Assembly type multi-high-rise steel specially-shaped column frame and prestress eccentric supporting system

An eccentric support, steel special-shaped column technology, applied in the direction of construction, building structure, etc., can solve the problems of brittle failure of rigid beam-column joints, and achieve the effect of reducing construction waste, avoiding environmental pollution, and efficient recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention is described in detail below in conjunction with accompanying drawing:

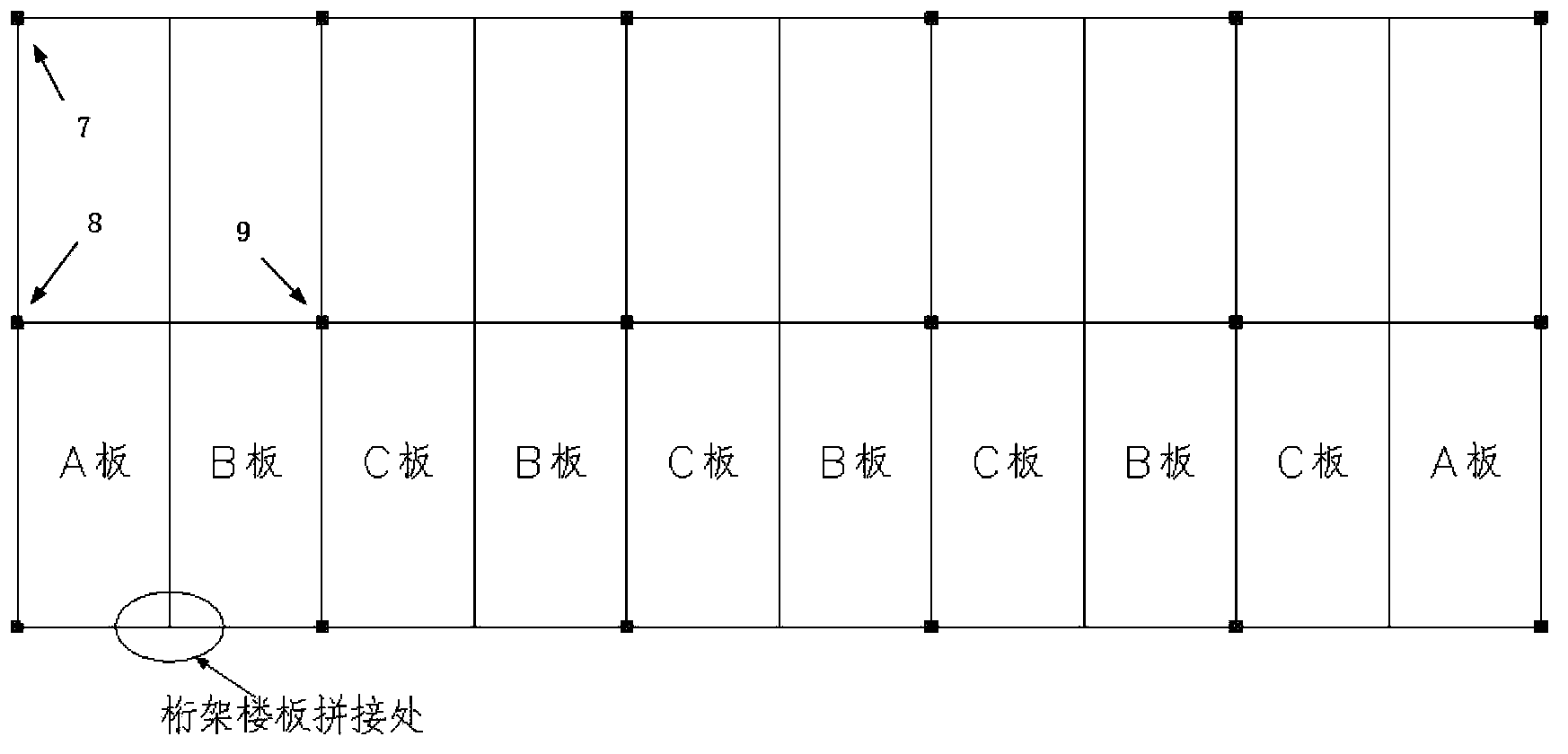

[0070] as attached figure 1As shown, the splicing position of the assembled truss plate of the present invention is set in the middle of the main girder, where the shear force and bending moment are relatively small. From the perspective of structural mechanics, the setting of the splicing position is reasonable.

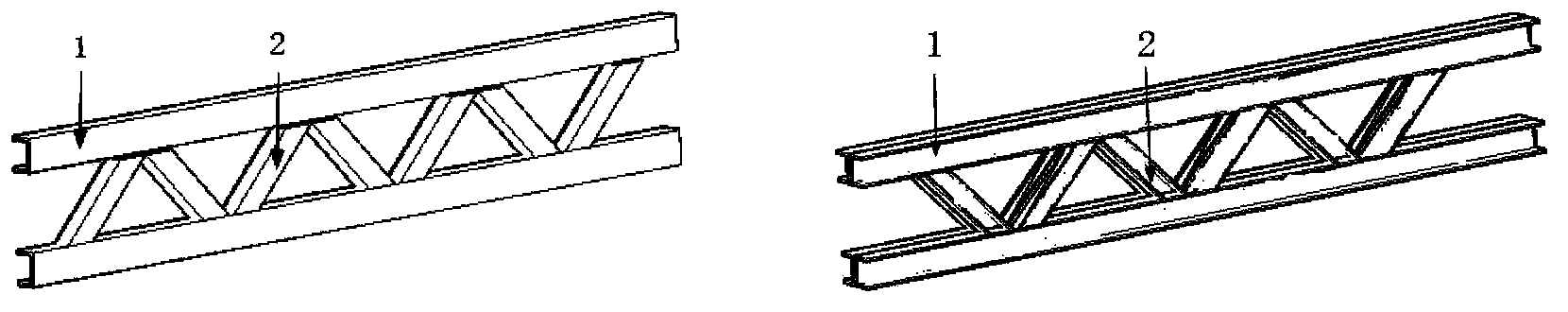

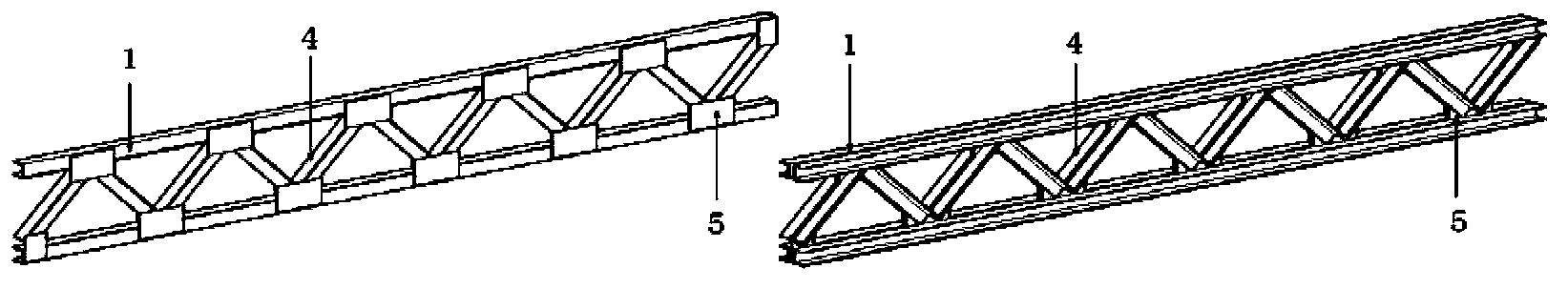

[0071] as attached figure 2 As shown, in the assembled multi-story steel special-shaped column frame-eccentric support system described in the present invention, the beam involved is a truss beam composed of channel steel splicing, including upper and lower chords I1 and webs 2, wherein the upper and lower chords Both I1 and web 2 are made of channel steel, and are divided into single-channel steel beam and double-channel steel beam. The channel steel beam is provided with connecting holes at a fixed distance, so that two single-channel steel beams can be bolted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com