Porous composite pole piece and preparation method and application thereof in all-solid-state lithium battery

A pole piece and porous structure technology, applied in the field of all-solid-state lithium batteries and their preparation, can solve the problems of reducing the energy density of the battery, increasing the interface impedance, affecting the electrochemical performance of the battery, etc., so as to reduce the interface impedance, increase the uniformity, avoid the The effect of energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

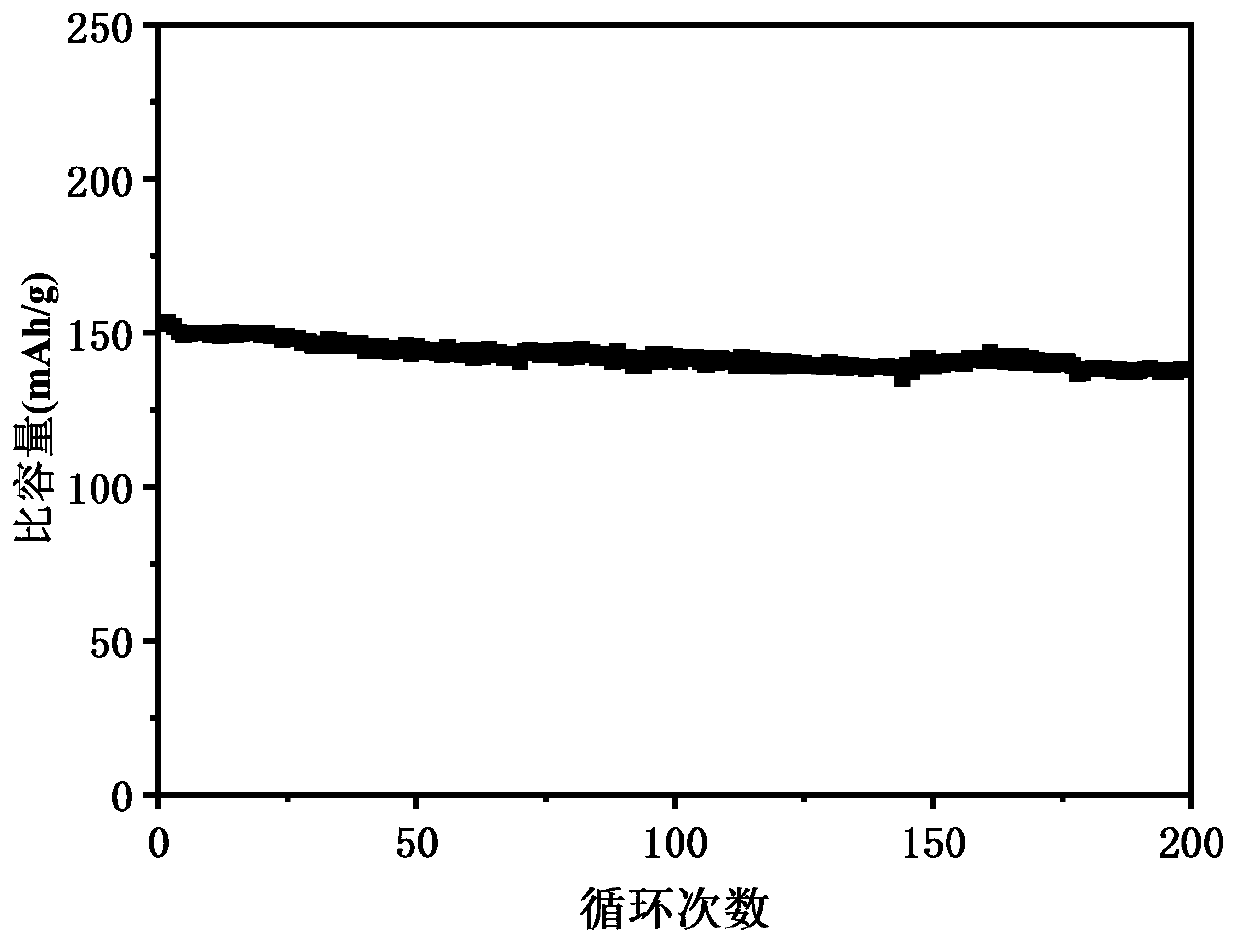

Embodiment 1

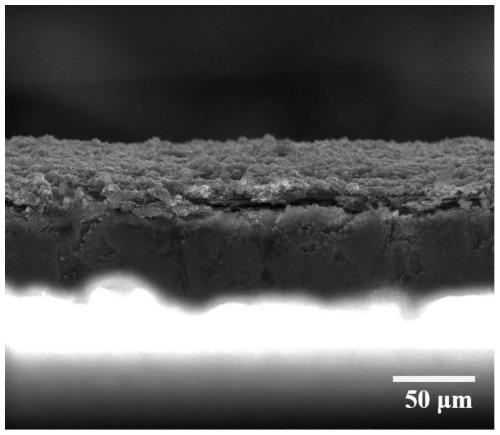

[0092] LiMn 2 O 4 , PVDF, acetylene black, NMP solvent, mixed according to 8:1:1, the solid content is 24%, and 1.5% (with LiMn 2 O 4 , PVDF, acetylene black total weight based on 300nm elemental sulfur powder (standard deviation of particle size σ = 5nm). Mix uniformly into slurry. Coat the slurry on the aluminum foil, control the coating thickness to 60μm, and dry it at 110°C for 3h; after drying, roll the pole piece, and then dry it at 180°C for 60 minutes. The positive electrode material layer with porous structure is compounded on the surface of the current collector, and its porosity is 34%.

[0093] The epoxy acrylate resin, triarylsulfonium hexafluoroantimonate and propylene oxide butyl ether are formulated into a curing agent in a ratio of 90:20:5. The curing agent, electrolyte (1MLiPF 6 Mix 1:1EC and DEC) according to the mass ratio of 1:4, and then immerse the dried pole piece in it. After the pole piece is completely soaked, the pole piece is taken out and placed under...

Embodiment 2

[0096] LiFePO 4 , PVDF, acetylene black, and NMP solvent are mixed according to 9:0.5:1, and the solid content is 30%. Add 1% of 800nm elemental sulfur powder (standard deviation of particle size σ=5nm) to it, and mix it evenly into a slurry. The slurry was coated on the aluminum foil, the coating thickness was controlled to 80μm, and it was dried at 80°C for 10h; after drying, the pole piece was rolled and then placed at 200°C for 30 minutes to dry. A positive electrode material layer with a porous structure is compounded on the surface of the current collector with a porosity of 30%.

[0097] The polyester acrylate resin, triarylsulfonium hexafluoroantimonate and propylene oxide butyl ether are formulated into a curing agent in a ratio of 95:15:5. The curing agent and electrolyte (0.7MLiPF 6 Mix 1:1EC and DEC) according to the mass ratio of 1:3, soak the dried pole piece in it, take out the pole piece and place it under a UV lamp for 14s after being completely soaked.

[0098] ...

Embodiment 3

[0100] LiFePO 4 , PVDF, acetylene black, and NMP solvent are mixed according to 8:1:1, and the solid content is 28%. Add 1.8% of 50nm elemental sulfur powder (standard deviation of particle size σ=5nm) to it, mix evenly into slurry, The slurry was coated on the aluminum foil, the coating thickness was controlled to be 75μm, and it was dried at 100°C for 6h; after drying, the pole piece was rolled and then dried at 160°C for 120 minutes. A positive electrode material layer with a porous structure is compounded on the surface of the current collector, and its porosity is 31%.

[0101] The epoxy acrylate resin, triarylsulfonium hexafluoroantimonate and propylene oxide butyl ether are formulated into a curing agent in a ratio of 100:22:5. The curing agent and electrolyte (1MLiTFSI dissolved in EC) are prepared according to the quality Mix at a ratio of 1:4.5, soak the dried pole piece in it, take out the pole piece after complete soaking, and place it under a UV lamp for curing for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com