Basic group adsorbent for capturing selenium in coal-fired flue gas and preparation method of basic group adsorbent

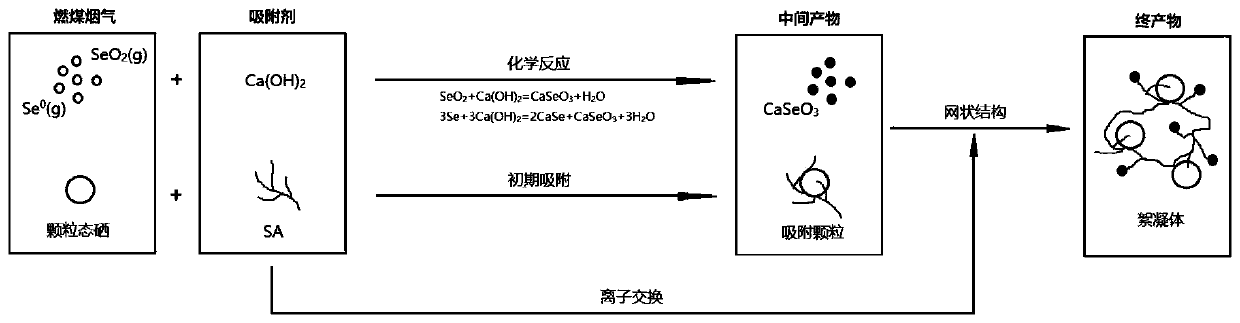

A technology of coal-fired flue gas and adsorbent is applied in the field of base adsorbent for capturing selenium in coal-fired flue gas and its preparation, which can solve the problem of small contact area and low effective utilization rate of solid adsorbent, which needs further exploration. and other problems, to achieve the effect of high stability, alleviation of environmental problems, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

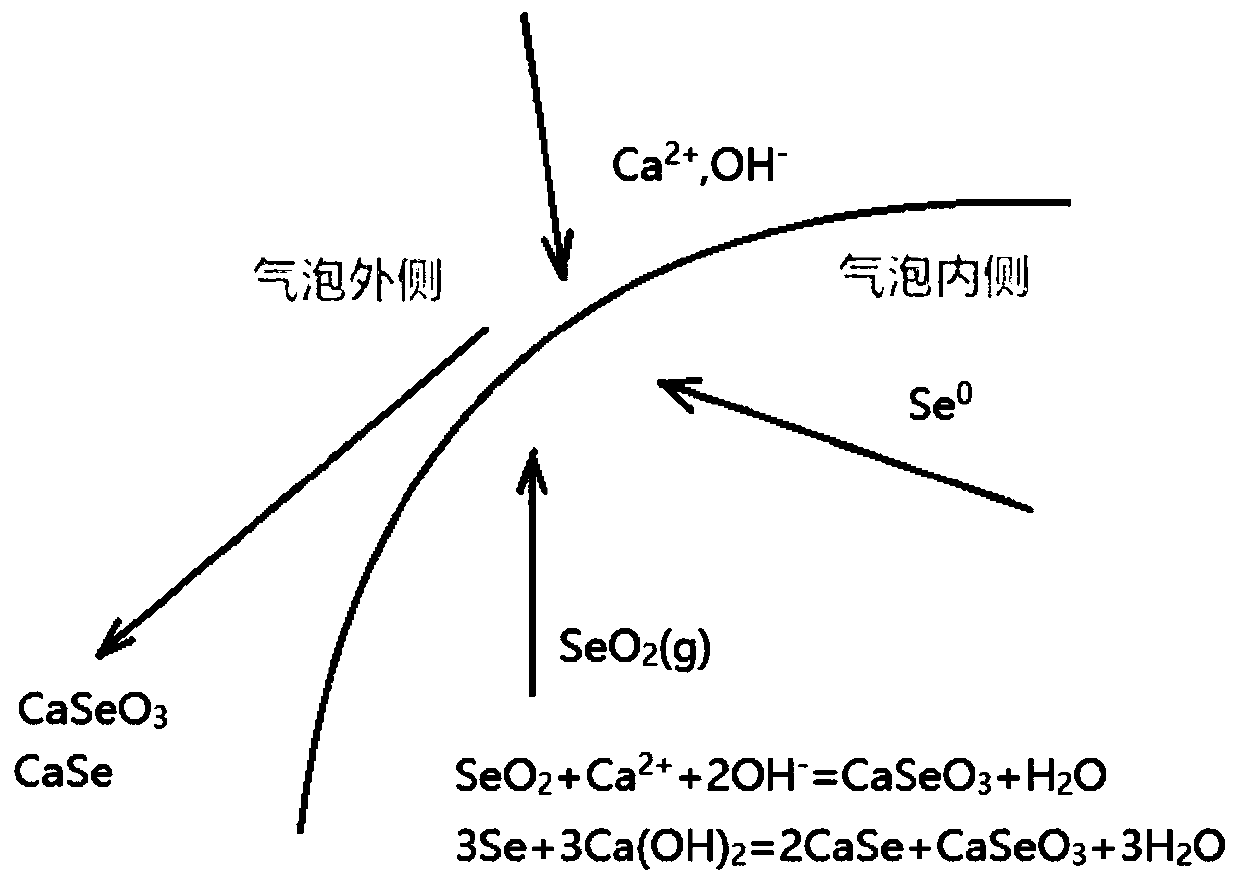

Method used

Image

Examples

preparation example Construction

[0030] see Figure 4 , the present invention also provides a preparation method of a base adsorbent for capturing selenium in coal-fired flue gas, the preparation method mainly includes the following steps:

[0031] Step 1, Preparation of Ca(OH) 2 solution.

[0032] Specifically, Ca(OH) was weighed in a mass ratio of 0.1 to 0.5 2 powder and sodium alginate powder, the Ca(OH) 2 The powder is added to deionized water and stirred with a glass rod until completely dissolved to obtain Ca(OH) 2 solution. In this embodiment, the Ca(OH) 2 The mass of the powder was 0.05 g.

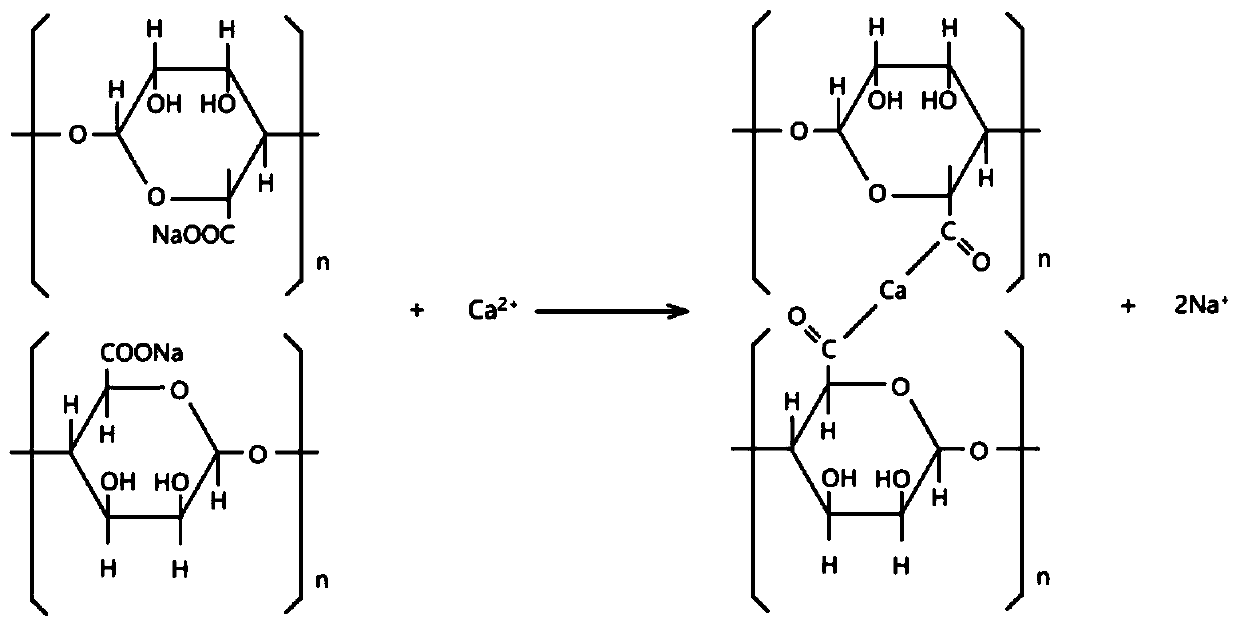

[0033] Step 2, to the Ca(OH) in several times 2 Sodium alginate powder was added to the solution and stirred to obtain a liquid-phase base adsorbent.

[0034] Specifically, although sodium alginate can be completely dissolved in most water-based systems, due to its extremely strong hydrophilicity, if it is put into water at one time and the stirring is not sufficient, the outer layer will absorb water and ...

Embodiment 1

[0040] The preparation method of the base adsorbent for capturing selenium in coal-fired flue gas provided in Example 1 of the present invention mainly includes the following steps: first, 0.05g Ca(OH) 2 The powder and 0.1g sodium alginate powder are dissolved in 100mL deionized water; when the solution is clear and transparent, pour the obtained base adsorbent into the gas washing bottle, turn on the thermostat, heating belt and other experimental instruments, and keep the temperature of the sublimation tube at 160℃±5℃, the feeding (fly ash) speed is about 0.1g / min, and the gas-phase selenium carrier gas (N 2 ) flow rate is 200ml / min, dilution gas (N 2 ) flow rate 1000ml / min, particulate carrier gas (N 2 ) flow rate was 800ml / min, and the reaction was performed for 1h. The results show that the de-selenium efficiency of the base adsorbent for capturing selenium in coal-fired flue gas obtained in Example 1 can reach 24.5%.

Embodiment 2

[0042] The preparation method of the base adsorbent for capturing selenium in coal-fired flue gas provided in Example 2 of the present invention mainly includes the following steps: first, 0.05g Ca(OH) 2 The powder and 0.5g sodium alginate powder are dissolved in 100mL deionized water; when the solution is clear and transparent, pour the obtained base adsorbent into the gas washing bottle, turn on the thermostat, heating belt and other experimental instruments, and keep the temperature of the sublimation tube at 160℃±5℃, the feeding (fly ash) speed is about 0.1g / min, and the gas-phase selenium carrier gas (N 2 ) flow rate is 200ml / min, dilution gas (N 2 ) flow rate 1000ml / min, particulate carrier gas (N 2 ) flow rate was 800ml / min, and the reaction was performed for 1h. The results show that the de-selenium efficiency of the base adsorbent for capturing selenium in coal-fired flue gas obtained in Example 2 can reach 49.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com