Welding method based on quartz tuning fork crystal three-temperature-area nitrogen blowing

A quartz tuning fork, temperature zone technology, applied in electrical components, impedance networks, etc., can solve problems such as affecting the quality of crystal production and contamination of quartz tuning forks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with embodiment.

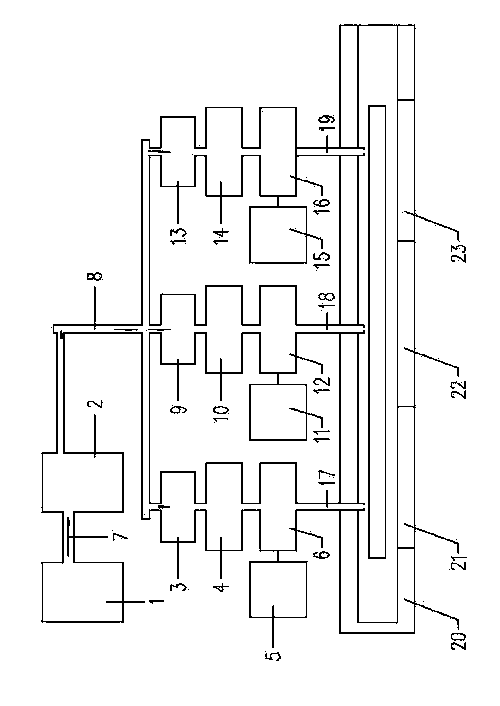

[0009] exist figure 1 Among them, the nitrogen generator 1 is connected to one end of the dryer 2 through the pipeline 7, and the other end of the dryer 2 is connected to the flow limiting valve A3, the flow limiting valve B9, and the flow limiting valve C13 respectively through the pipeline 8; the flow limiting valve A3 is filtered through Device A4, heating wire A6, drying temperature zone pipeline 17 are connected to drying temperature zone 21, and the other end of heating wire A6 is connected to adjustable converter A5; flow limiting valve B9 passes through filter B10, heating wire B12, preheating temperature zone The pipeline 18 is connected to the preheating temperature zone 22, and the other end of the heating wire B12 is connected to the adjustable converter B11; the flow limiting valve C13 is connected to the high temperature temperature zone 23 through the filter C14, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com