Method for micro-treatment of cement concrete road surface

A technology of cement concrete and concrete pavement, which is applied in the direction of roads, roads, road repairs, etc., to achieve the effects of convenient construction, improved road operation efficiency, and reduced road maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

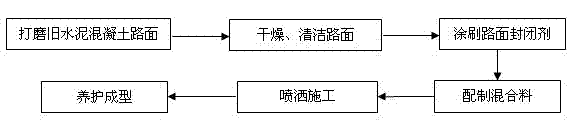

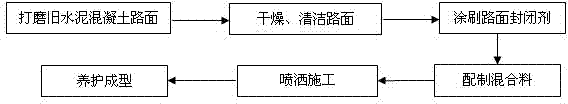

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the present invention will be further described below in conjunction with examples.

[0025] The embosser (Shenli Construction Machinery Factory, Changge City, Henan Province), milling machine (such as German Hunter road milling machine, Wirtgen milling machine), groove cutting machine (Jingjiang Dongfang Highway Engineering Machinery) involved in the present invention Manufacturing companies) are available in the market;

[0026] Hair dryers (Jining Roadway Machinery Manufacturing Co., Ltd.) or vacuum cleaners (Zhengzhou Baifang Environmental Protection Technology Co., Ltd.) that can supply hot air are available in the market;

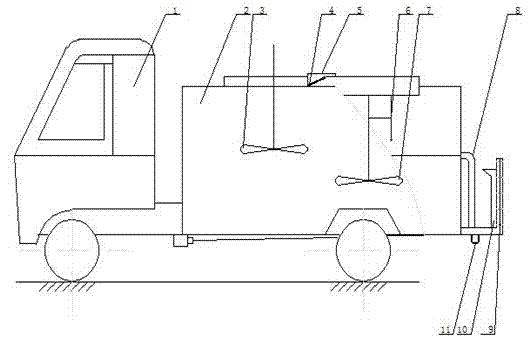

[0027] The asphalt spreader can be purchased on the market (Hangzhou Meitong Special Machinery Manufacturing Co., Ltd.), or it can be modified on this basis, and an agitator (Yancheng Huai Yu Heating Equipment Co., Ltd.), and equipped with a Honda generator, the nozzle is 9520 or 9530 nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com