A lead-free piezoelectric ceramic, atomizing sheet and preparation method

A lead-free piezoelectric and atomizing sheet technology, applied in spraying devices, liquid spraying devices, etc., can solve problems such as poor market application, hidden dangers to human health, ecological environment pollution, etc., to ensure product consistency and improve Yield rate, effect of avoiding hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

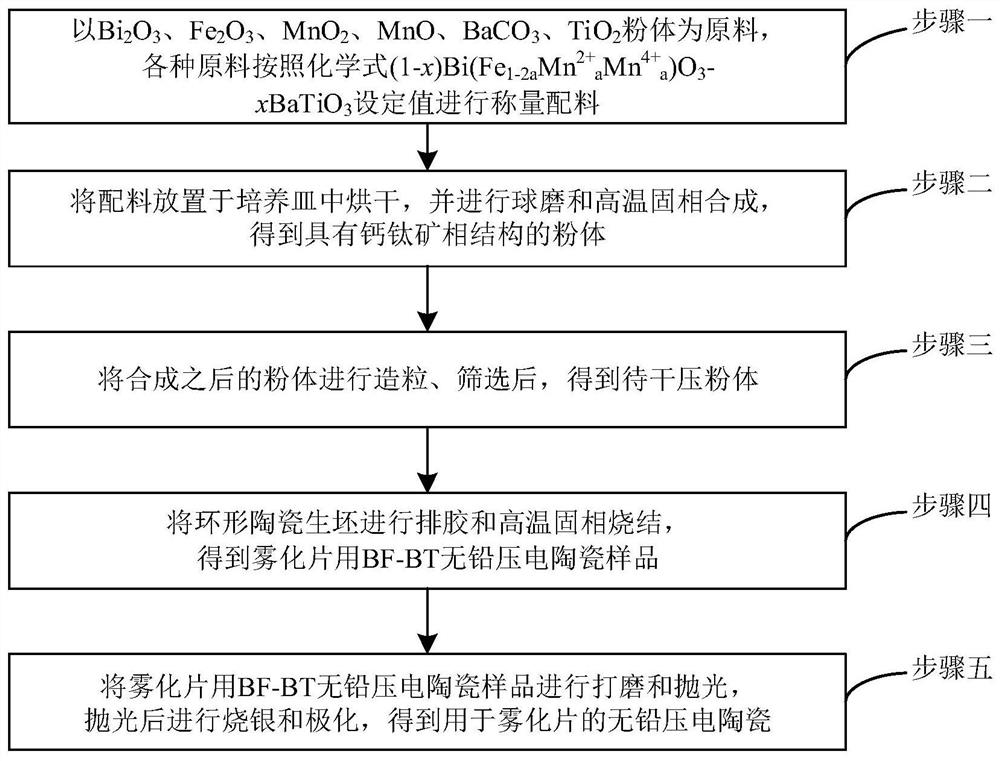

Method used

Image

Examples

Embodiment 3

[0056] In embodiment three, specific chemical formula can be:

[0057] 0.73Bi(Fe 0.996 mn 2+ 0.002 mn 4+ 0.002 )O 3 -0.27BaTiO 3 +0.0001La 2 o 3 +0.0002Li 2 CO 3 +0.0002ZnO+0.0001Nb 2 o 5

Embodiment 4

[0058] In embodiment four, concrete chemical formula can be:

[0059] 0.75Bi(Fe 0.99 mn 2+ 0.005 mn 4+ 0.005 )O 3 -0.25BaTiO 3 +0.0001La 2 o 3 +0.0002Li 2 CO 3 +0.0002ZnO+0.0001Nb 2 o 5

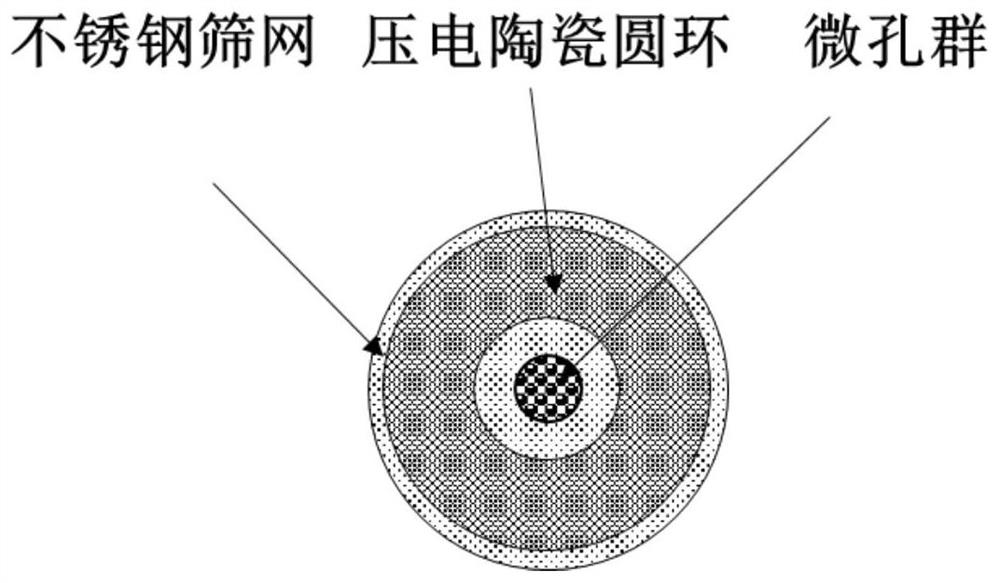

[0060] The lead-free piezoelectric ceramics used in the atomization sheet provided by the present invention can significantly improve the trigonal distortion of the material, reduce the symmetry of the material, and improve the intrinsic contribution of the piezoelectric performance by substituting trace amounts of Mn ions for Fe ions. The lead-free piezoelectric ceramics have good anti-aging characteristics, and there is no problem of hydrolysis, and can work well in water-based solutions, which has obvious advantages over atomizers made of KNN ceramics. Moreover, the lead-free piezoelectric ceramic of the present invention has the characteristics of wide phase boundary and stable performance, which is beneficial to ensure product consistency in large-scale production, improve y...

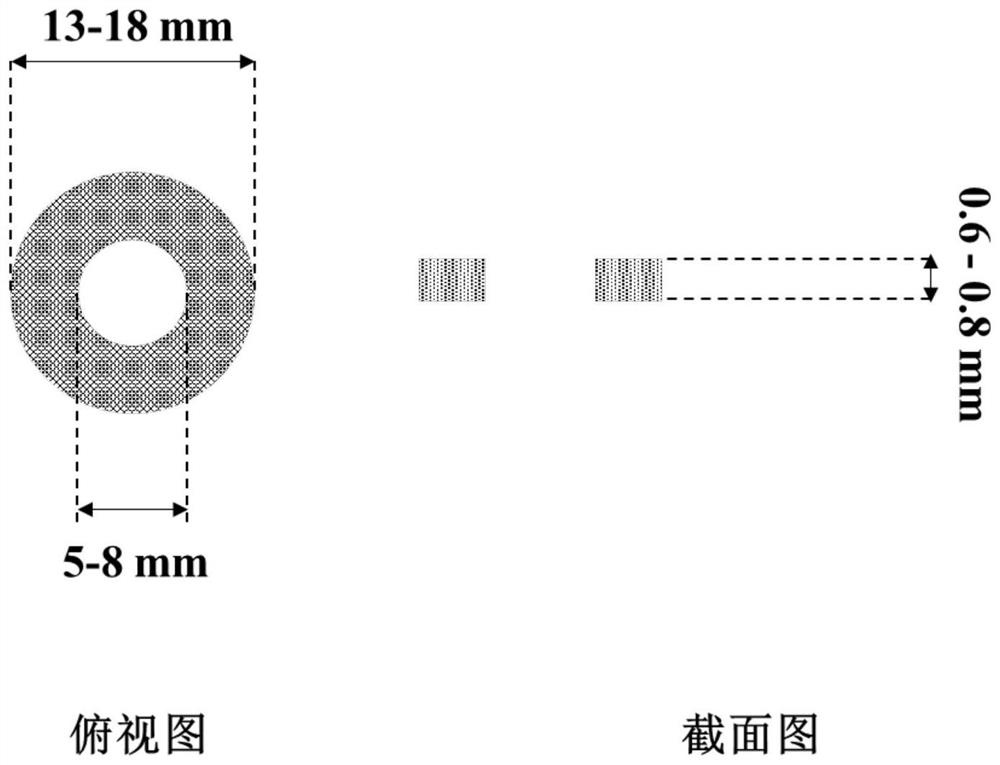

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com