Acousto-optic modulator

An acousto-optic modulator with a smooth surface technology, which is applied in the directions of instruments, optics, nonlinear optics, etc., can solve the problems of low modulation speed and narrow application range, and achieve the effect of wide working frequency band, small thickness and high response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

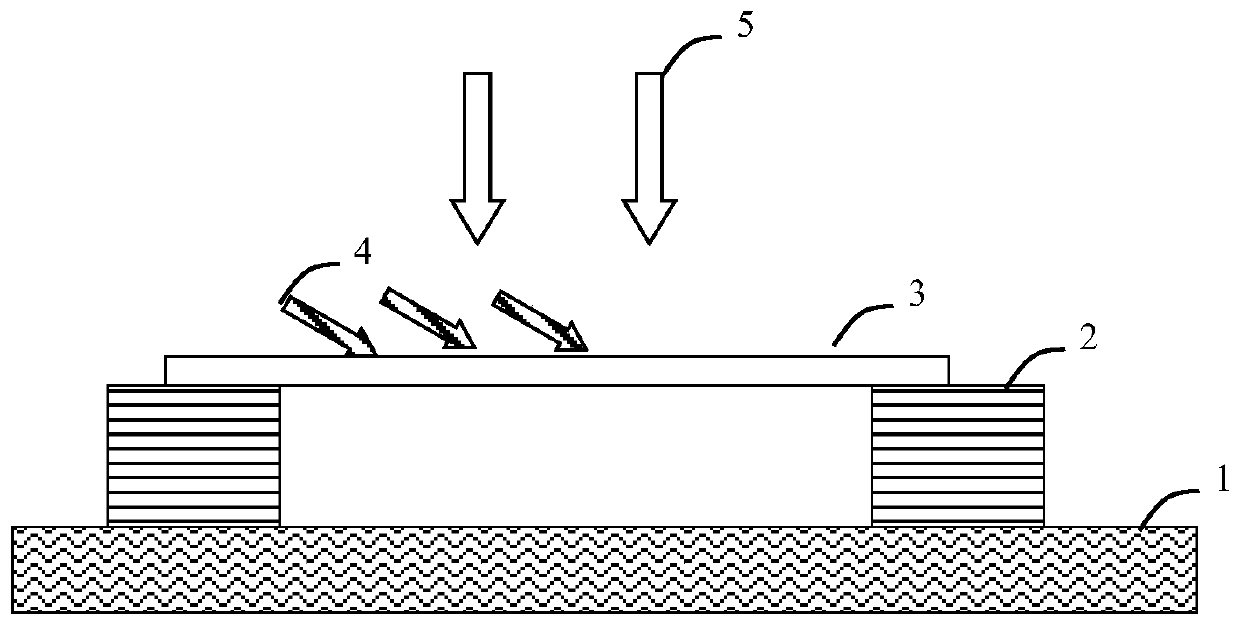

[0029] Such as figure 1 As shown, in this embodiment, an acousto-optic modulator includes a base 1, a vertical cylindrical lubricating layer 2 is fixed on the base 1, the lubricating layer 2 is hollow, and the base 1 covers the bottom of the lubricating layer 2. The upper surface of the lubricating layer 2 is provided with a two-dimensional material 3, and the two-dimensional material 3 covers the top opening of the lubricating layer 2. The base 1, the lubricating layer 2 and the two-dimensional material 3 form a closed gas chamber, and the gas chamber The filled gas is nitrogen, which has good stability, does not easily react with the two-dimensional material 3, the lubricating layer 2 and the base 1, and has good air tightness.

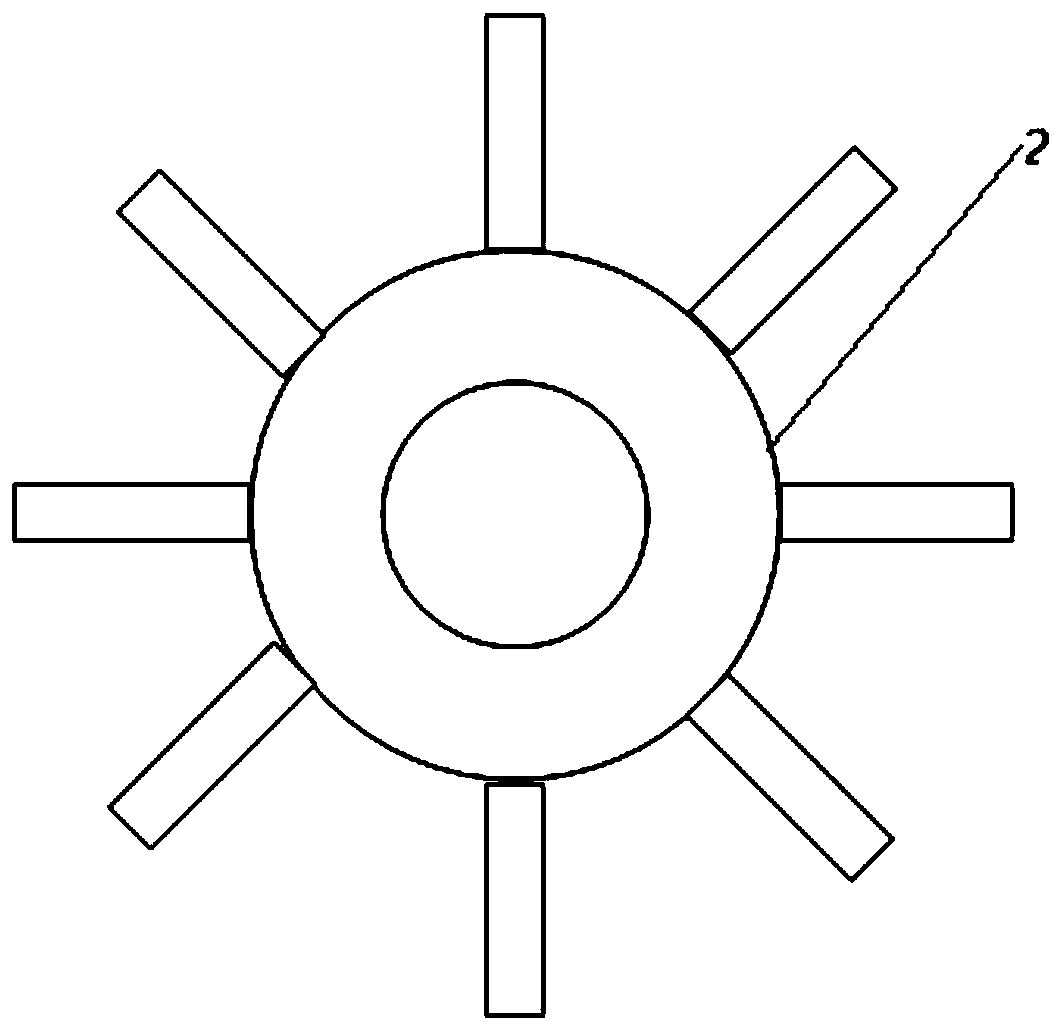

[0030] The lubricating layer 2 has a cylindrical and hollow structure. The outer wall of the lubricating layer 2 is provided with a plurality of radiating strips circumferentially fixed with a height of 500 nanometers, an outer diameter of 20 micrometer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com