High-temperature heat transfer medium and preparation method thereof

A heat transfer working fluid, high temperature technology, applied in chemical instruments and methods, heat exchange materials, energy input, etc., can solve problems such as casualties and large economic losses, achieve low steam pressure, simple preparation methods, and meet the needs of transmission Effects of thermal and/or performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

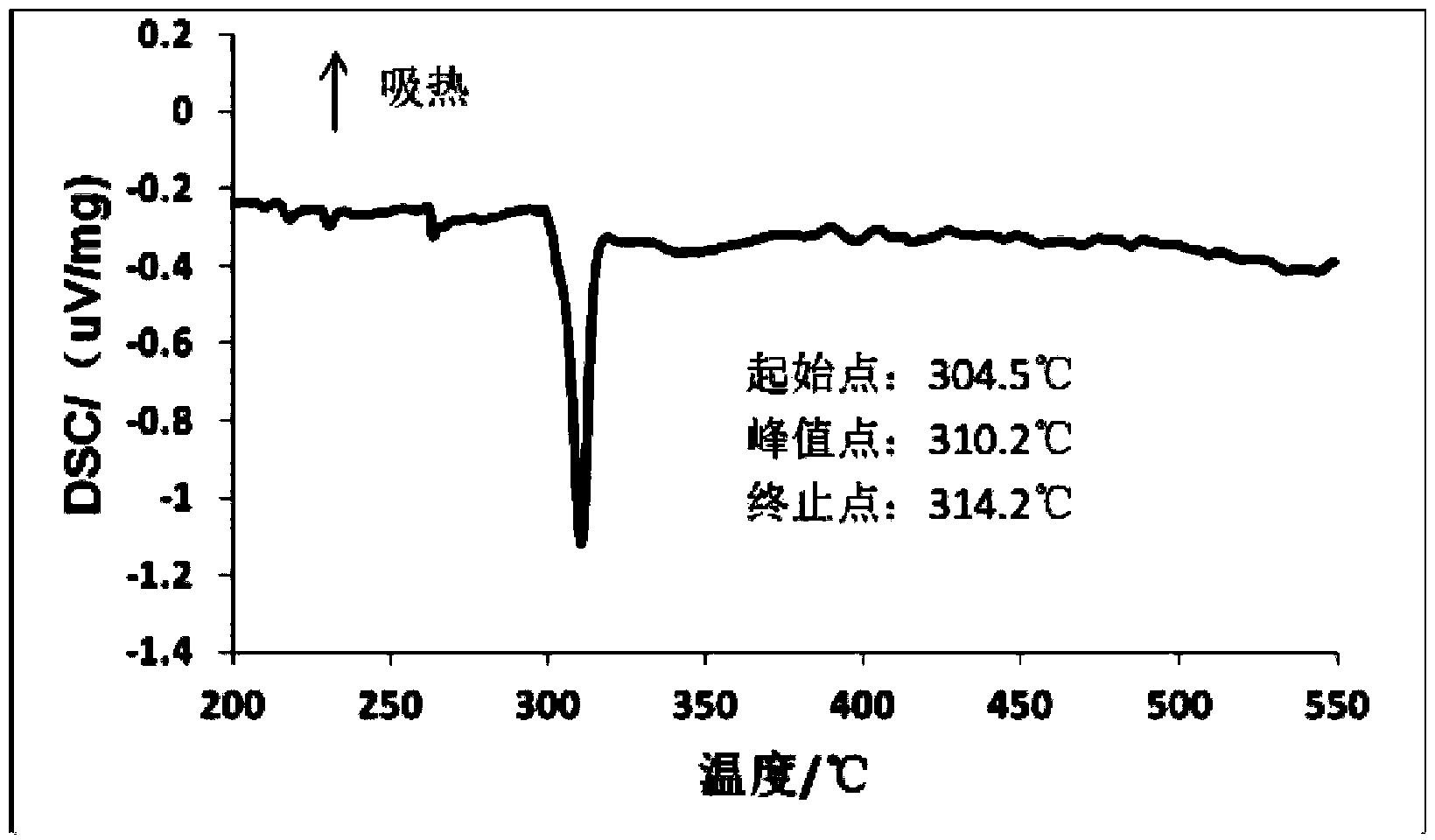

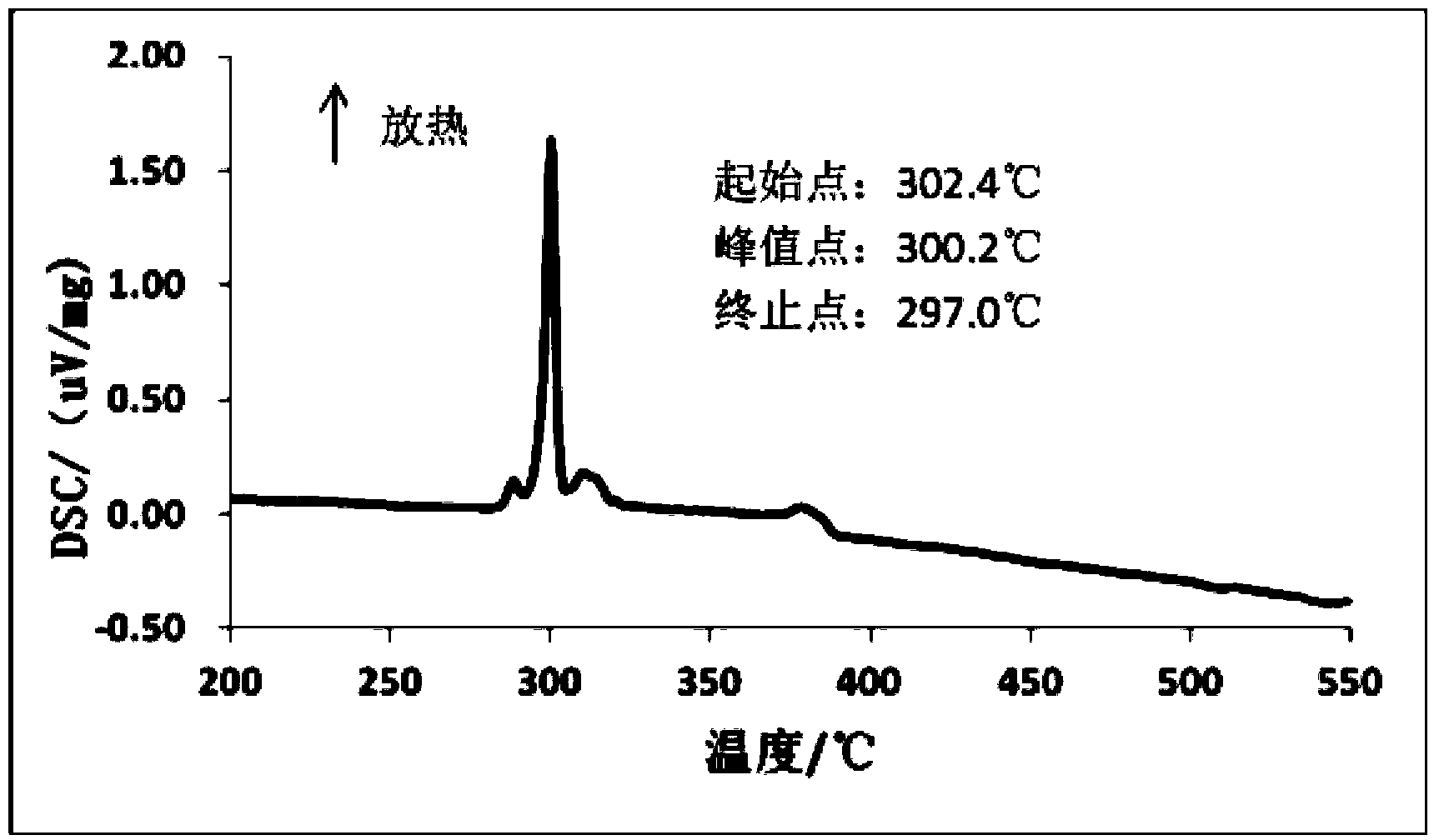

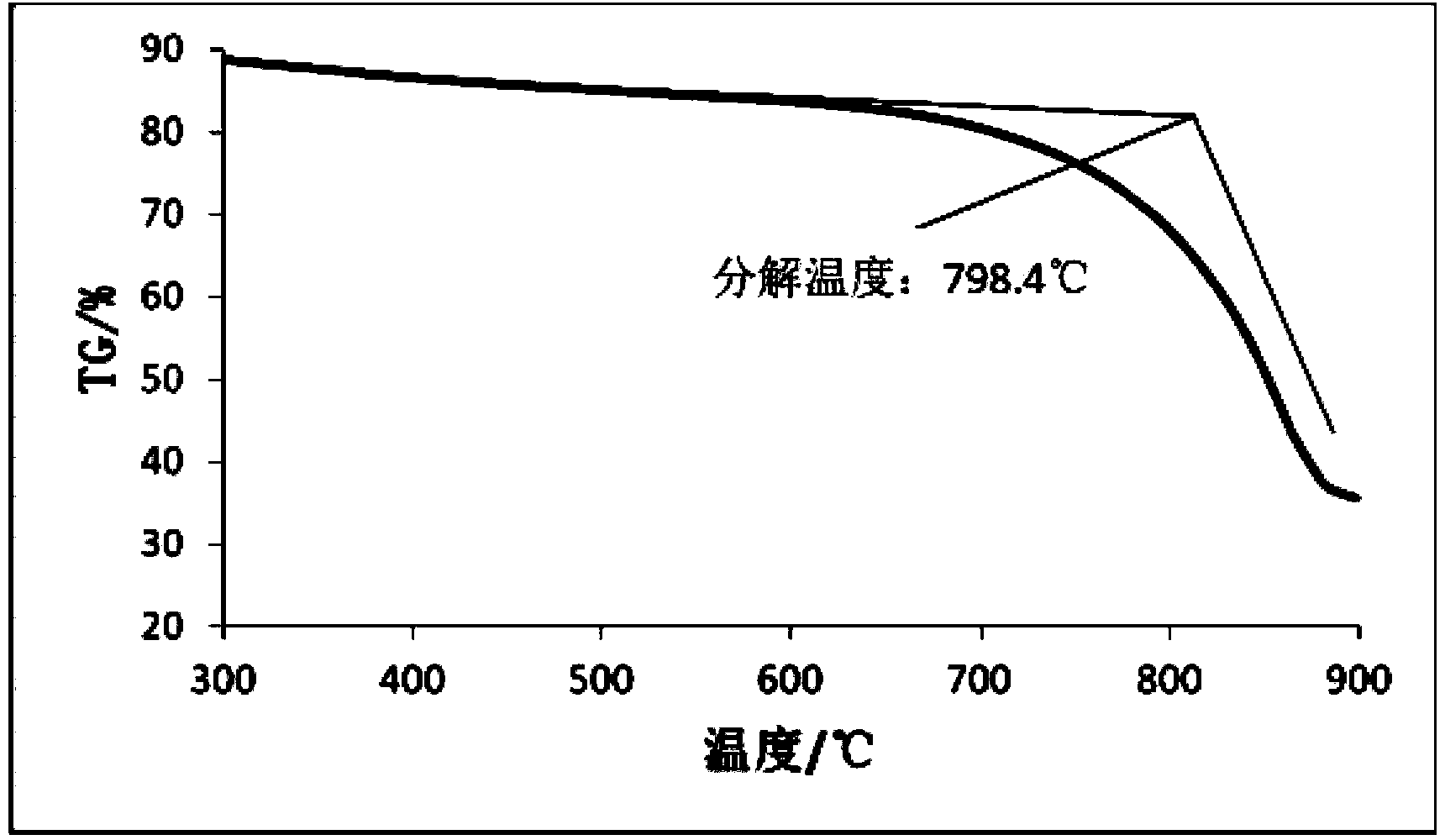

[0026] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] As a specific example, firstly, each component (industrial grade) of the high-temperature heat transfer fluid is uniformly mixed according to the following weight ratio: NaBr: 5 parts; Ca(Br) 2 : 18 parts; KBr: 27 parts; LiBr: 50 parts, mixed with 50 grams of mixture, put it into a beaker and carry out preliminary stirring and mixing with a glass rod; Turn on the power of the pulverizer and turn it for 15-20s, so that the four compounds are basically fully and uniformly mixed; then put the uniformly mixed mixture into an electric furnace with a stirrer and gradually heat it to 305°C while stirring until the mixture melts ; Then while continuing to heat and stir, gradually heat the mixture to and stabilize to 500°C, and then continue to stir for 45 minutes. After the crystallization and other impurities in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com