hydrogen-containing double-capping agent and concentrated Sulfuric acid catalyst, slowly warming up to 35°C for 6.5 hours to obtain hydrogen-terminated silicone oil.

[0029] 2. Preparation proc...

specific Embodiment 2

[0035] The present invention provides a kind of preparation method of gemini type organosilicon defoamer, it comprises the steps:

[0036] 1. Preparation process of hydrogen-terminated silicone oil:

[0037] The raw material of the hydrogen-terminated silicone oil includes 2 parts by weight of a hydrogen-terminated double head agent, 12 parts by weight of a molecular chain extender, and 0.2 parts by weight of an acid catalyst; The head-sealing agent is 1,1,3,3-tetramethyldisiloxane, the molecular chain extender is octamethylcyclotetrasiloxane (D4), and the acid catalyst is concentrated sulfuric acid catalyst;

[0038] The preparation method of the hydrogen-terminated silicone oil comprises the following steps: adding octamethylcyclotetrasiloxane (D4), hydrogen-containing double-capping agent and concentrated Sulfuric acid catalyst, slowly warming up to 40°C for 7 hours to obtain hydrogen-terminated silicone oil.

[0039] 2. Preparation process of hydroxyl-terminated polyethe...

specific Embodiment 3

[0045] The present invention provides a kind of preparation method of above-mentioned hydroxyl-terminated polyether modified organosilicon, it comprises the following steps:

[0046] 1. Preparation process of hydrogen-terminated silicone oil:

[0047] (1) The raw materials for preparing hydrogen-terminated silicone oil include hydrogen-terminated double-capping agent, molecular chain extender and acid catalyst, and the parts by weight of the hydrogen-terminated double-capping agent, molecular chain extender and acid catalyst are respectively 1 part, 6.41 and 0.15 parts, wherein, the hydrogen-terminated double-capping agent is 1,1,3,3-tetramethyldisiloxane, the molecular chain extender is octamethylcyclotetrasiloxane famous D4, and the acid catalyst is concentrated sulfuric acid.

[0048] (2) The preparation method of hydrogen-terminated silicone oil comprises as follows successively: add 27.6 grams of octamethylcyclotetrasiloxane, 10 grams of hydrogen-terminated double-cappin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com