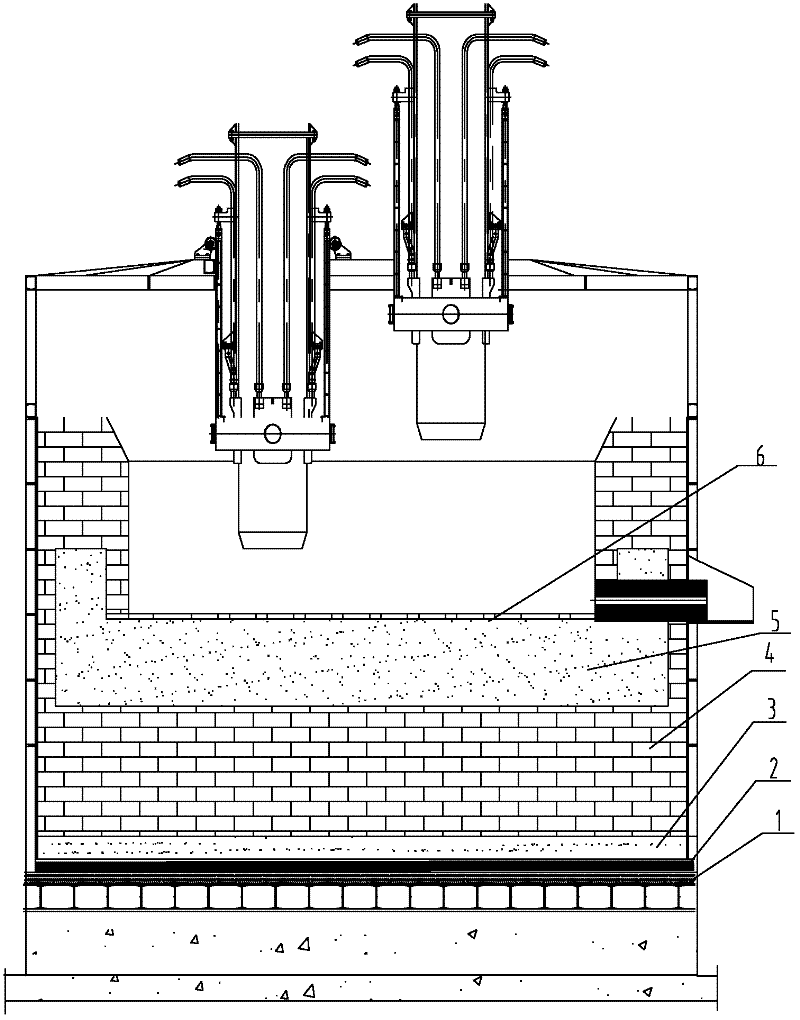

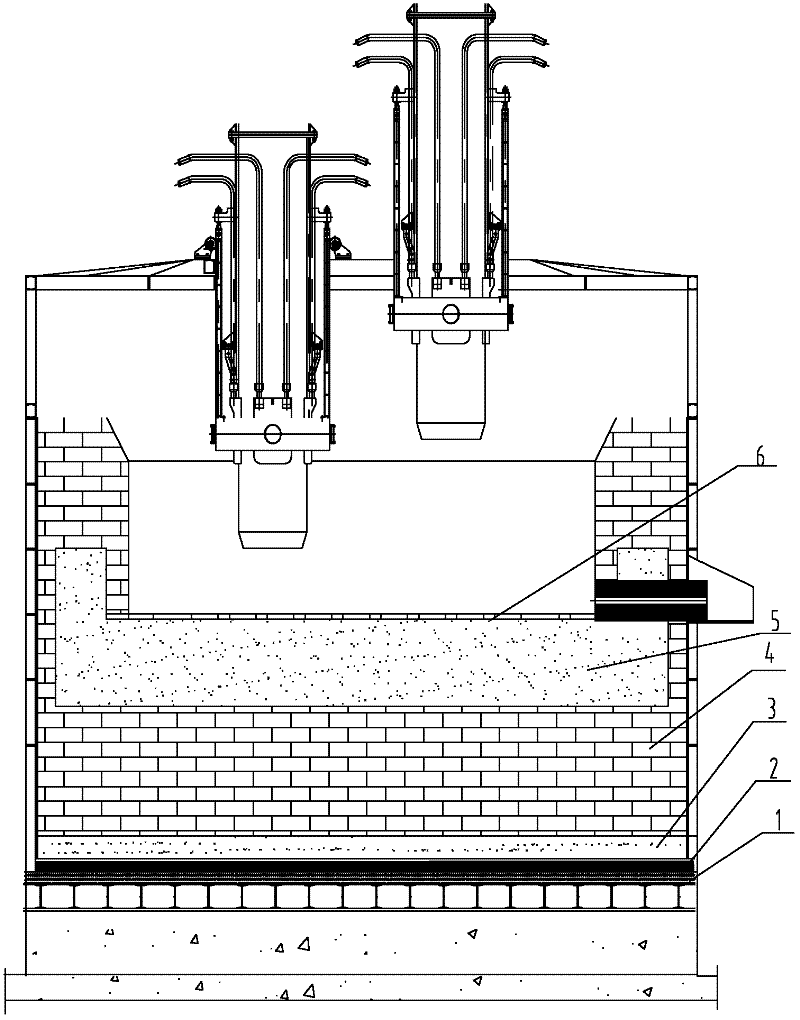

Submerged arc furnace body and constructing method thereof

A submerged arc furnace and furnace body technology, applied in the submerged arc furnace field, can solve the problems of shortening the service life of the submerged arc furnace, increasing the cost of metal smelting, burning through the bottom of the submerged arc furnace, etc., achieving good volume stability and improving smelting effect, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] Lay asbestos boards on the foundation to form an asbestos board layer; lay refractory grains on the asbestos board layers to form a refractory grain layer; build refractory bricks on the refractory grain layer, and fill with refractory soil between each layer of refractory bricks until the refractory brick layer with a predetermined height is formed; while laying the refractory bricks, asbestos boards are laid on the furnace wall, and the gaps between the furnace wall asbestos boards and the refractory bricks at the bottom of the furnace are filled and tamped with refractory particles; then A 12cm thick ramming material is evenly laid on the refractory brick layer, and the ramming material is tamped to 8 cm; a 12 cm thick ramming material is then evenly laid, and the ramming material is rammed to 8 cm, and the above steps are repeated until a predetermined thickness of the ramming material layer is obtained. After laying magnesia bricks on the layer, the bottom of the su...

Embodiment 2

[0140] The method of Example 1 was used to build a submerged arc furnace, except that the ramming material was purchased from Dashiqiao Hongyan Refractory Co., Ltd., and the model was HLD-85A.

[0141] The submerged arc furnace was used for metal smelting, and the results showed that the submerged arc furnace was used normally for 18 months, and the bottom of the furnace did not burn through.

Embodiment 3

[0143] The submerged arc furnace was built by the method of Example 1, except that the ramming material was purchased from Dashiqiao Hongyan Refractory Co., Ltd., and the model was HLD-12A.

[0144] The submerged arc furnace was used for metal smelting, and the results showed that the submerged arc furnace was used normally for 30 months, and the bottom of the furnace did not burn through.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com