Cross-flow hot-air type combine harvester humid material conveying feeding device

A technology of combine harvester and feeding device, which is applied in the direction of harvester, heating device, drying solid materials, etc. The effect of improving work stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

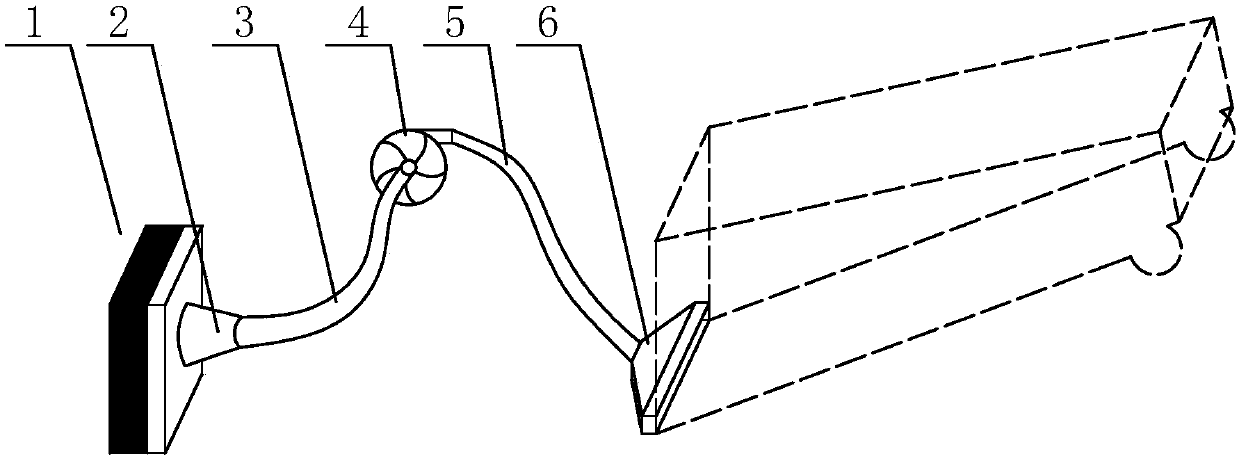

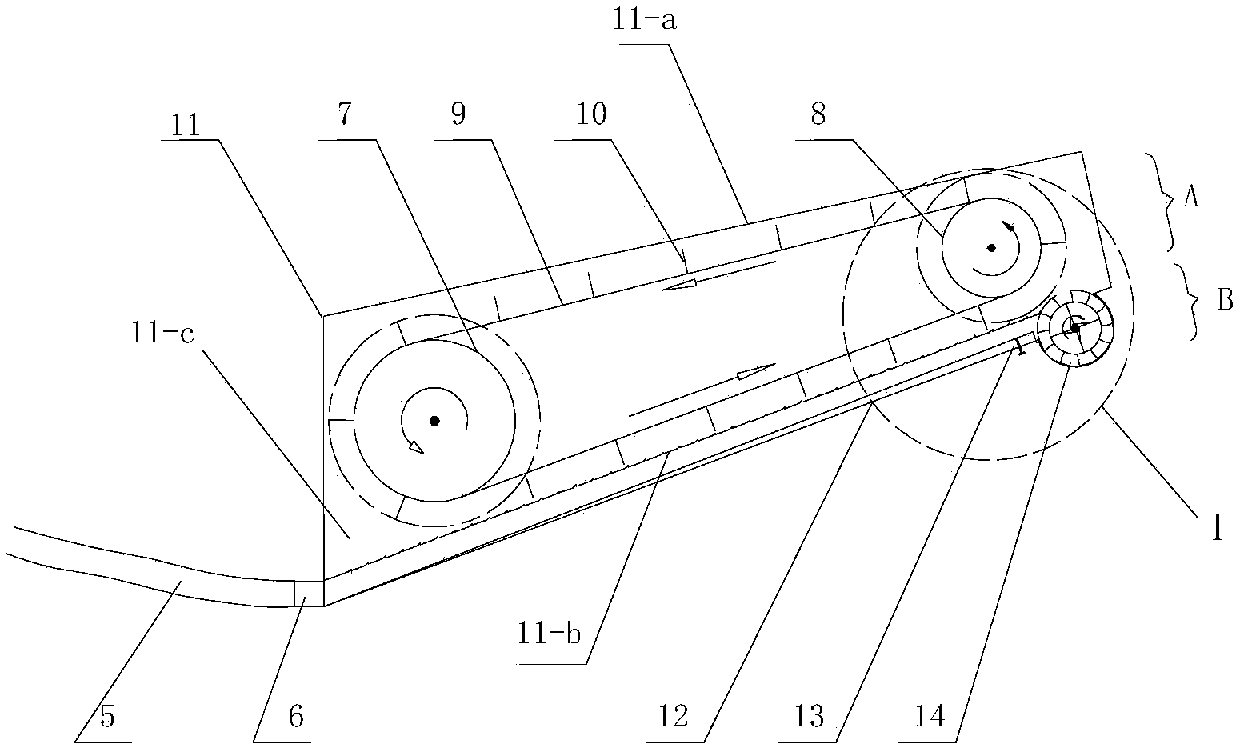

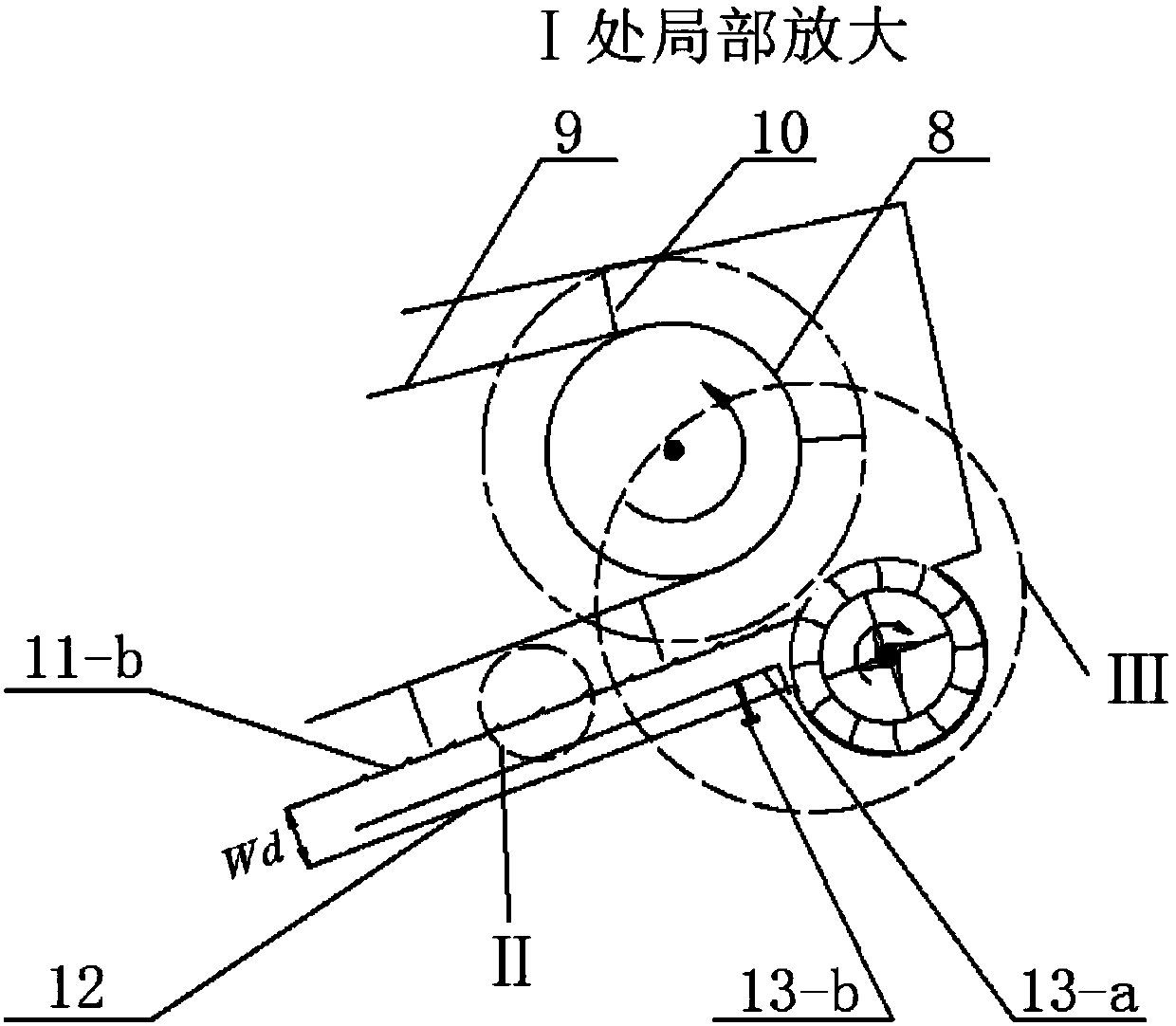

[0036] like figure 1 As shown, the wet material conveying and feeding device of the cross-flow hot air combine harvester described in the present invention is composed of two parts: hot air pumping and material conveying. The hot air pumping part is to use the air pump to extract the waste hot air from the engine radiator of the combine harvester through the pipeline, and quickly transport the waste hot air to the outside, providing fast flow for the whole cross-flow hot air combine harvester wet material conveying and feeding device The hot air flow is made up of an engine radiator 1, an air draft deflector 2, an exhaust duct 3, an air extraction pump 4, an air supply duct 5, and an air supply deflector 6. One end of the air extraction duct 3 is connected to the engine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com