Production of fluoride acrylic-resin multipolymer anti-adhesive agent

A technology of acrylate and copolymer, which is applied in the field of preparation of fluorine-containing acrylate copolymer anti-sticking agent, can solve the problems of low surface energy anti-sticking effect and sticking, and achieve low peel strength, good film-forming performance, and adhesion Focus on high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

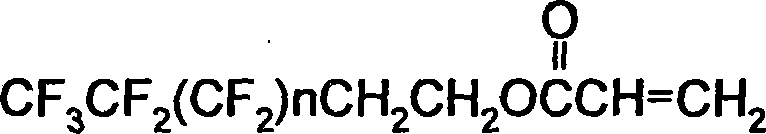

[0036] N 2Under the atmosphere, add solvent, non-fluorine monomer and fluorine-containing monomer, heat up to 55 ° C, after the monomer is completely dissolved, add 0.8wt% initiator solution of the total monomer mass dropwise, the mass concentration of the initiator is 20wt% , the dropping time is 8 hours, after the dropping, the temperature is raised to 95°C, the reaction is continued for 4 hours, and cooled to room temperature to obtain a uniform fluorine-containing acrylate copolymer release agent solution.

[0037] The obtained fluorine-containing acrylate copolymer anti-adhesive agent solution is diluted with the selected polymerization solvent to a solution with a solid content of 5%, and is made into a film according to the method of GB / T 1729-1979, dried at room temperature for 12 hours, and then Dry in an oven at 80°C for 2 hours to obtain a fluorine-containing acrylate copolymer anti-adhesive film.

[0038] The non-fluorine monomers and fluorine-containing monomers ...

example 2

[0051] N 2 Under the atmosphere, add solvent and non-fluorine monomer, heat up to 55 ℃, after the monomer is completely dissolved, add dropwise 0.8wt% initiator solution of the total monomer mass, the quality of the initiator accounts for 20wt% of the total mass of the solution. Add fluorine-containing monomer when the initiator solution is added dropwise for 3 hours. The total dropping time is 8 hours. After the initiator is dropped, the temperature is raised to 95°C, and the reaction is continued for 4 hours, and cooled to room temperature to obtain a uniform fluorine-containing acrylate copolymer anti-sticking Agent solution, polymerization monomer, ratio and film-making method thereof are identical with example 1.

example 3

[0053] The method for preparing the fluorine-containing acrylate copolymer release agent solution in this example is the same as Example 1, wherein the difference from Example 1 is that the content of the fluorine-containing monomer in this example is 20wt%, and the content of butyl acrylate is 53wt%. Polymerization monomer, ratio and film-making method thereof are identical with example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com