Fresh-keeping pad containing spunlaced composite fiber layers and preparation method thereof

A composite fiber and fresh-keeping mat technology, applied in the direction of cellulose plastic material layered products, chemical instruments and methods, lamination, etc., can solve the problems of low product strength, complicated production, easy breakage, etc., to improve mechanical properties, strengthen effect, the effect of good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

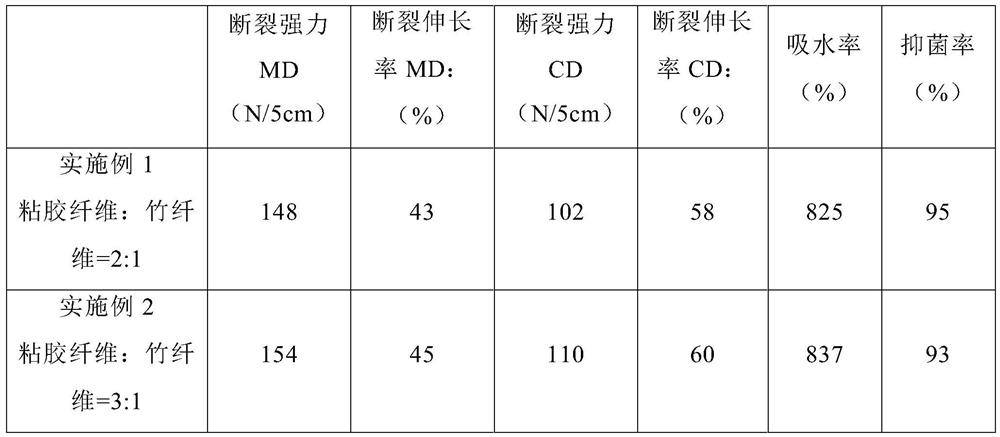

Embodiment 1

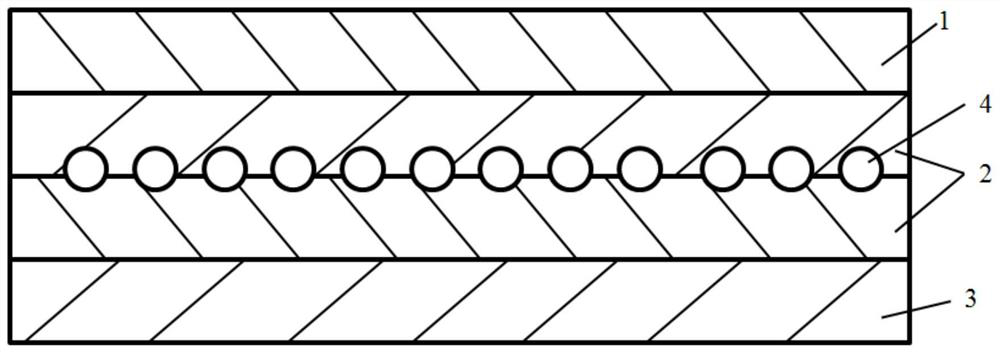

[0049] like figure 1 , the fresh-keeping pad of this embodiment is obtained by pressing spunbonded non-woven fabric 1, two layers of spunlace composite fiber layer 2 and plastic film 3 from top to bottom, and the preparation raw materials of spunlace composite fiber layer include a mass ratio of 2:1 Viscose fiber and bamboo fiber, areal density 250g / m 2 , the spunlace composite fiber layer is prepared by the pearl pattern spunlace process, and the functional material 4 is filled between the two spunlace composite fiber layers, namely water-absorbent resin and chitosan.

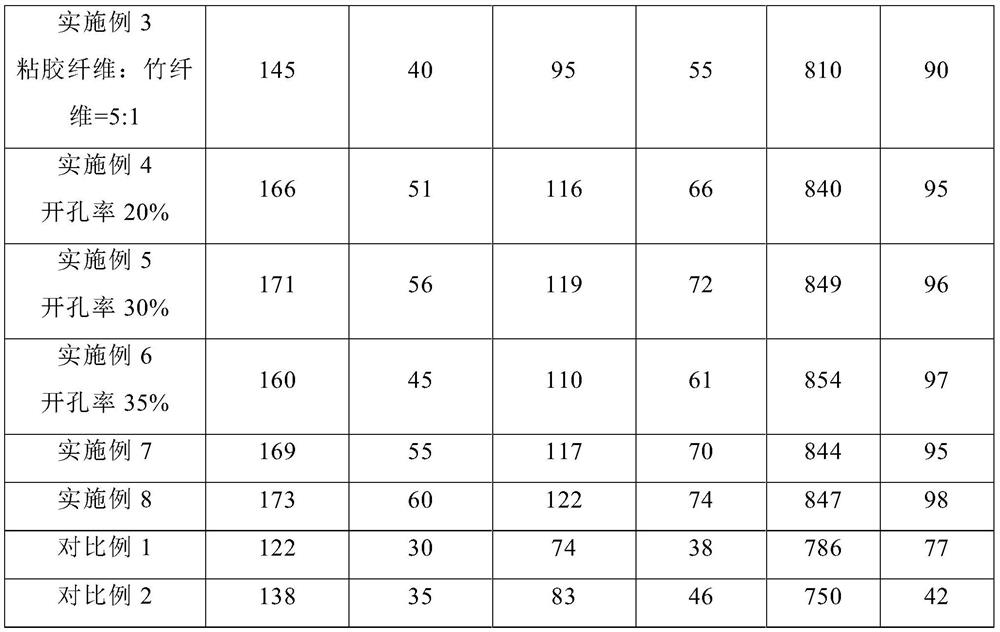

[0050] This embodiment adopts the combination of drum type spunlace technology and pearl texture design. The drum sleeve has a concave circular texture, which forms a pearl texture. The inside of the circular texture is provided with uniform holes. The opening ratio of the drum sleeve is 20%. The diameter of the circular texture is 5 mm, the depth of the depression is 0.5 mm, the distance between adjacent ci...

Embodiment 2

[0059] In the fresh-keeping pad of this example, the raw materials for the preparation of the spunlace composite fiber layer include viscose fiber and bamboo fiber with a mass ratio of 3:1, and other structures and preparation methods are the same as in Example 1.

Embodiment 3

[0061] In the fresh-keeping pad of this example, the raw materials for the preparation of the spunlace composite fiber layer include viscose fiber and bamboo fiber with a mass ratio of 5:1, and other structures and preparation methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com