Low-platinum core-shell catalyst, preparation method thereof and fuel cell

A core-shell catalyst and core technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor catalytic performance of low-platinum core-shell catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

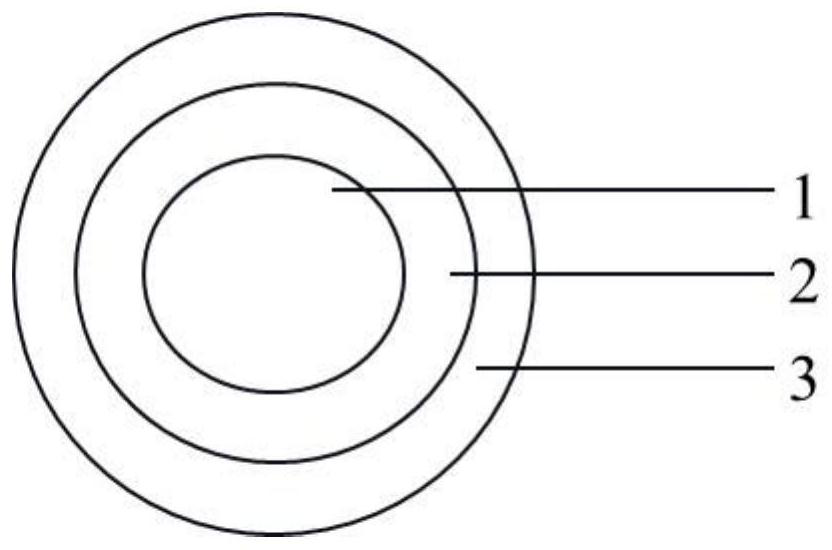

[0059] Described catalyst comprises complex body, and described complex body comprises inner core, the middle layer that coats described inner core, the shell that coats described middle layer; The preparation method of described complex body comprises the following steps:

[0060] S01, preparing a first mixed solution comprising transition metal nanoparticles, a noble metal salt and a first reducing agent, performing a first heating reduction reaction under alkaline conditions, and preparing transition metal nanoparticles coated with noble metal on the surface;

[0061] S02, preparing a second mixed solution containing the product in S01, a platinum salt and a second reducing agent, and performing a second heat reduction treatment under alkaline conditions to prepare the inner core, the intermediate layer covering the inner core, the coating A complex formed by an outer shell covering said intermediate layer;

[0062] The molar ratio of the platinum, noble metal and transitio...

Embodiment 1

[0118] Transition metal nanoparticles and preparation method thereof

[0119] Select any transition metal of Fe, Co, Ni, Cu, dissolve the hydrochloride or sulfate of the transition metal in absolute ethanol, form a transition metal salt dispersion through mixing and ultrasonic treatment, and the prepared transition metal salt The concentration is 0.02mol / L;

[0120] Prepare NaBH 4 Add the reducing agent alcohol dispersion into the transition metal salt dispersion to obtain the first mixed solution by adding the reducing agent alcohol dispersion while stirring, and control the dropping rate to 1-3mL / min and the stirring speed to 300 ~600 rpm; wait for NaBH 4 After the ethanol solution is added dropwise, continue to stir the transition metal salt and NaBH 4 The mixed solution of ethanol was used for 2 hours, and then the reduced transition metal nanoparticles were gradually separated by a centrifuge at 10000rpm, and the separated transition metal nanoparticles were washed wit...

Embodiment 2

[0122] Transition metal nanoparticles coated with noble metal intermediate layer and preparation method thereof

[0123] The obtained transition metal nanoparticles are dispersed in 50mL ethylene glycol solution, transferred to a flask, and ultrasonically dispersed and stirred to obtain the alcohol dispersion of the transition metal nanoparticles; Weigh chloroauric acid (AuCl 3 ·HCl·4H 2 O) be dissolved in ethylene glycol solution, wherein, the mol ratio of the chloroauric acid dropped into and the transition metal nano-particle is 1:3, make chloroauric acid be completely dissolved in ethylene glycol solution by stirring and prepare described noble metal chlorine Alcoholic dispersion of compounds;

[0124] The alcohol dispersion of the noble metal chloride is added to the alcohol dispersion of the transition metal nanoparticles in a manner of stirring while dropping, wherein, the speed of dropping is 1-2 mL / min; the speed of stirring is 500 ~600rpm; add 2mol / L NaOH solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com