Thermo-oxidative ageing resistance black filling polypropylene composite material and preparation method thereof

A technology of composite material and polypropylene, which is applied in the field of anti-thermal oxygen aging black filled PP composite material and its preparation, can solve the problems of reducing the effective antioxidant and reducing the heat-resistant aging life of the material, so as to increase the solubility and improve the heat resistance. Effects of Oxygen Aging and Heat Aging Resistance Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

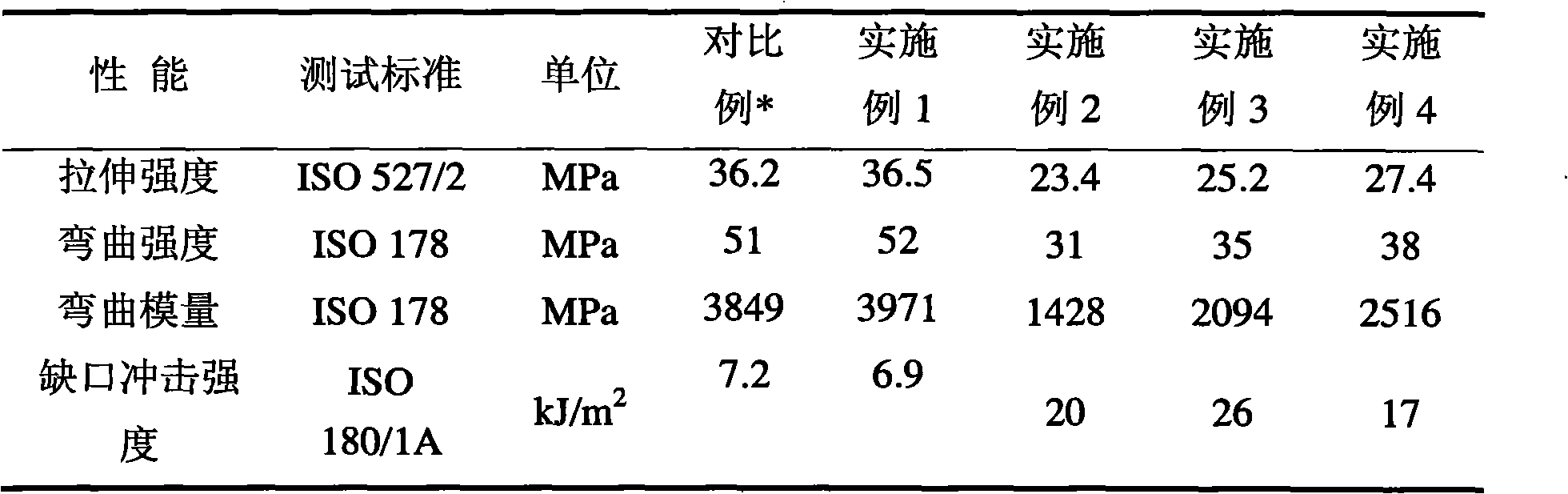

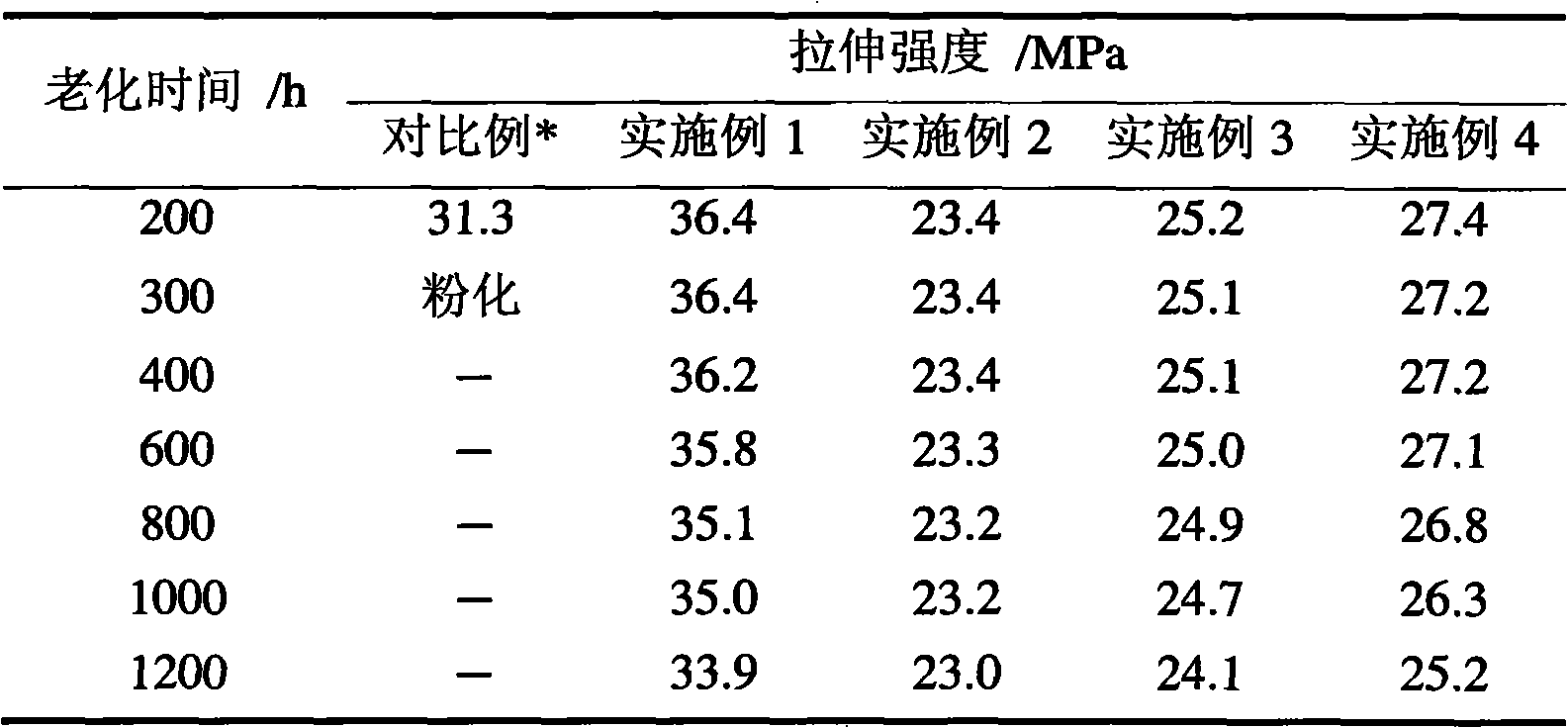

Examples

Embodiment 1

[0031] A thermal-oxidative aging-resistant black filled PP composite material, which is composed of the following raw materials in weight percent: polypropylene (brand: M1200HS) 50%; talcum powder 40%; ethylene-hexene copolymer 5%; acid absorber 1.5% %; compound antioxidant 1.5%; processing aid 0.6%; carbon black 0.6%; white mineral oil 0.8%.

[0032] The acid absorbing agent is DHT-4A hydrotalcite. The composite antioxidant is preferably A+B type, wherein A is 1,3,5-tris(3,5-di-tert-butyl-4-hydroxybenzyl)-s-triazine-2,4,6 -(1H,3H,5H)triketone 1.0%, B is tris(2,4-di-tert-butylphenyl)phenylphosphite 0.3% and bis(2.4-di-tert-butylphenyl)pentaerythritol diphosphite Esters 0.2% composition. The processing aid is composed of 0.3% of ethylene bisstearamide and 0.3% of A-C540A (Shenzhen Qinling Import and Export Trade Co., Ltd.). Described carbon black is 50L (German Degussa Company).

[0033] The specific steps of the preparation method are as follows: firstly add polypropylene,...

Embodiment 2

[0036] A thermal-oxidative aging-resistant black filled PP composite material is composed of the following raw materials in weight percent: polypropylene (brand: M800HS) 75%; calcium carbonate 10%; ethylene-octene copolymer 12%; acid absorber 0.5% %; compound antioxidant 1.2%; processing aid 0.5%; carbon black 0.6%; white mineral oil 0.2%.

[0037] The acid absorbing agent is zinc oxide. Described composite antioxidant is preferably A+B type, wherein, A is 0.8% of tetrafunctional glycidylamine epoxy resin, and B is two (2.4-di-tert-butylphenyl) pentaerythritol diphosphite 0.2% and Di(octadecyl)thiodipropionate 0.2% composition. The processing aid is composed of 0.3% of ethylene bis stearamide and 0.2% of polyethylene wax. Described carbon black is M717 (U.S. Cabot Company).

[0038] The steps of the preparation method are as follows: firstly add polypropylene, elastomer, white mineral oil, acid absorbing agent, composite antioxidant, processing aid and carbon black into a h...

Embodiment 3

[0041]A thermal and oxidative aging-resistant black filled PP composite material, which is composed of the following raw materials in weight percentage: polypropylene (grade: HJ4045) 65%; filler 16%; ethylene-propylene-octene terpolymer 15%; Acid absorbent 1.0%; composite antioxidant 1.4%; processing aid 0.6%; carbon black 0.6%; white mineral oil 0.4%.

[0042] The filler is 10% calcium carbonate and 6% barium sulfate.

[0043] The acid absorbing agent is hydrocalumite. The composite antioxidant is preferably A+B type, wherein A is 1.0% of tetrafunctional glycidylamine epoxy resin, B is 0.2% of di(octadecyl)thiodipropionate and bis(2.4-di 0.2% composition of tert-butylphenyl) pentaerythritol diphosphite. The processing aid consists of 0.3% ethylene bis stearamide and 0.3% stearic acid. Described carbon black is N472 (Jin Qiushi (Tianjin) Chemical Co., Ltd.).

[0044] The steps of the preparation method are as follows: firstly add polypropylene, elastomer, white mineral oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com