Multilayered structure absorbing core used for nursing pad and manufacturing method thereof

A technology of absorbent core and absorbent products, which is applied in the field of hygiene and nursing products, can solve the problems of hot and humid nursing pads, tearing of nursing pads, and no longer absorbency, etc., and achieve rapid liquid diversion, increased load-bearing performance, and tensile strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

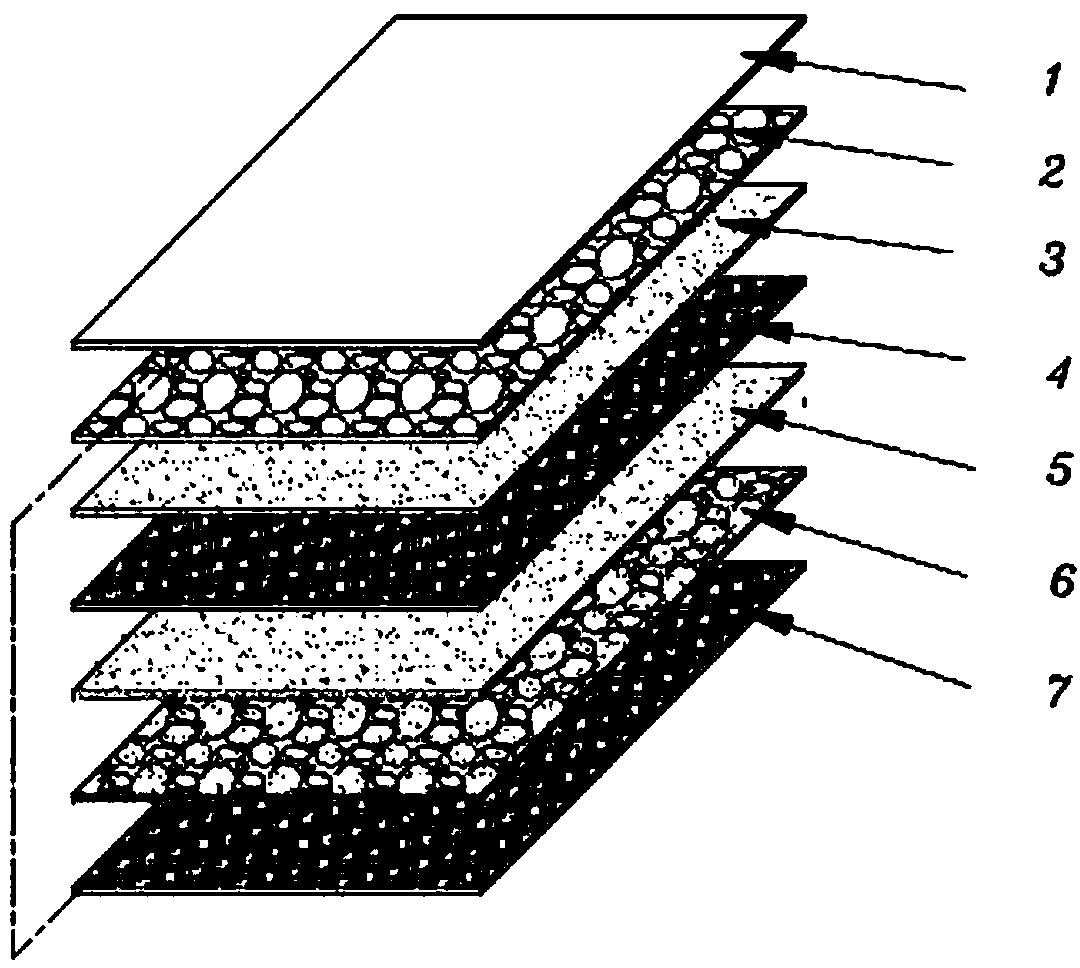

Embodiment 1

[0129] The absorbent core structure of this embodiment is as Figure 9 shown. The weight of the absorbent core is 155±10g / m 2 . Among them, the first layer is the top layer, and the weight is 20g / m 2 High-strength toilet paper; the second layer is the diversion layer, and the content of wood pulp fibers (such as semi-treated fluff pulp) used is 18g / m 2 ; The third layer is the first polymer water-absorbing material layer, and the content of polymer water-absorbing resin (such as BASF 7059) is 16g / m 2 ;The fourth layer is the isolation layer, and the weight is 16g / m 2 The fluffy non-woven fabric; the fifth layer is the second polymer water-absorbing material layer, and the content of polymer water-absorbing resin (such as BASF 7059) is 16g / m 2 ;The sixth layer is the liquid storage layer, the content is 20g / m 2 High-molecular water-absorbing resin (such as Sumitomo 60S) with a content of 35g / m 2 A mixed layer of wood pulp fibers (such as semi-treated fluff pulp); the sev...

Embodiment 2

[0133] The absorbent core structure of this embodiment is as Figure 10 shown. The weight of the absorbent core is 155±10g / m 2 . Among them, the first layer is the top layer, and the weight is 13g / m 2 high-strength toilet paper; the second layer is the diversion layer, and the content of wood pulp fibers (such as semi-treated fluff pulp) used is 20g / m 2 ; The third layer is the first polymer water-absorbing material layer, and the content of polymer water-absorbing resin (such as BASF 7059) used is 18g / m 2 ;The fourth layer is the isolation layer, and the weight is 18g / m 2 non-woven fabric; the fifth layer is the second polymer water-absorbing material layer, and the content of polymer water-absorbing resin (such as BASF 7059) used is 18g / m 2 ;The sixth layer is the liquid storage layer, the content is 20g / m 2 High-molecular water-absorbing resin (such as Sumitomo 60S) with a content of 35g / m 2 A mixed layer of wood pulp fibers (such as semi-treated fluff pulp); the sev...

Embodiment 3

[0138] The absorbent core structure of this embodiment is as Figure 11 shown. The weight of the absorbent core is 155±10g / m 2 . Among them, the first layer is the top layer, and the weight is 13g / m 2 high-strength toilet paper; the second layer is the diversion layer, and the content of wood pulp fibers (such as semi-treated fluff pulp) used is 20g / m 2 ; The third layer is the first polymer water-absorbing material layer, and the content of polymer water-absorbing resin (such as BASF 7059) is 18g / m 2 ;The fourth layer is the isolation layer, and the weight is 18g / m 2 The fluffy non-woven fabric; the fifth layer is the second polymer water-absorbing material layer, and the content of polymer water-absorbing resin (such as BASF 7059) is 18g / m 2 ;The sixth layer of liquid storage layer, the content is 20g / m 2 High-molecular water-absorbing resin (such as Sumitomo 60S) with a content of 35g / m 2 A mixed layer of wood pulp fibers (such as semi-treated fluff pulp); the sevent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

| Total weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com