Forsterite spherical sand and preparation method and application thereof

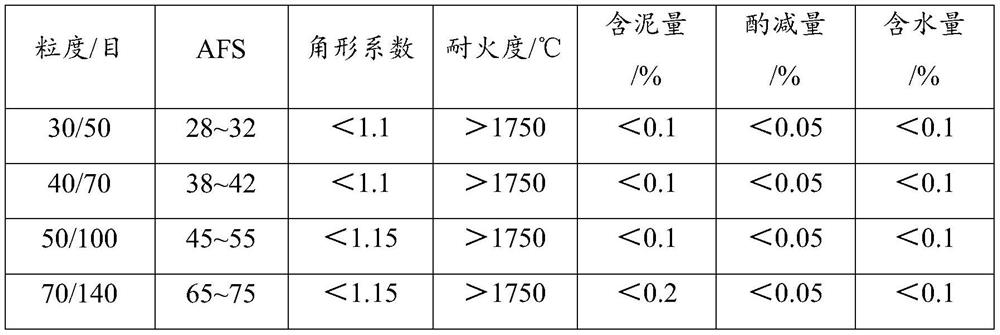

A forsterite and spherical sand technology, applied in the field of precision casting materials, can solve the problems of limited use range, many surface holes, large angle coefficient, etc., and achieve the effect of high recycling rate, dense surface without holes, and low angle coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of forsterite spherical sand provided by the present invention specifically comprises the following steps:

[0029] (1) The magnesite, quartz sand and flux are crushed and powdered respectively, and the fineness of the powder is required to pass through a 400-mesh sieve, that is, a powder material with a particle size of less than 0.038mm;

[0030] (2) Mix the above three powders according to a certain ratio, and the ingredients require MgO and SiO in the mixture 2 The molar ratio of the molar ratio is ≥2:1, and then the powder is mixed evenly with a mixer. The main raw materials are magnesite and quartz sand, and the flux includes one or a combination of nickel slag, bauxite and kaolin ;

[0031] Among them, the content of MgO in magnesite ≥ 45wt% (such as ≥ 45wt%, ≥ 50wt%, ≥ 65wt%, ≥ 80wt%); SiO in quartz sand 2 Content ≥ 90wt% (≥ 90wt%, ≥ 95wt%, ≥ 98wt%); CaO content ≤ 4wt%, Al 2 o 3 Content≤5wt%;

[0032] (3) A certain amount of mixed raw...

Embodiment 1

[0040] The preparation method of the forsterite spherical sand provided by the present embodiment specifically comprises the following steps:

[0041] 1), milling: respectively making magnesite ore, quartz sand and nickel slag into fine powder below 400 mesh;

[0042] 2) Ingredients: Take the raw materials of magnesite powder, quartz powder and nickel slag powder, and measure them respectively, according to the molar ratio of MgO:SiO 2 ≥2:1, take 72 parts of magnesite powder, 25 parts of quartz powder, and 3 parts of nickel slag powder for batching, and mix them evenly in the mixer;

[0043]3), granulation: take a certain amount of the above-mentioned mixture and place it in a granulator, spray atomized binder into the granulator, the binder is a PVA aqueous solution with a mass concentration of 0.5%, and start granulation. During the granulation process, dry powder is added in batches according to the degree of dryness and humidity of the material. The number of dry powder a...

Embodiment 2

[0053] The preparation method of the forsterite spherical sand provided by the present embodiment specifically comprises the following steps:

[0054] 1), milling: respectively making magnesite ore, quartz sand and nickel slag into fine powder below 400 mesh;

[0055] 2) Ingredients: Take the raw materials of magnesite powder, quartz powder and nickel slag powder, and measure them respectively, according to the molar ratio of MgO:SiO 2 ≥2:1, take 60 parts of magnesite powder, 20 parts of quartz powder, and 1 part of nickel slag powder for batching, and mix them evenly in the mixer;

[0056] 3), granulation: take a certain amount of the above-mentioned mixture and place it in a granulator, spray atomized binder into the granulator, the binder is a PVA aqueous solution with a mass concentration of 0.3%, and start granulation. During the granulation process, dry powder is added in batches according to the degree of dryness and humidity of the material. The number of dry powder a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com