Three-screw pump machine barrel and ceramic treatment method of inner surface of three-screw pump machine barrel

A three-screw pump and inner surface technology, applied in the direction of machines/engines, surface reaction electrolytic coating, pump components, etc., can solve the problems of easy aging anisotropy, high temperature sensitivity, etc., achieve good adhesion performance and prolong service time , high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0038] Specific embodiment one: a kind of three-screw pump barrel described in this embodiment, the inner wall of this pump barrel is coated with a layer of ceramic film, and this layer of ceramic film includes 90% to 95% Al 2 o 3 , the thickness is between 50μm and 70μm, and the hardness is 800HV.

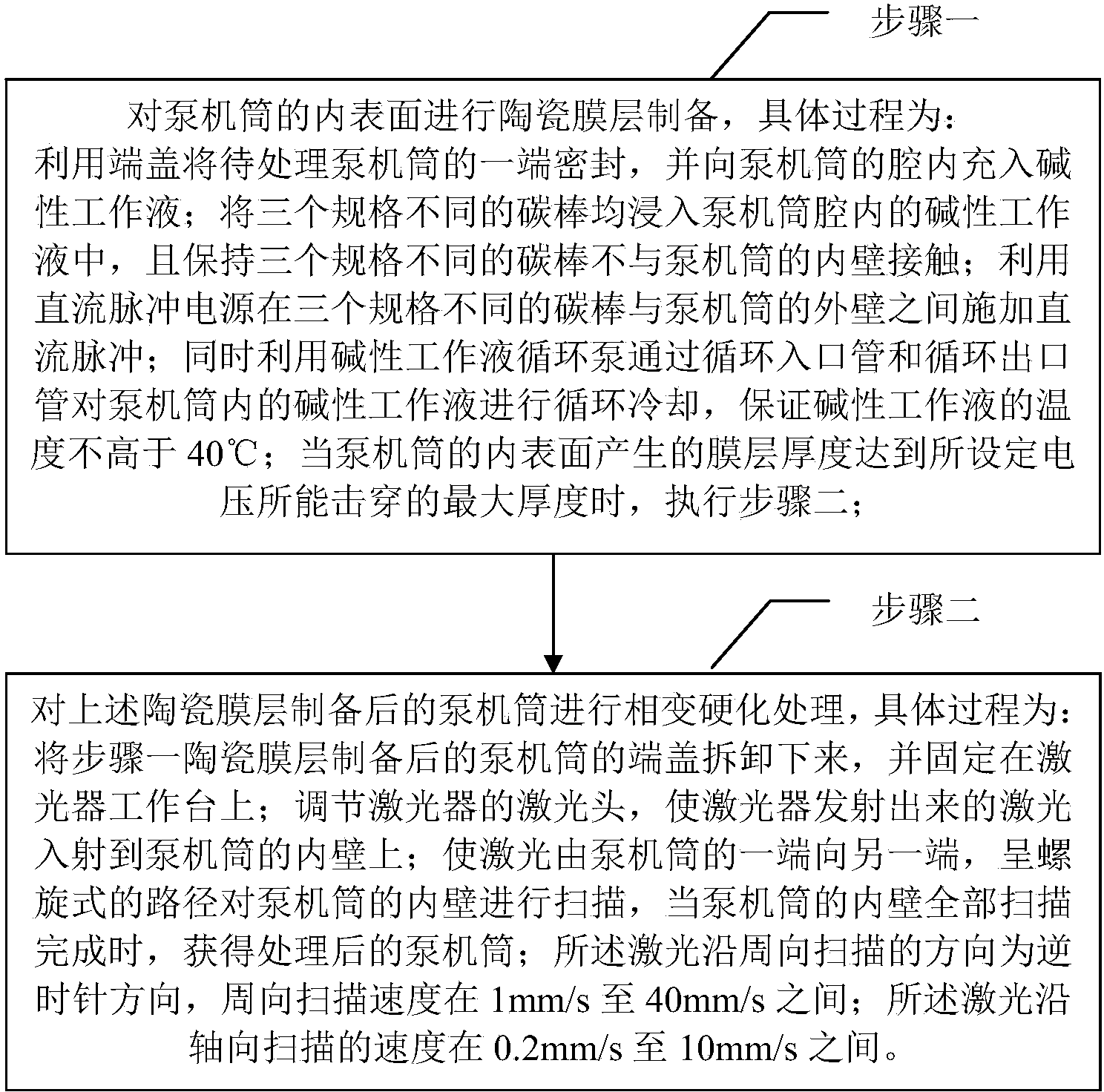

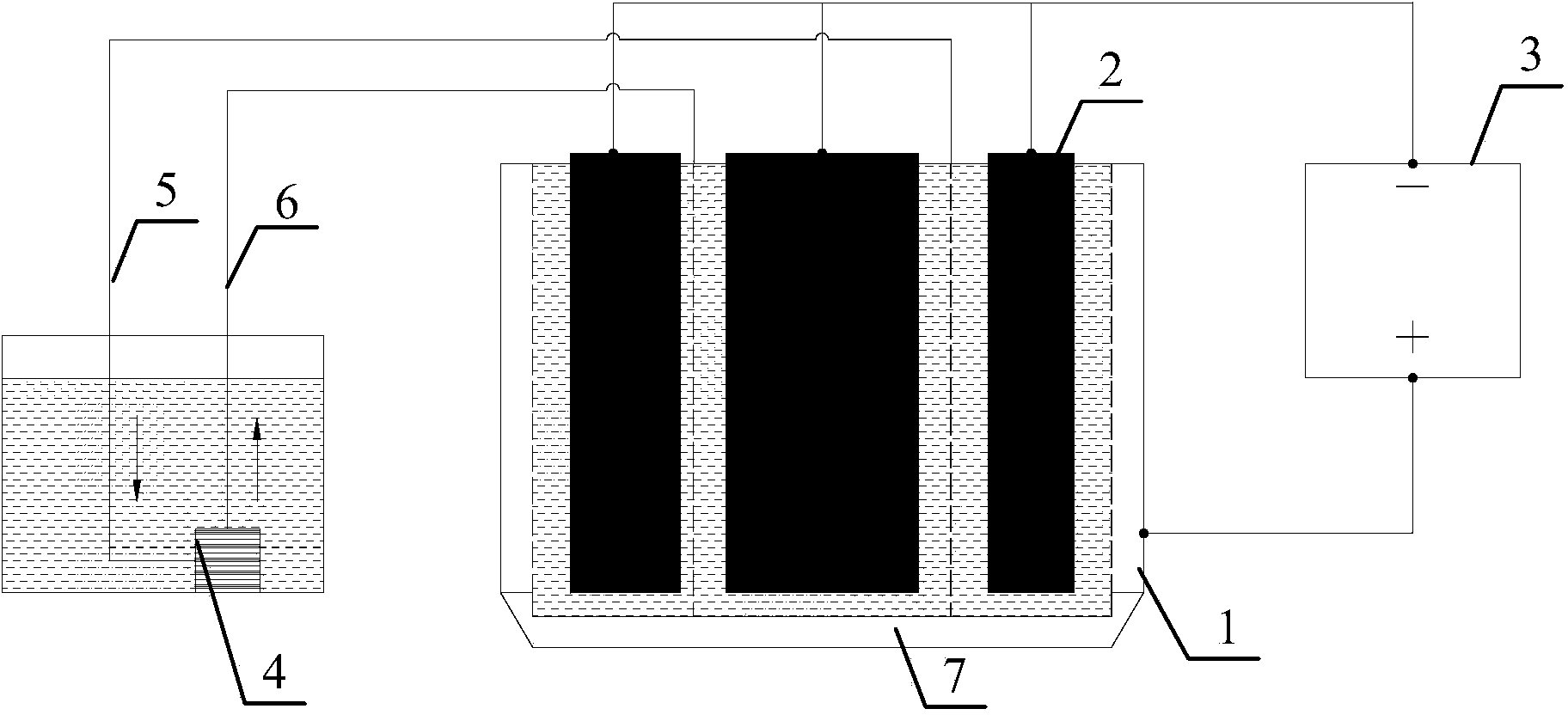

[0039] Specific implementation mode two: refer to figure 1 , figure 2 , image 3 and Figure 4 Specifically explain this embodiment, a method for ceramicizing the inner surface of a three-screw pump barrel described in this embodiment, the method includes the following steps:

[0040] Step 1: Prepare a ceramic film layer on the inner surface of the pump barrel 1, the specific process is:

[0041] Use the end cover 7 to seal one end of the pump barrel 1 to be treated, and fill the cavity of the pump barrel 1 with alkaline working fluid;

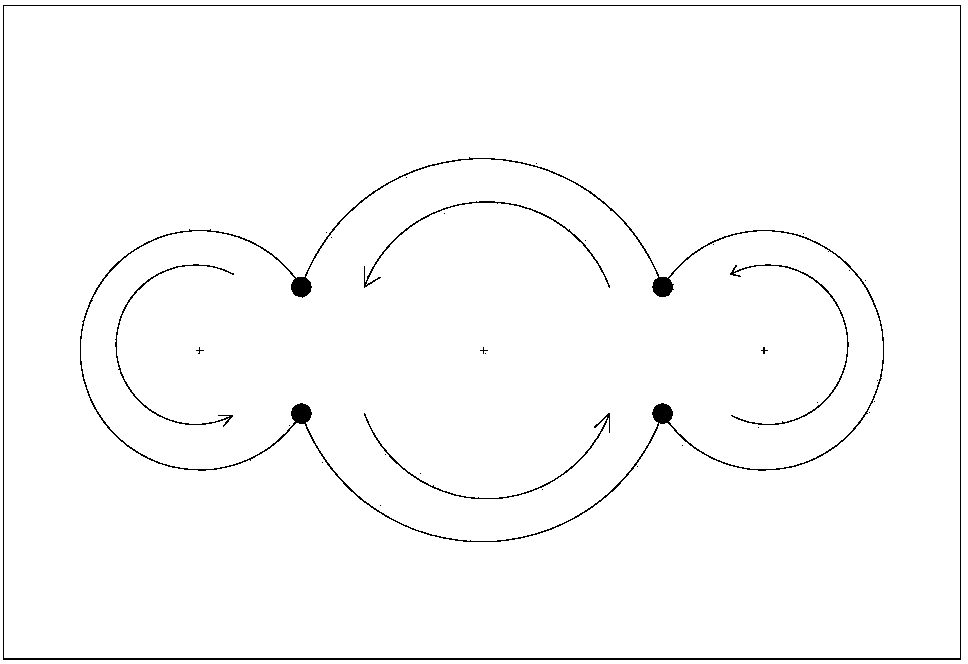

[0042] Dip three carbon rods 2 with different volumes into the alkaline working fluid in the chamber of the pump barrel 1, and keep the th...

specific Embodiment approach 3

[0054] Specific Embodiment 3: This embodiment is a further description of the method for ceramicizing the inner surface of a three-screw pump barrel described in Specific Embodiment 2. In this embodiment, before step 1, the pump barrel is first 1 to clean, the specific method includes the following steps:

[0055] Step 11: Immerse the pump barrel 1 in clean water, clean the inner wall of the pump barrel 1 with clean water for 1 to 3 minutes, and then dry the pump barrel 1;

[0056] Step 1 and 2: Immerse the pump barrel 1 cleaned in step 1 in acetone or absolute ethanol, let it stand for 3 minutes to 5 minutes, and then dry the pump barrel 1 to obtain the cleaned pump barrel 1 .

specific Embodiment approach 4

[0057] Embodiment 4: This embodiment is a further description of the method for the ceramic treatment of the inner surface of a three-screw pump barrel described in Embodiment 2. In this embodiment, the solute of the alkaline working fluid described in Step 1 Includes: KOH and NaSiO 3 , where the concentration of KOH is 2g / L to 4g / L, NaSiO 3 The concentration is 10g / L to 15g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com