Automobile circuit board heat dissipation device

A heat dissipation device and circuit board technology, which is applied in the direction of electrical components, electrical equipment structural parts, cooling/ventilation/heating transformation, etc., can solve the problem of increasing the volume and weight of the heat dissipation system, not having impact resistance, and limited cooling capacity, etc. problem, to achieve the effect of improving heat dissipation performance, rapid heat dissipation, and improving rapid emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

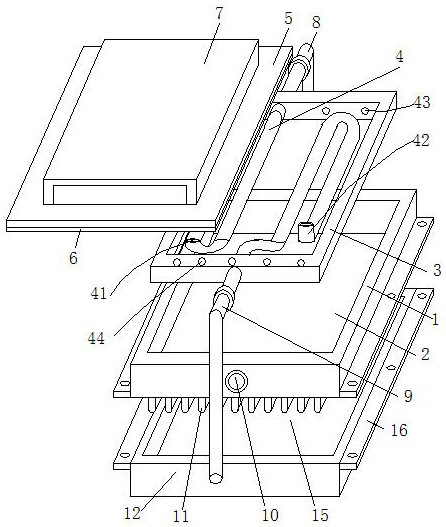

Method used

Image

Examples

specific Embodiment 2

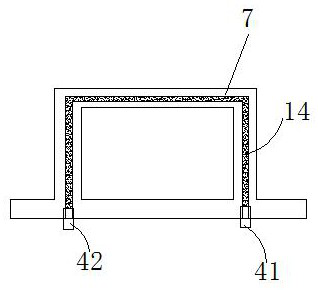

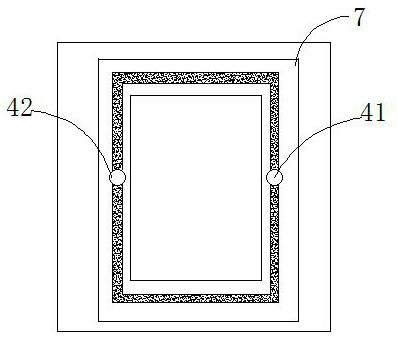

[0053] Such as Figure 5 , 7 shown; others are the same as the first embodiment, the difference is that the structure of the radiator shell 301 of the heat dissipation assembly 11 is different.

[0054] The radiator shell 301 includes a housing box 3011, a spiral shield 3012, a support frame 3013, and a cooling motor mount 3014;

[0055] A spiral protective cover 3012 is installed on the upper surface of the shell box 3011. The spiral protective cover 3012 is made of a hollow copper tube and is in a spiral shape. The spiral protective cover 3012 is divided into an upper protective cover and a lower plate cover; the lower plate cover It communicates with the upper protective cover up and down, and the inside is filled with volatile coolant;

[0056] The upper protective cover is fixedly connected with the shell box body 3011 through the support frame 3013, the end of the support frame 3013 is fixedly connected with the shell box body 3011, and the center part of the support f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com