Patents

Literature

40results about How to "Increased mechanical load capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

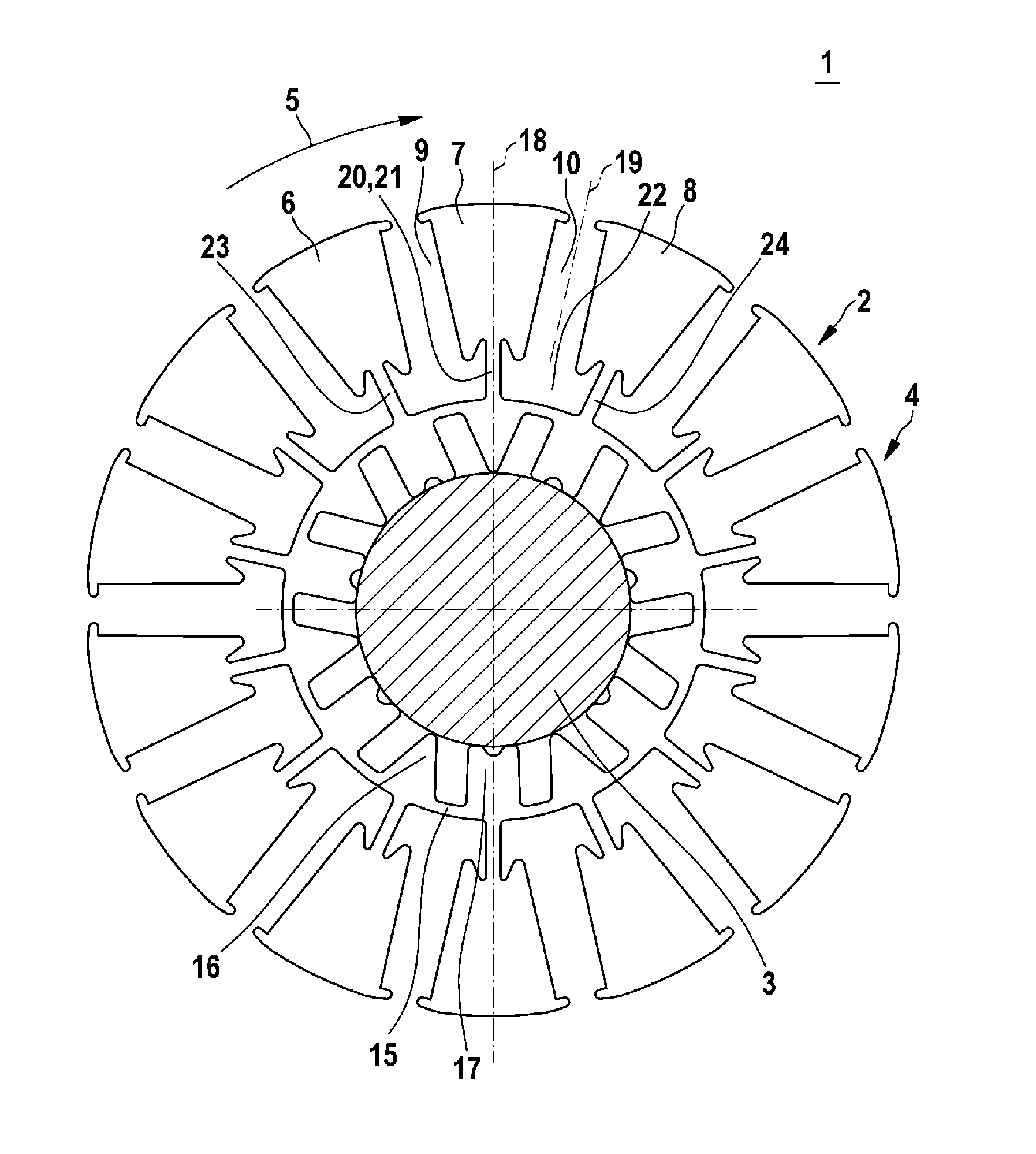

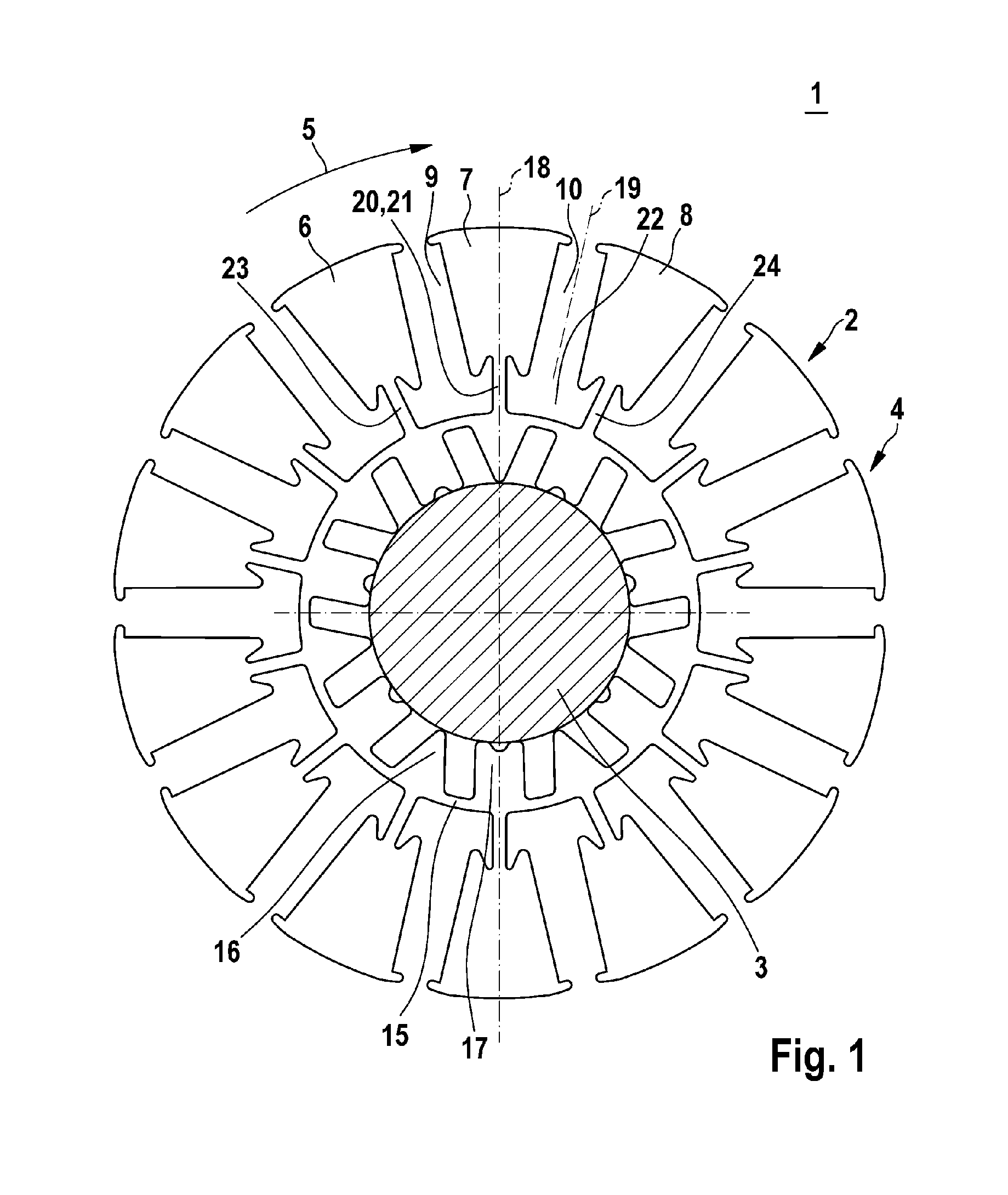

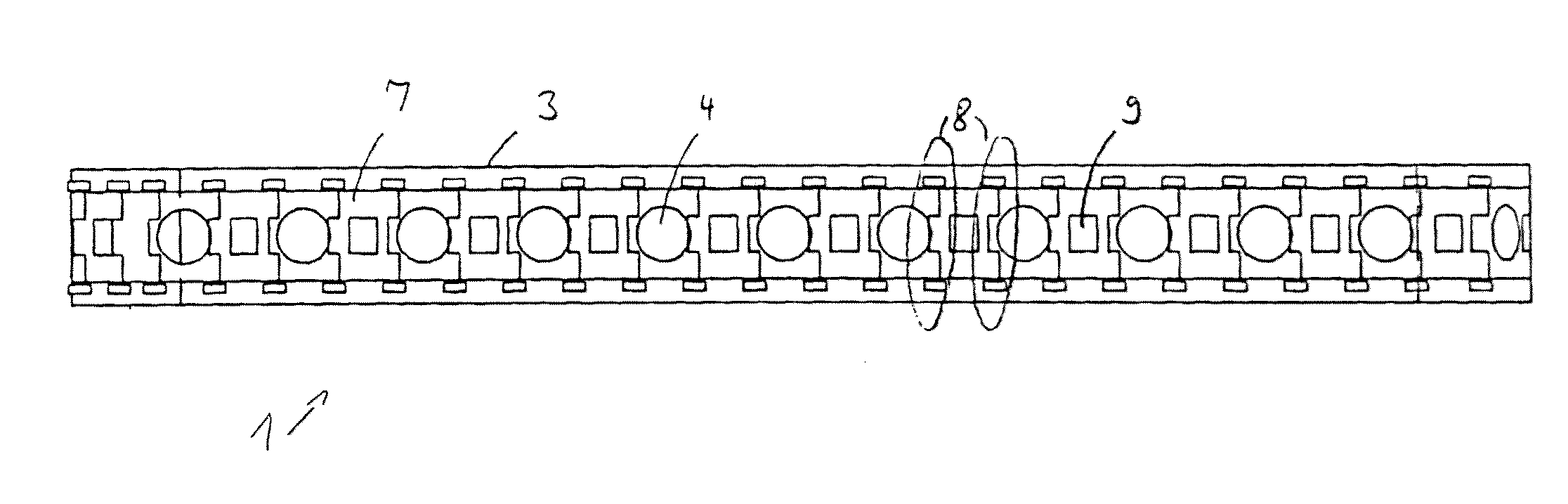

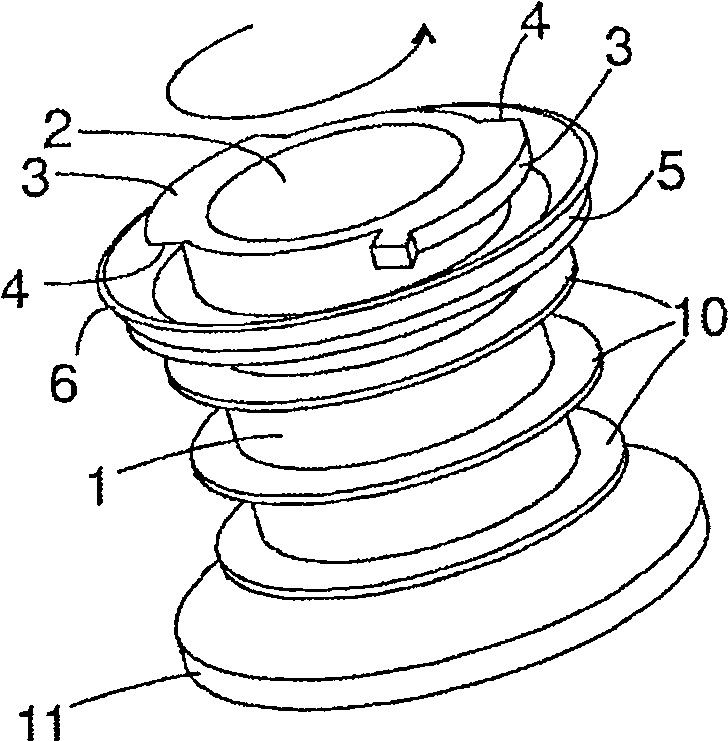

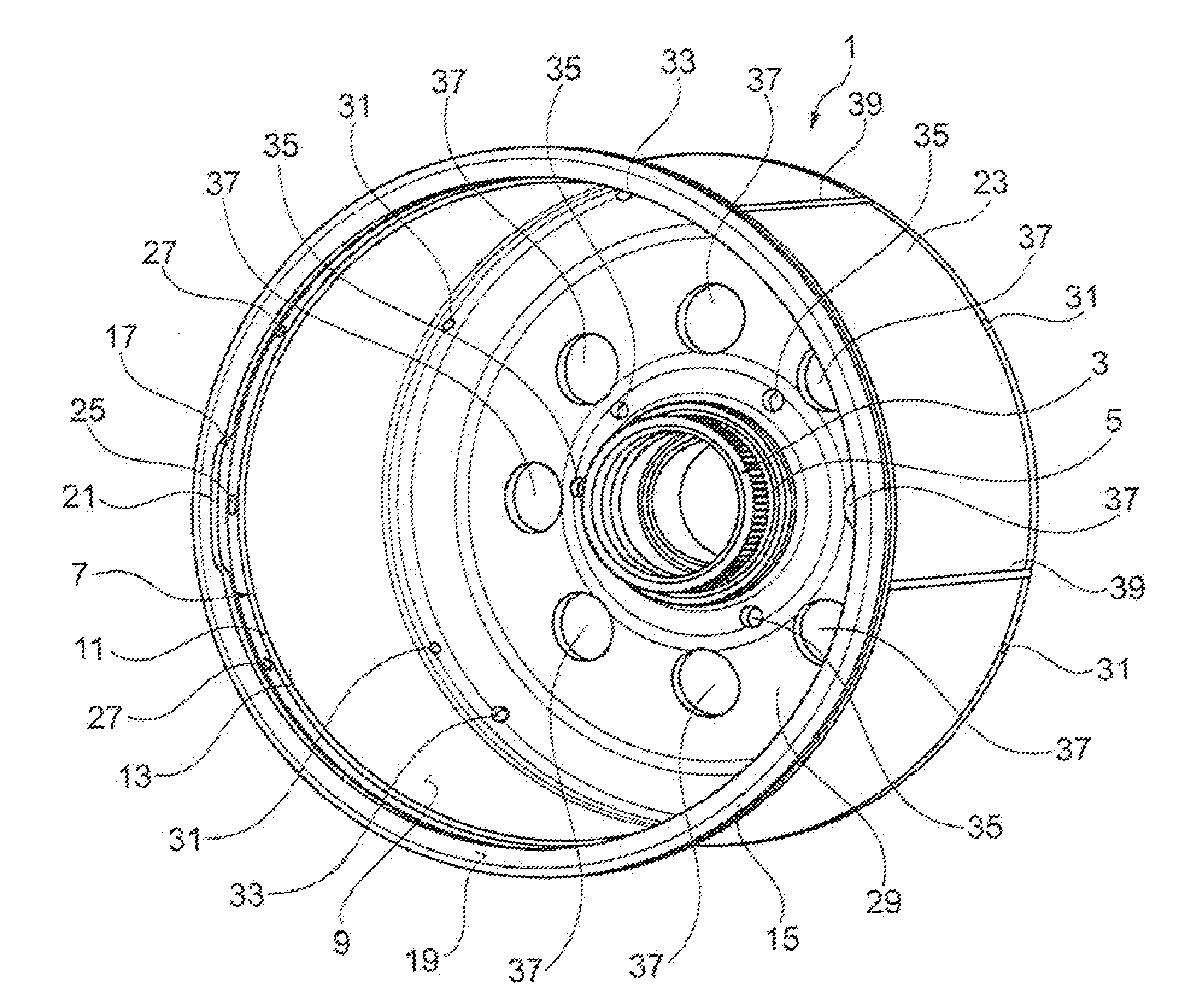

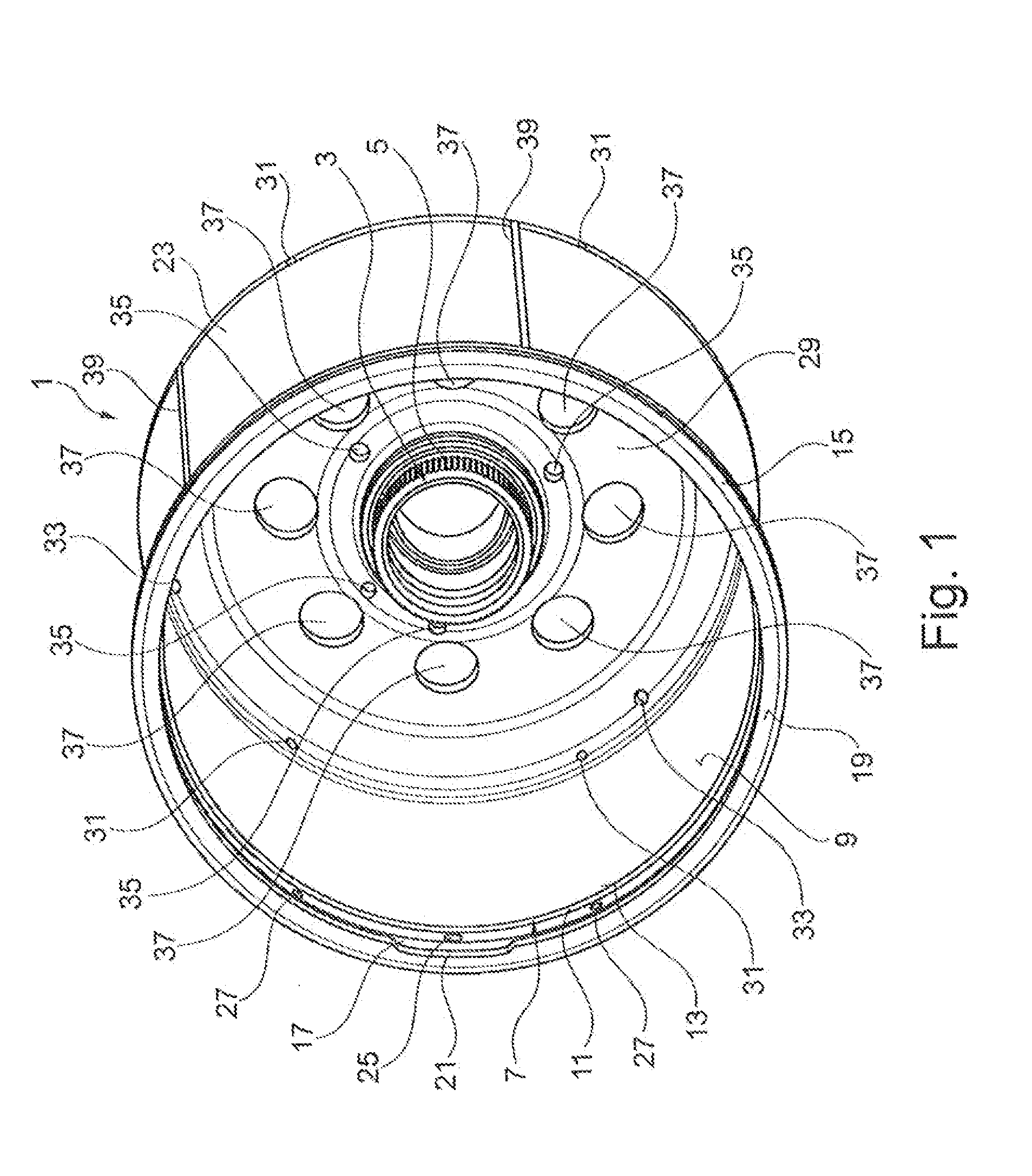

Electric machine

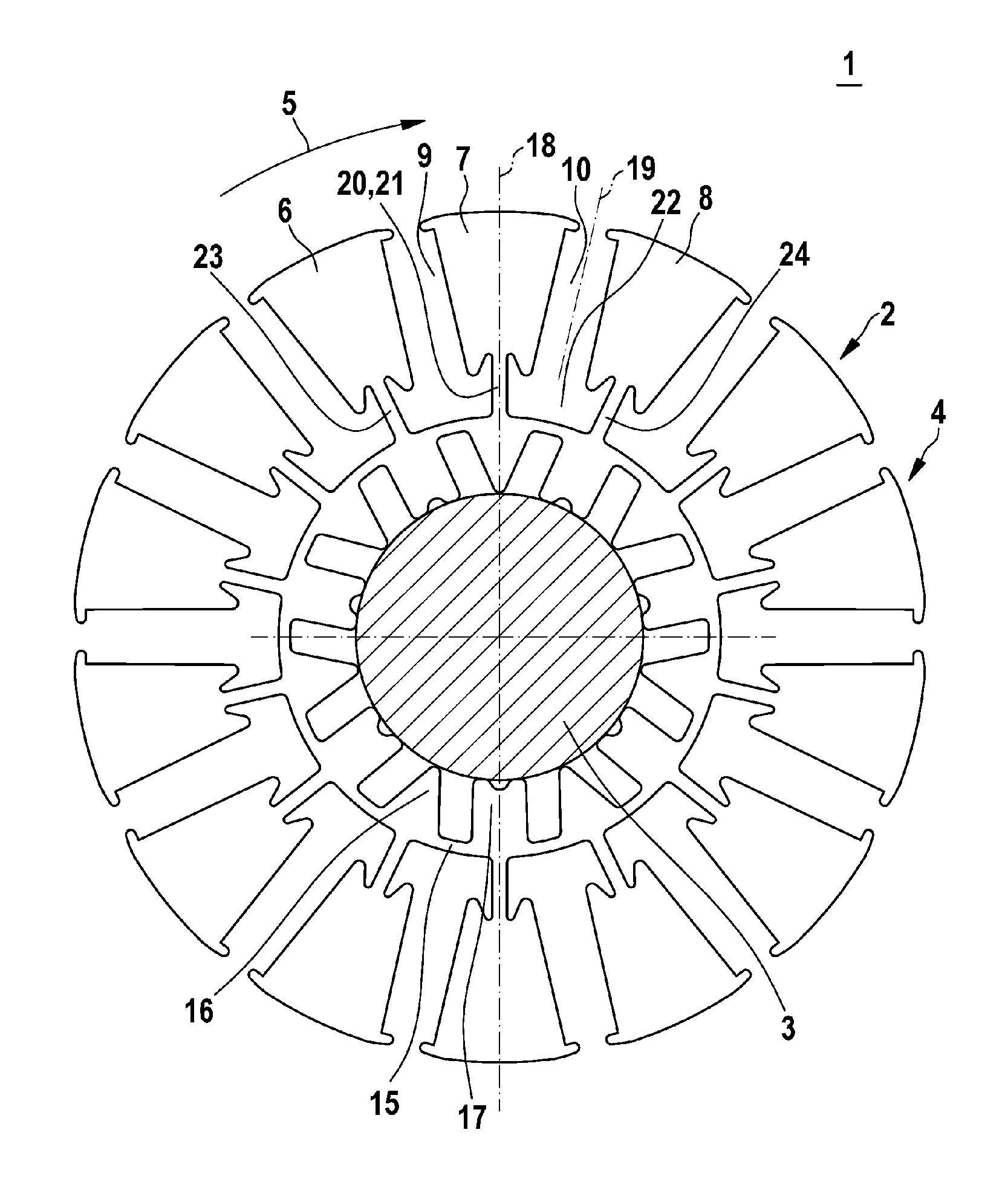

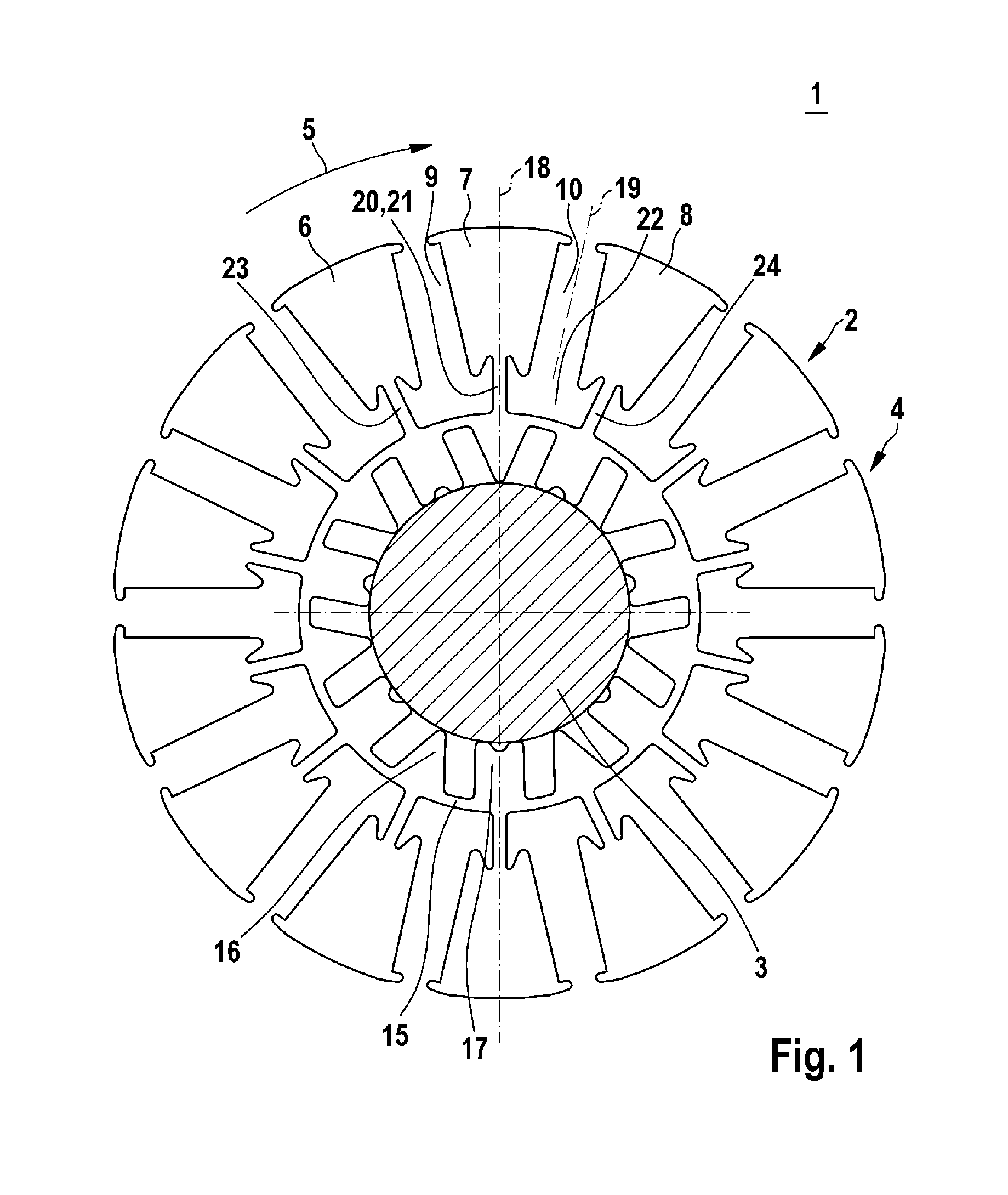

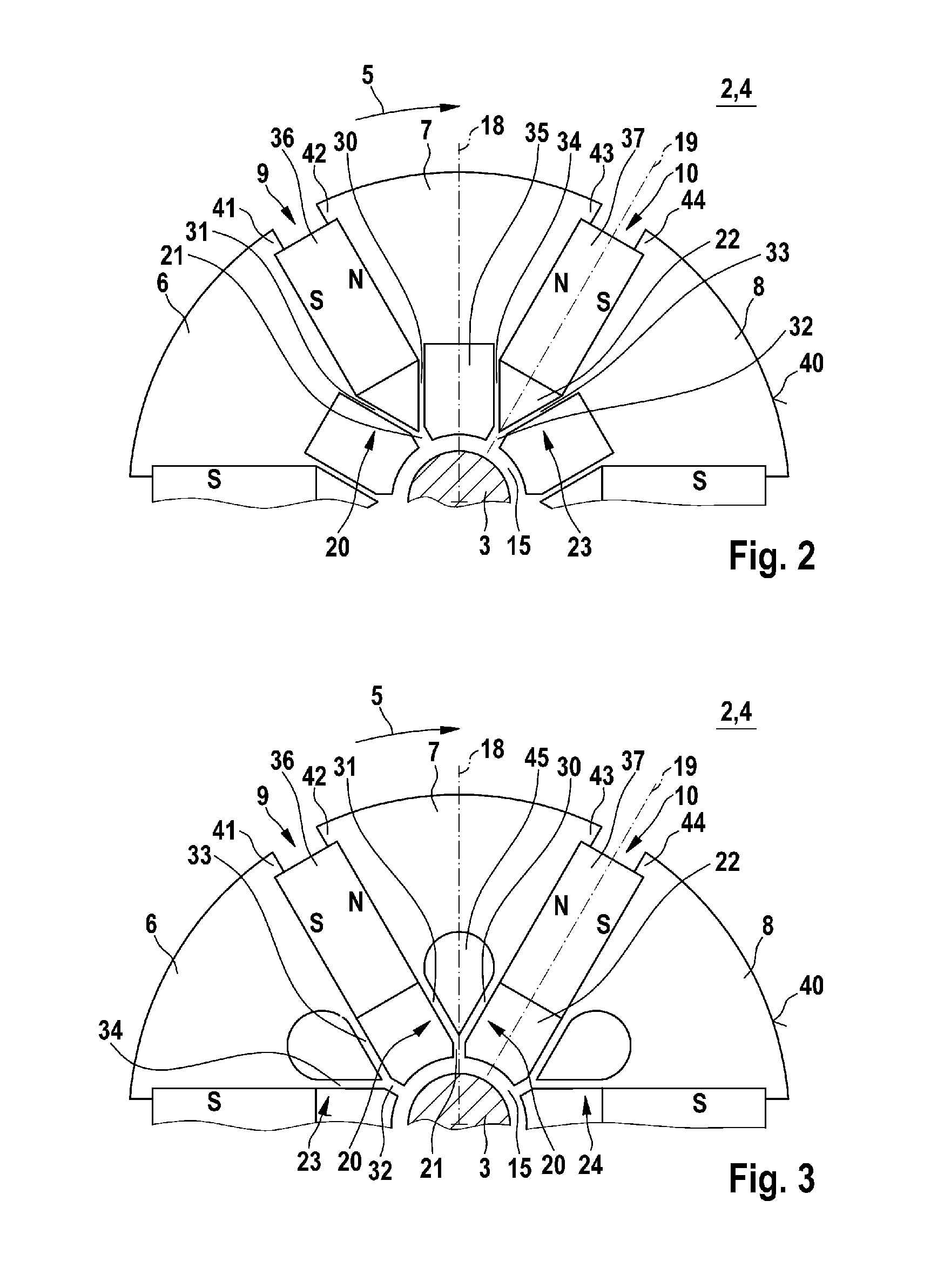

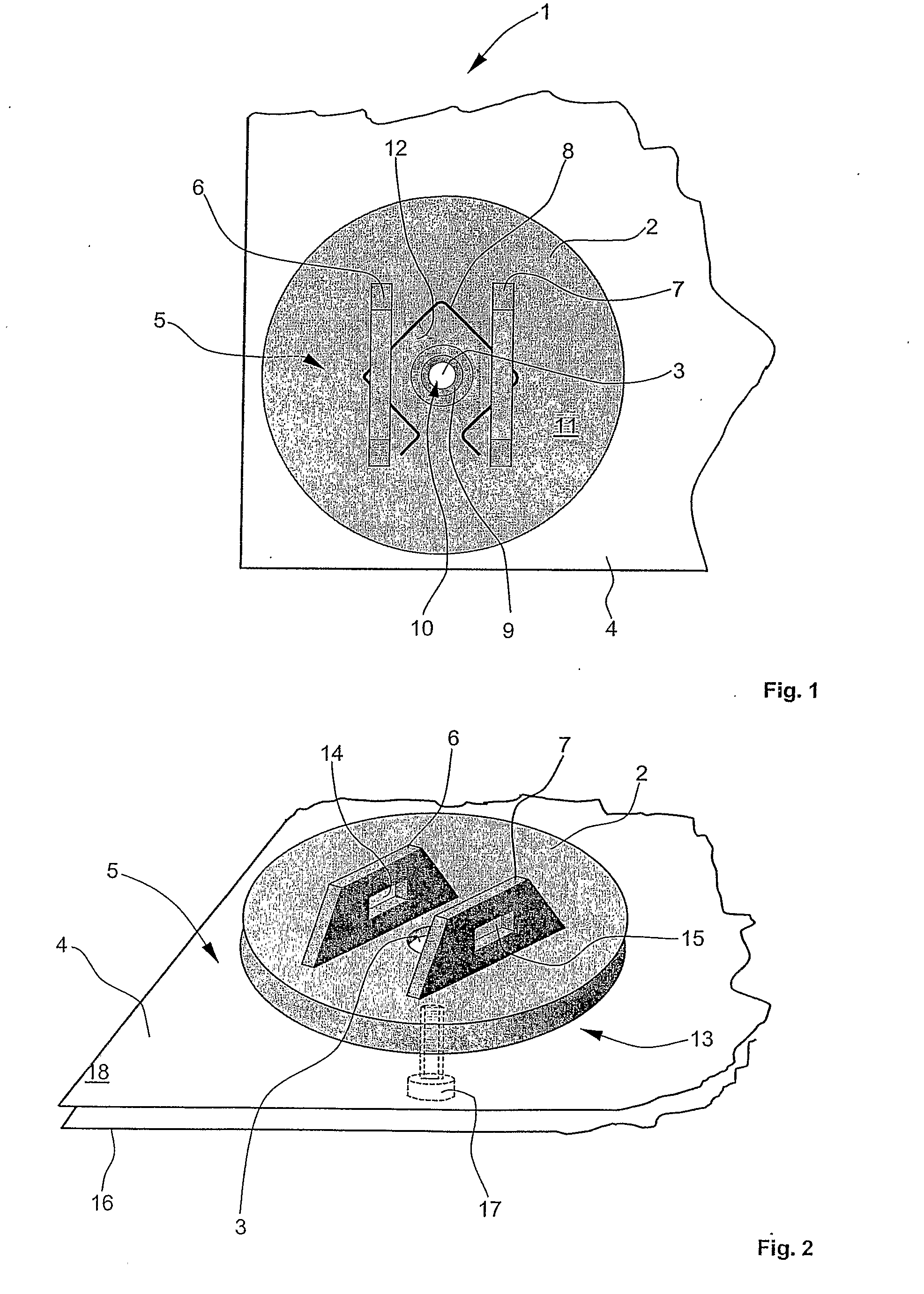

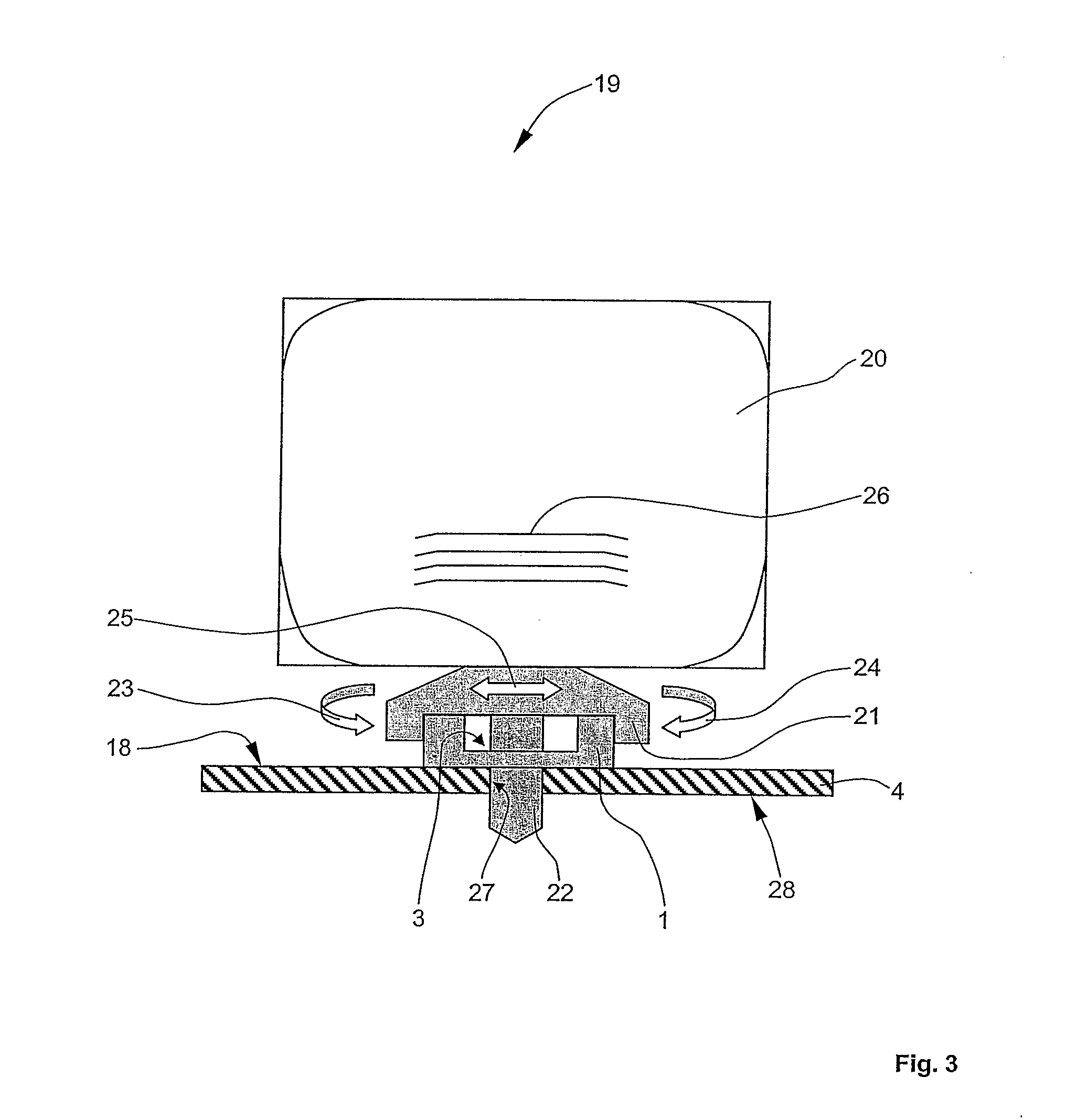

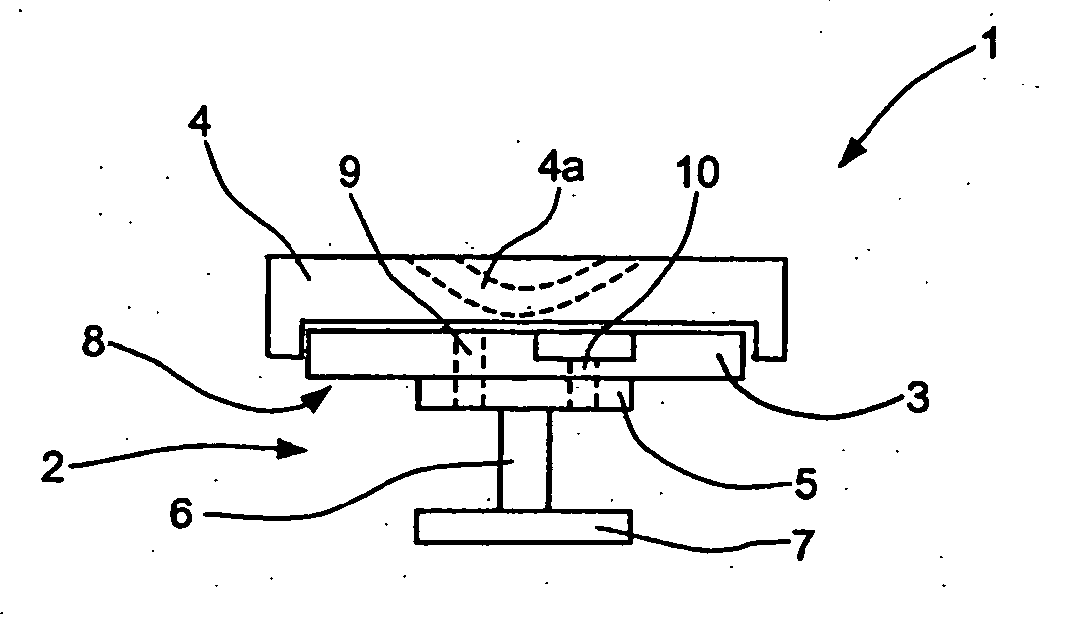

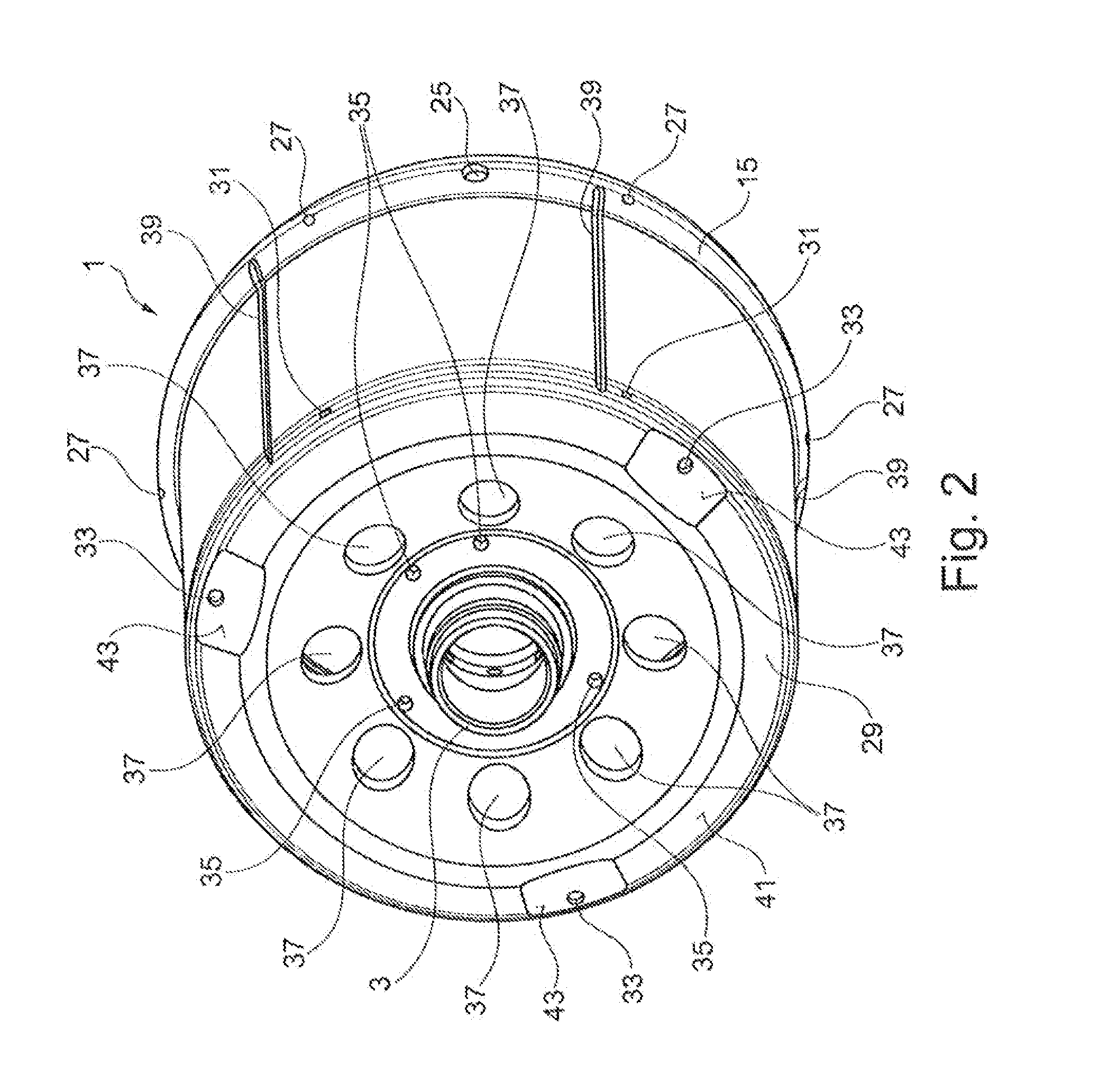

InactiveUS20120112591A1Minimizing flux lossMagnetic flux losses for a predetermined mechanical load capacity can be reducedMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic currentElectric machine

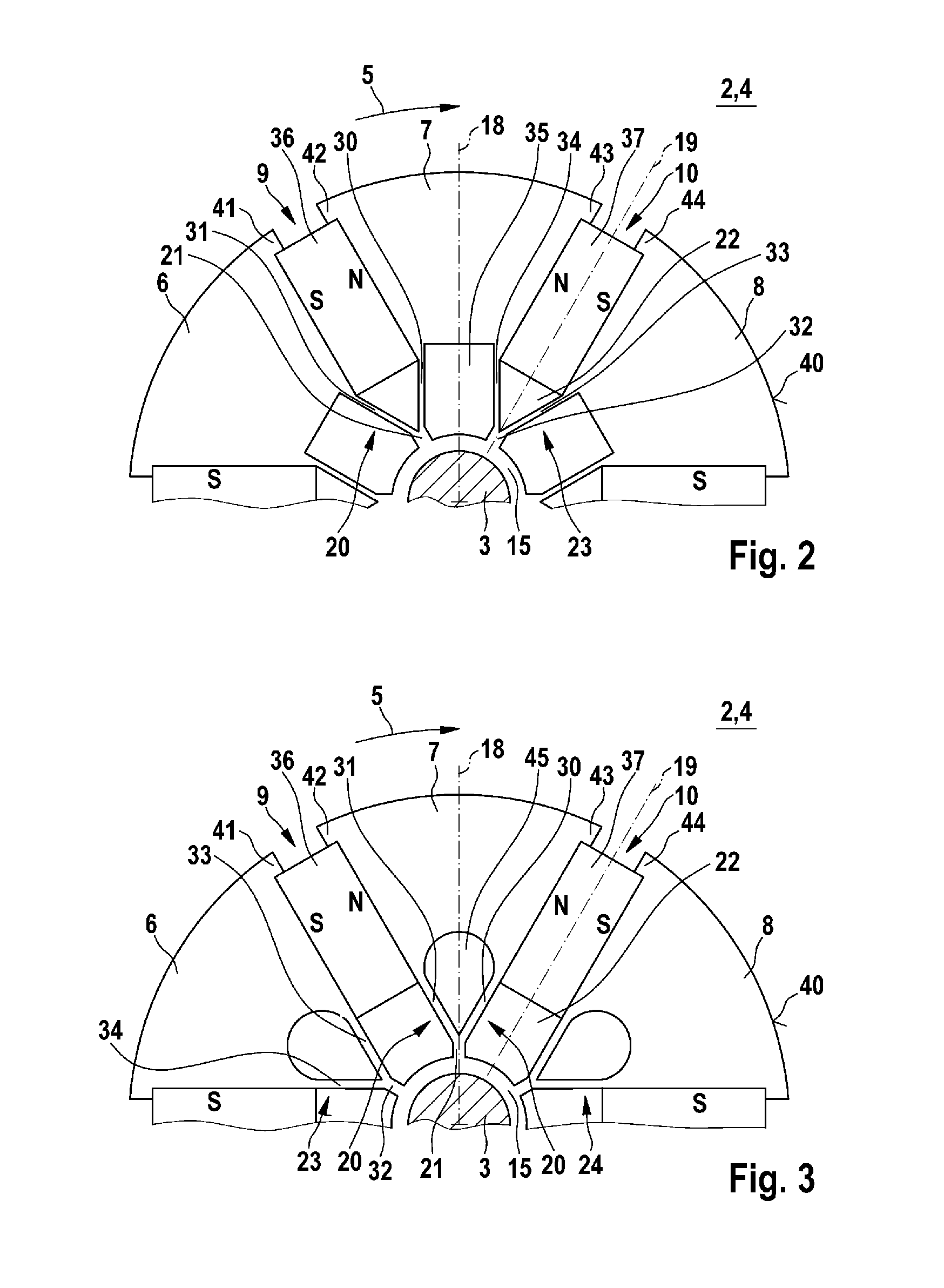

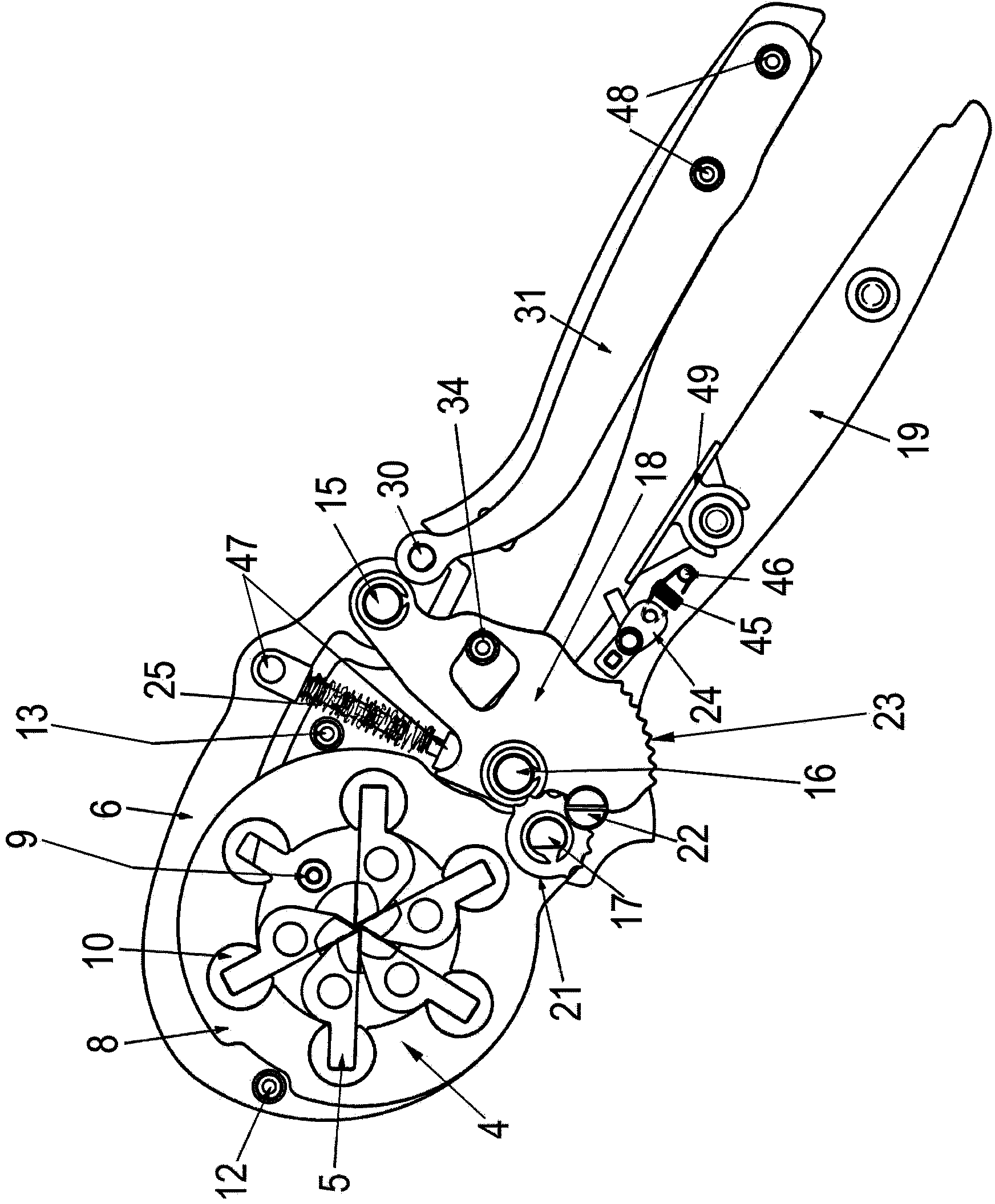

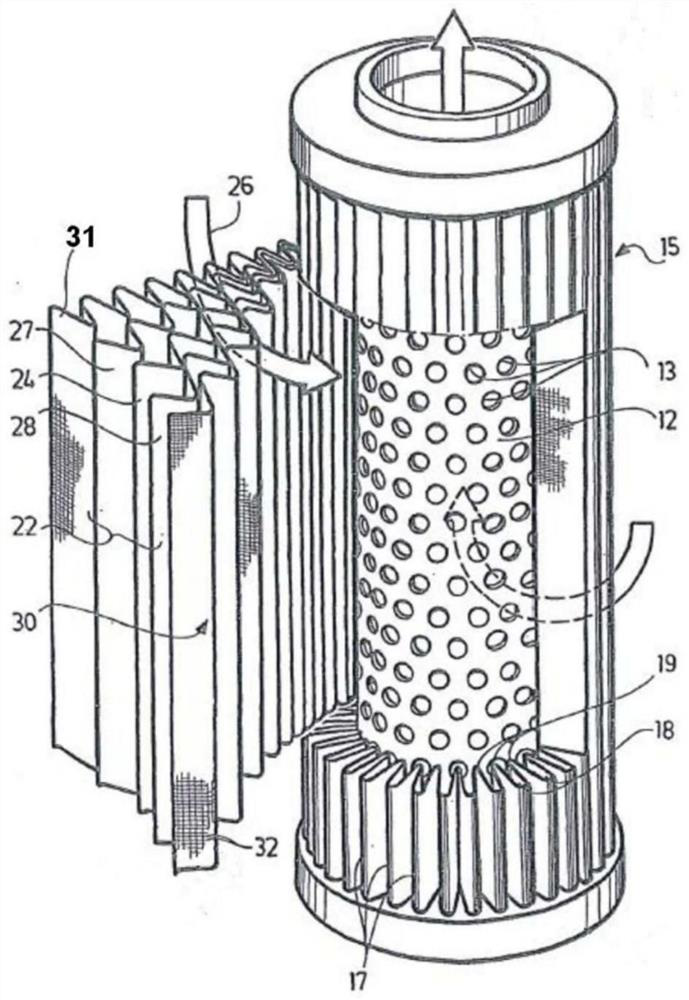

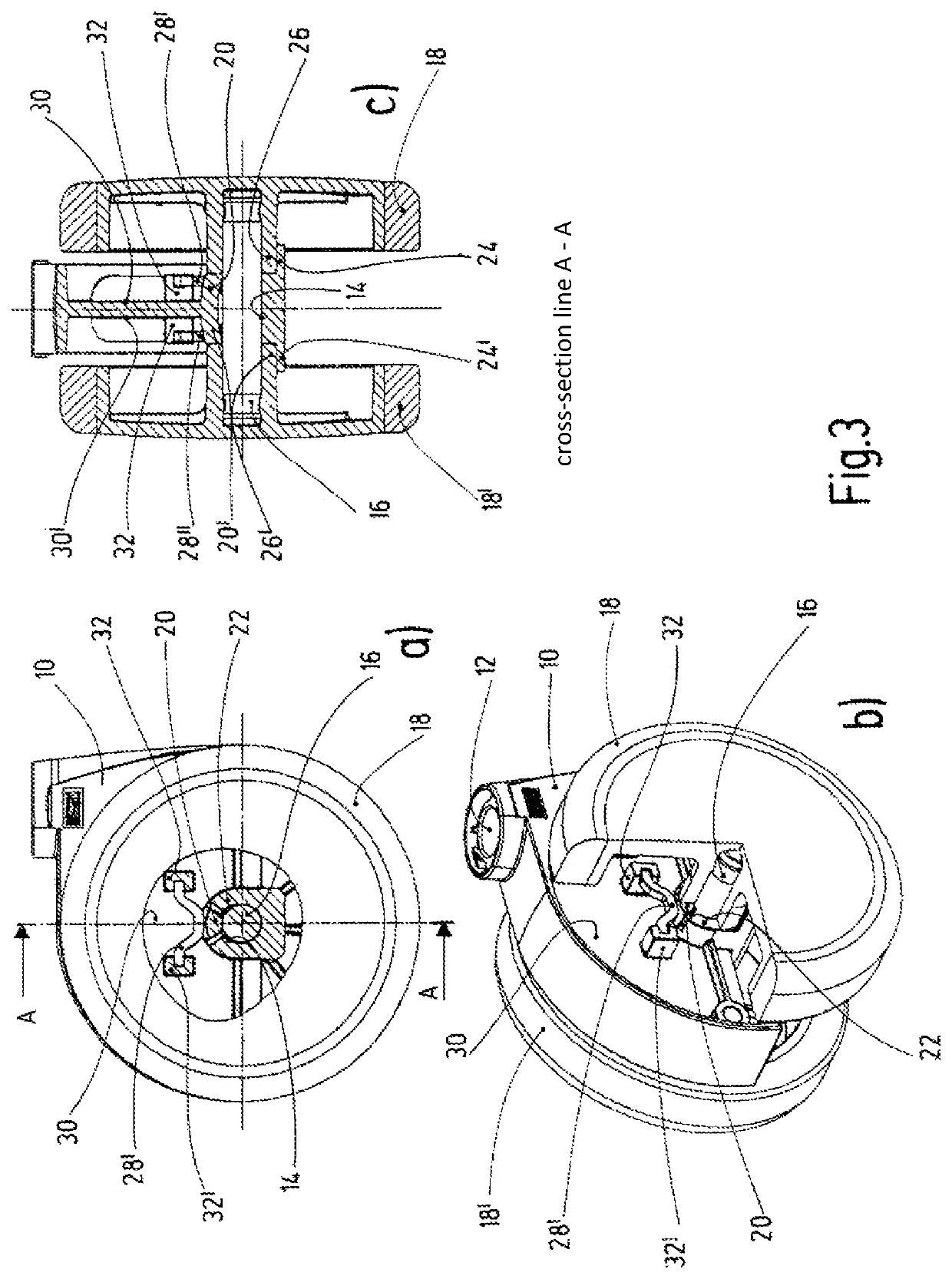

An electric machine (1), particularly used as an electric motor, has a rotor (2) comprising a plurality of disks (4). A disk (4) of the rotor (2) is divided in a circumferential direction (5) into a plurality of disk sectors (6, 7, 8) between which magnetic pockets (9, 10) are designed. Furthermore, the disk (4) has an inner fastening collar (15) and connecting members (20, 23, 24) connecting the disk sectors (6, 7, 8) to the fastening collar (15). Such a connecting member (20) comprises a main web (21), a side arm (30) branching off the main rib (21) in the circumferential direction (5), and a side arm (31) branching off the main web (21) opposite to the circumferential direction (5). High mechanical stability of the disk (4) can thus be ensured, wherein magnetic flow losses are reduced.

Owner:ROBERT BOSCH GMBH

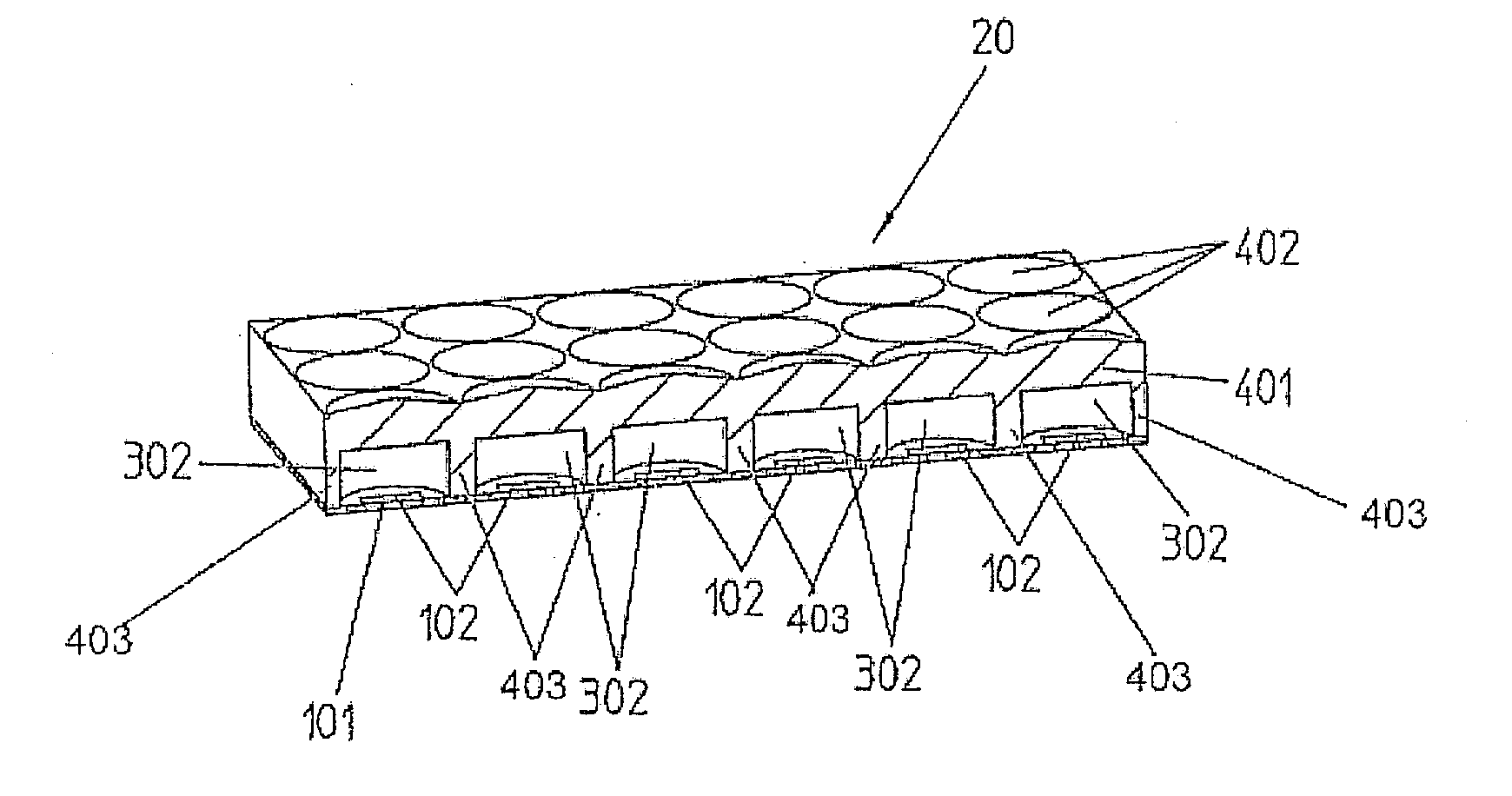

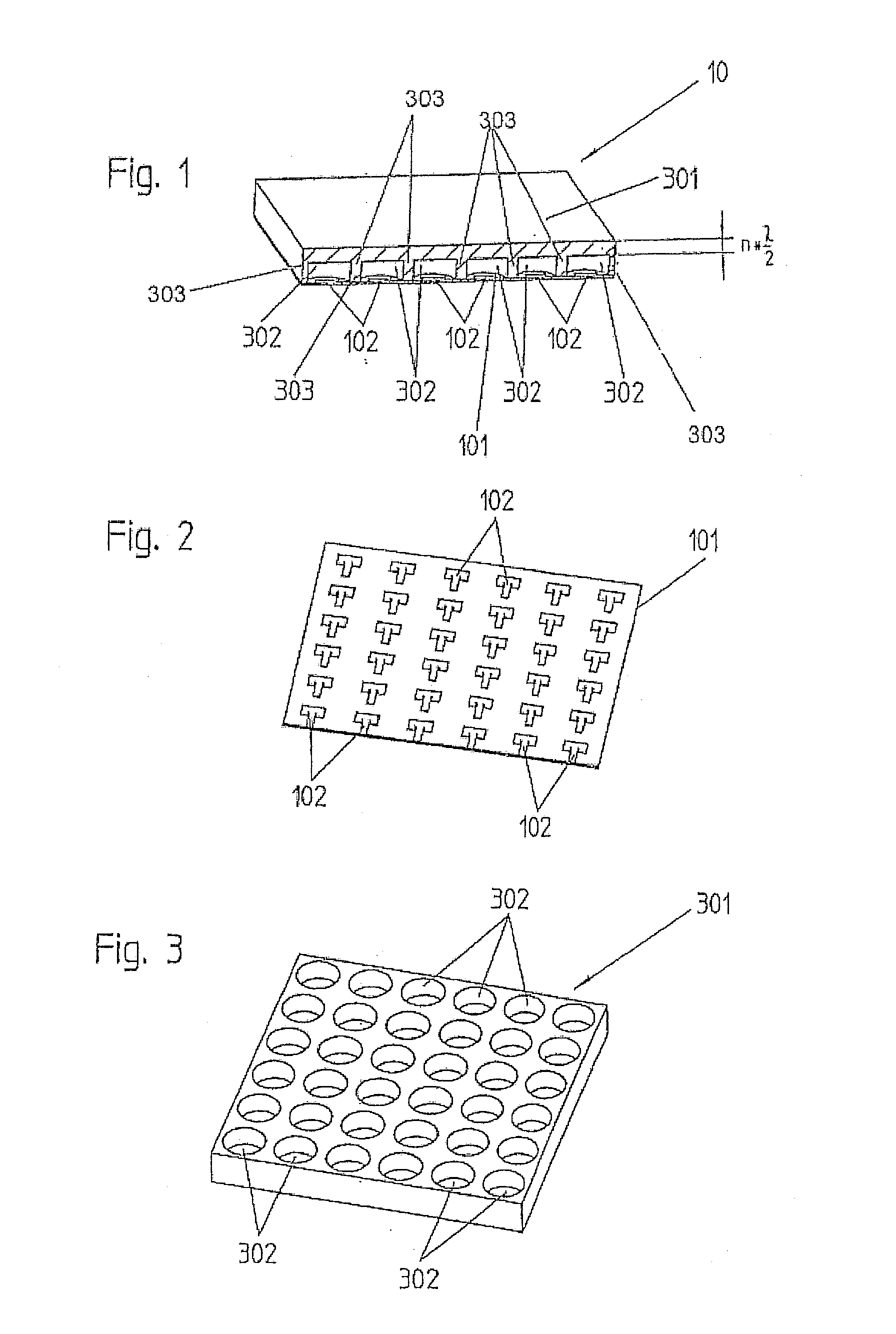

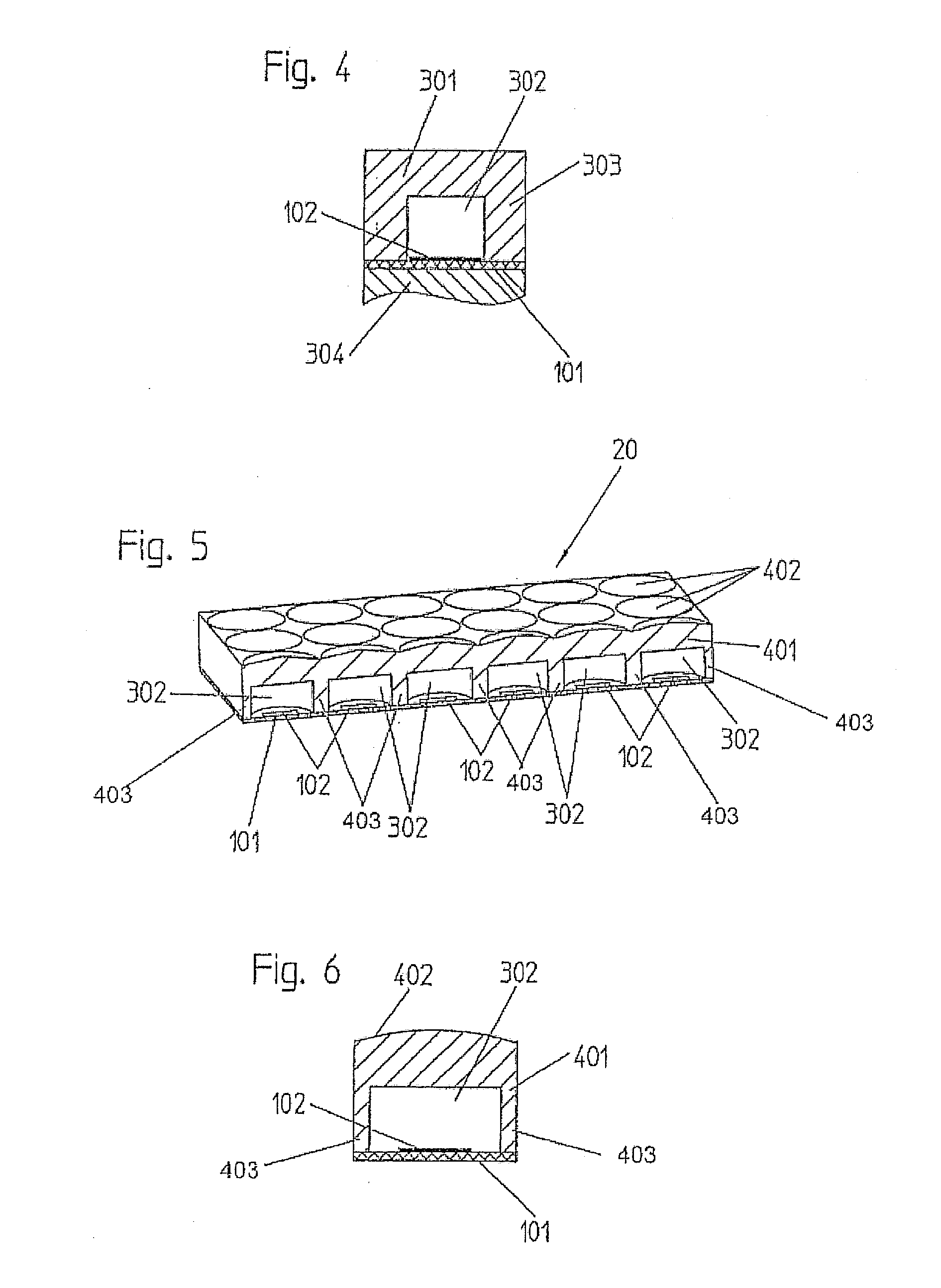

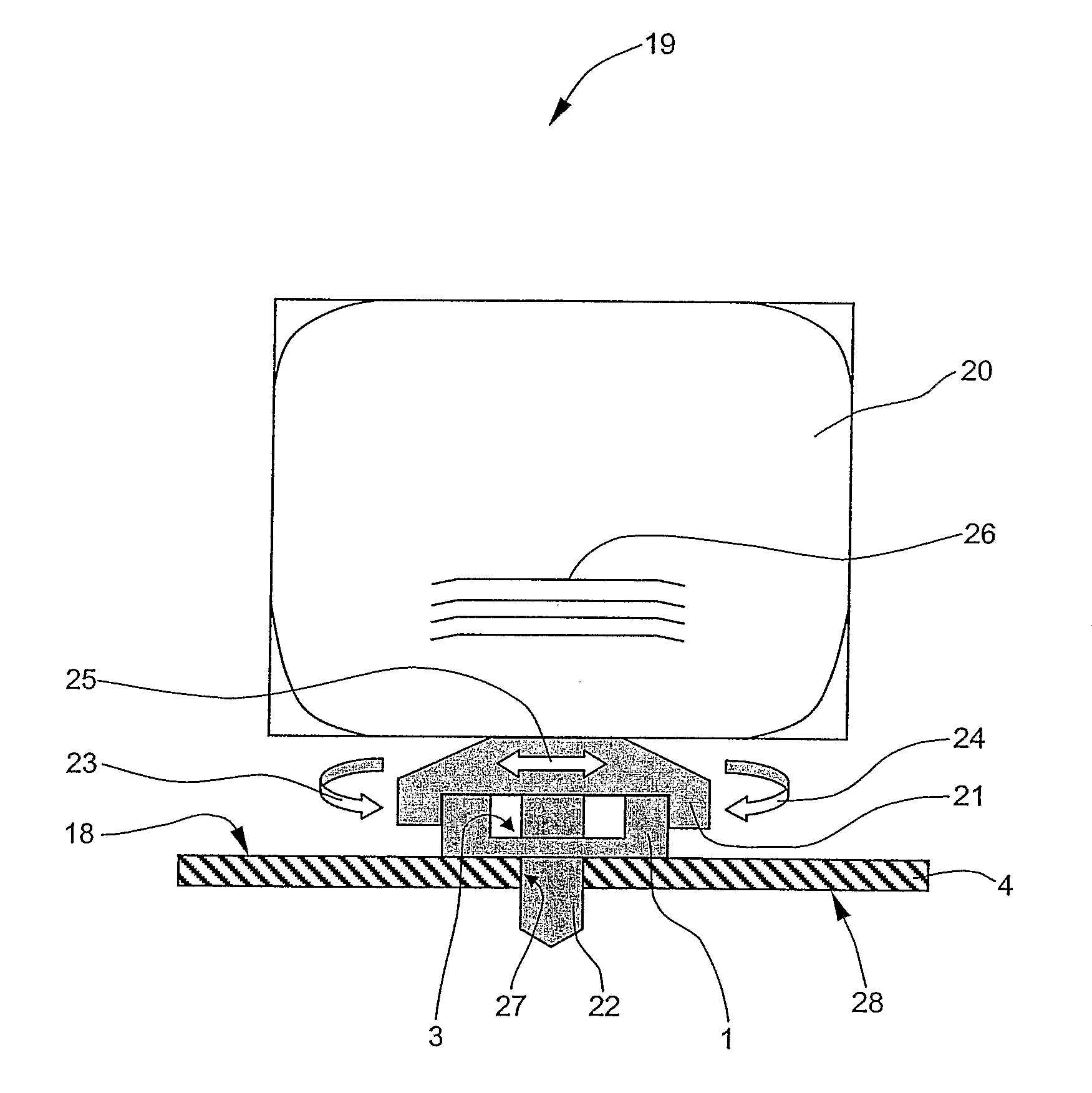

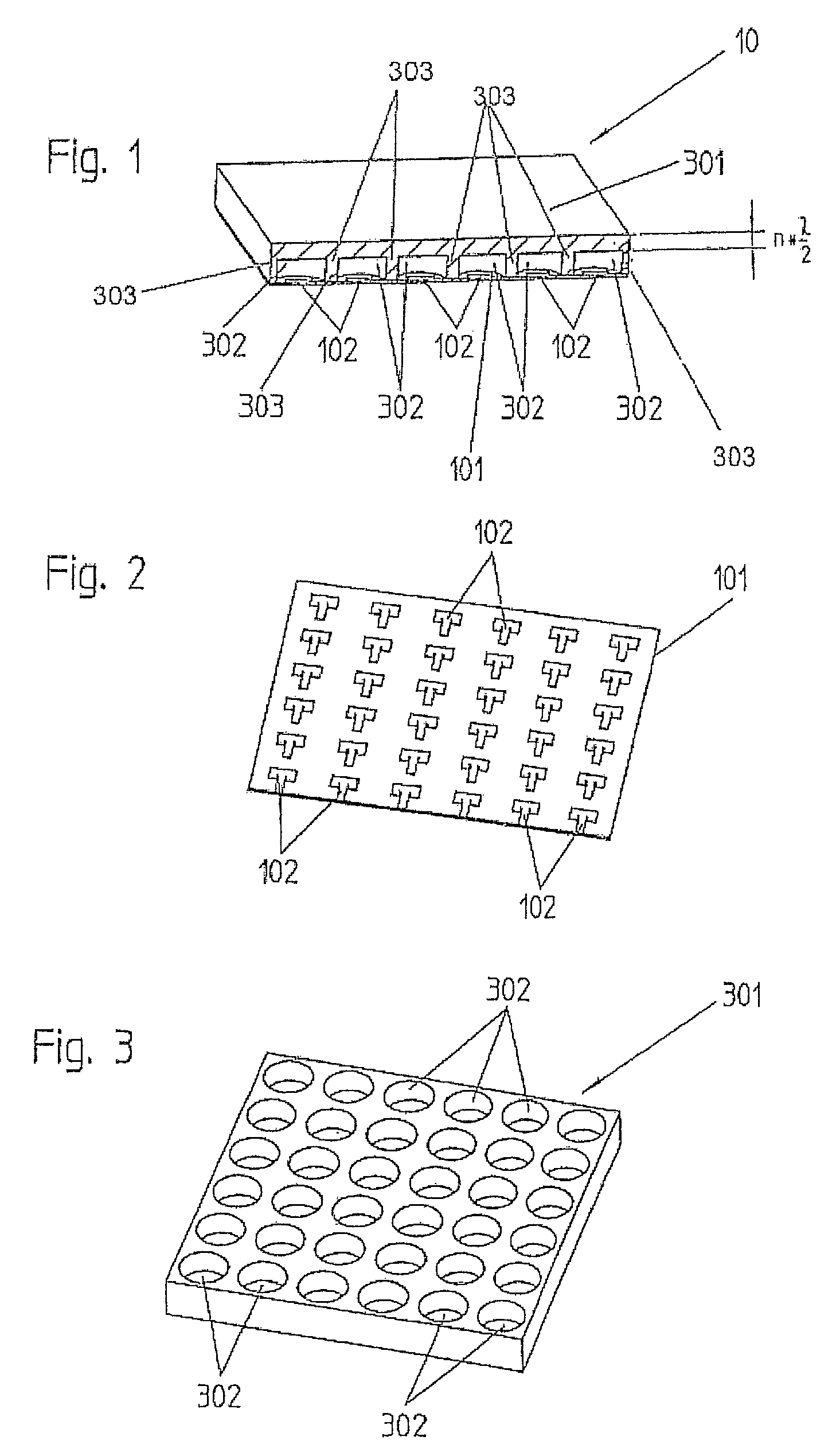

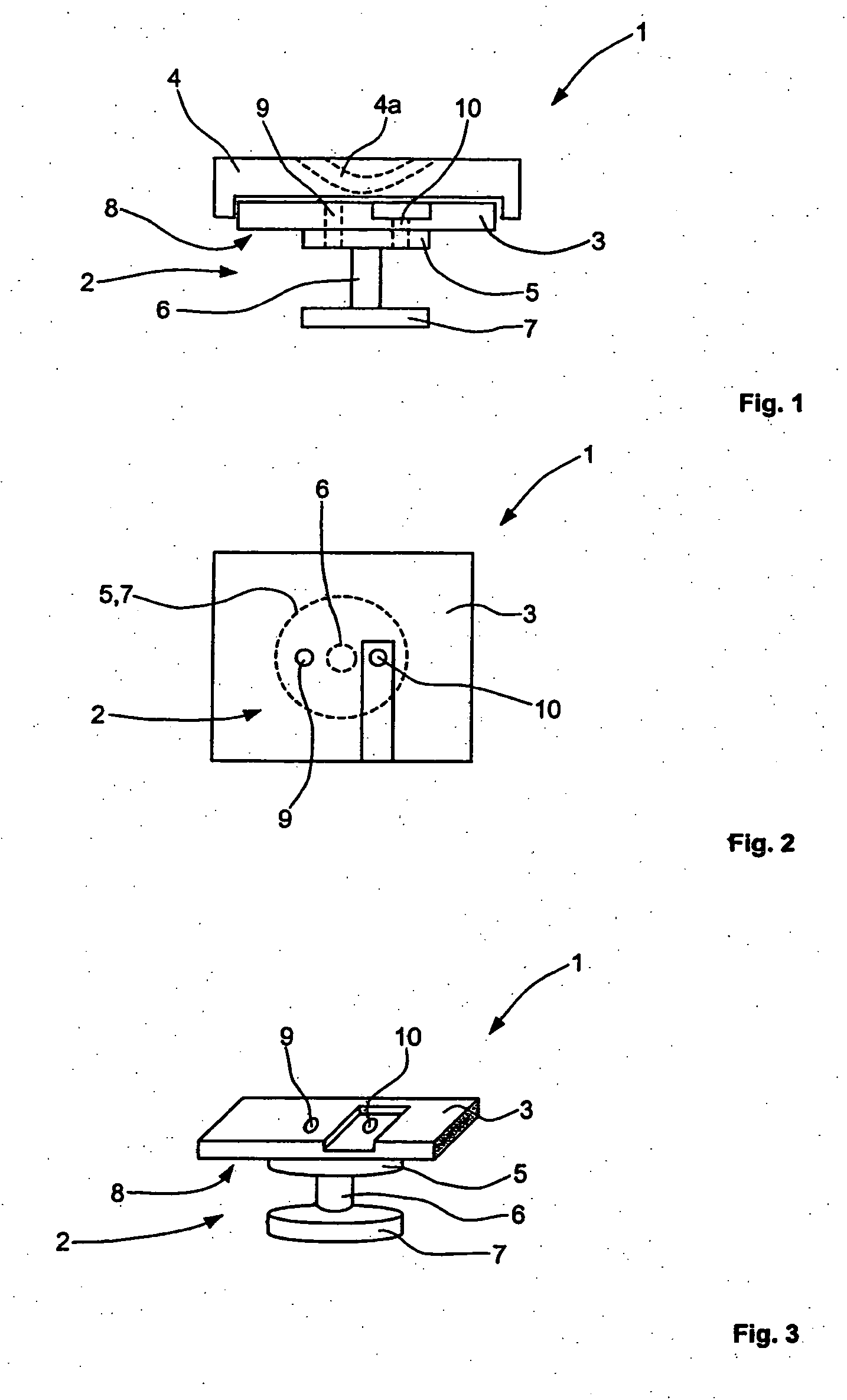

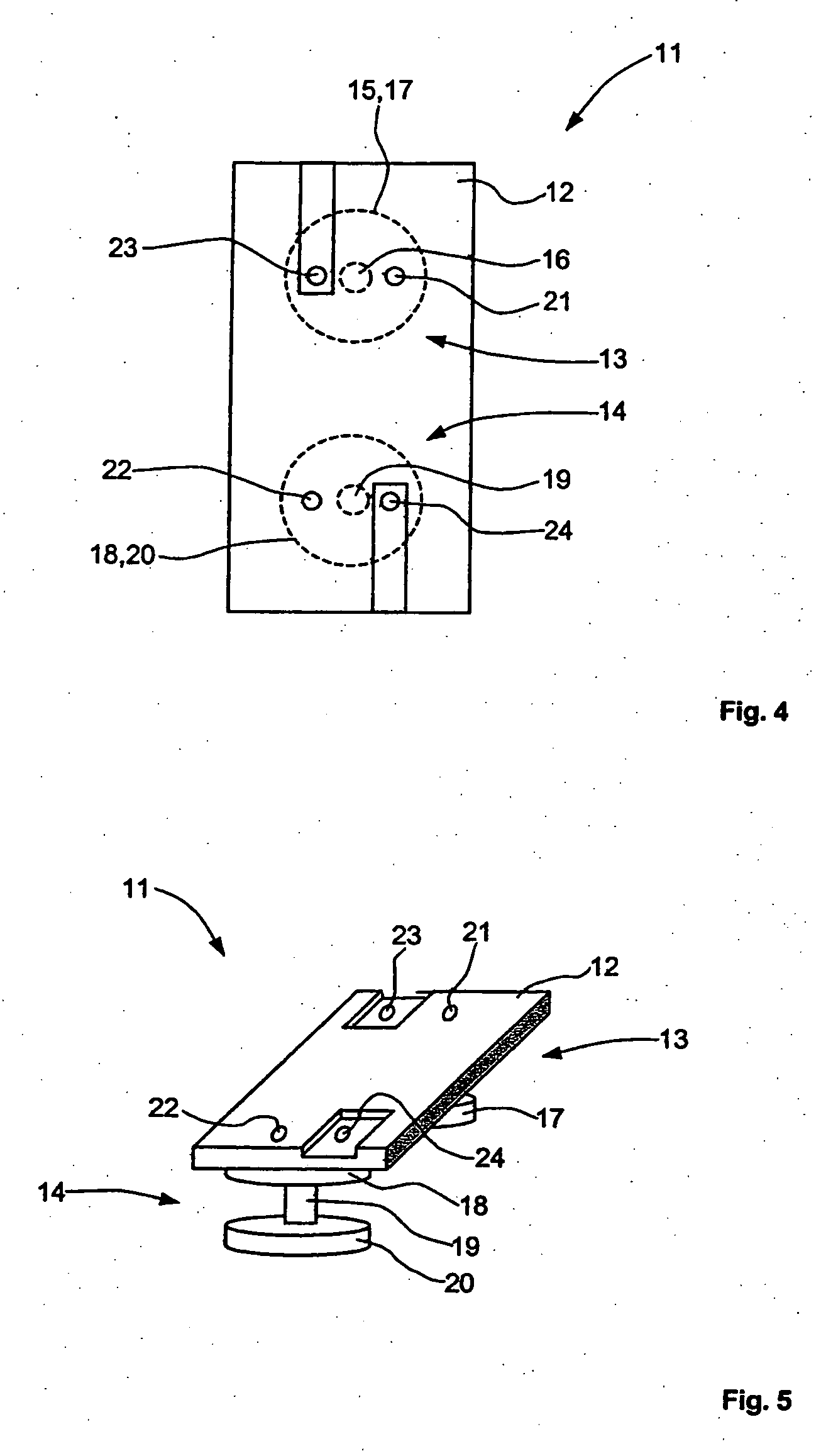

Planar antenna with cover

Provided is a planar antenna based system for use as a radar level meter, microwave barrier or other suitable system. The system includes a planar radiator element arranged on a substrate, and a cover plate element made from a dielectric to cover the planar radiator element. In one alternative embodiment, the cover plate includes a cavity proximate the planar radiator element, into which the microwaves generated by the planar radiator element can be coupled. In another alternative, the cover plate is provided in a surface-flush position against the substrate in the edge region of the cavity. These arrangements may be provided in a plurality so as to support an overall system containing multiple radiator elements.

Owner:VEGA GRIESHABER GMBH & CO

Electric machine

InactiveUS8729767B2Magnetic flux losses for a predetermined mechanical load capacity can be reducedIncreased mechanical load capacityMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMechanical stability

An electric machine (1), particularly used as an electric motor, has a rotor (2) comprising a plurality of disks (4). A disk (4) of the rotor (2) is divided in a circumferential direction (5) into a plurality of disk sectors (6, 7, 8) between which magnetic pockets (9, 10) are designed. Furthermore, the disk (4) has an inner fastening collar (15) and connecting members (20, 23, 24) connecting the disk sectors (6, 7, 8) to the fastening collar (15). Such a connecting member (20) comprises a main web (21), a side arm (30) branching off the main rib (21) in the circumferential direction (5), and a side arm (31) branching off the main web (21) opposite to the circumferential direction (5). High mechanical stability of the disk (4) can thus be ensured, wherein magnetic flow losses are reduced.

Owner:ROBERT BOSCH GMBH

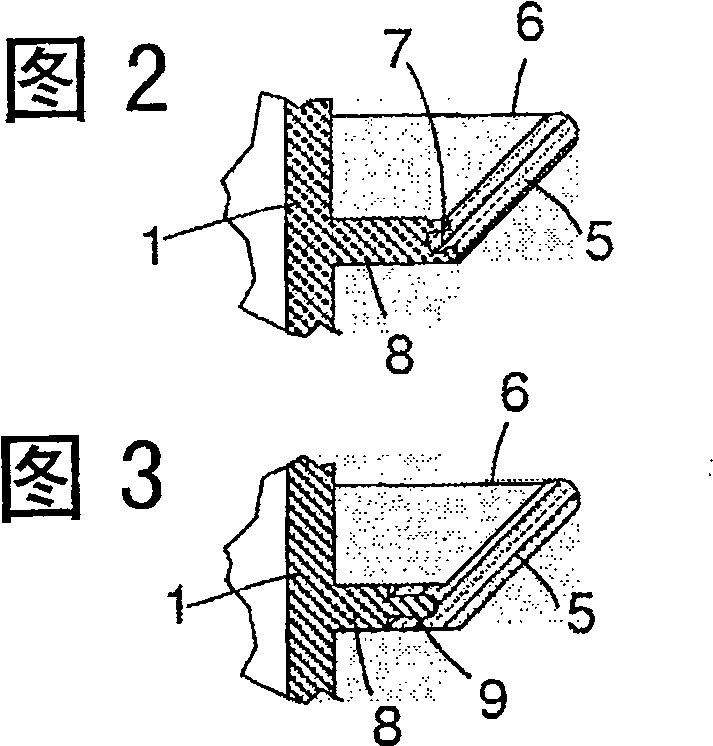

Vessel of a portable handheld work apparatus

InactiveUS20080087080A1Increase liquid tightness and carrying capacityReduce thicknessOilsumpsMachines/enginesTongue and grooveBiomedical engineering

Owner:ANDREAS STIHL AG & CO KG

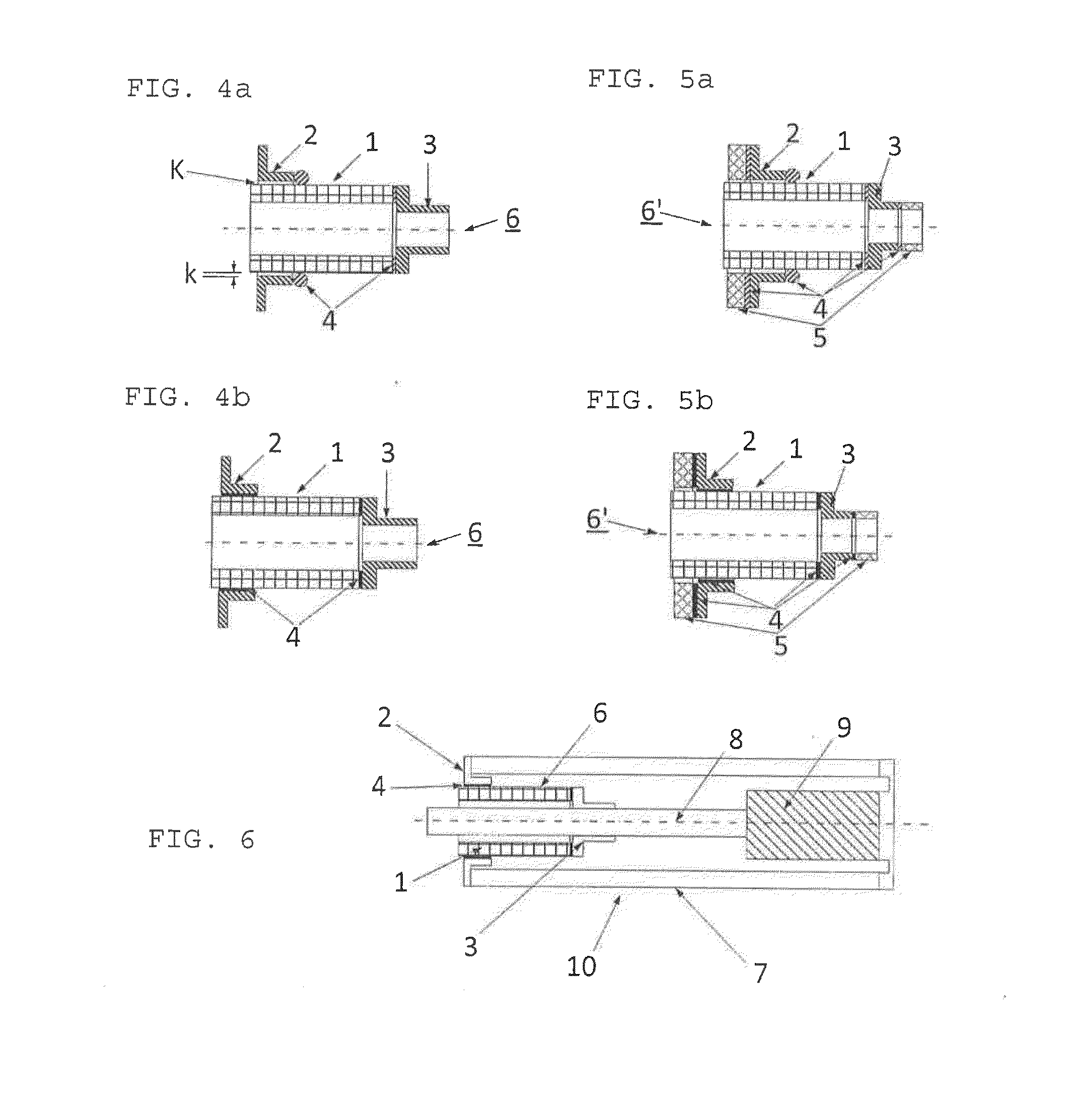

Method for Joining a First Component Formed of a Plastic Material to a Second Component, and Joining Element and Device

InactiveUS20080206012A1Simple and fast productionReduce processNutsLaminationPlastic materialsEngineering

This invention firstly relates to a method for joining a first component made of a plastic material, in particular a thermoplastic and / or thermosetting plastic material, to a second component by applying a joining element on the first component, wherein the joining element has a supporting plate formed of a thermoplastic and / or thermosetting plastic material and comprising a connecting means and a supporting plate bore. The method comprising the steps of incorporating a bore into the first component; welding the supporting plate to the first component; and joining the first component and the second component by incorporating a joining means arranged on the second component into the connecting means. Due to welding of the supporting plate to the first component, a rivet joint, otherwise generally required for joining the supporting plate to the first component, can be omitted, whereby the production of a junction by means of the inventive joining means is considerably simplified. Moreover, weakening of the first component as well as formation of corrosion processes due to different materials used for riveting being adjacent can be avoided. In addition, the invention relates to a joining element for creating a junction in accordance with the method. Furthermore, the invention relates to a device, in particular for performing the method.

Owner:AIRBUS OPERATIONS GMBH

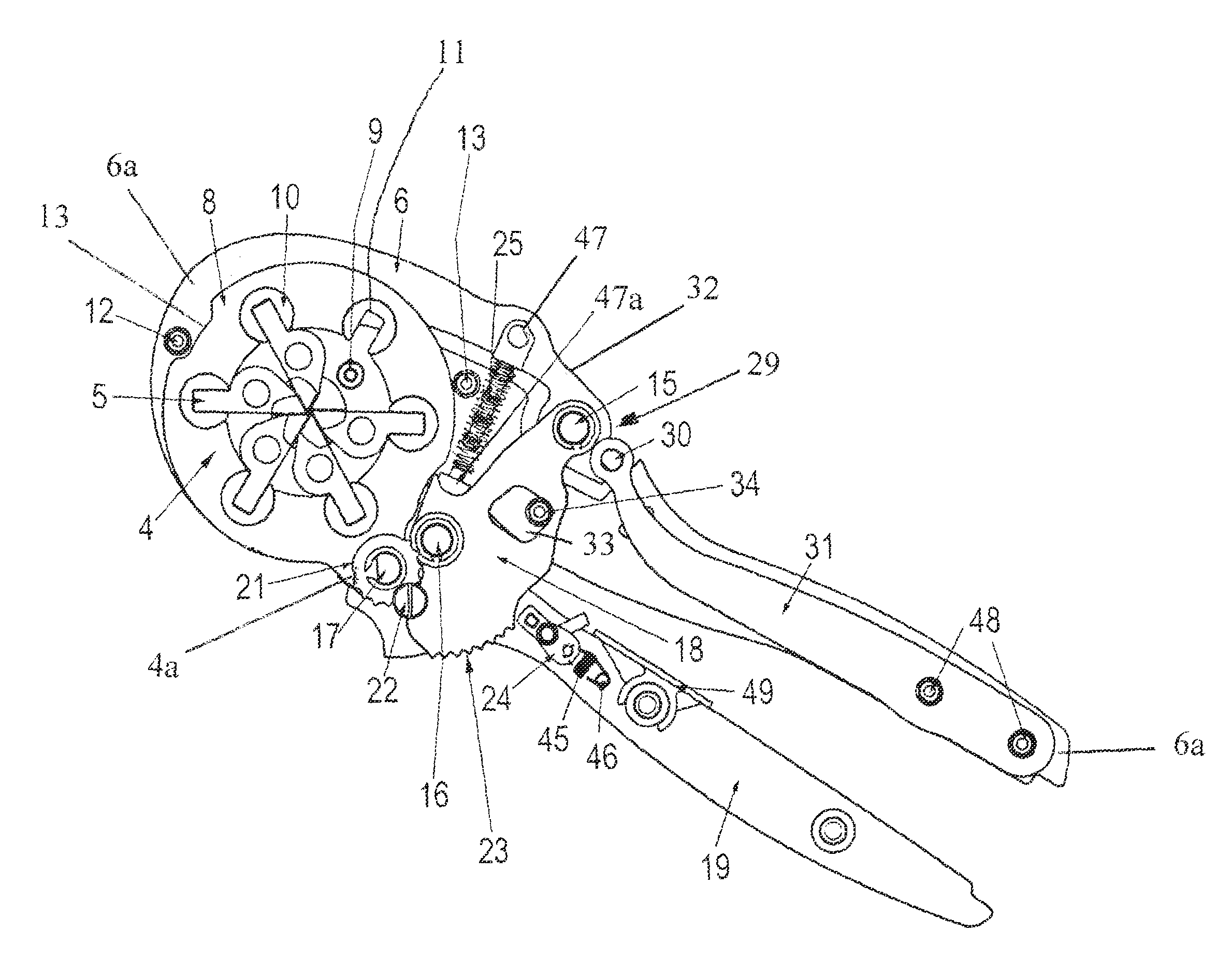

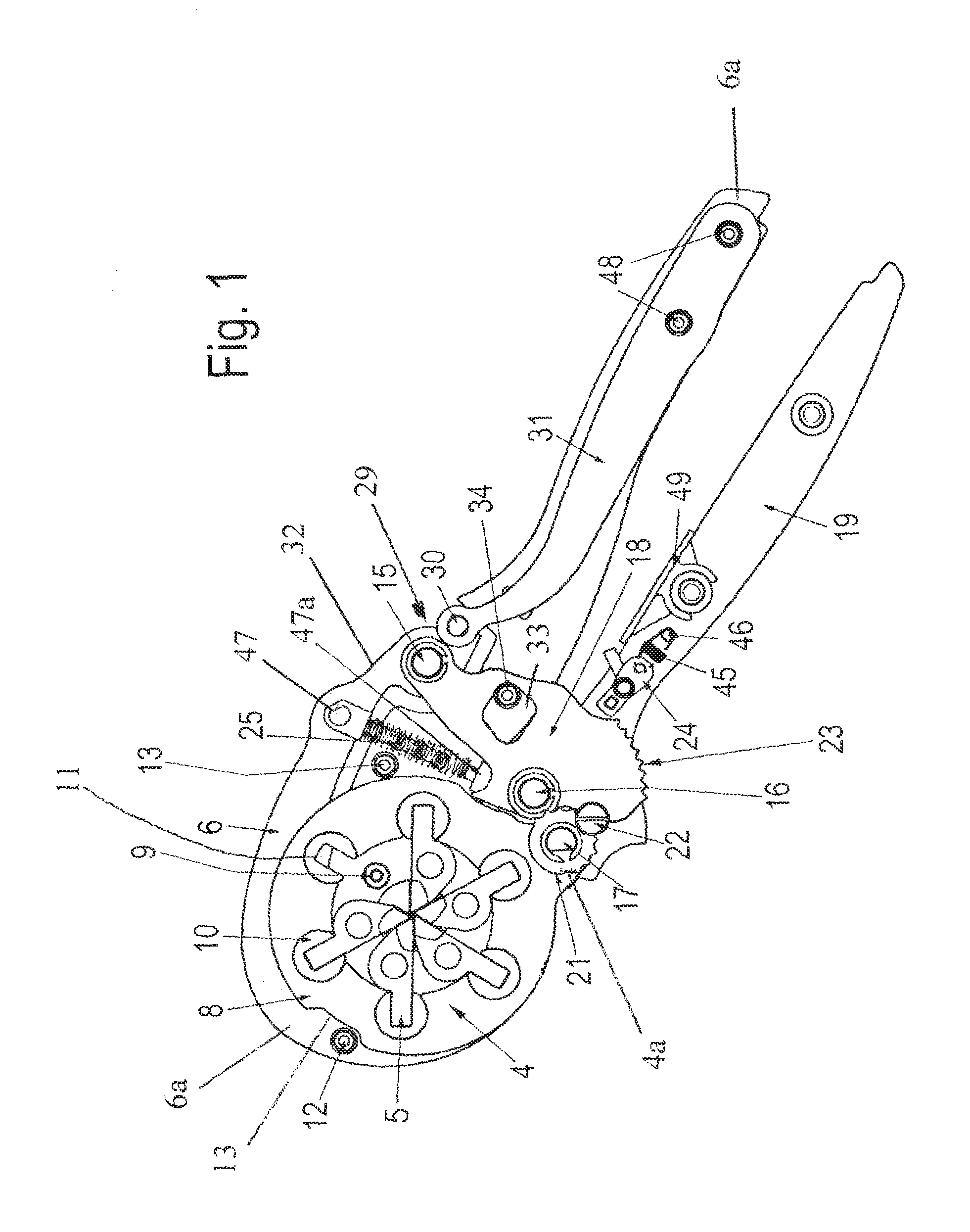

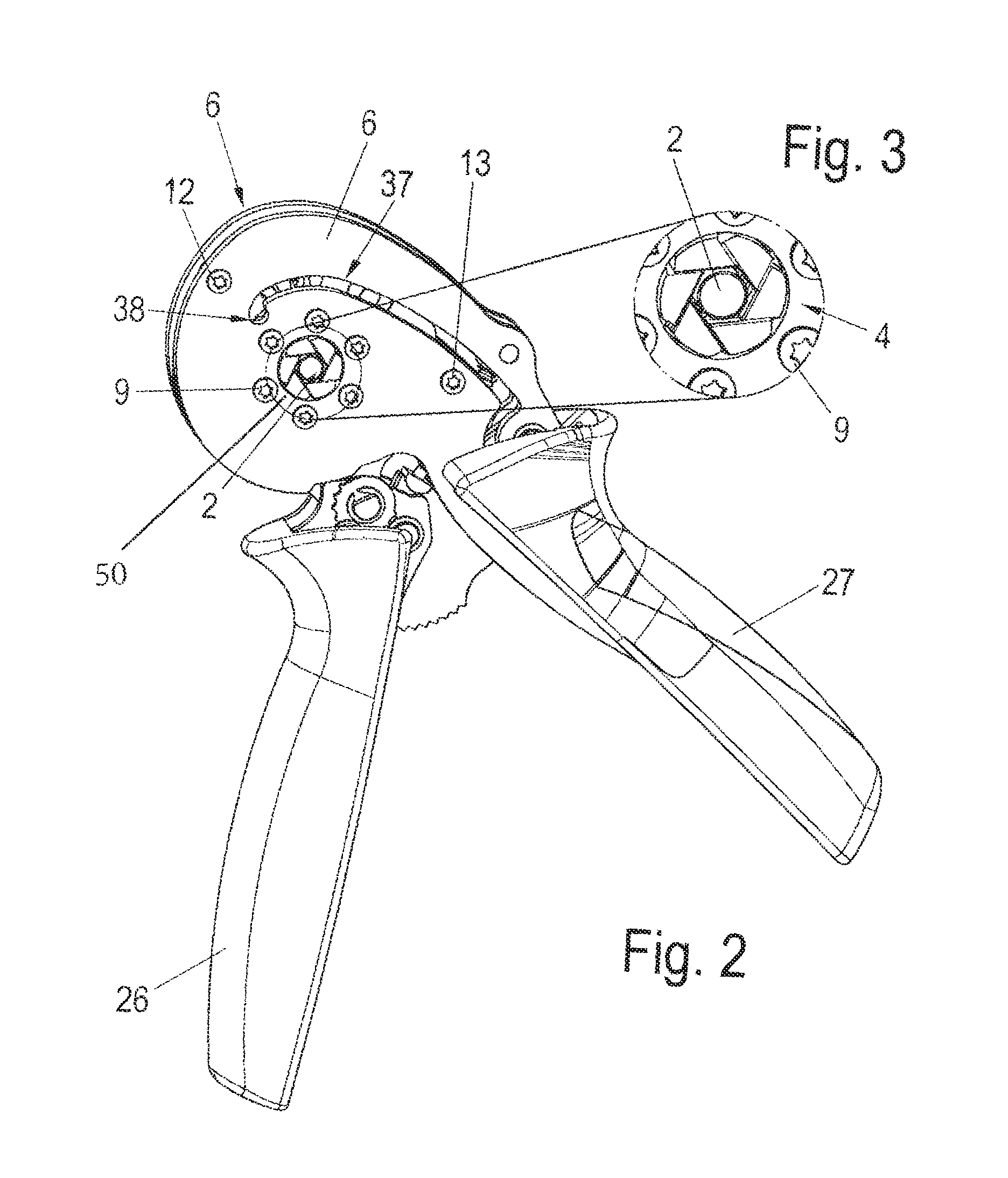

Crimping tool for wire end ferrules

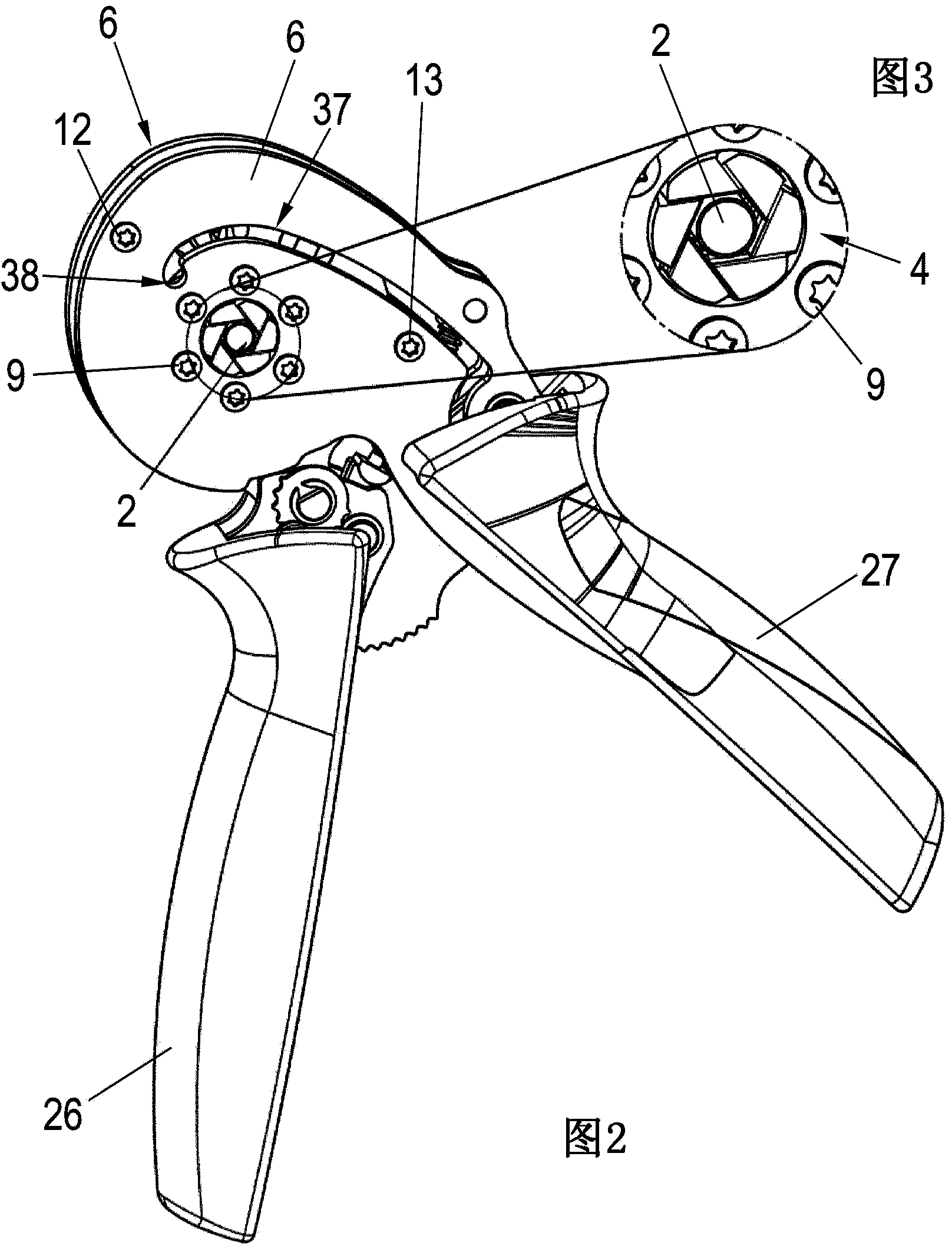

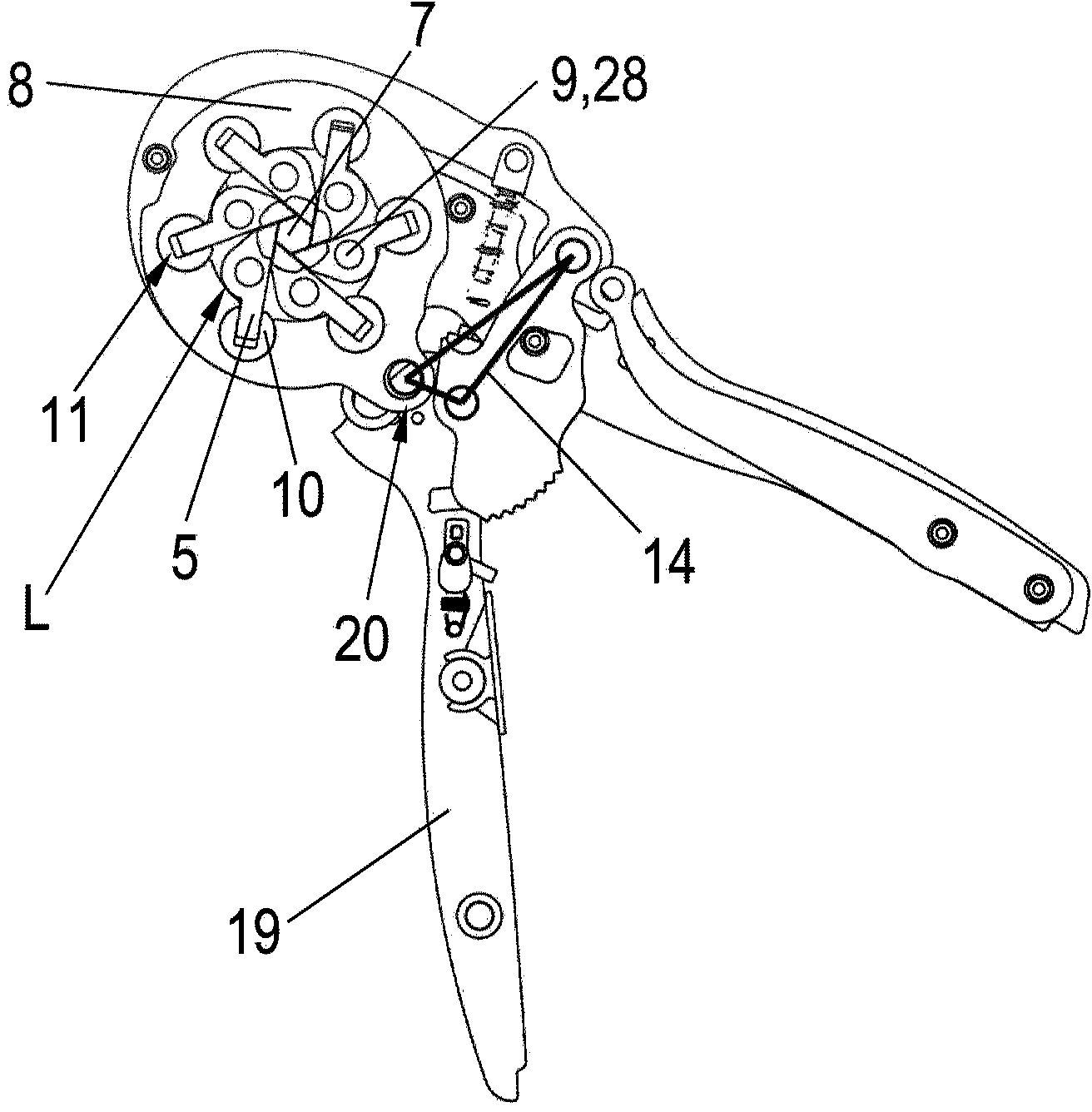

ActiveUS9496671B2Reduce mechanical stressGreat carrying cross sectionLine/current collector detailsPliersElectrical conductorMechanical engineering

A scissors-type crimping tool for crimping a female contact onto an electrical conductor, comprising a planar base member having body and first lever portions; an annular crimping die member connected for rotation between die-open and die-crimping positions relative to the base member body portion; a toggle link arrangement connecting a second lever for pivotal movement relative to the base member body portion; and a cascade spring arrangement operable by the toggle arrangement from a non-stressed condition to a stressed caged condition during initial movement of the second lever in the closed direction, and to a stressed condition during further movement of the second lever, thereby to afford processing of different cross-sections of ferrules and conductors in the crimping die, and to apply the force of the stressed cascade spring arrangement to the crimping die member during the final stage of the crimping operation.

Owner:WEIDMULLER INTERFACE GMBH & CO KG

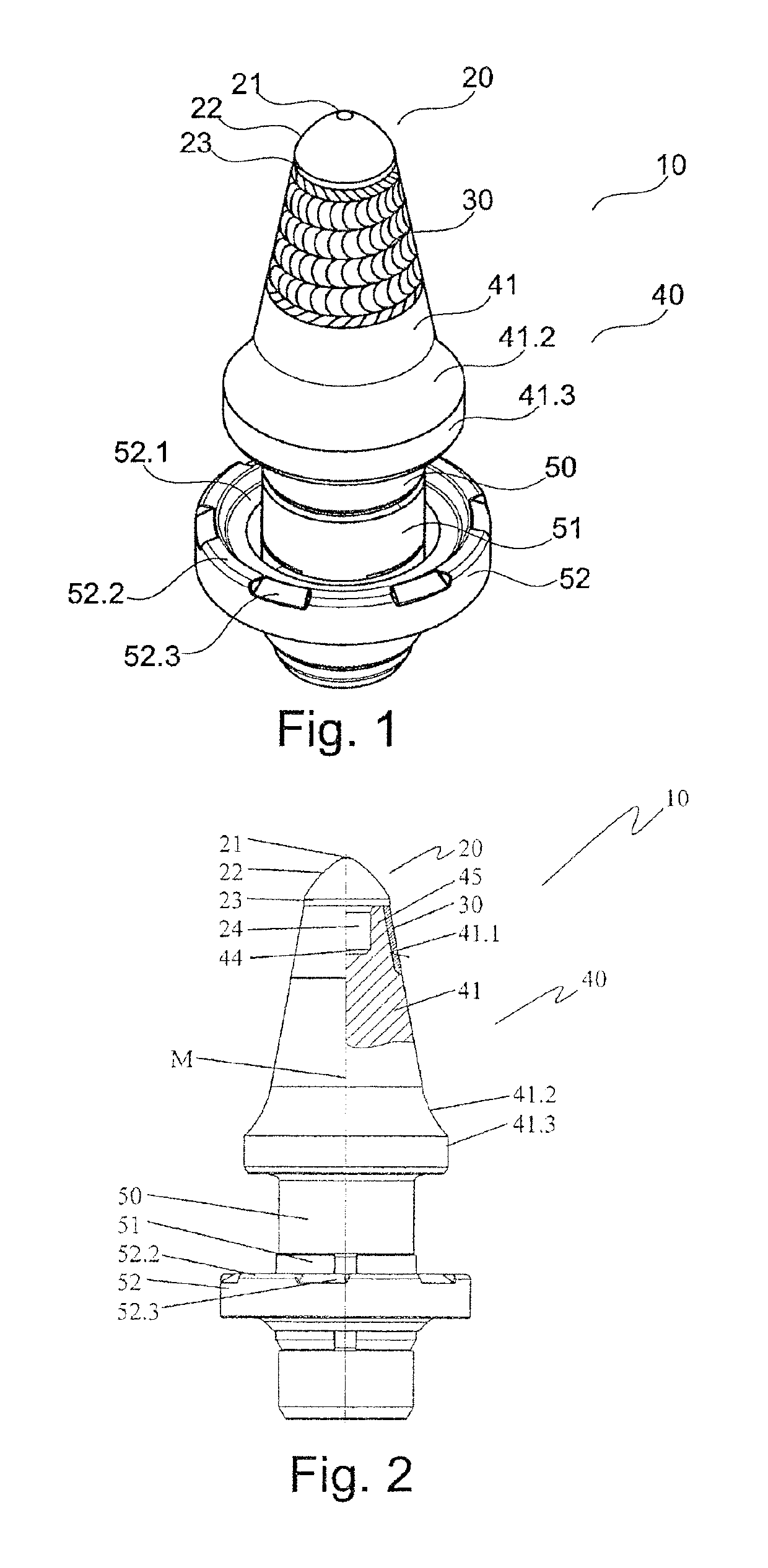

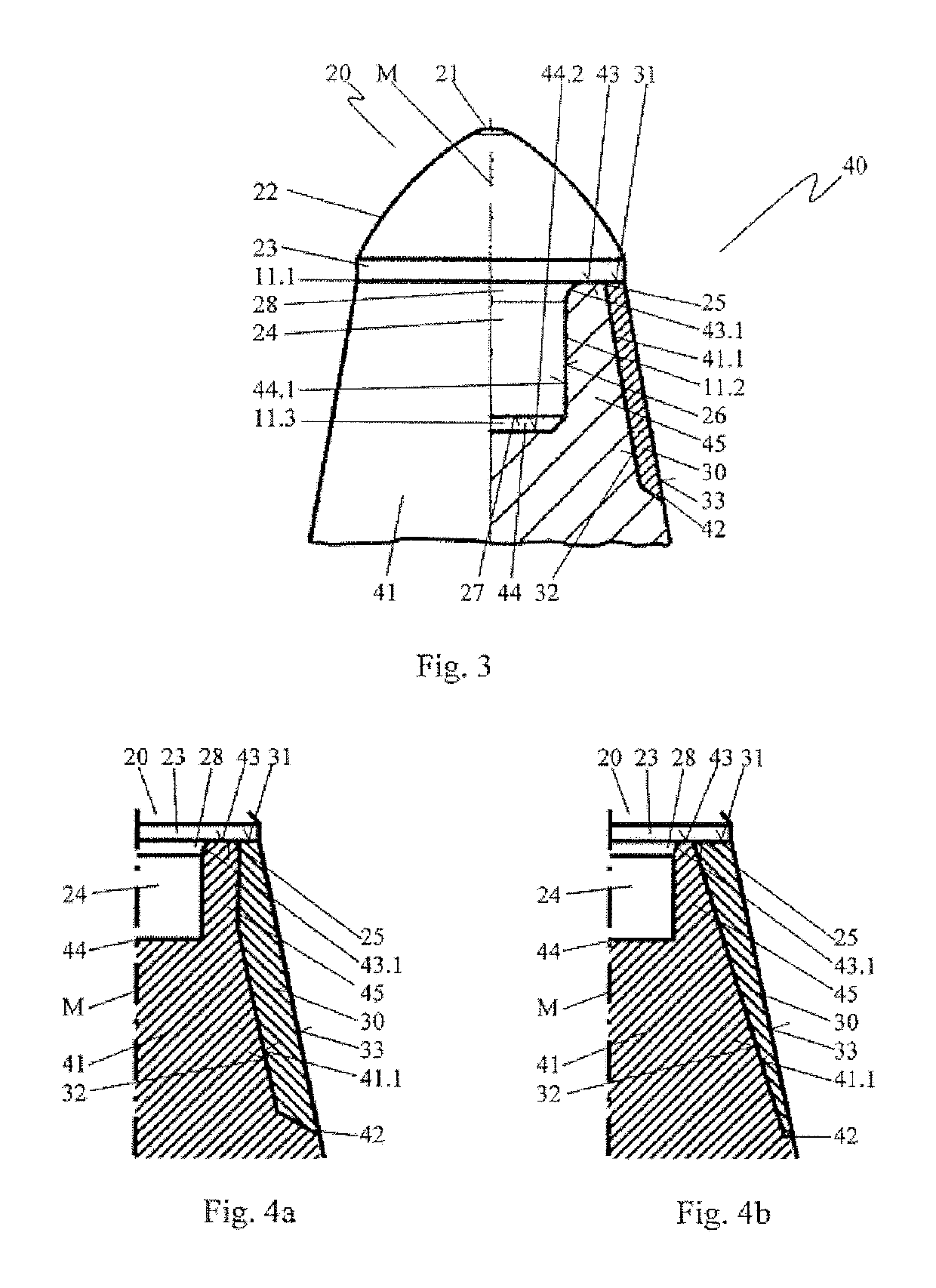

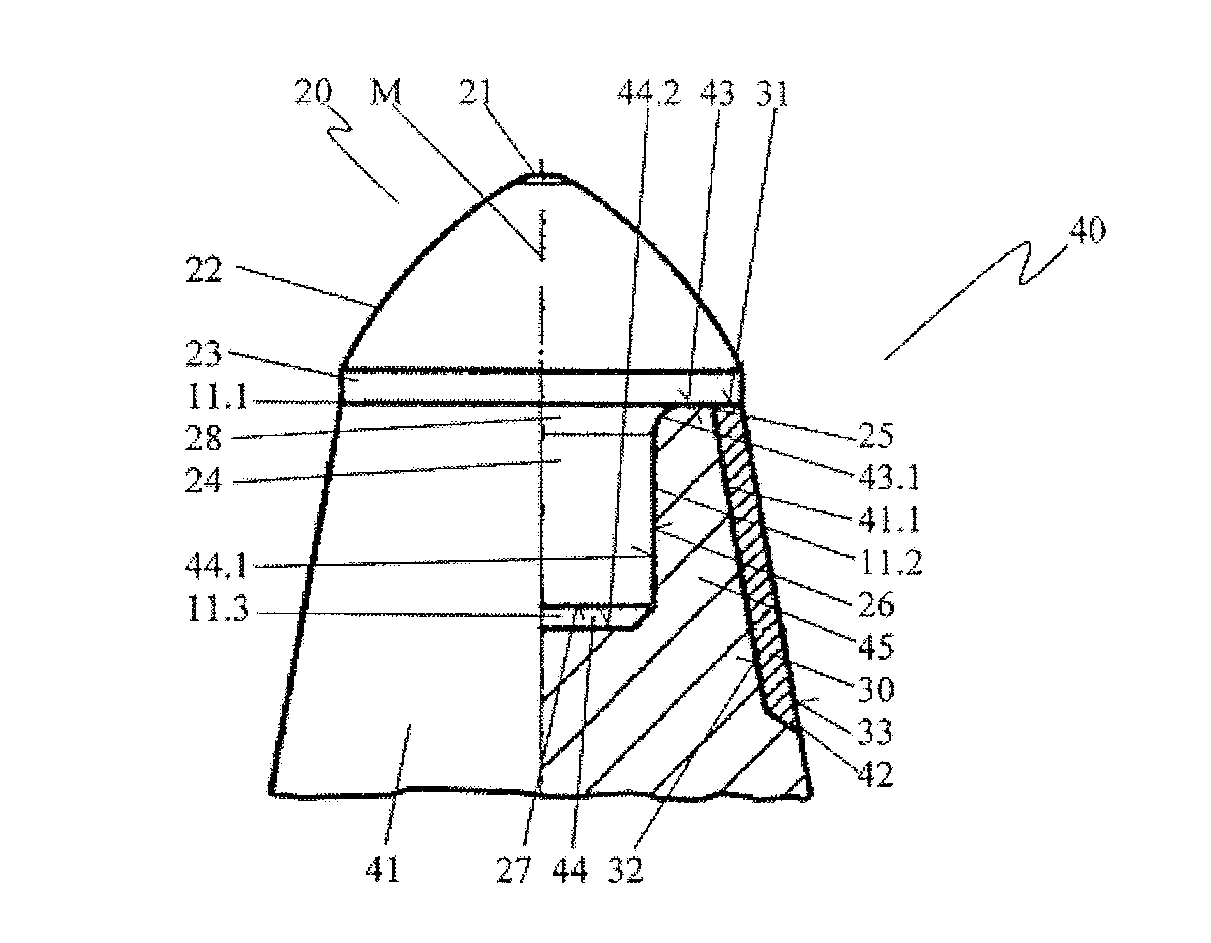

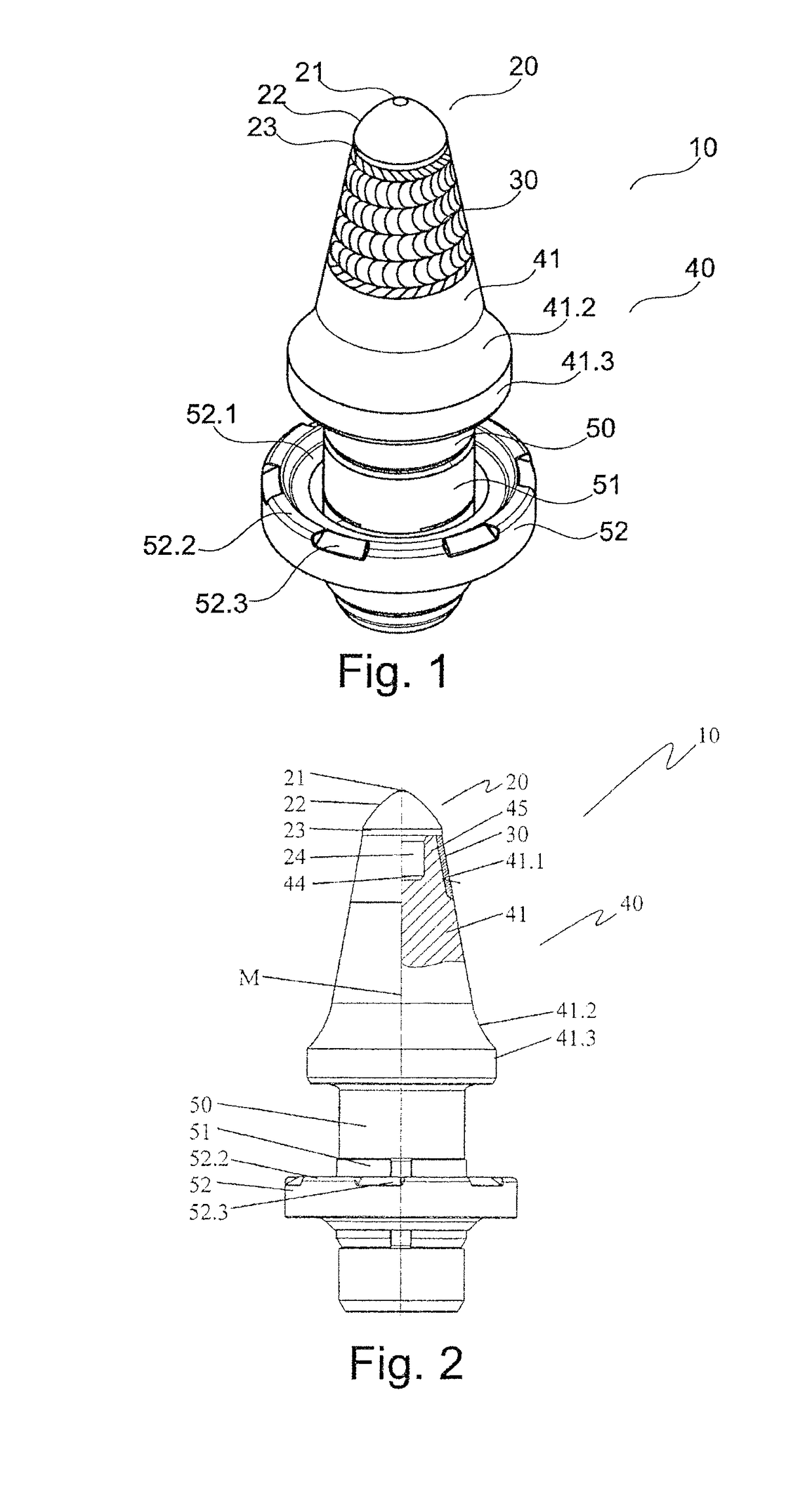

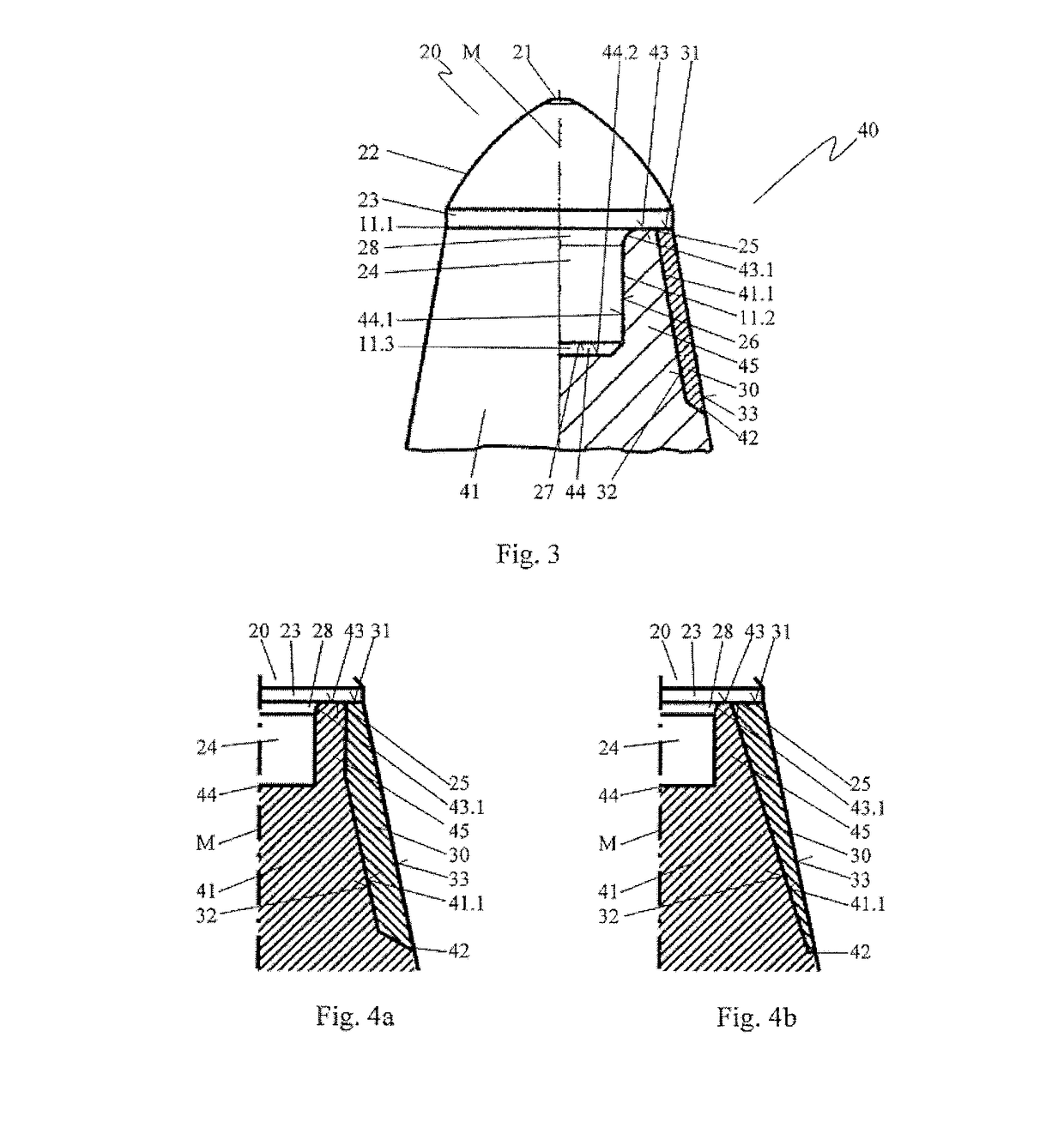

Pick, in particular a round-shank pick

ActiveUS10415385B2Increased mechanical load capacityReduced risk of breakageDrill bitsSlitting machinesHard metalWear resistant

A round-shank pick, comprising a pick head and a pick shank, the pick head including a base part and a cutting element, which is connected to the base part and is composed of a hard material, in particular hard metal, wherein the base part has a wear-resistant layer on the outer surface thereof at the connection to the cutting element, which wear-resistant layer covers at least one segment of the outer surface of the base part facing the cutting element and wherein an end face of the wear-resistant layer facing the cutting element is covered by the cutting element. The base part has an axially oriented cut-out for receiving a fastening segment of the cutting element, the base part has a counter surface facing the cutting element and extending around the cut-out, and the counter surface and the end face of the wear-resistant layer form a continuous flat surface.

Owner:BETEK

Multilayer Building Membrane with Foam Core

InactiveUS20150298427A1Increase valueExcellent mechanical resistance valueRoofingSynthetic resin layered productsTear resistanceEngineering

The invention relates to a multilayer building membrane with two outer layers, one of which is designed as a film layer that can be elastically extended in a unidirectional manner and which contains an elastically deformable thermoplastic urethane designated as TPU. A membrane core is arranged between the two outer layers of the building membrane and is connected to said two outer layers, and the building membrane has a tensile strength of at least 40% in the longitudinal and transverse directions and a tear resistance, based on a 50 mm wide membrane strip, of at least 120 N, a maximum sd value of 20 m with respect to the vapor permeability of the building membrane, and a value corresponding to a water column of at least 8 m with respect to the water permeability of the building membrane. The invention proposes that the membrane core has a foam layer which consists of a foamed thermoelastic material, wherein a foam layer adjoins each of the two outer layers. The invention further proposes a facade-sealing strip which is designed as strips made of an aforementioned building membrane. The invention additionally proposes a roofing sheet which is designed as strips made of an aforementioned building membrane.

Owner:HOGG HERMANN

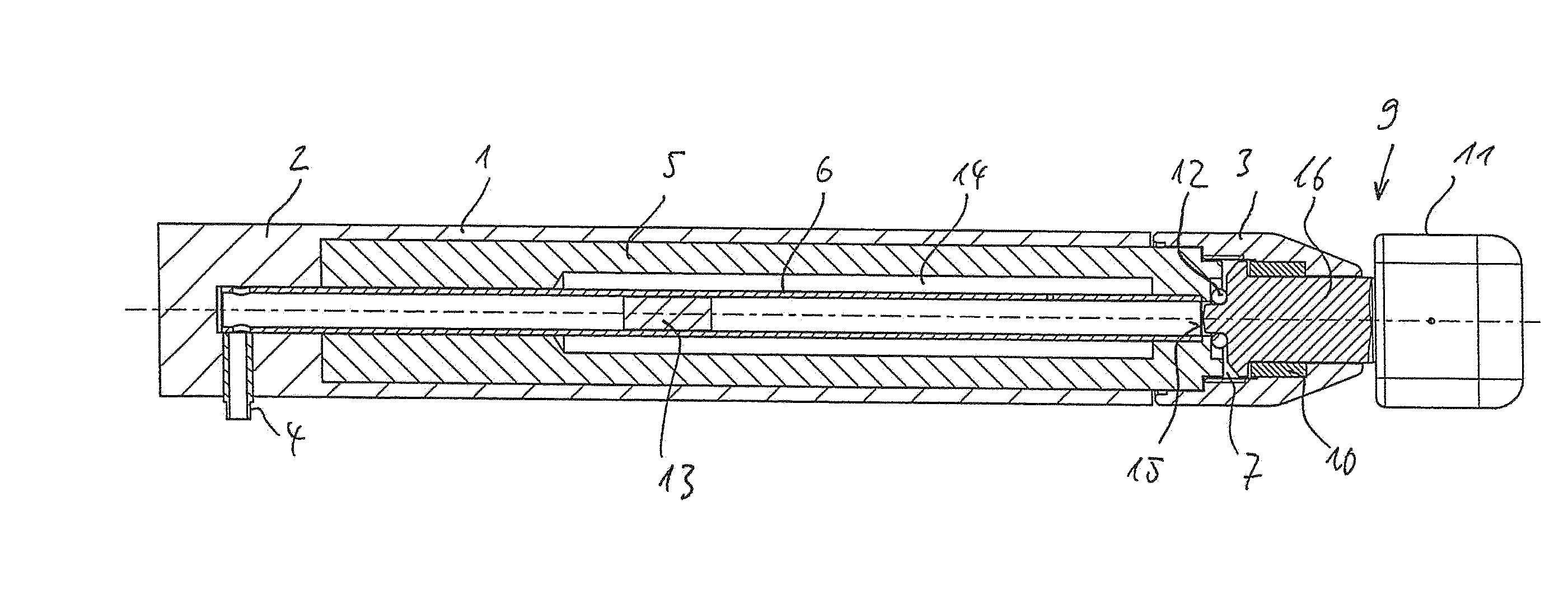

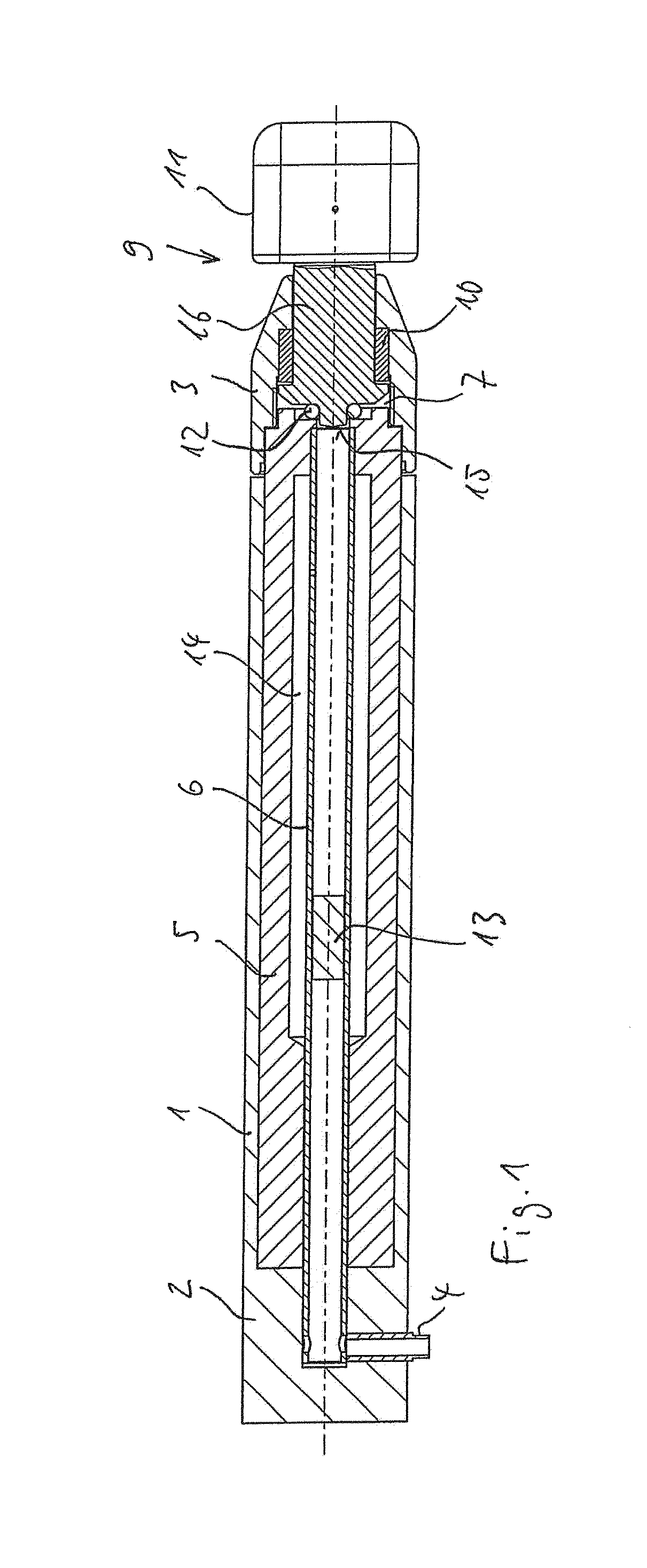

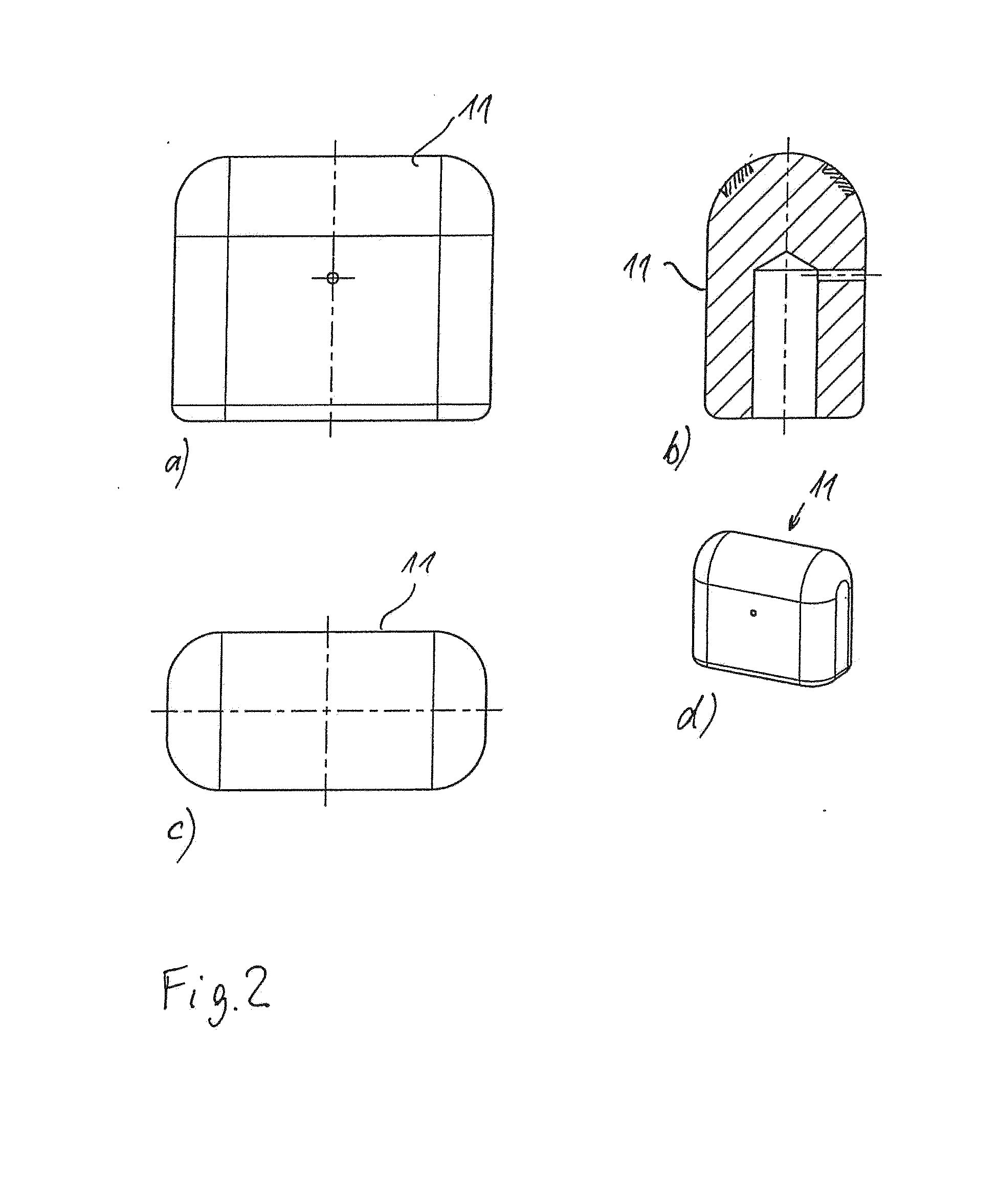

Apparatus for treating the human or animal body with mechanical strokes

ActiveUS20160089296A1Less careIncreased mechanical load capacitySurgeryVibration massageRisk strokeAnimal body

The invention relates to an apparatus for treating a human or animal body by mechanical strokes, wherein an applicator for being placed on the patient's body surface has a basically oblique front area portion in an angle between 30° and 60° to the stroke direction.

Owner:STORZ MEDICAL

Crimping tool for wire end ferrules

ActiveCN104396099AIncrease the itineraryLarge load-bearing cross-sectionLine/current collector detailsPliersElectrical conductorKinematics

The invention relates to a crimping tool (1) for wire end ferrules (2), contact bushings, cable lugs or similar on electrical conductors (3), which comprises a crimping die (4) that is formed from at least four crimping indenters (5), and additionally comprises at least one base plate (6) and at least one lever (19) with which the opening (7) of the crimping die (4) can be reduced by means of toggle-lever kinematics (14), as well as a force-path compensation device for absorbing the required remaining travel of the crimping die (4), as elastic deformation work, if said crimping die (4) has already travelled as far as it can go when crimping a wire end ferrule (2) but a distance still remains to be covered in order for a barrier (24) to release the opening of the crimping die (4), said force-path compensation device being in the form of a cascade spring (29) one part (32) of which is part of the base plate (6) and the other part (31) of which is part of the lever (19).

Owner:WEIDMUELLER INTERFACE GMBH & CO KG

Planar antenna with cover

ActiveUS9178275B2High bandwidthAllow useWaveguide hornsAntenna supports/mountingsElectricityDielectric

Provided is a planar antenna based system for use as a radar level meter, microwave barrier or other suitable system. The system includes a planar radiator element arranged on a substrate, and a cover plate element made from a dielectric to cover the planar radiator element. In one alternative embodiment, the cover plate includes a cavity proximate the planar radiator element, into which the microwaves generated by the planar radiator element can be coupled. In another alternative, the cover plate is provided in a surface-flush position against the substrate in the edge region of the cavity. These arrangements may be provided in a plurality so as to support an overall system containing multiple radiator elements.

Owner:VEGA GRIESHABER GMBH & CO

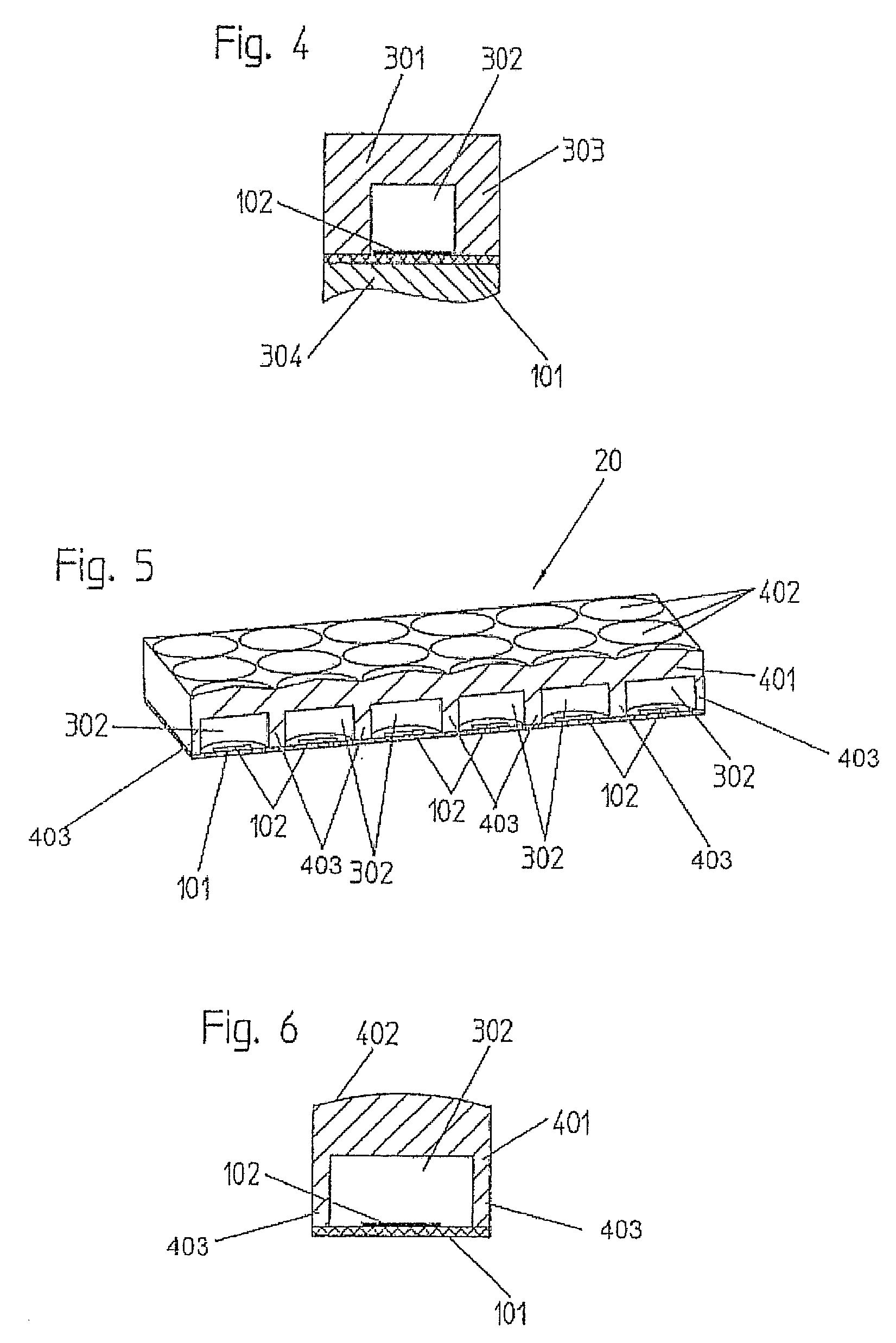

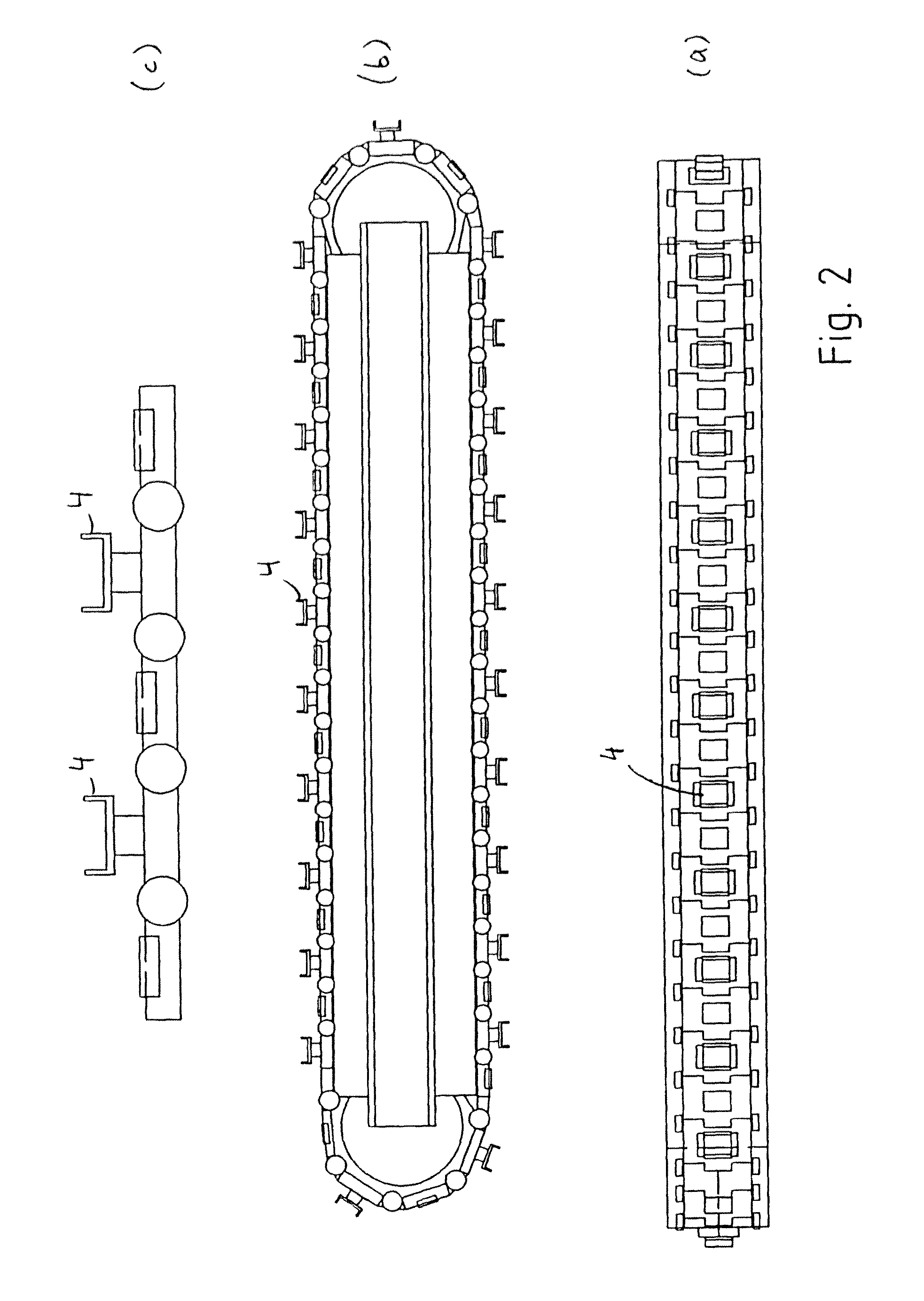

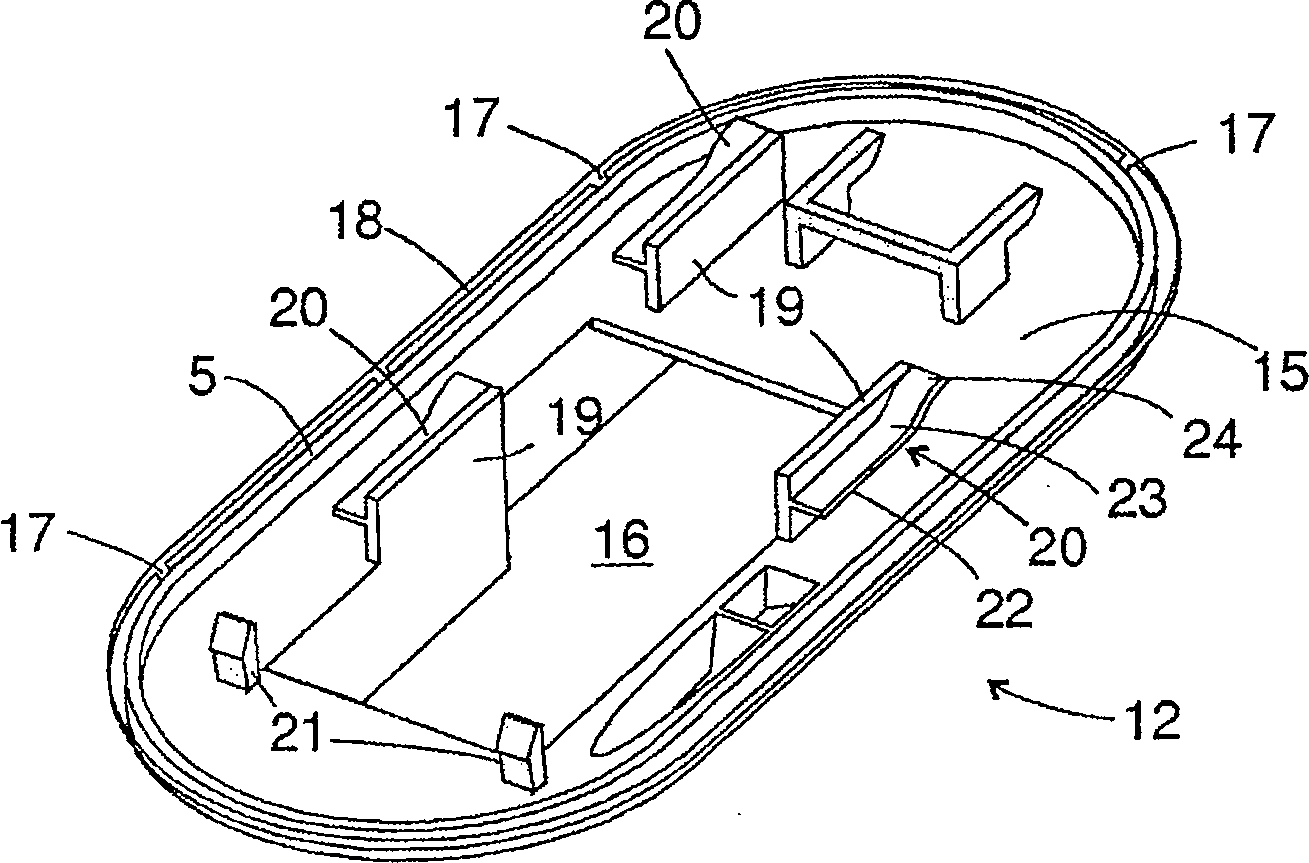

Conveyor device, conveyor chain as well as chain link

Owner:POLMAN ECKHARD

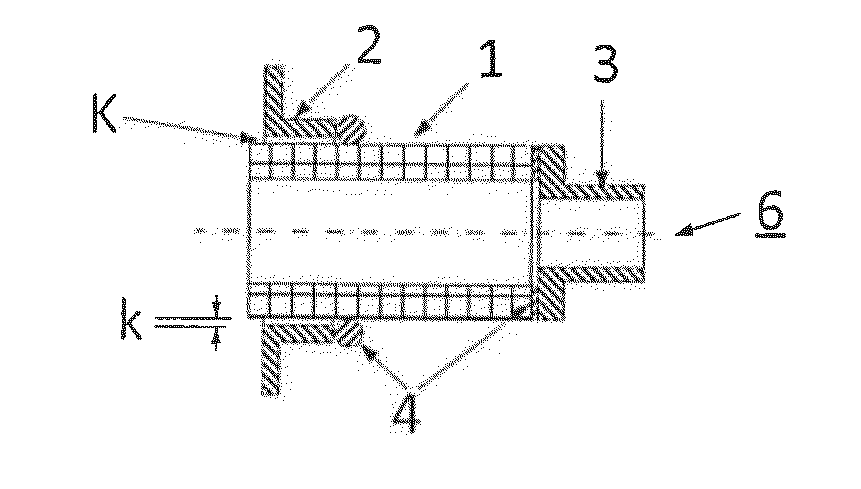

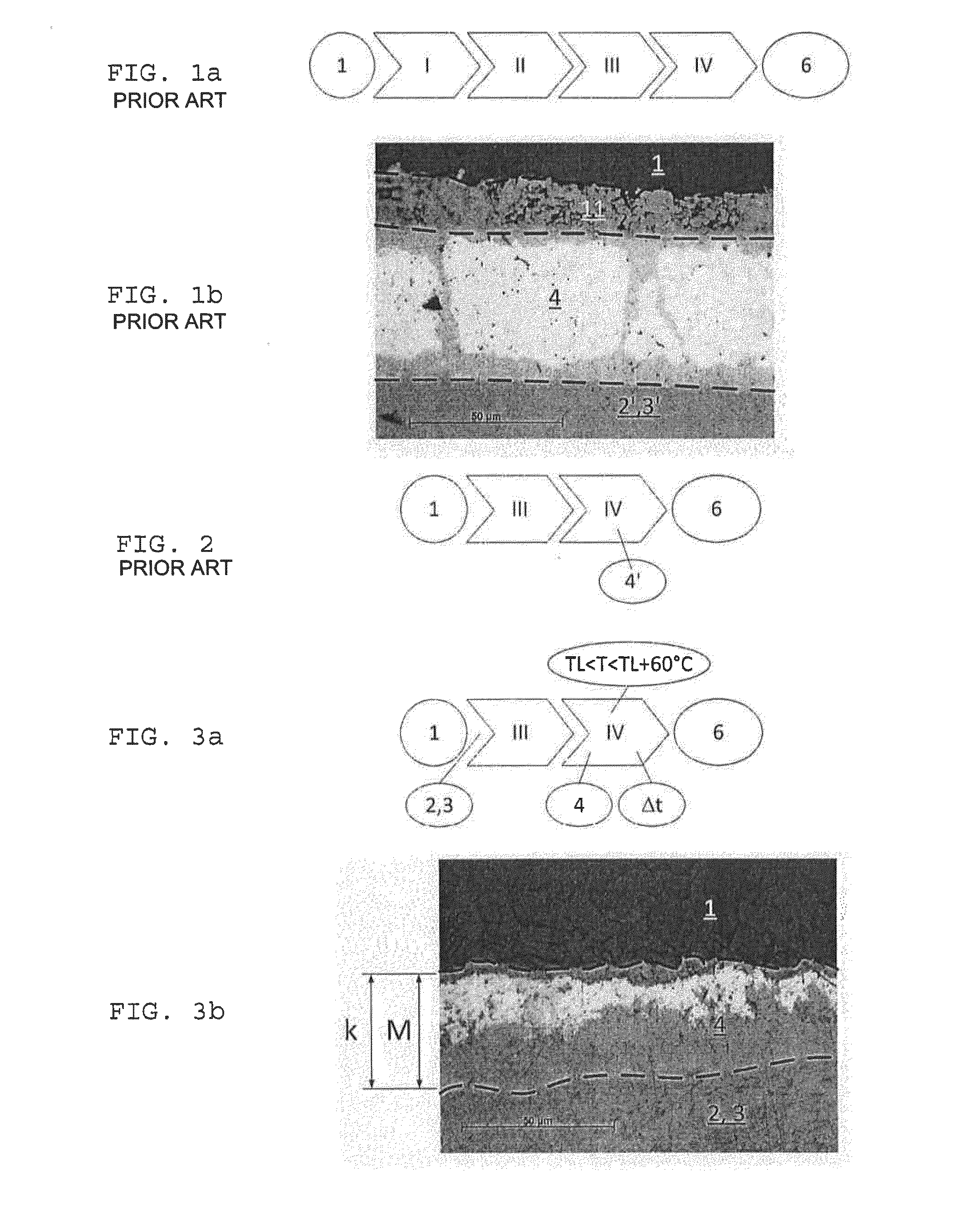

Method for producing a metal-ceramic soldered connection

InactiveUS20160228966A1Low costDifficult to procureWelding/cutting media/materialsWelding/soldering/cutting articlesSilicon oxideOxygen

A method for producing a material-bonding metal-ceramic soldered connection of an uncoated ceramic body to a metal part uses a metallic solder and begins by choosing the metal part with a 50% fraction of an oxygen-affine element; choosing the ceramic body with at least 80% aluminum oxide, zirconium oxide, silicon oxide or an alloy thereof; choosing an inactive, eutectic or near-eutectic solder; and forming a structure with the ceramic body and the metal part with an intermediate space between the their opposing surfaces. The solder is introduced into the intermediate space or the vicinity thereof. The structure is heated in a vacuum at a soldering temperature (T) greater than the liquidus temperature (TL) of the solder for a soldering period. The connection is applied between a ceramic bushing and a high-temperature sensor.

Owner:KISTLER HLDG AG

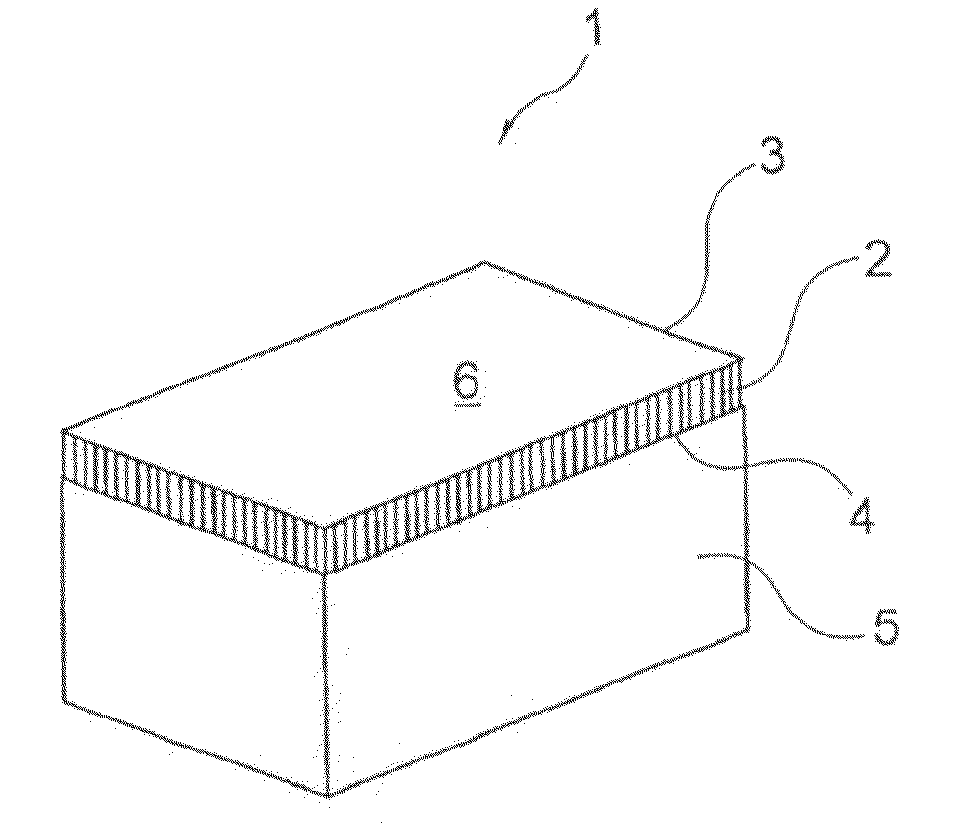

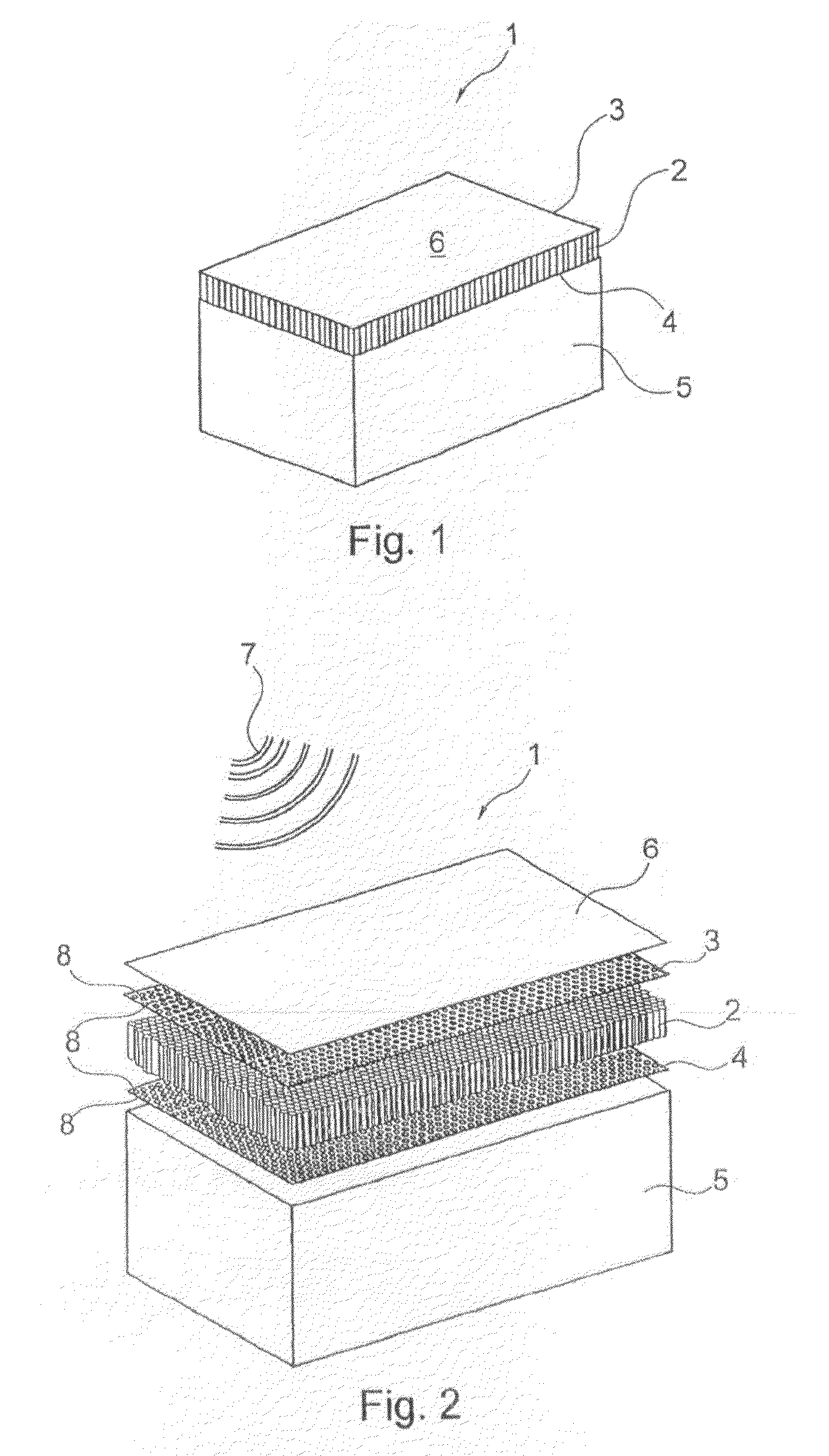

Sandwich element for sound-absorbing inner cladding of transport means, especially for sound-absorbing inner cladding of aircraft fuselage cells

InactiveUS20100247848A1Improve sound absorptionSolve insufficient capacityLayered productsFuselage insulationAirplaneHoneycomb

A sandwich element for a sound-absorbing inner cladding of transport means, such as aircraft fuselage cells, comprising a honeycomb-shaped core structure and cover layers applied to both sides of the core structure. At least one cover layer is constructed as permeable to air at least in sections and a covering is disposed at least in sections on at least one cover layer, wherein a sound absorption layer is disposed at least in sections in the area of at least one cover layer.A plurality of passages in the cover layers allow efficient transmission of the sound impinging on the sandwich element from outside as far as the sound absorption layer of the sandwich element.

Owner:AIRBUS OPERATIONS GMBH

Component for assembly on a wall with expanded foam behind the same and refrigerator provided with the same

ActiveCN100507412CDon't expect to hardenIncreased mechanical load capacityDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

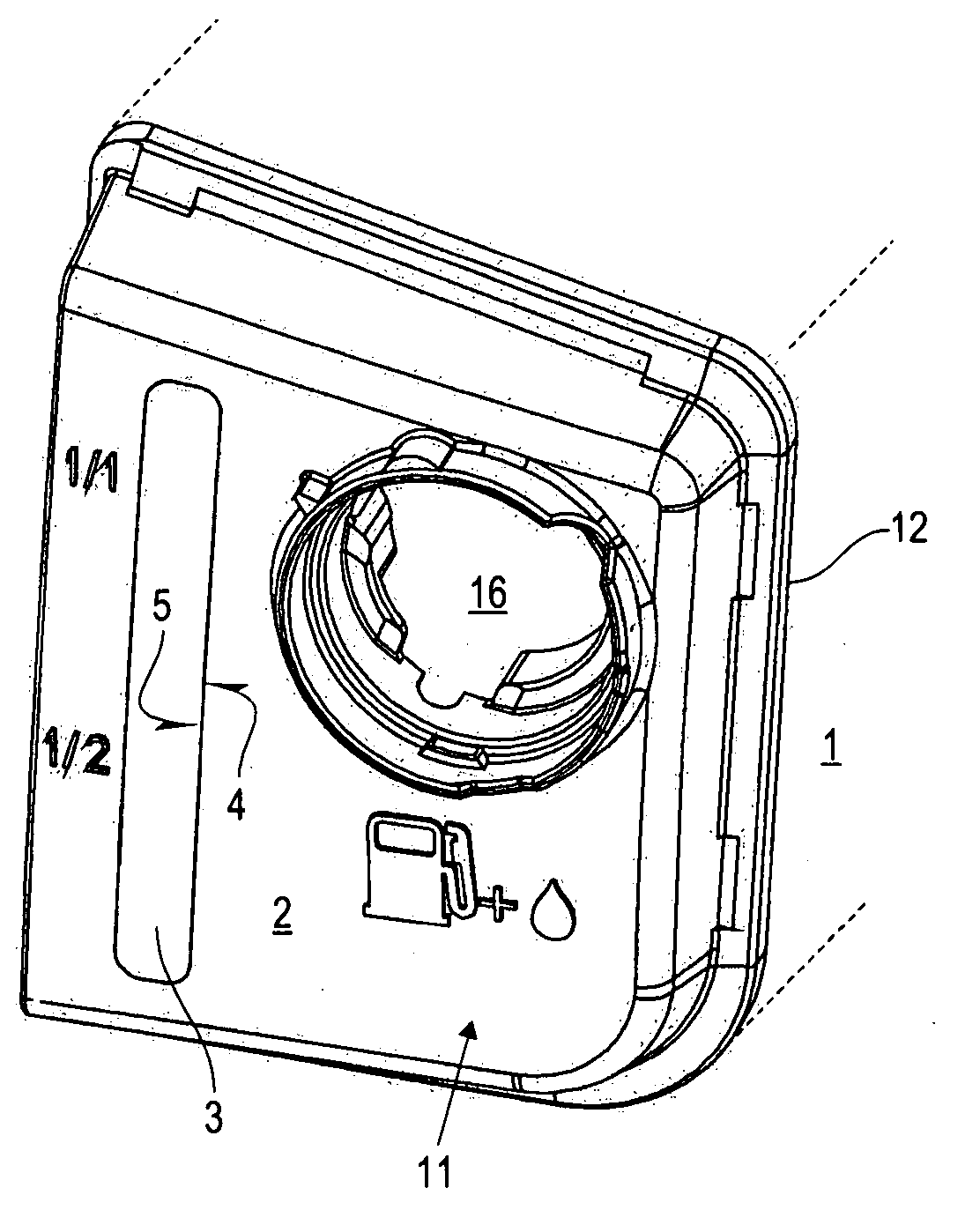

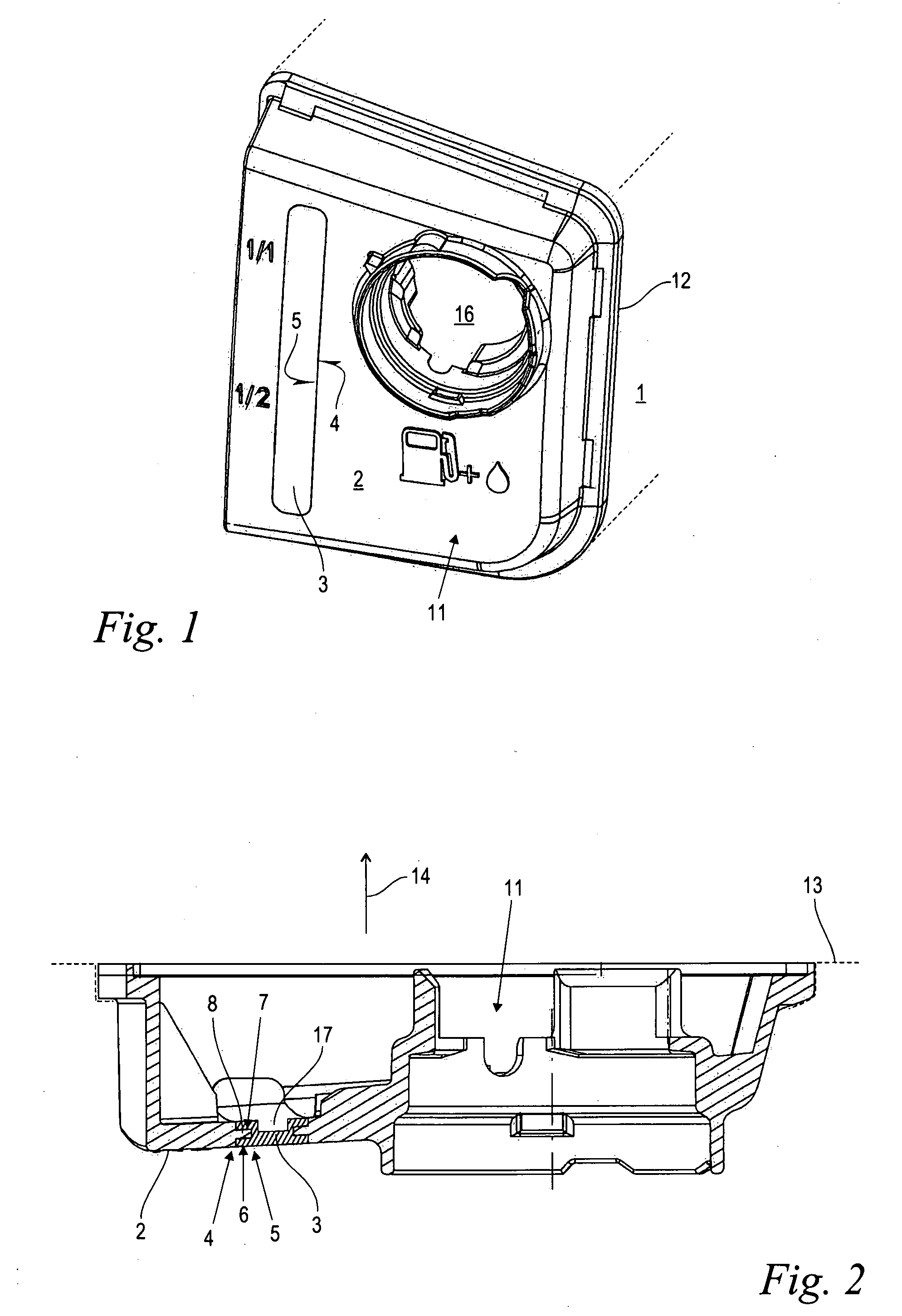

The invention relates to a component for assembly on an opening in a wall, comprising a component main body (1) and a flexible skirt (5), projecting from the main body (1), made from a more flexible material than the main body (1) and formed on the main body (1) in a sealing manner.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

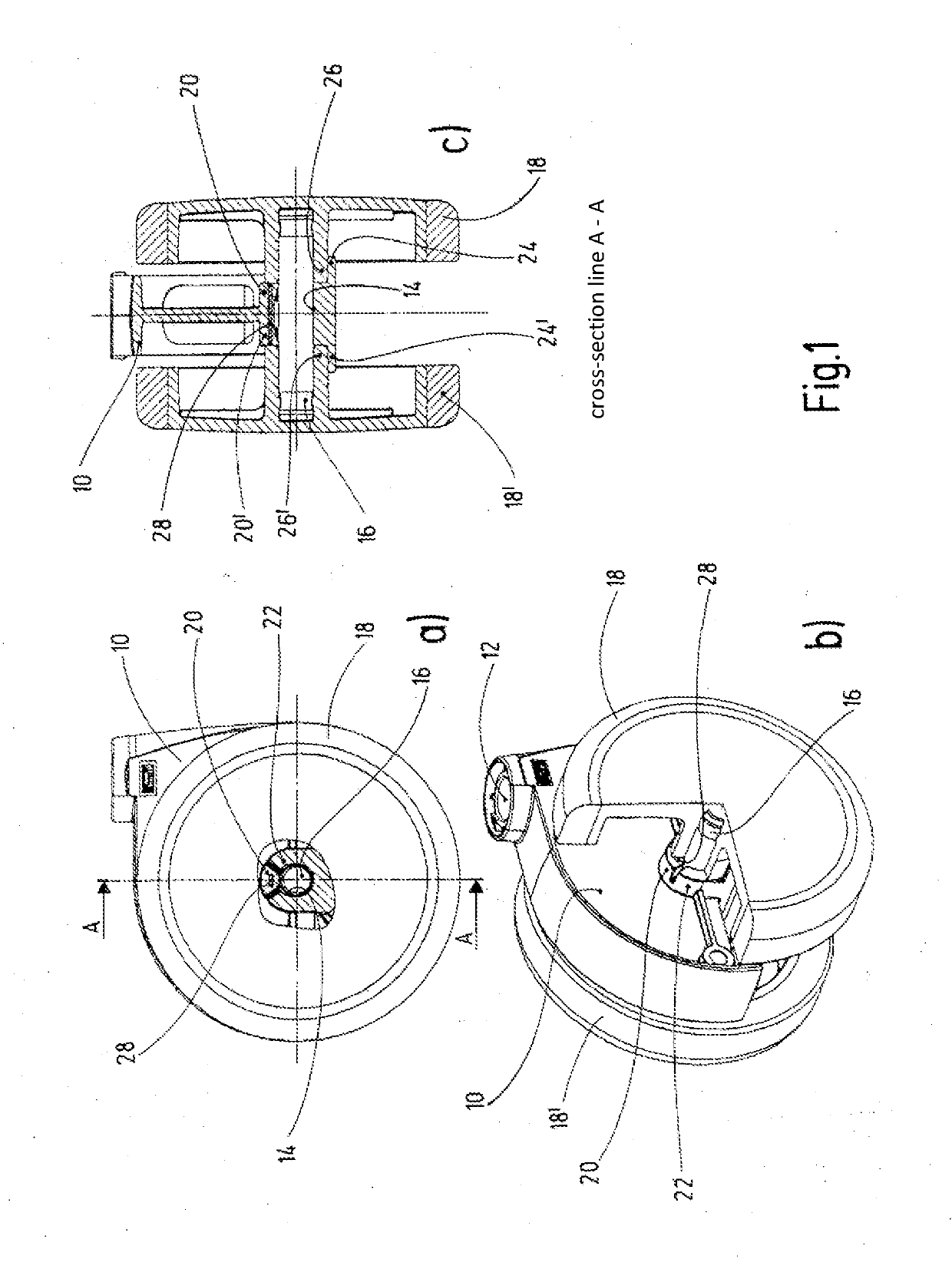

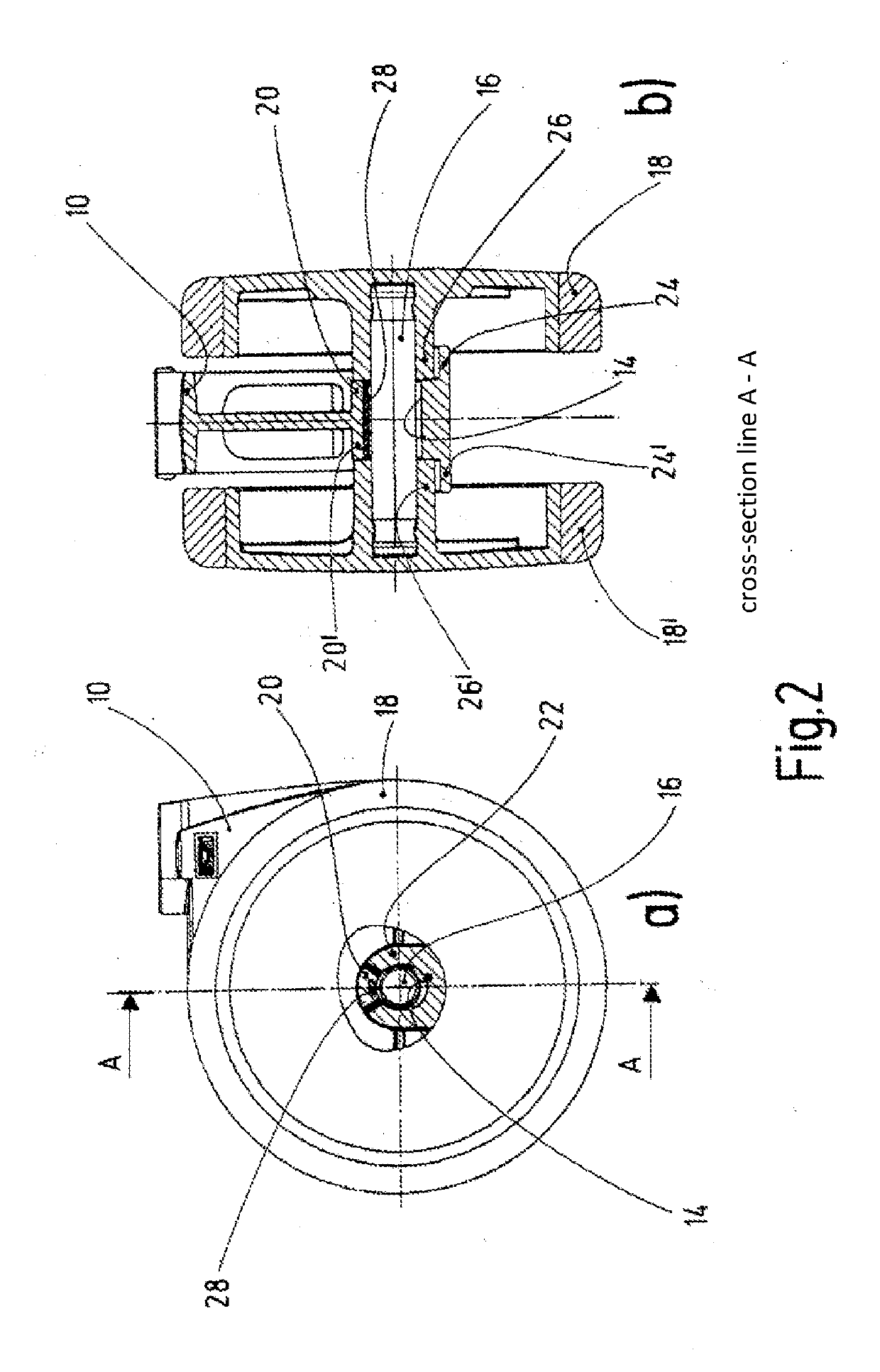

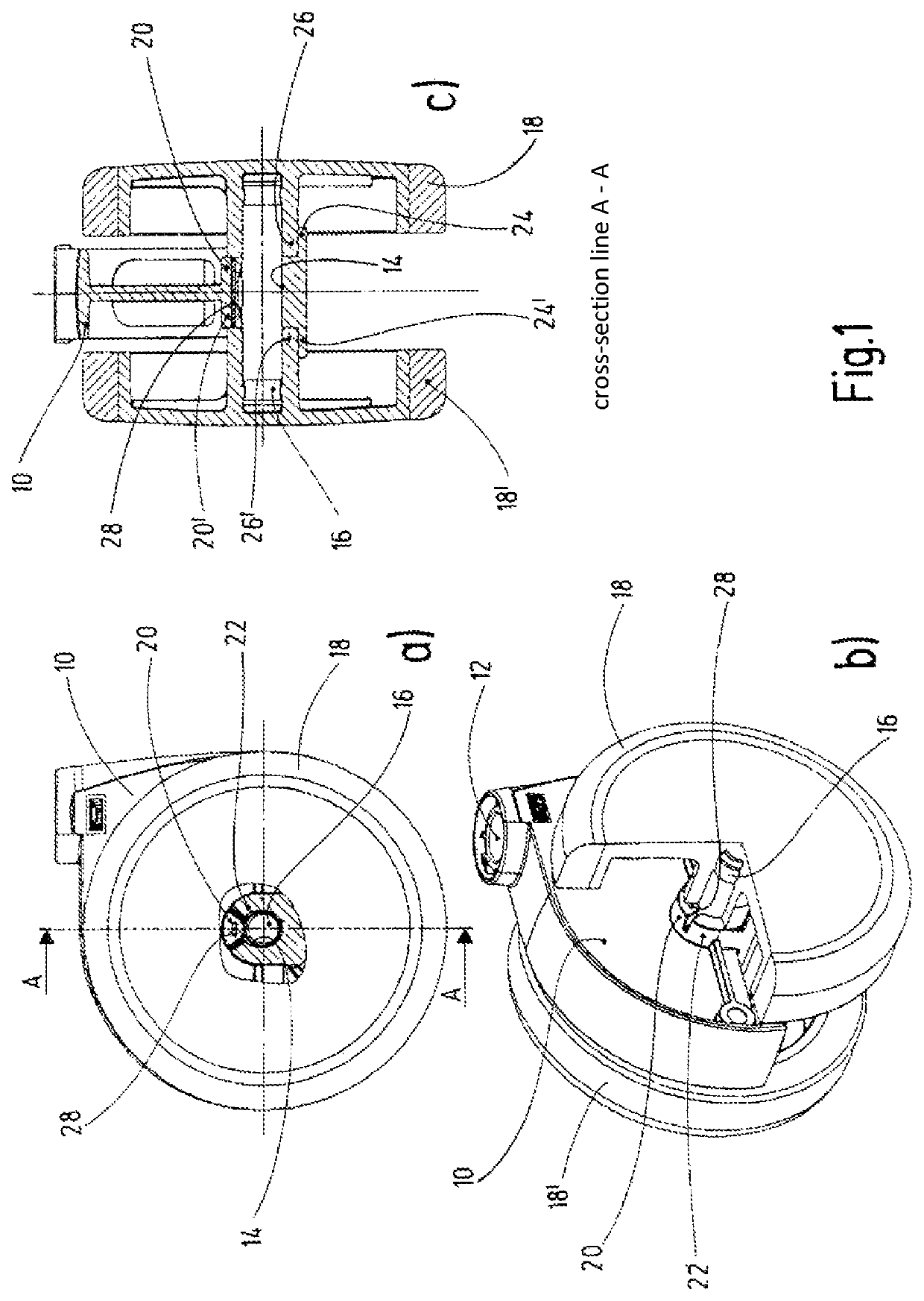

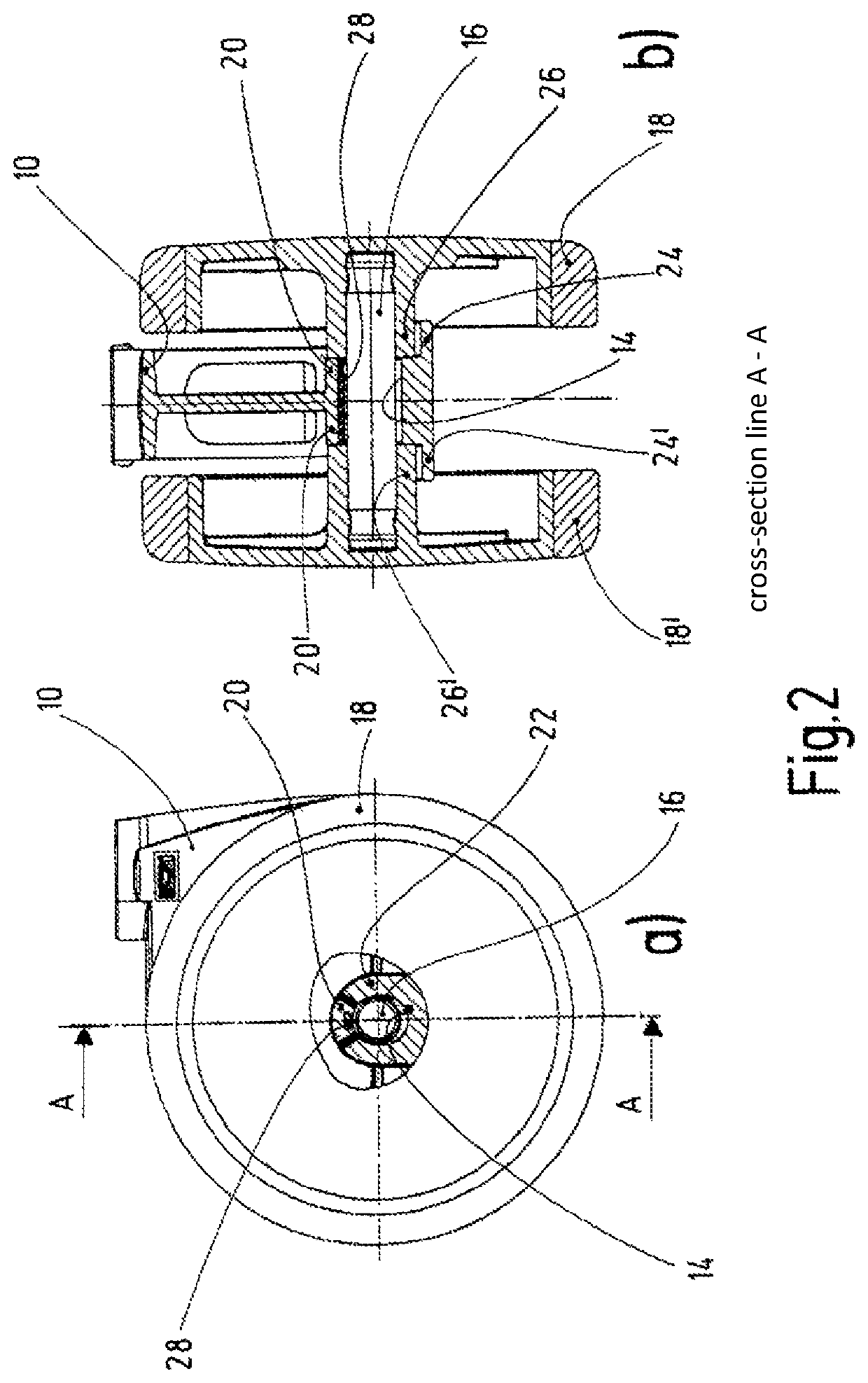

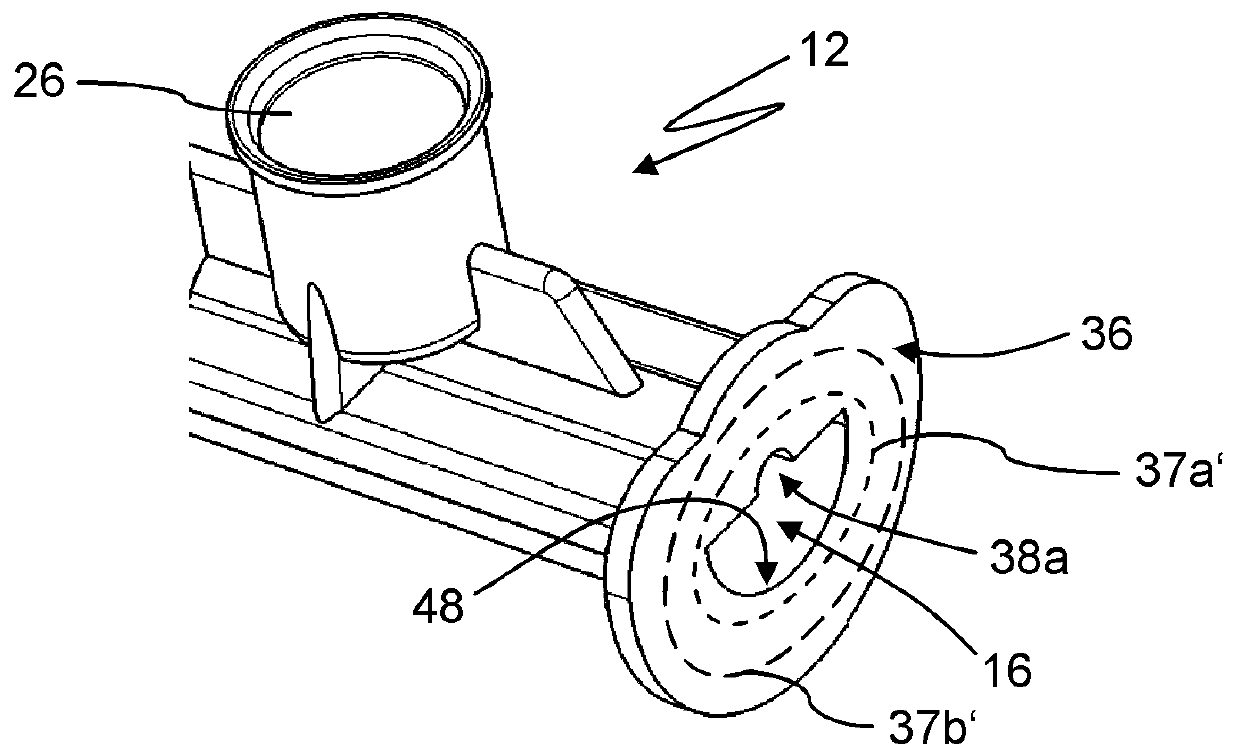

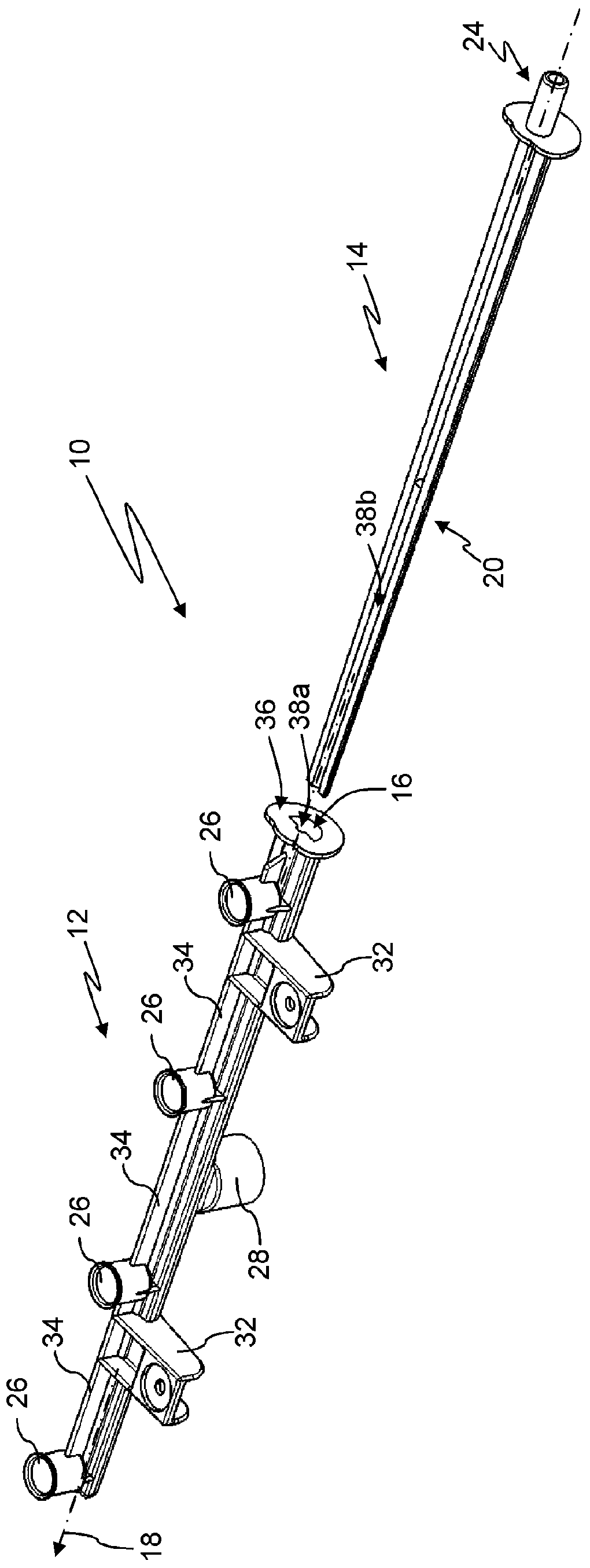

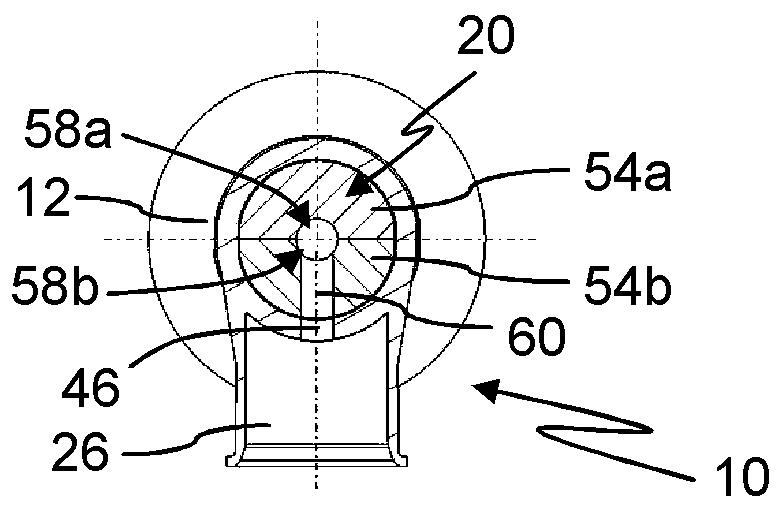

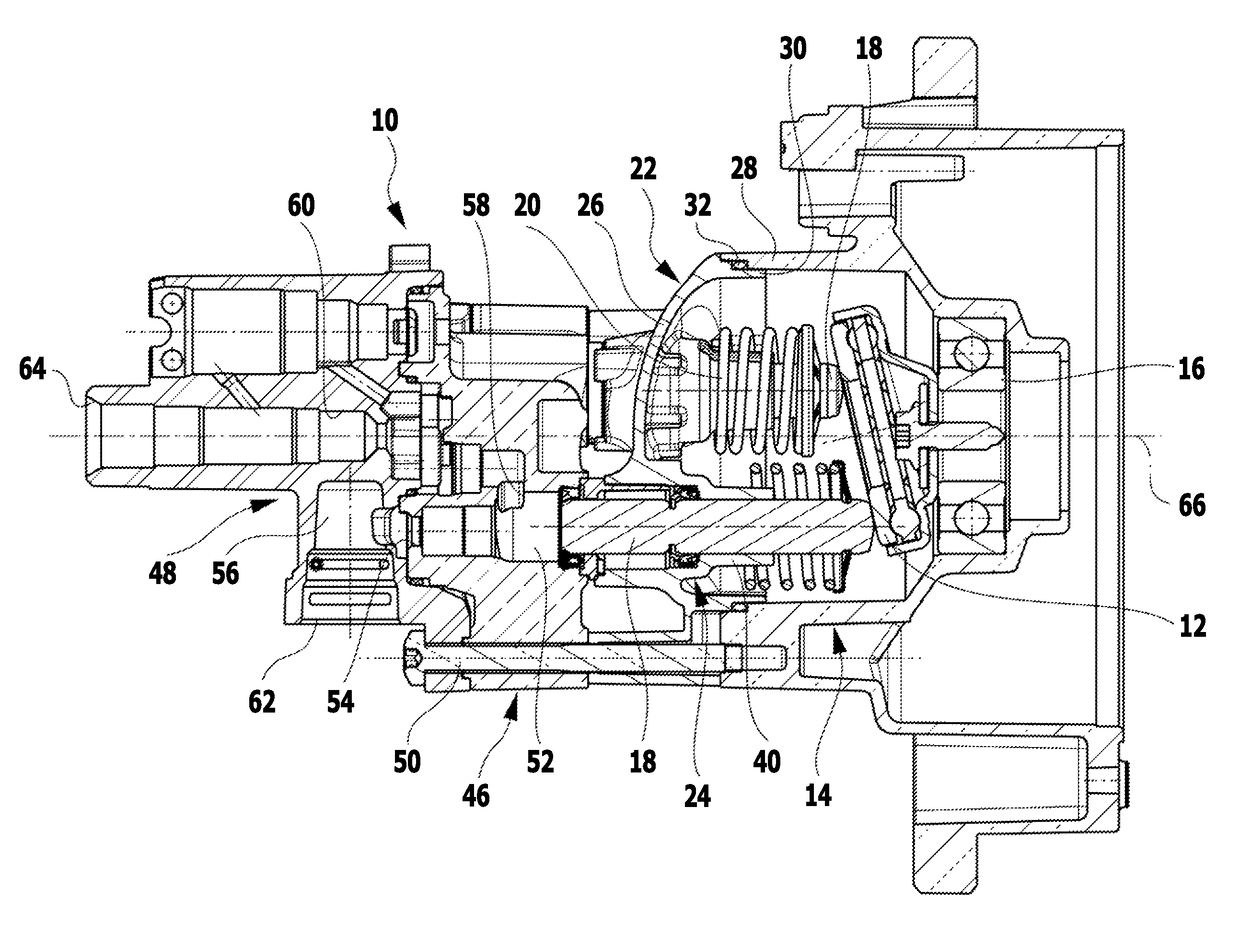

Caster with braking device

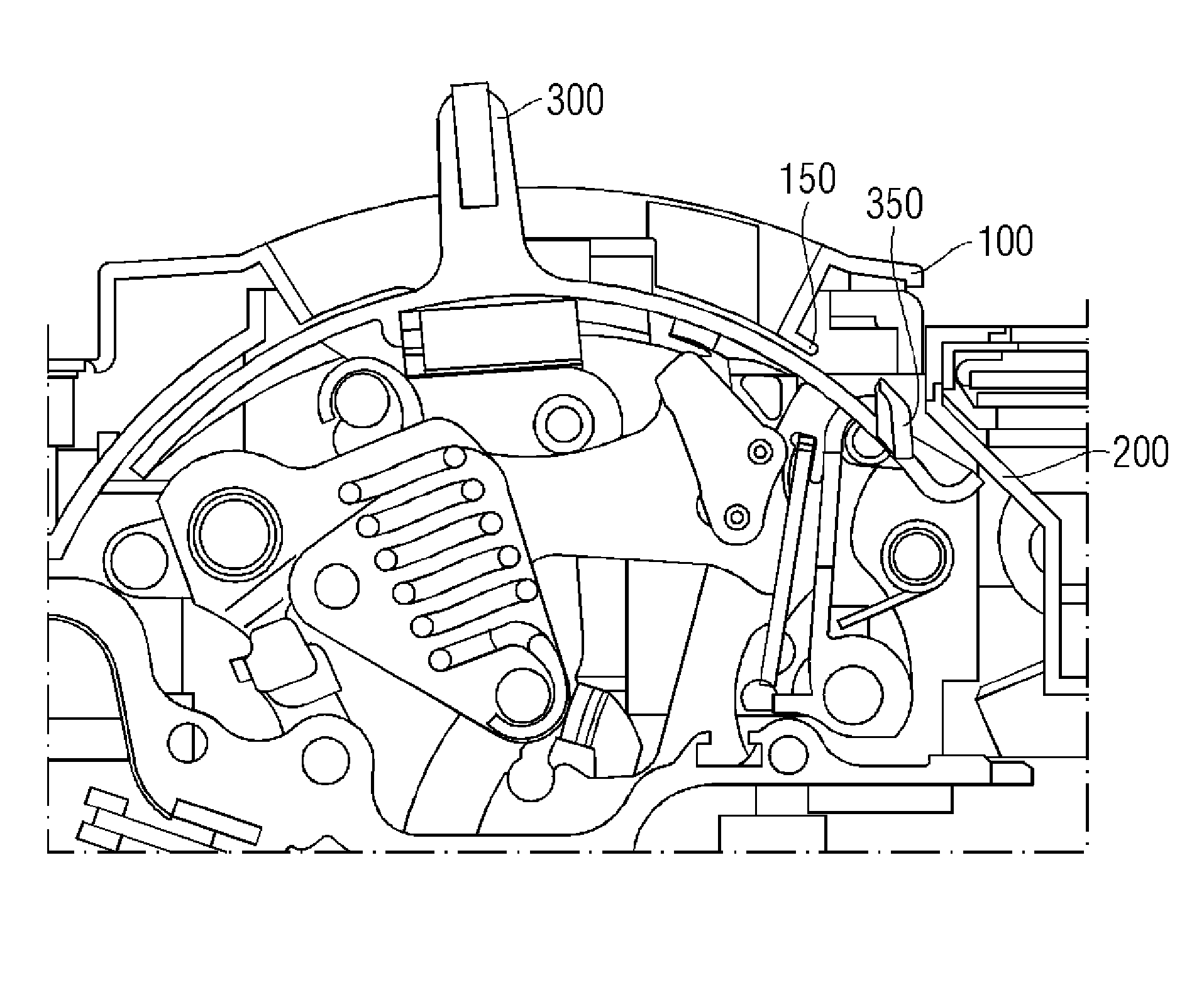

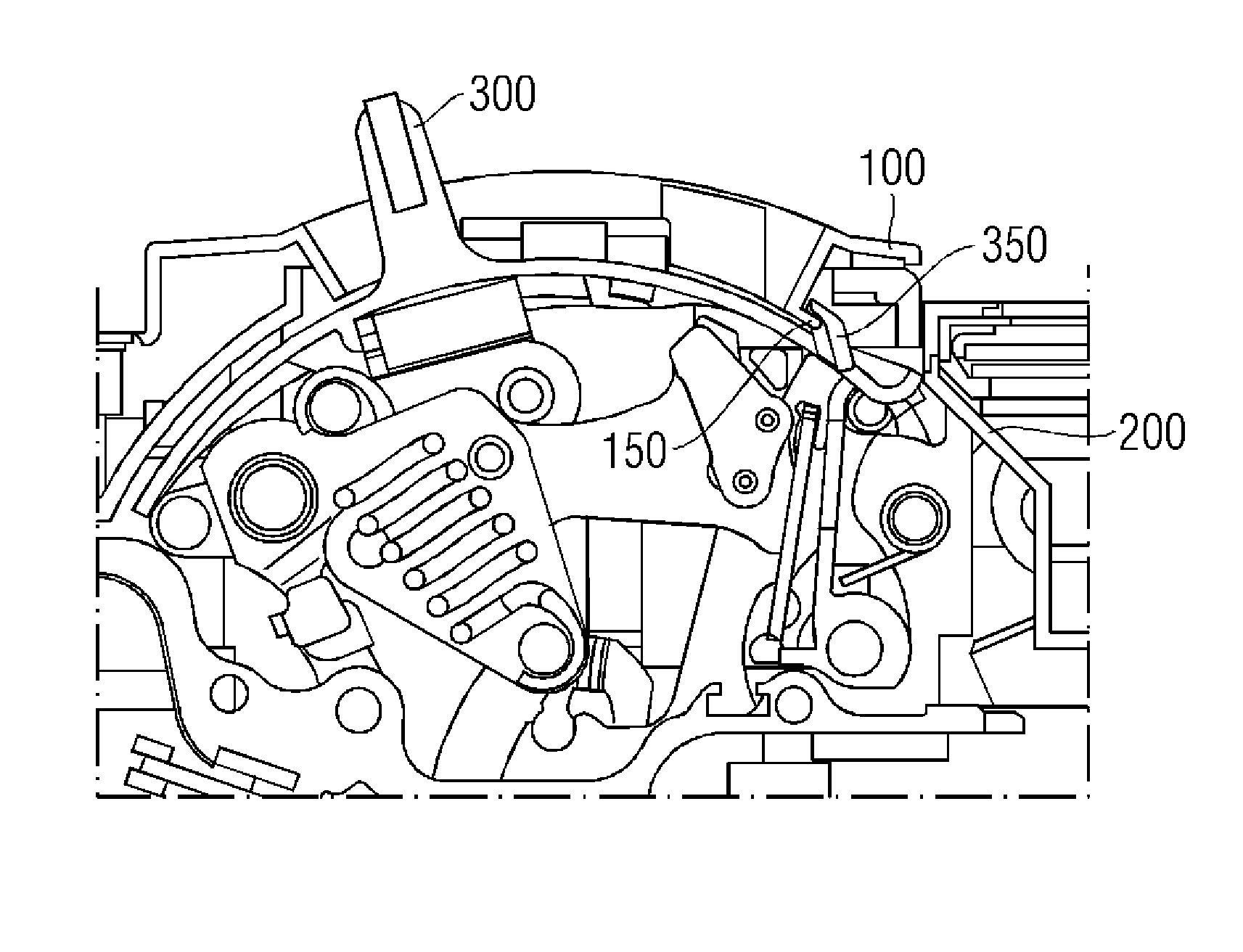

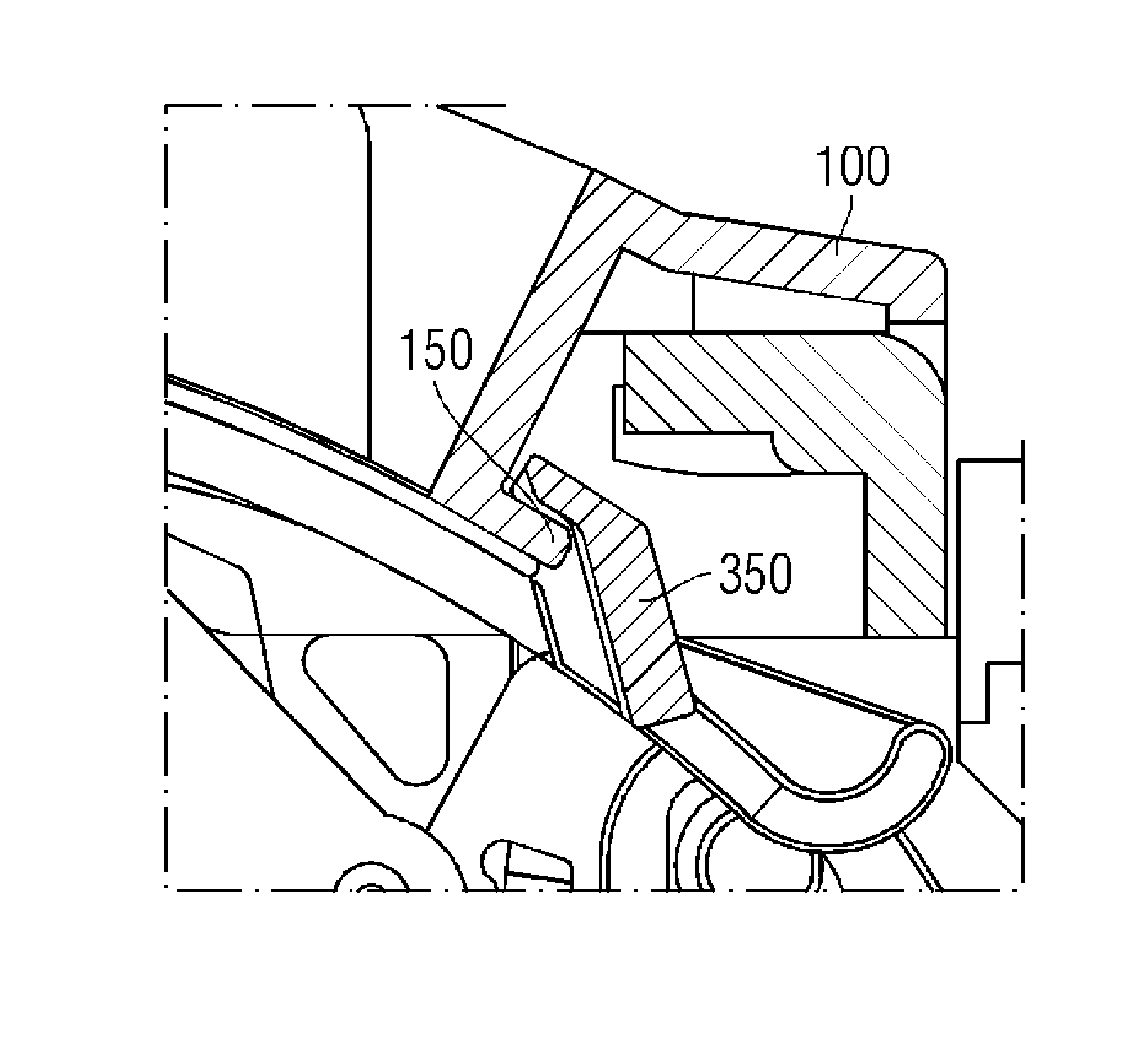

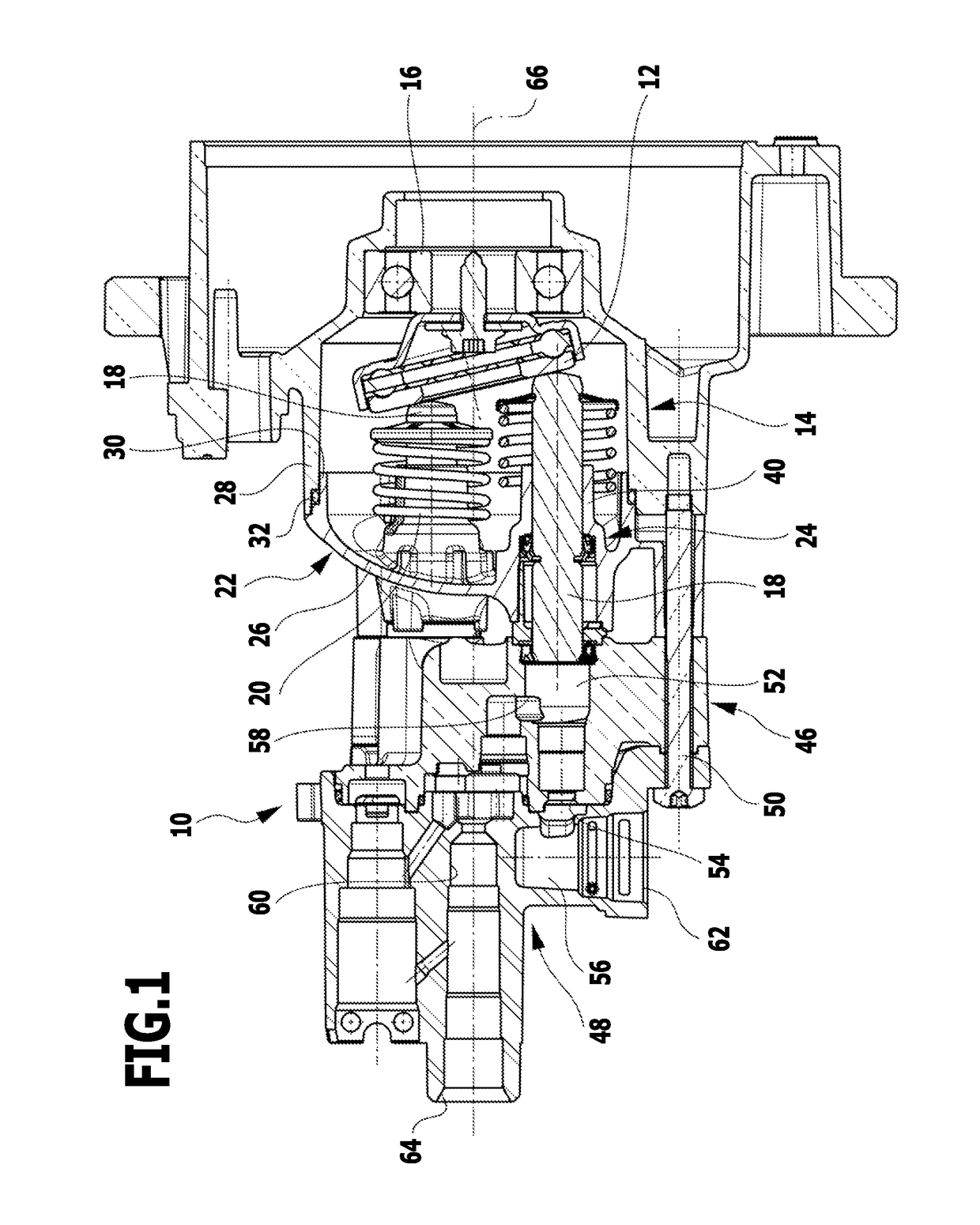

ActiveUS20190308450A1Increased mechanical load capacityImprove mechanical performanceCastorsEngineeringCaster

The present disclosure relates to a caster, having a housing, having an axle pin which is arranged in a housing opening which is oriented substantially horizontally, and on which at least one wheel is mounted, having, at the top, a pin opening oriented substantially vertically, for receiving a pivot pin, and having a braking device which brakes the at least one wheel, wherein the housing opening for the axle pin allows limited vertical displaceability of the axle pin and the braking device comprises at least one resilient housing part which acts on the axle pin. In order to provide a mechanically reliable braking device, the braking device is additionally provided with at least one spring element which cooperates with the at least one resilient housing part and amplifies the effect of its braking force and / or increases the mechanical load-bearing capacity of the at least one resilient housing part.

Owner:GROSS FROELICH

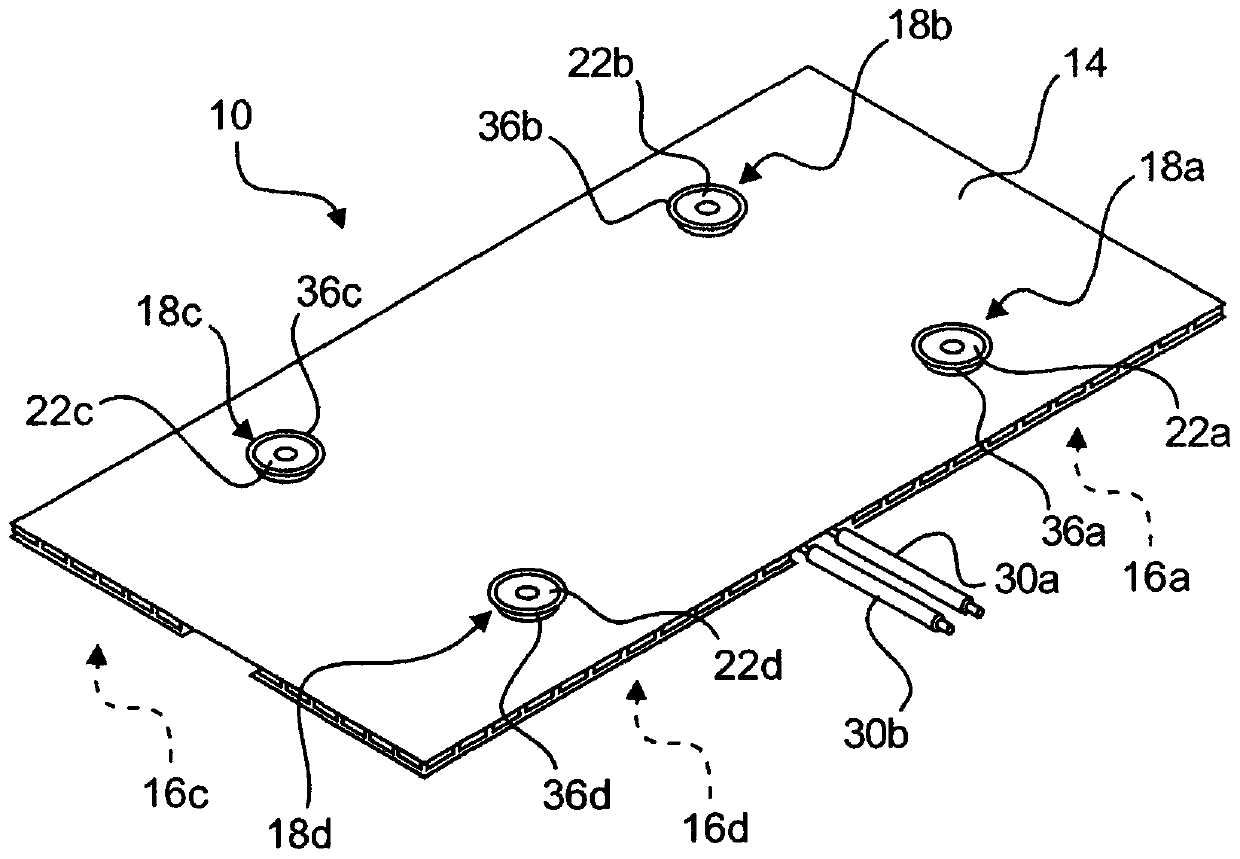

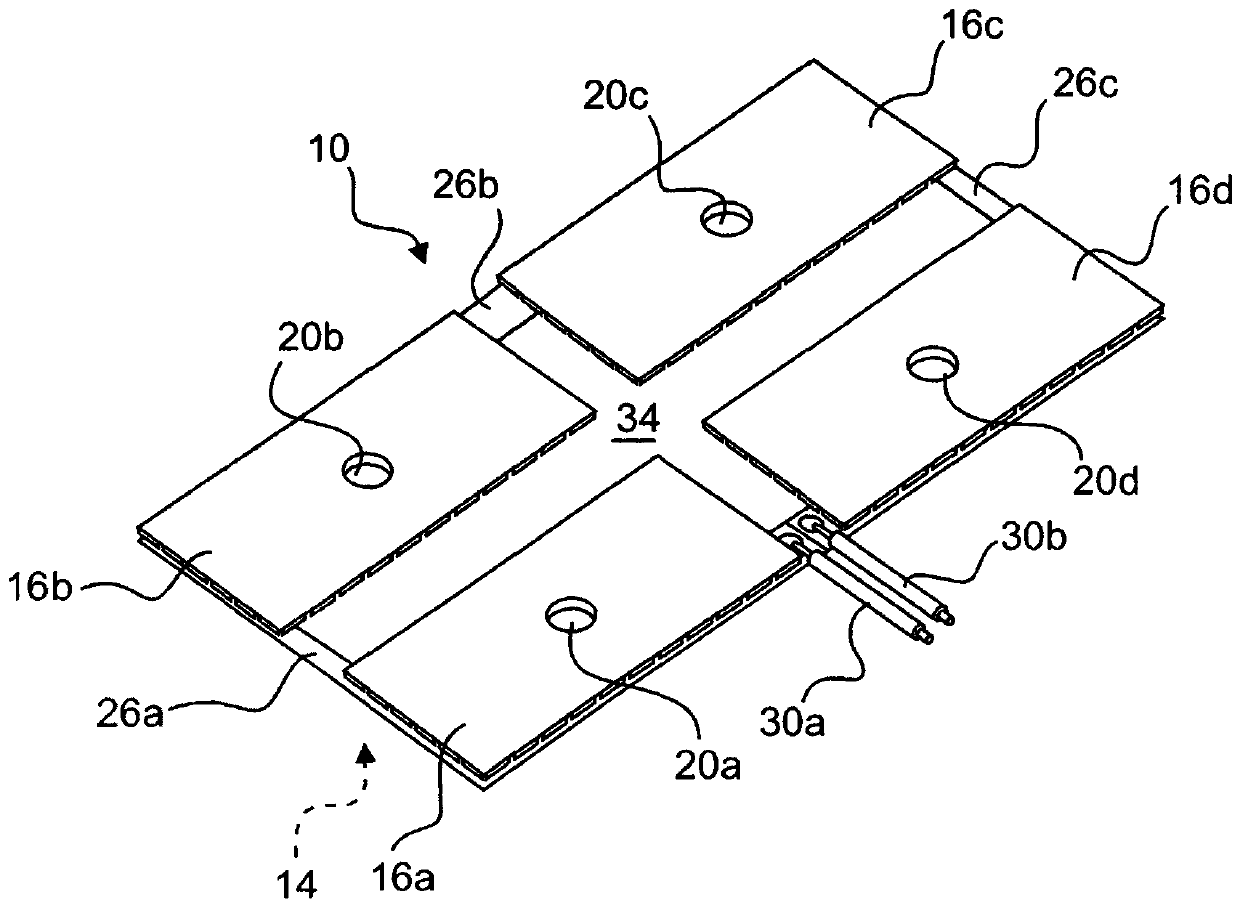

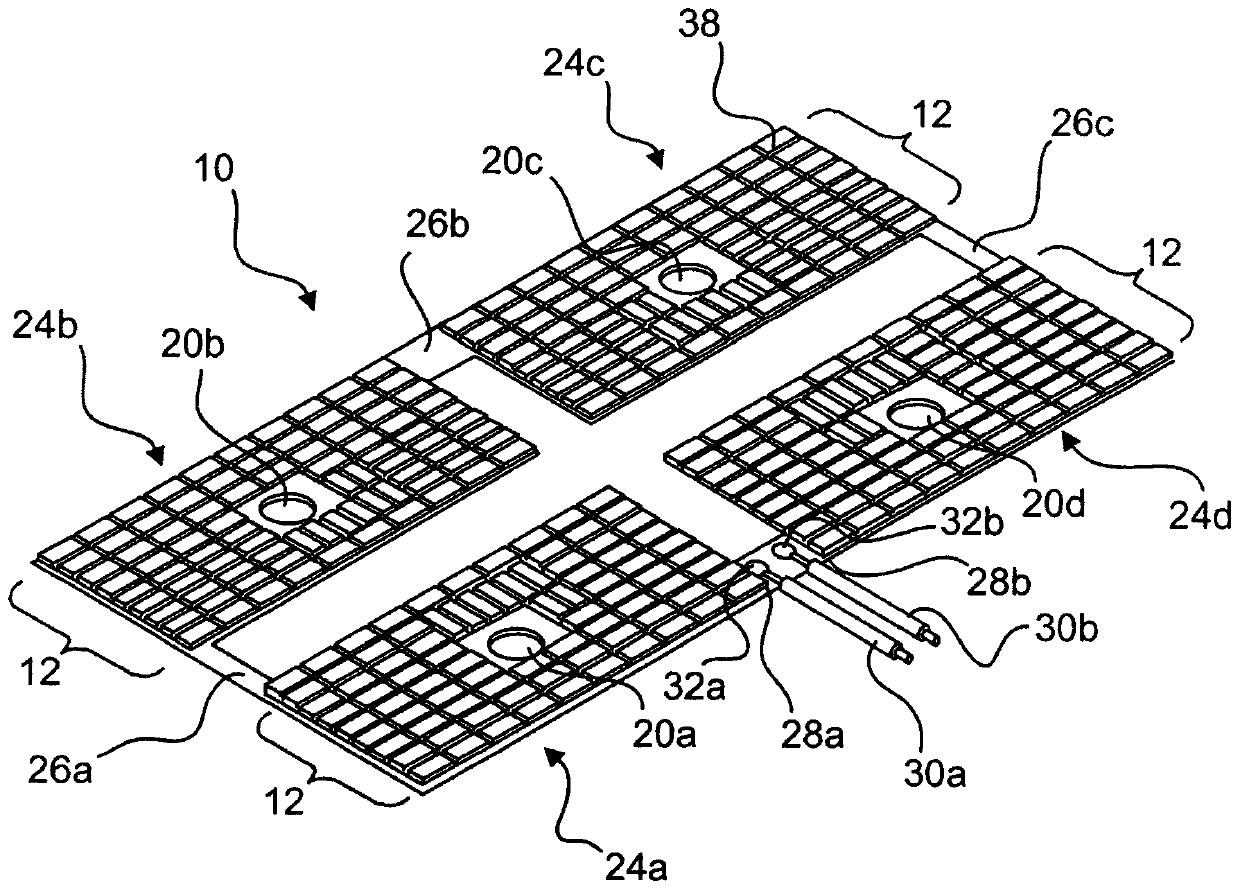

Thermoelectric device

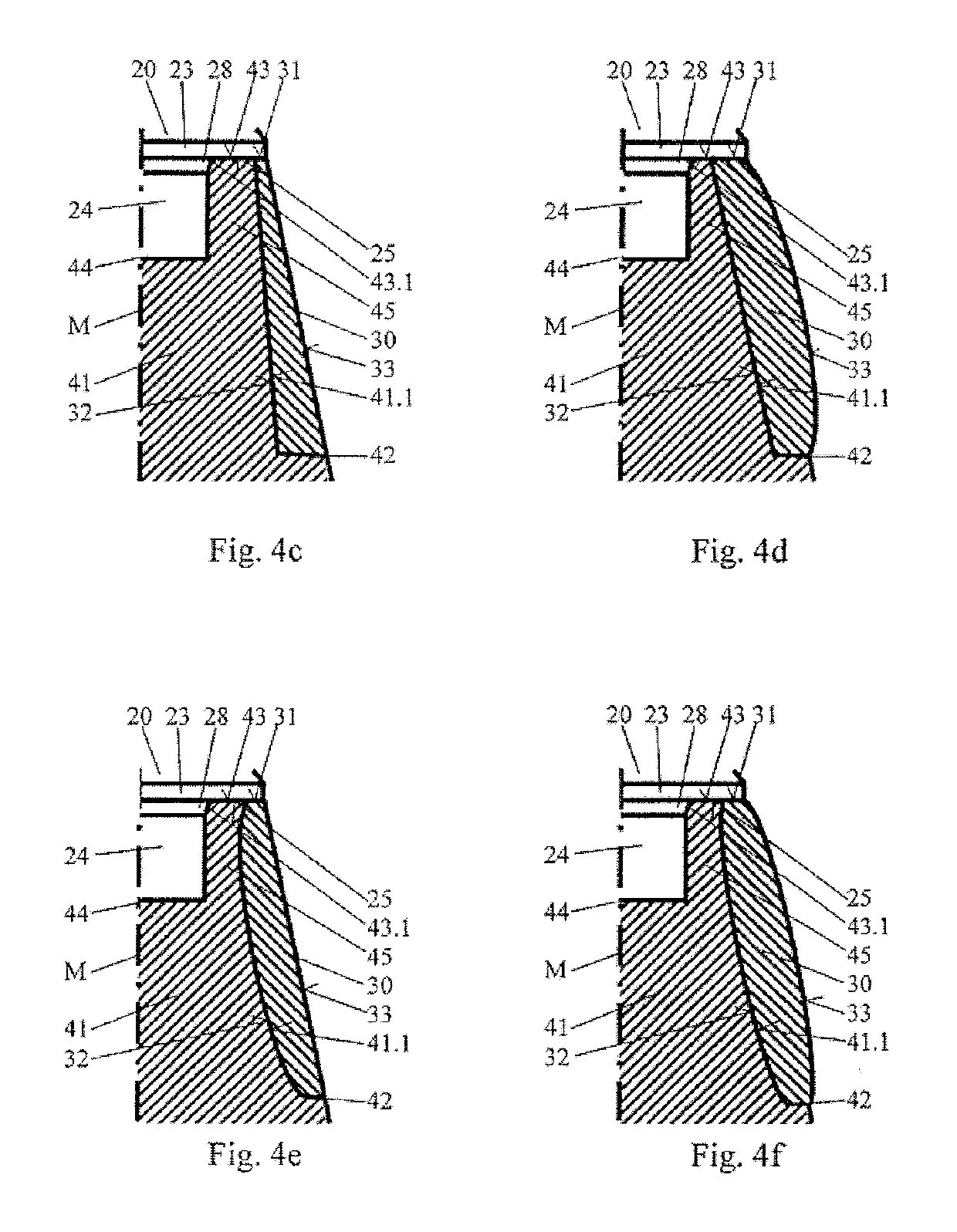

InactiveCN110073149AAvoid mechanical stressReduce risk of damageVehicle seatsAir-treating devicesEngineeringSemiconductor

The invention relates to a thermoelectric device (10), having a plurality of differently doped semiconductors (12), which are connected to each other in an electrically conductive manner, having at least one carrier substrate (14), which is arranged on a first side of the semiconductor (12), and having at least one carrier substrate (16a-16d), which is arranged on a second side of the semiconductor (12), opposite the first side, wherein at least one carrier substrate (14, 16a-16d) arranged on the first side or the second side of the semiconductor (12) has at least one recess (18a-18d, 20a-20d)extending through the carrier substrate (14, 16a-16d) and surrounded by substrate material, which is designed to receive a fastening means (22a-22d).

Owner:GENTHERM INC

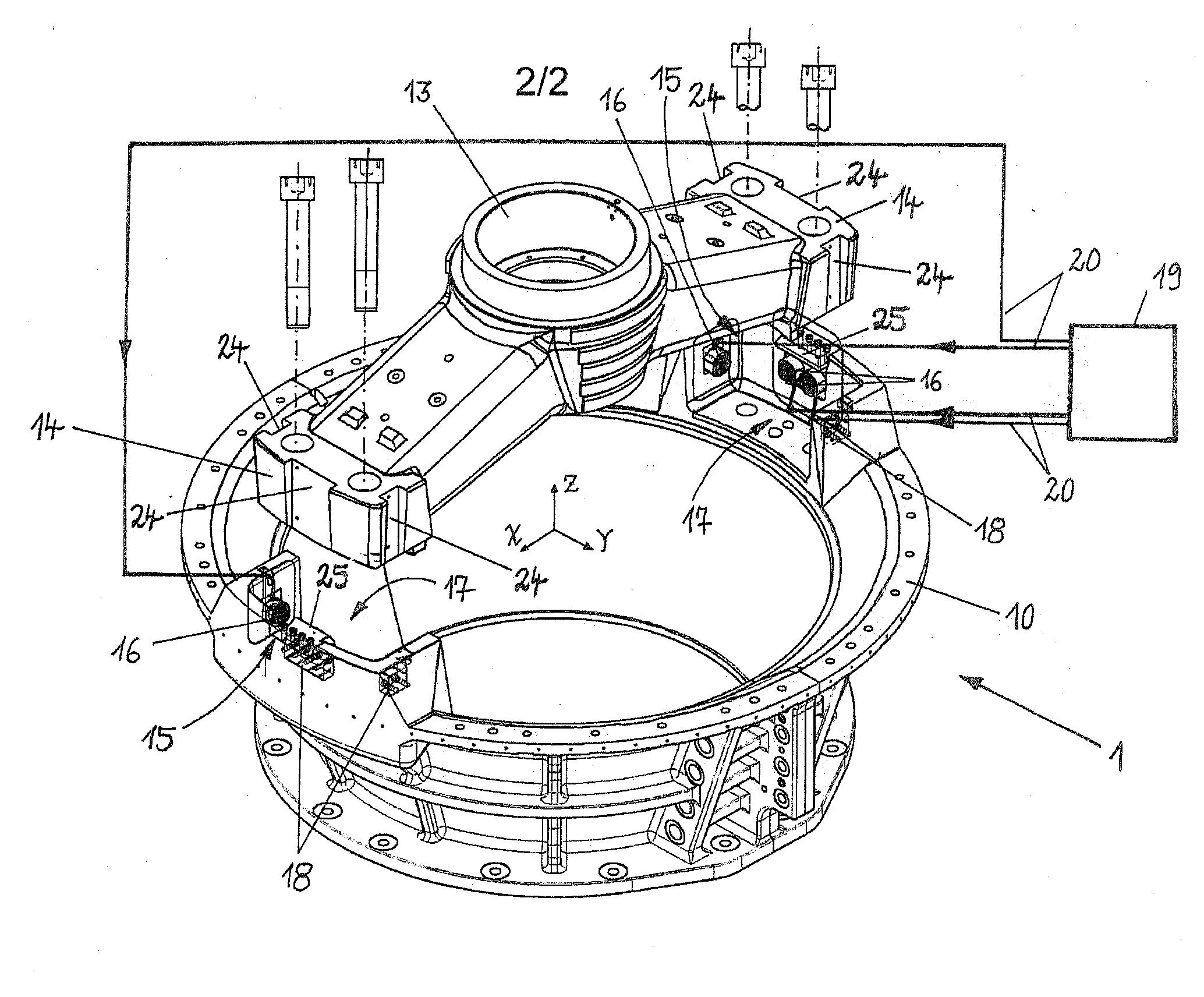

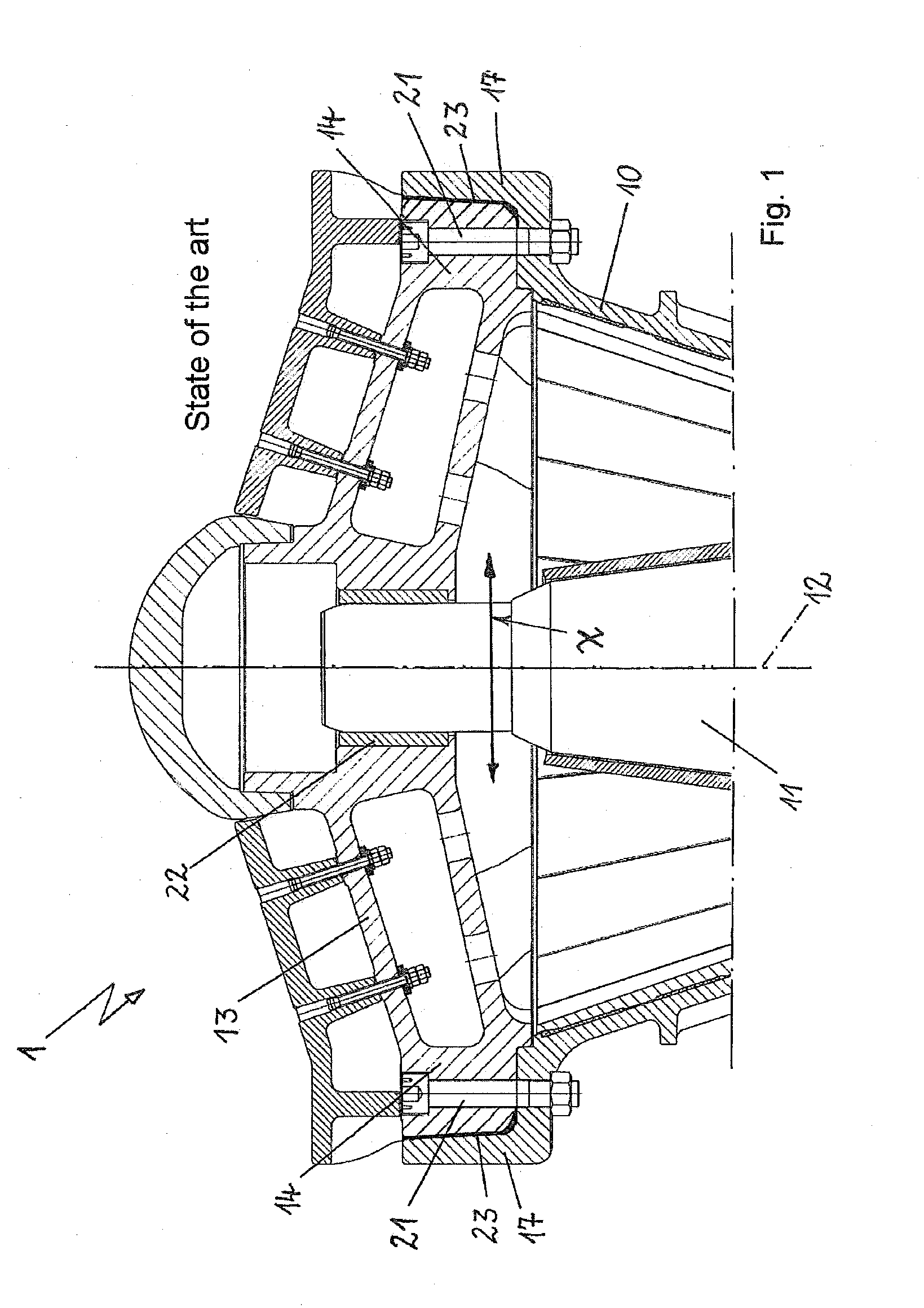

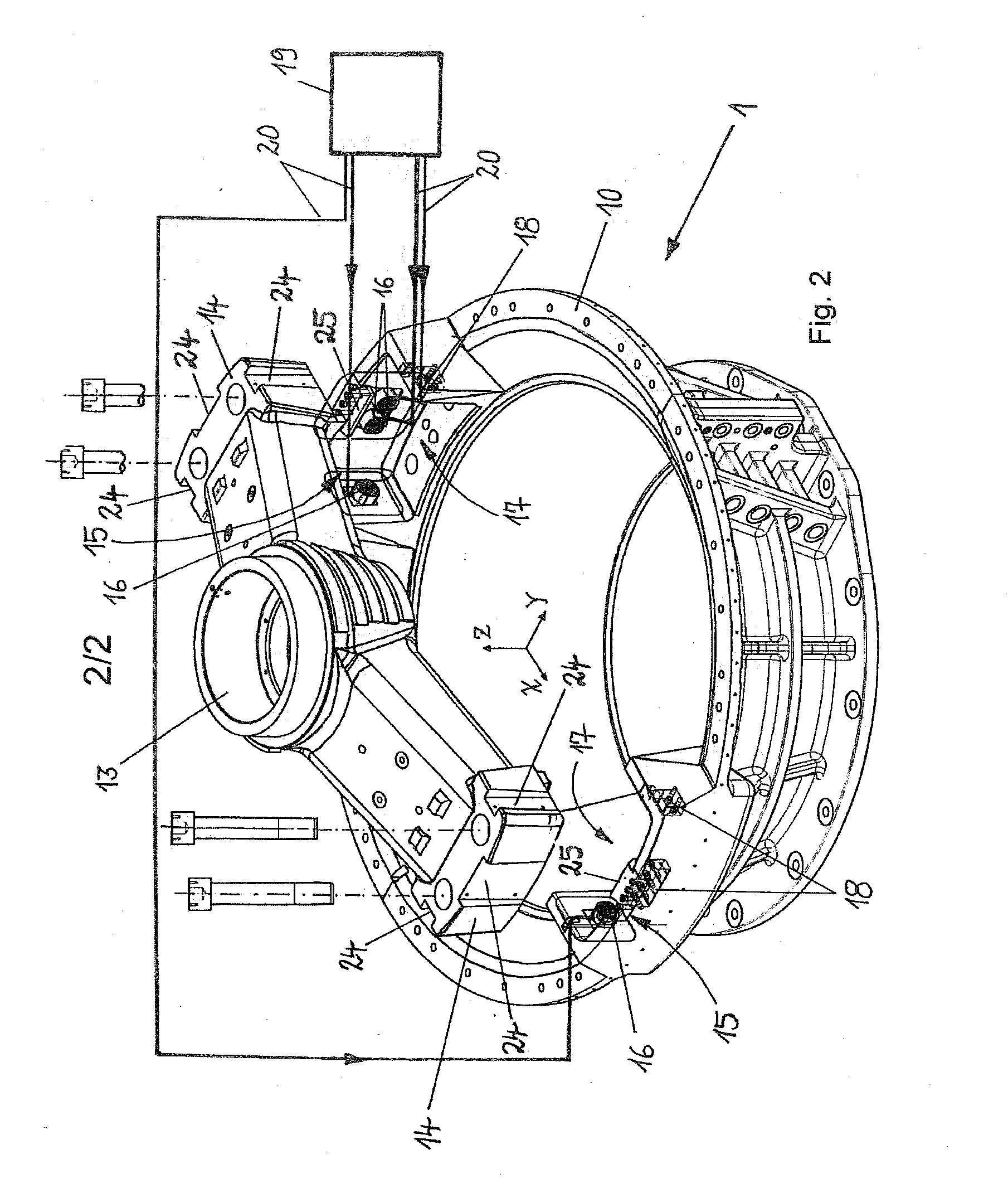

Gyratory crusher for comminuting material to be crushed

ActiveUS20150273475A1Increased mechanical load capacityEasy to disassembleLoad modified fastenersScrewsEngineeringCrusher

The invention relates to a gyratory crusher for comminuting material to be crushed, comprising a crusher housing, in which a crusher shaft is arranged, said shaft being held in the crusher housing so that it can tumble about a vertical axis. To accommodate the crusher shaft, the crusher is provided with a cross member which extends diametrically across the crusher housing and the cross member ends of which are connected to the crusher housing. According to the invention, the connection of the cross member ends to the crusher housing has at least one hydraulic tensioning device.

Owner:F L SMIDTH & CO AS

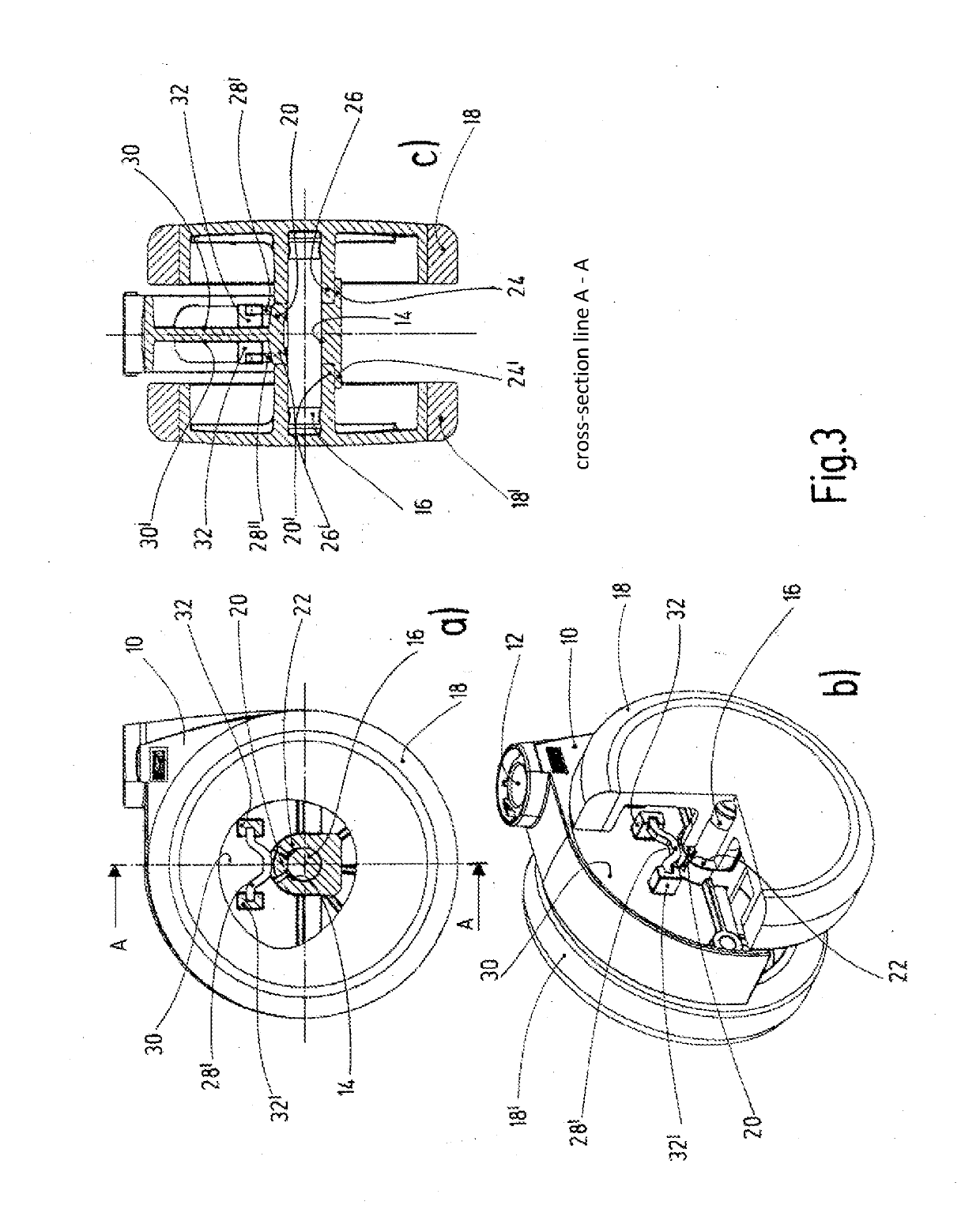

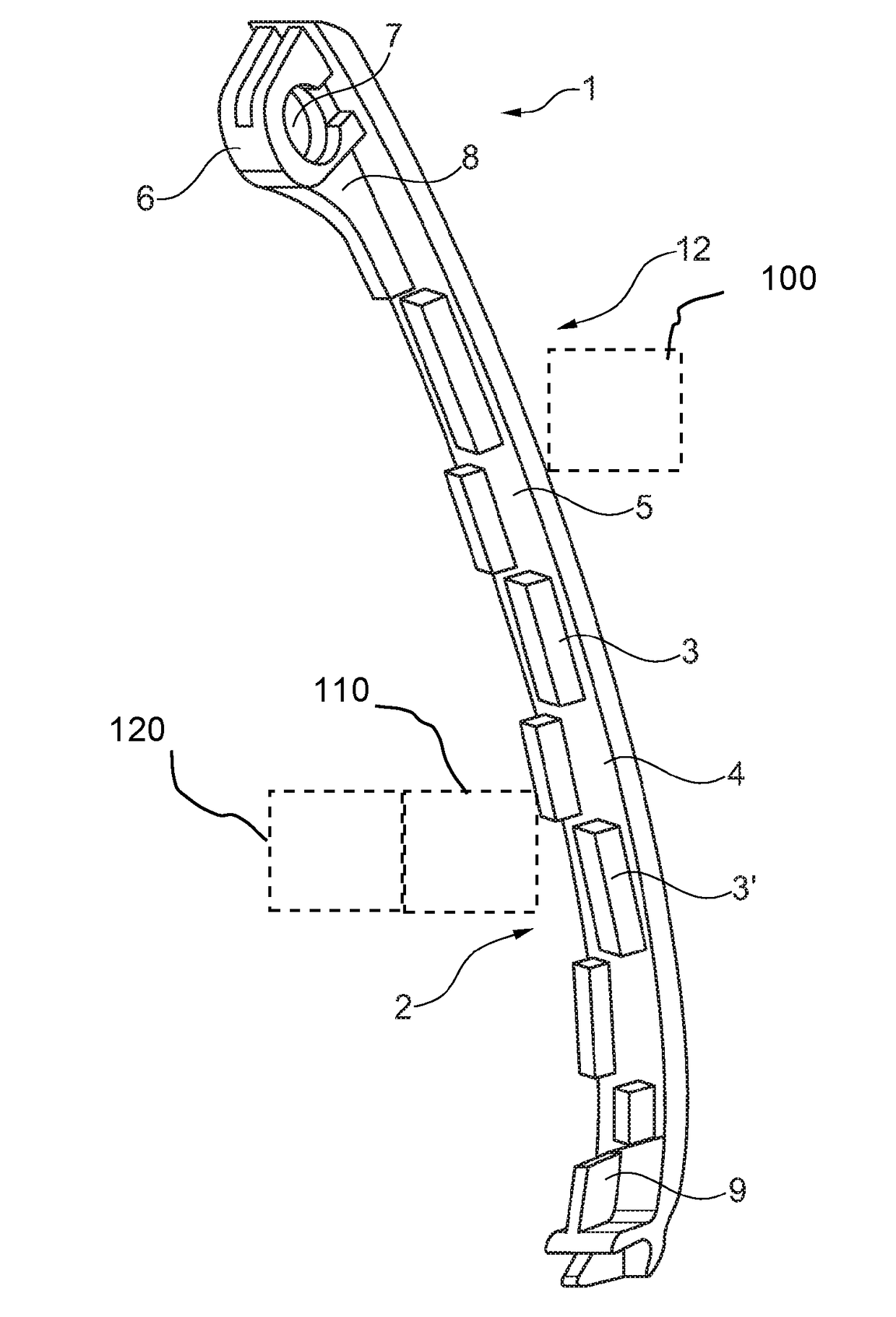

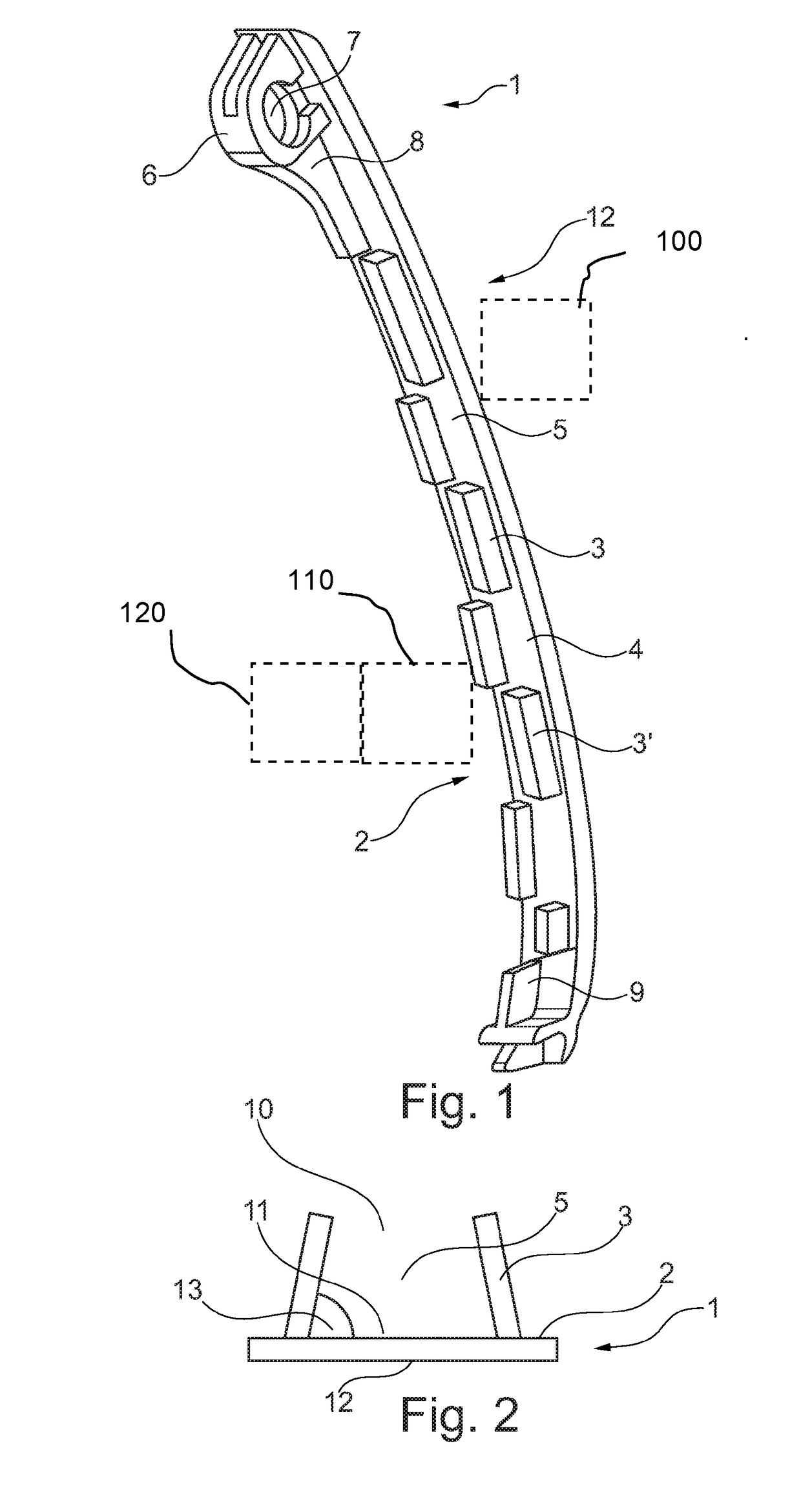

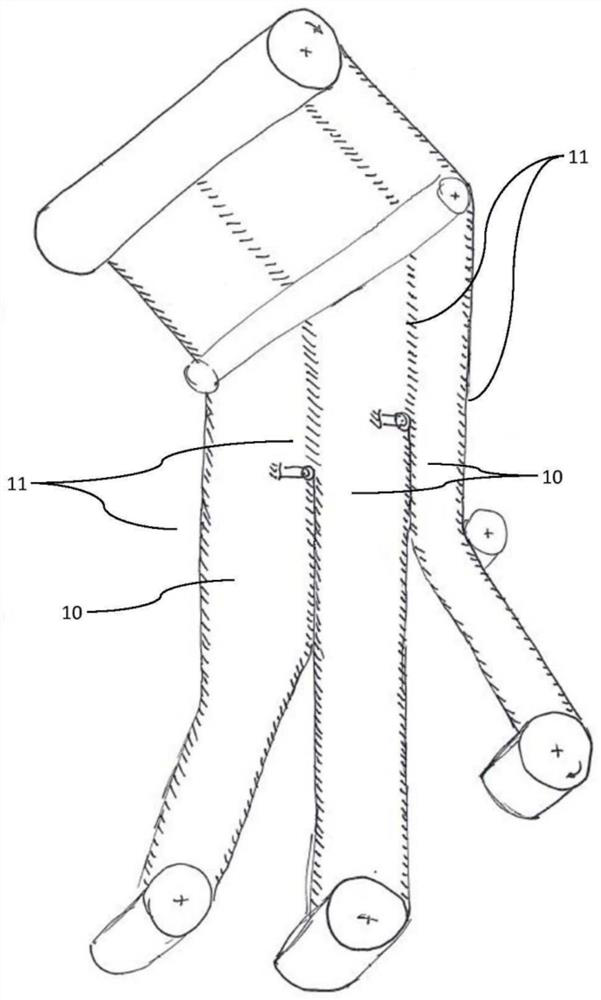

Supporting body comprising a receiving groove for a reinforcement panel

ActiveUS20170138442A1Simple manufacturing processIncreased mechanical load capacityGearingMechanical engineeringTraction drive

A supporting body (1) for guiding or tensioning a circumferential traction mechanism of a traction drive, a front side (12) that has an elongated sliding surface for making contact with the traction mechanism, a rear side (2) that lies opposite and includes an elongated receiving groove (5) for form-fittingly receiving a reinforcement panel, the receiving groove (5) being formed by delimiting elements (3) which protrude, at the sides of the groove, from the rear side, and at least two delimiting elements (3, 3′) on one side of the receiving groove (5) being separated in the longitudinal direction by a spacing in the form of a gap (4).

Owner:SCHAEFFLER TECH AG & CO KG

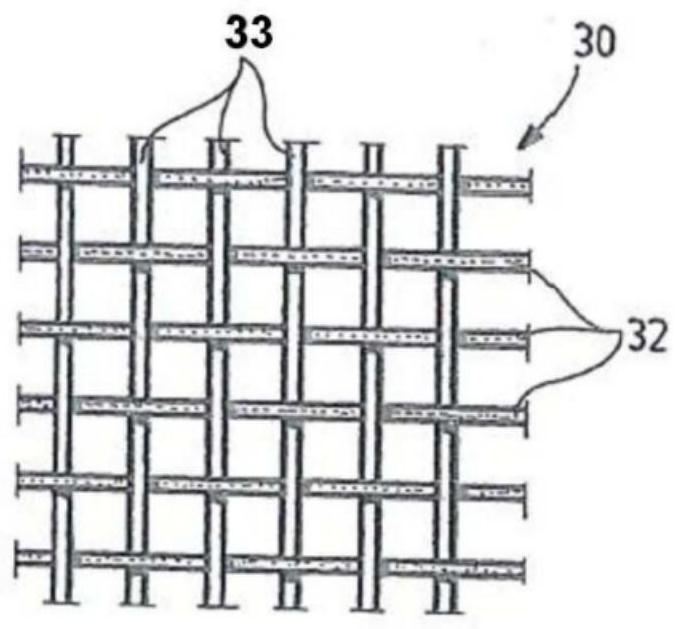

Fabric layer, flat material, filter element, filter and method for producing a fabric layer

ActiveCN111809288AEasy to processEasy to fixDispersed particle filtrationMembrane filtersMechanical engineeringPleat

The invention relates to a fabric layer, in particular a protective fabric and / or backing fabric, for a corrugated or pleated flat material of a filter element, wherein the flat material comprises a plurality of pleats 17 or corrugations running parallel to one another, which form successive pleat or corrugation peaks 18 and pleat or corrugation troughs 19, which are connected to one another by apleat flank, wherein a fluid can flow through the flat material, wherein the fabric layer comprises a first fabric region, in particular a first fabric strip 10, and at least one second fabric region,in particular a second fabric strip 11, the threads whereof, in particular weft threads, merge into one another, wherein the first fabric region, in particular the first fabric strip, comprises a first type of weave and the second fabric region, in particular the second fabric strip, a second type of weave, which differs from the first type of weave.

Owner:ARGO HYTOS GRP AG

Pick, in particular a round-shank pick

ActiveUS20180003051A1Promote formationInexpensive and durable wear-resistantDrill bitsSlitting machinesHard metalWear resistant

The invention relates to a pick, in particular a round-shank pick, comprising a pick head and a pick shank, wherein the pick head consists of at least a base part and a cutting element, which is connected to the base part and is composed of a hard material, in particular hard metal, wherein the base part has a wear-resistant layer on the outer surface thereof at the connection to the cutting element, which wear-resistant layer covers at least one segment of the outer surface of the base part facing the cutting element and wherein an end face of the wear-resistant layer facing the cutting element is covered by the cutting element. According to the invention, the base part has an axially oriented cut-out for receiving a fastening segment of the cutting element, the base part has a counter surface facing the cutting element and extending around the cut-out, and the counter surface and the end face of the wear-resistant layer form a continuous flat surface. The invention further relates to two methods for producing such a pick. The pick formed in such a way has low abrasive wear.

Owner:BETEK

Caster with braking device

ActiveUS11052704B2Increased mechanical load capacityImprove mechanical performanceCastorsIndustrial engineeringCaster

The present disclosure relates to a caster, having a housing, having an axle pin which is arranged in a housing opening which is oriented substantially horizontally, and on which at least one wheel is mounted, having, at the top, a pin opening oriented substantially vertically, for receiving a pivot pin, and having a braking device which brakes the at least one wheel, wherein the housing opening for the axle pin allows limited vertical displaceability of the axle pin and the braking device comprises at least one resilient housing part which acts on the axle pin. In order to provide a mechanically reliable braking device, the braking device is additionally provided with at least one spring element which cooperates with the at least one resilient housing part and amplifies the effect of its braking force and / or increases the mechanical load-bearing capacity of the at least one resilient housing part.

Owner:GROSS FROELICH

Device for locking a cover of an electrical switch

InactiveCN102983025AIncreased mechanical load capacityProtective switch detailsElectric switchesEngineeringElectrical switching

A device for locking a cover of an electrical switch. A device is disclosed including a removable cover of a housing of an electrical switch and a handle. In at least one embodiment, the handle, by way of its position, switches the electrical switch between different states. Further, the handle is connected to the housing and the handle includes a contour which is embodied, at least in one position of the handle, to interact with the cover for locking the removable cover.

Owner:SIEMENS AG

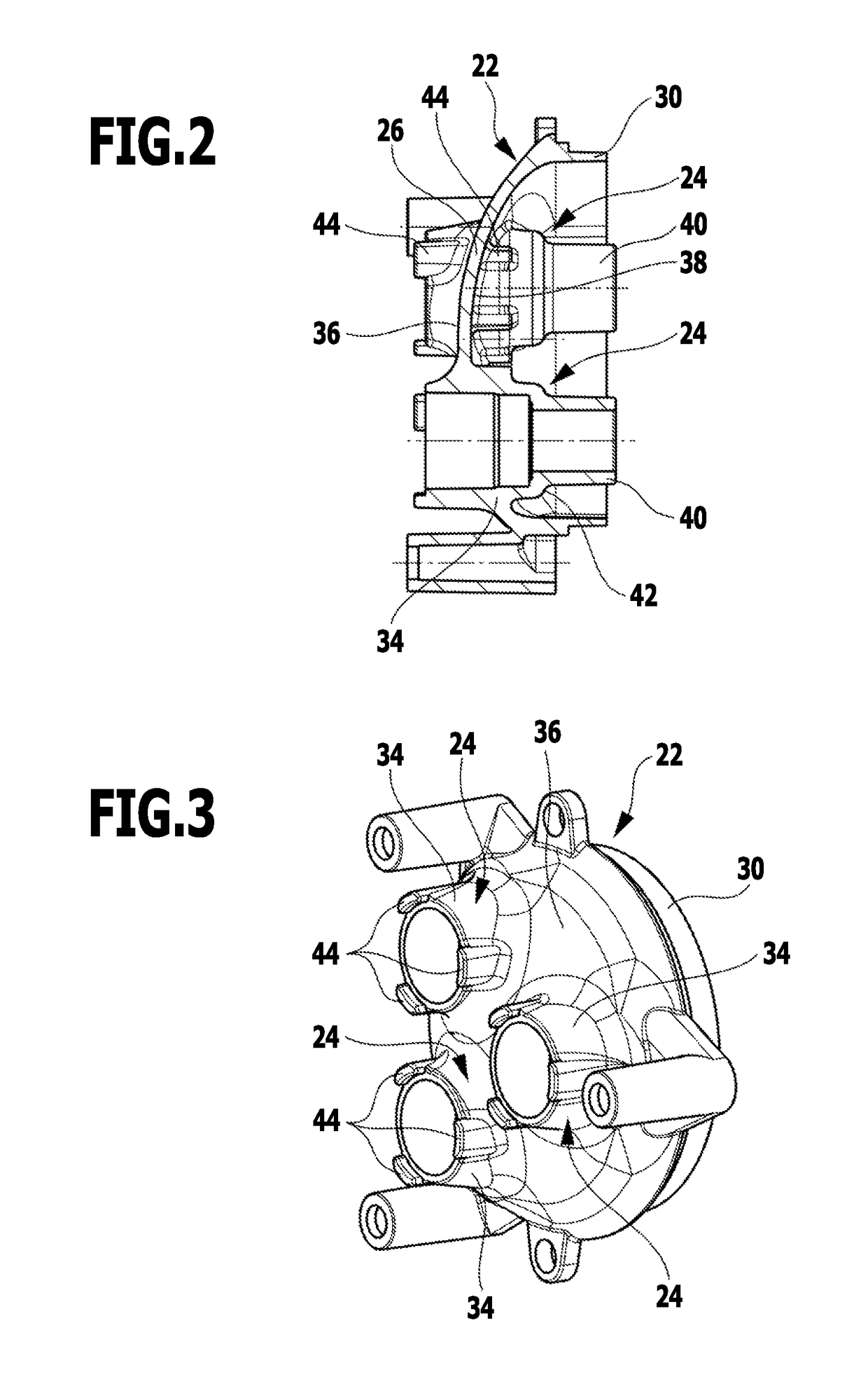

Water distributor for an internal combustion engine

ActiveCN110374764AEnsure impermeabilitySimple designNon-fuel substance addition to fuelEngine manufactureCombustion chamberPlastic materials

A water distributor (10) for water to be injected into a combustion chamber of an internal combustion engine is provided with a housing (12) that has a receiving chamber (16), wherein the receiving chamber extends in a longitudinal direction (18) of the housing and gradually decreases. An insertion element (14) with an insertion section (20) is provided and the insertion section (20) is inserted into the receiving chamber (16) and extends and decreases in the longitudinal direction in correspondence to the receiving chamber (16). A water inlet (24) and at least one water outlet (26) are provided. A distributor channel (22) connects the water inlet (24) in fluid communication to the at least one water outlet (26). The distributor channel (22) is delimited at least partially by the insertionelement (14). The housing (12) and the insertion element (14) are connected water-tightly to each other at an end face (36) of the housing (12). The housing and the insertion element are made a plastic material.

Owner:MOLDTECS 01 2022 GMBH

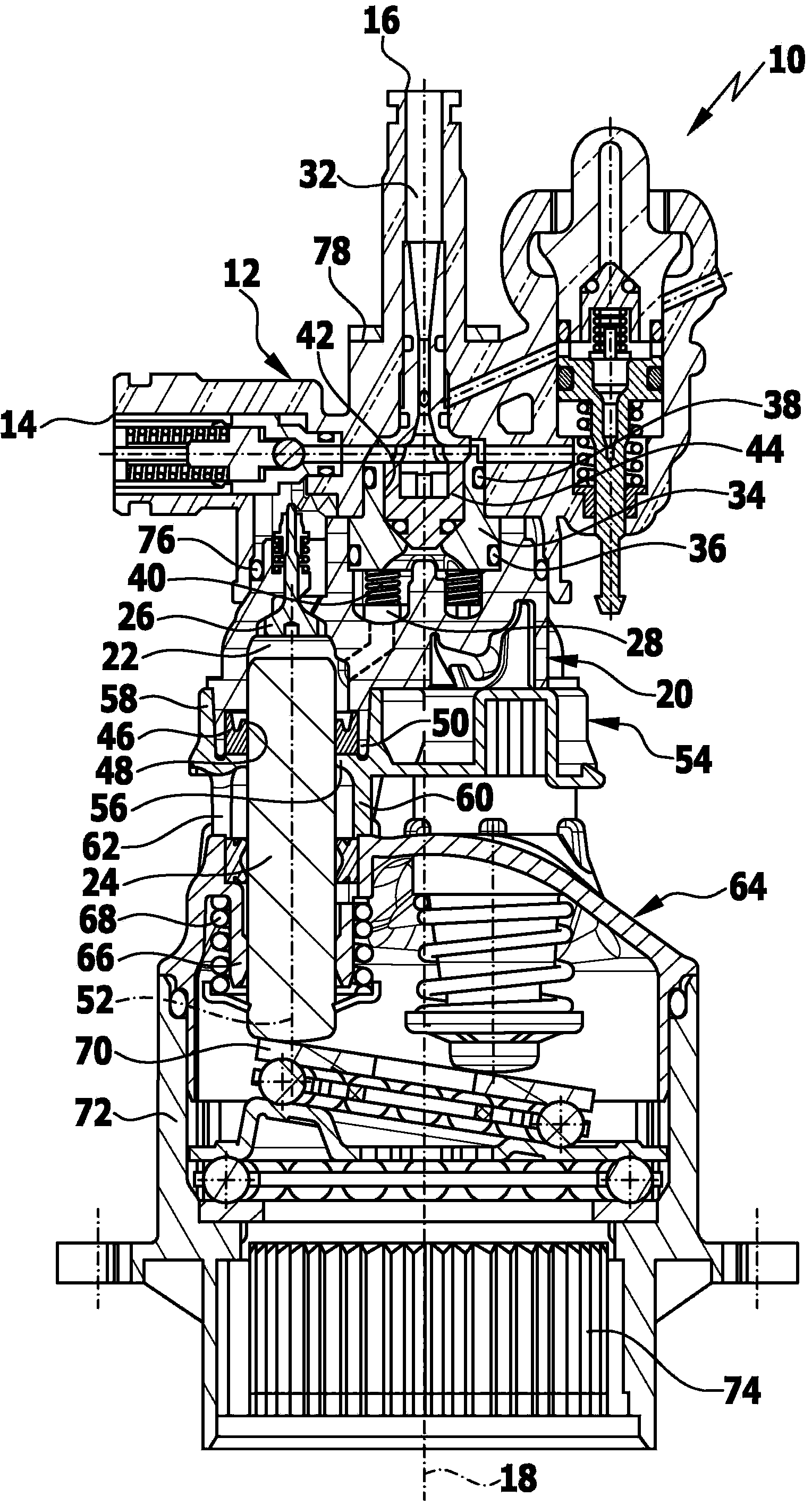

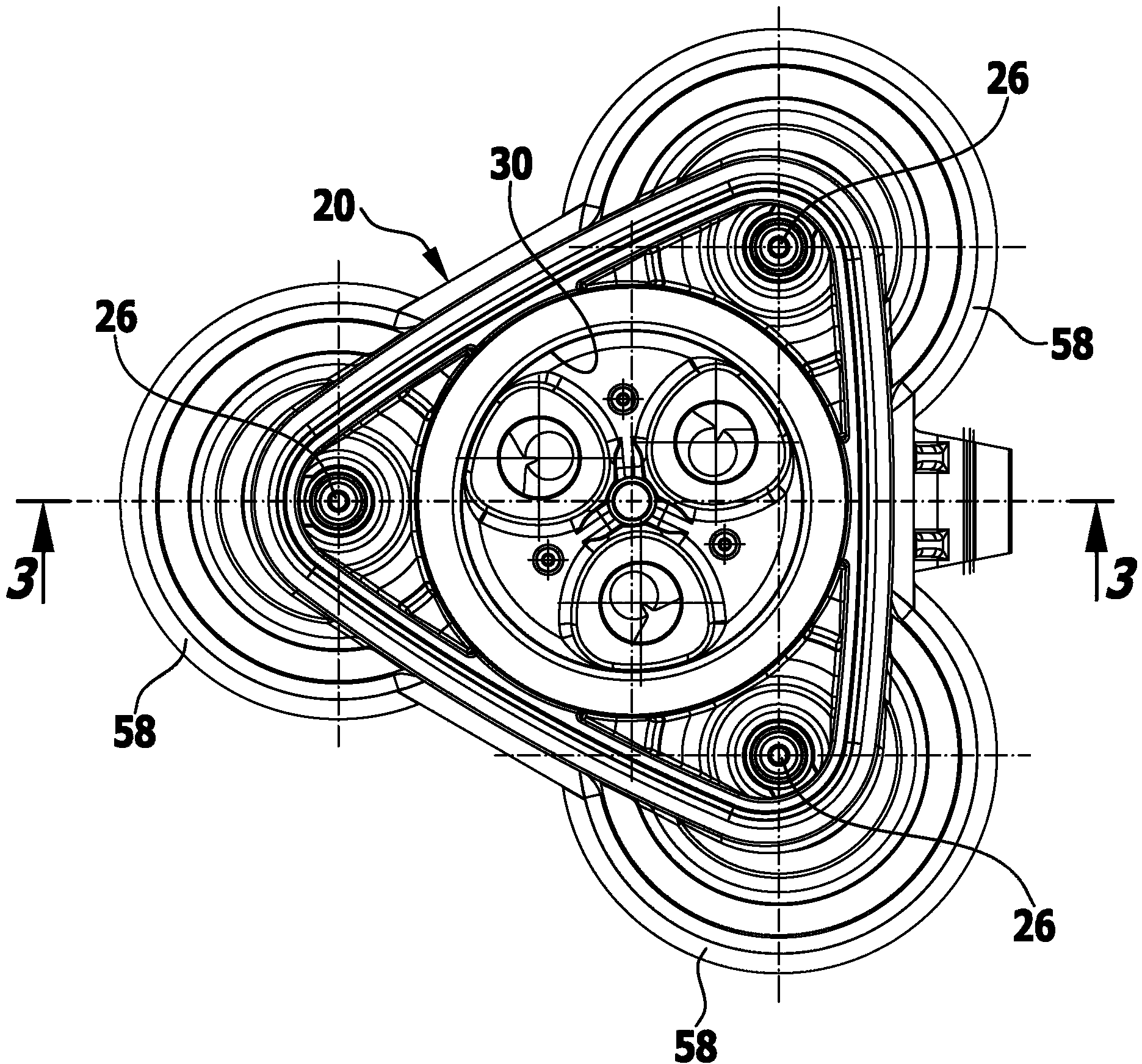

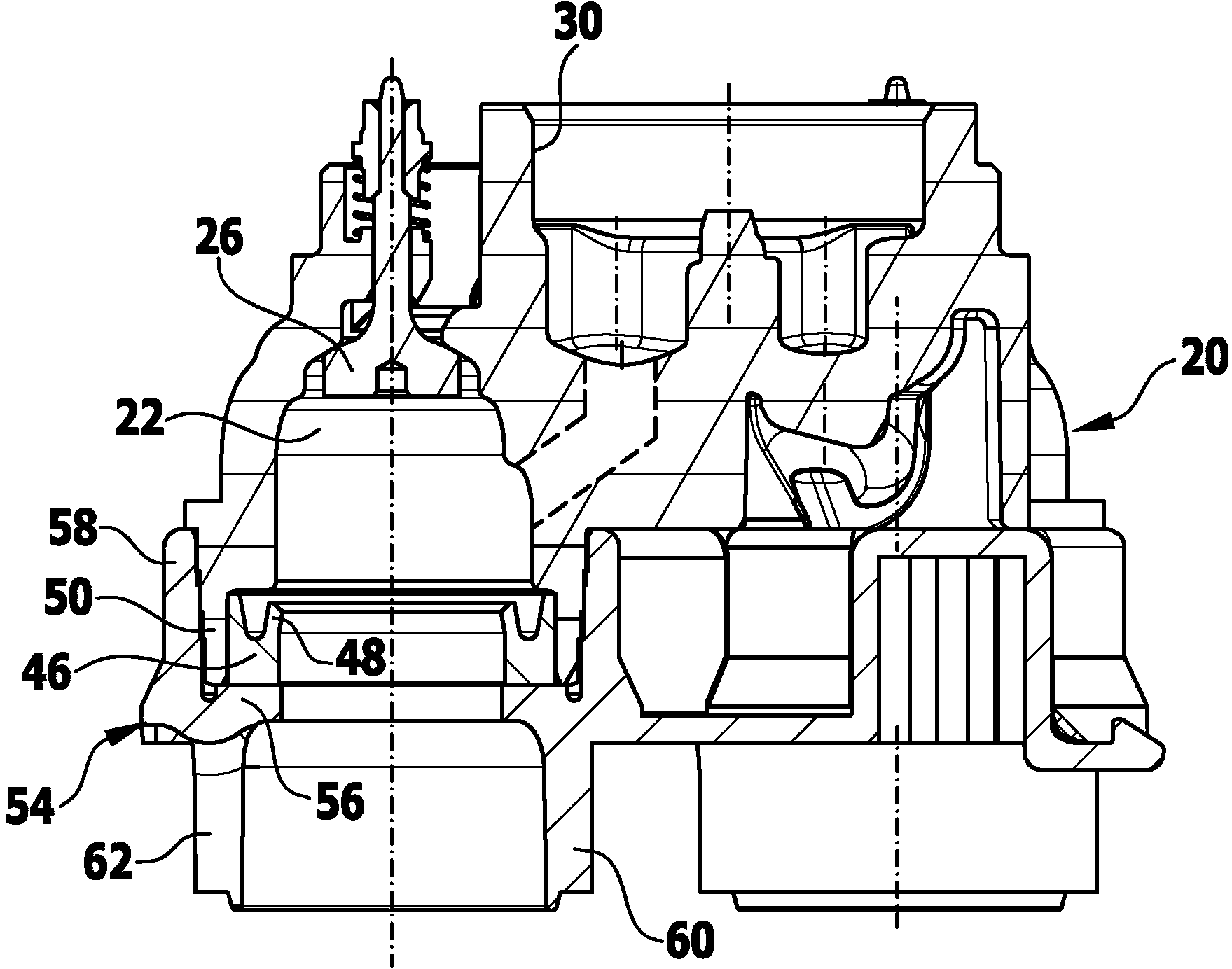

Swash plate compressor having a curved piston guide wall

ActiveUS9932971B2Increase heat load capacityReduce weightPositive displacement pump componentsMulti-stage pumpsPump chamberPiston Guide

A piston pump for a high-pressure cleaning appliance is provided, which includes a plurality of pistons that are movable back and forth and each of which enters a pump chamber and is displaceably held at a piston guiding part. The piston guiding part has a supporting wall on which a plurality of guiding elements, each of which guides a piston, are disposed. In order to be able to produce the piston pump in a more cost-effective manner, it is proposed according to the invention that the supporting wall is curved.

Owner:ALFRED KARCHER GMBH & CO KG

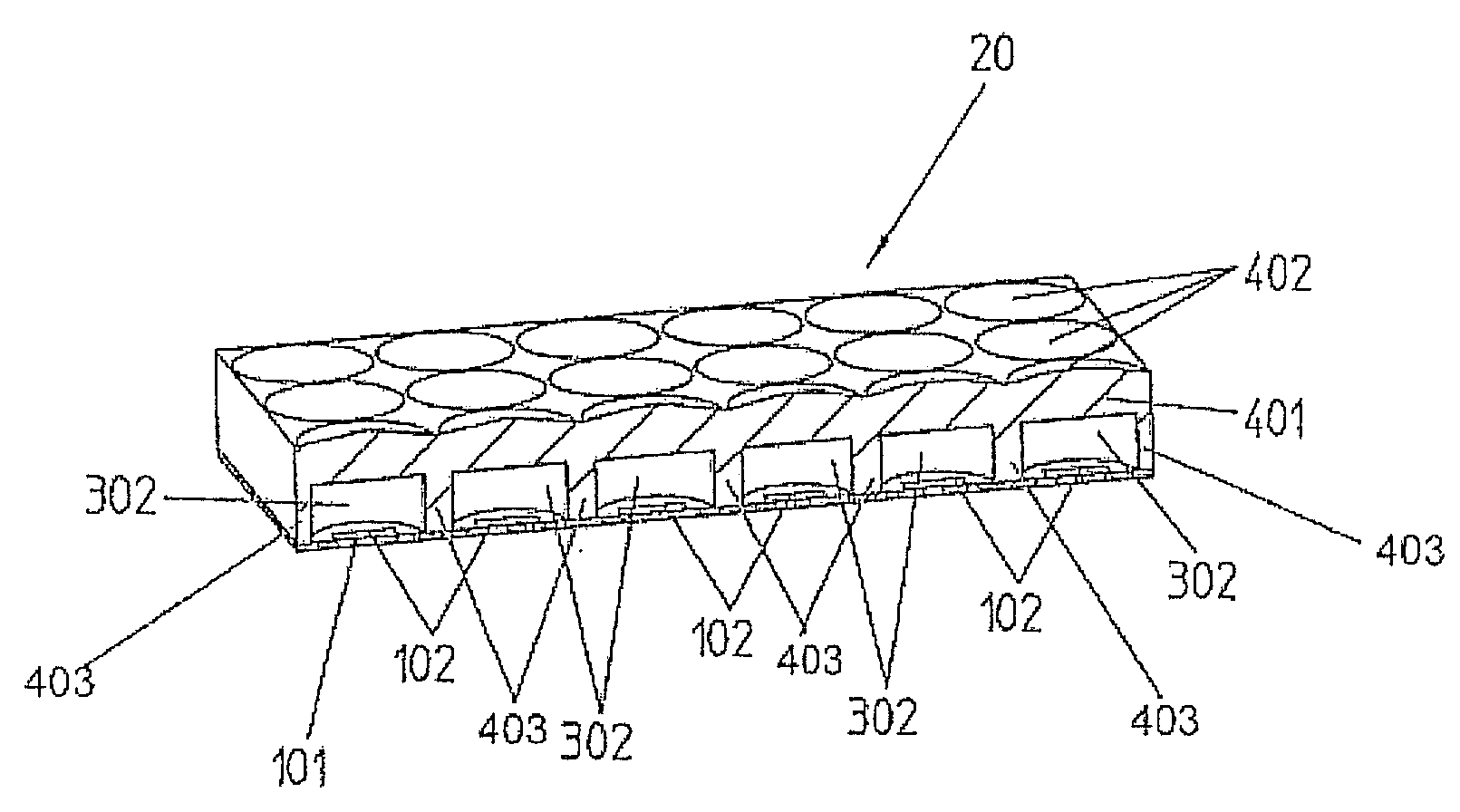

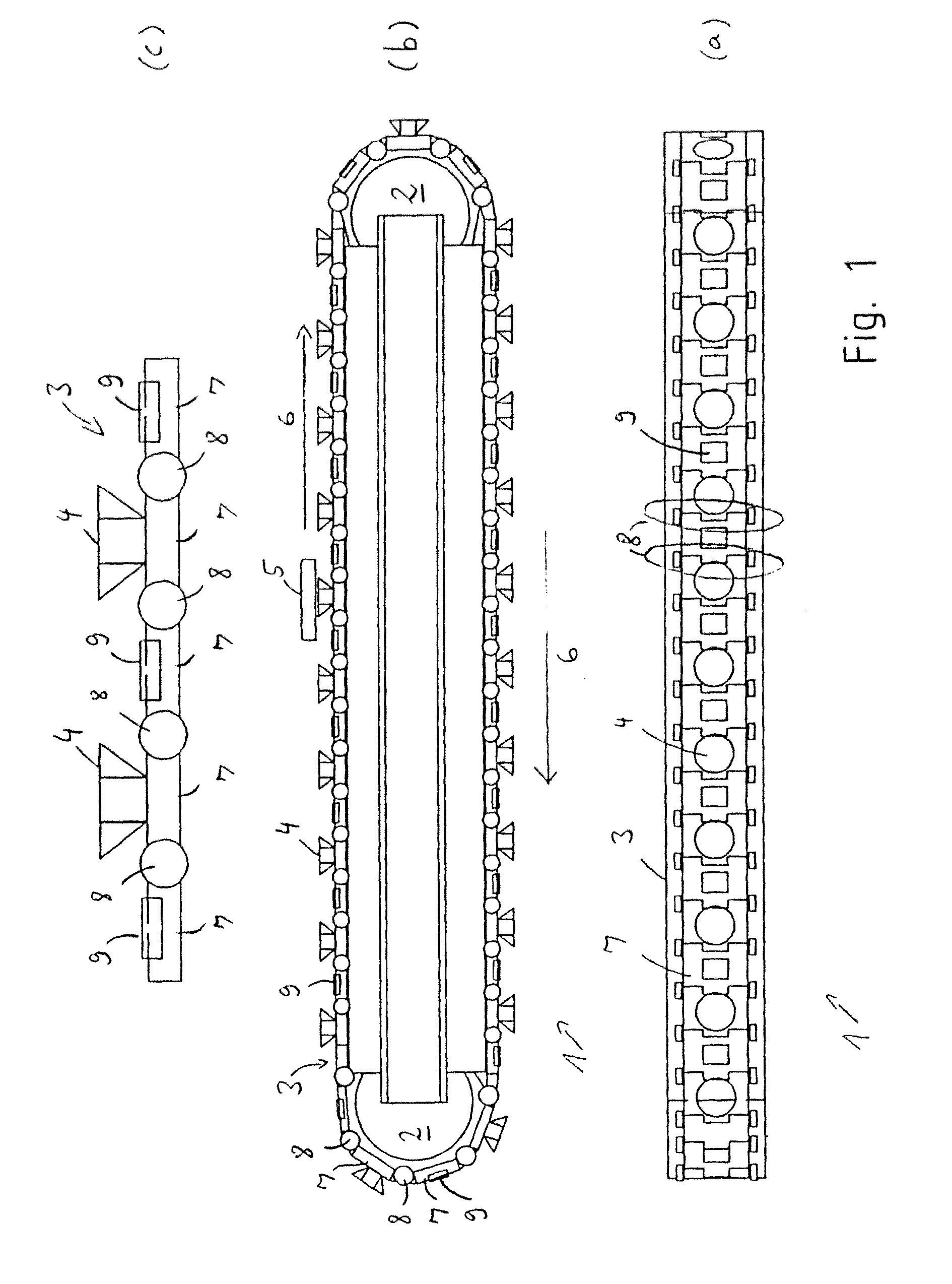

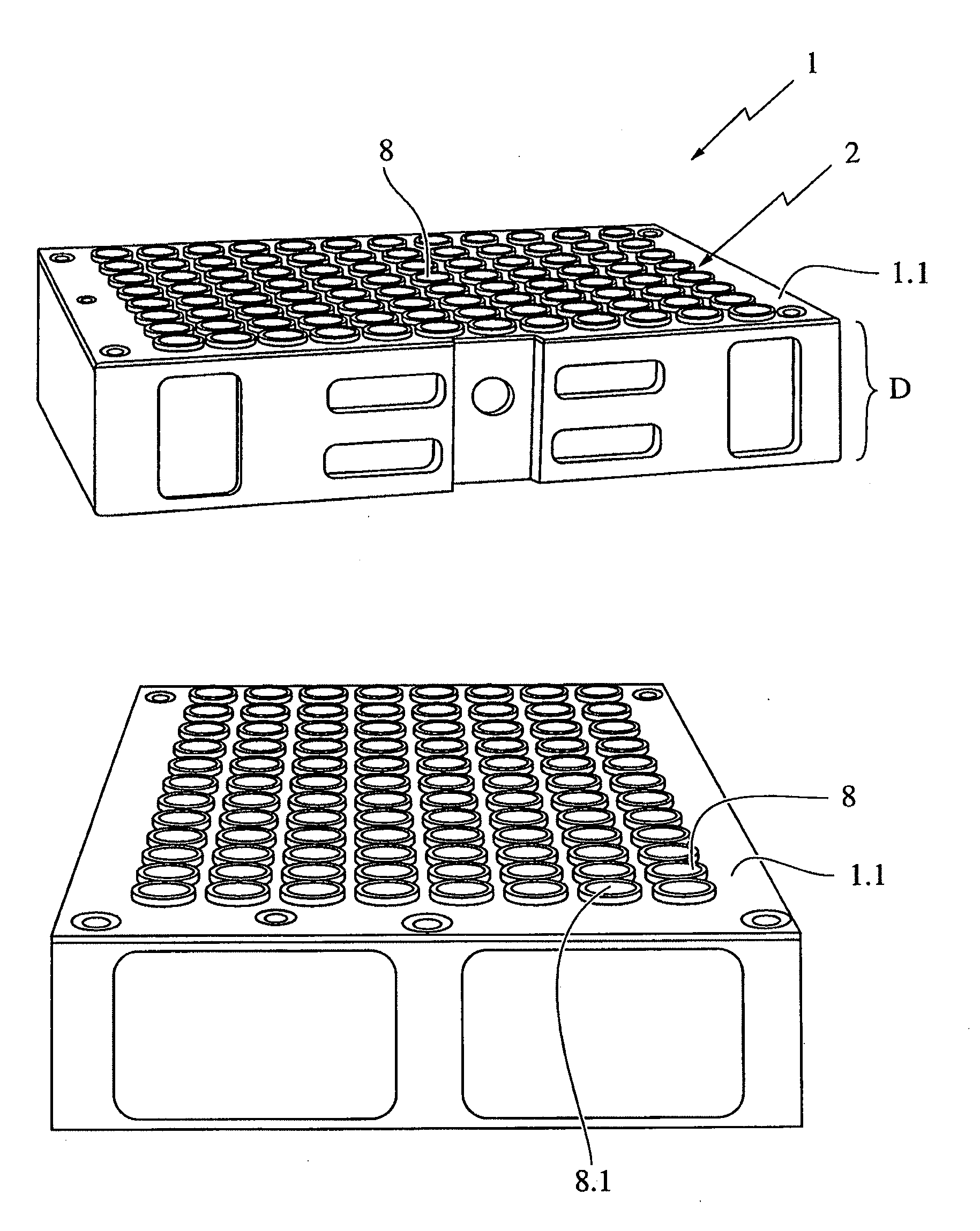

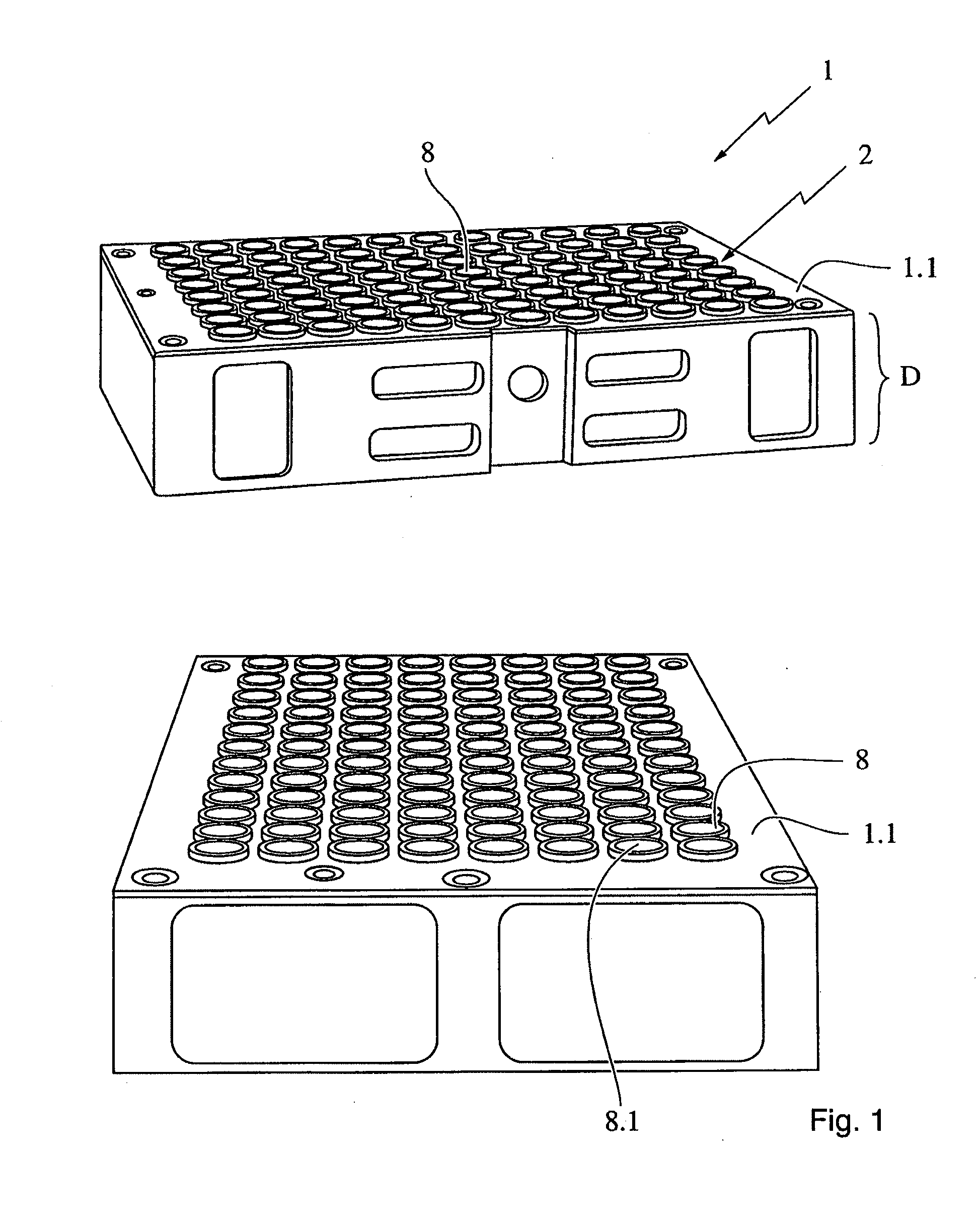

Sample Carrier and Method for Achieving Comparable Analytical Results By Aligning Test Substances on a Uniform Plane

InactiveUS20110245106A1Improve comparabilityQuality improvementLibrary screeningLaboratory glasswaresAnalysis methodPhysics

A sample carrier such as a multi-well platform with one or more recesses, in each of which a substance to be analyzed is disposed, and an analysis method in which one or more substances, each of which is located in a recess of the sample carrier, are aligned on a uniform plane relative to the surface of the sample carrier before being analyzed.

Owner:GRUNENTHAL GMBH

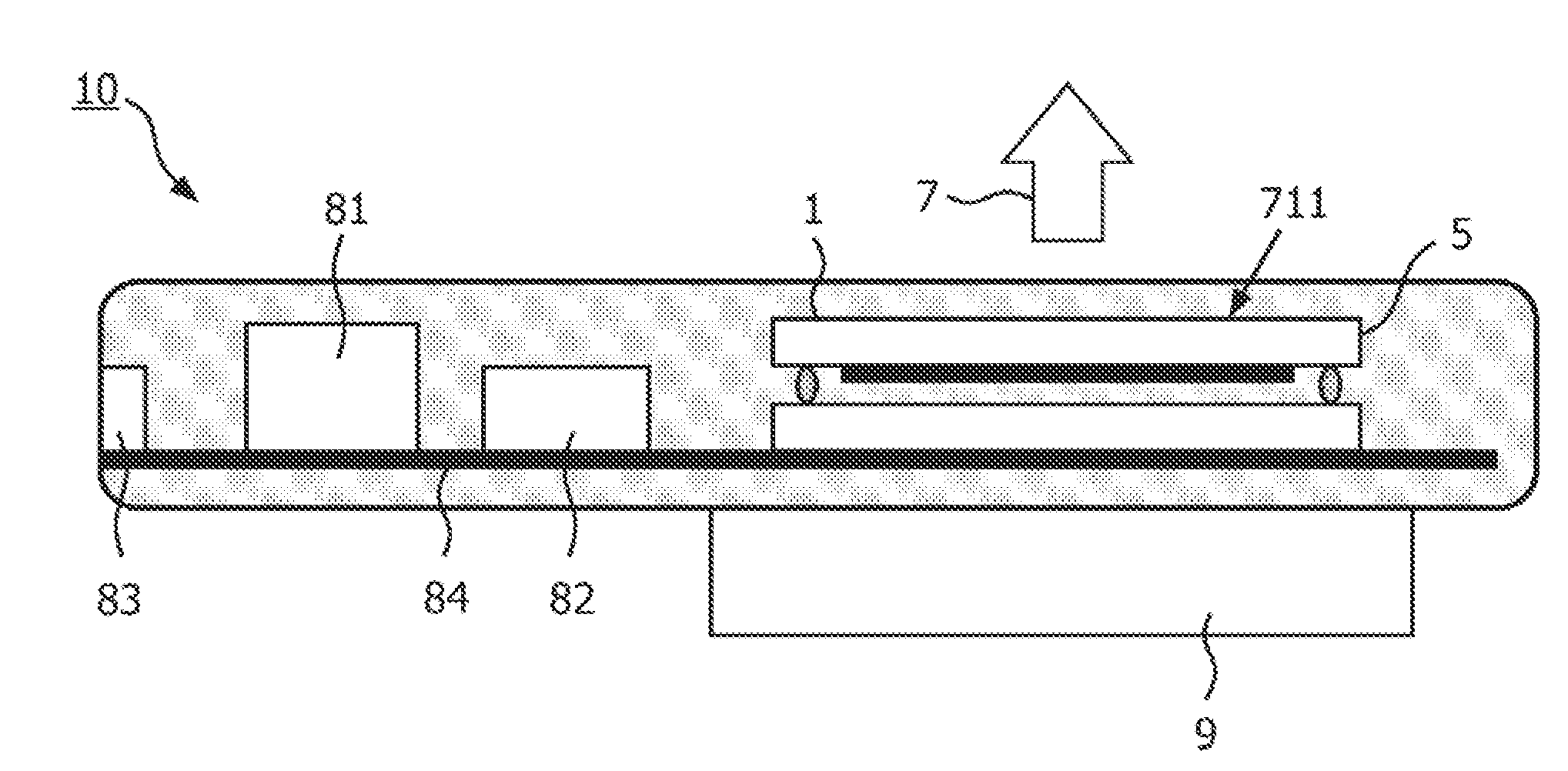

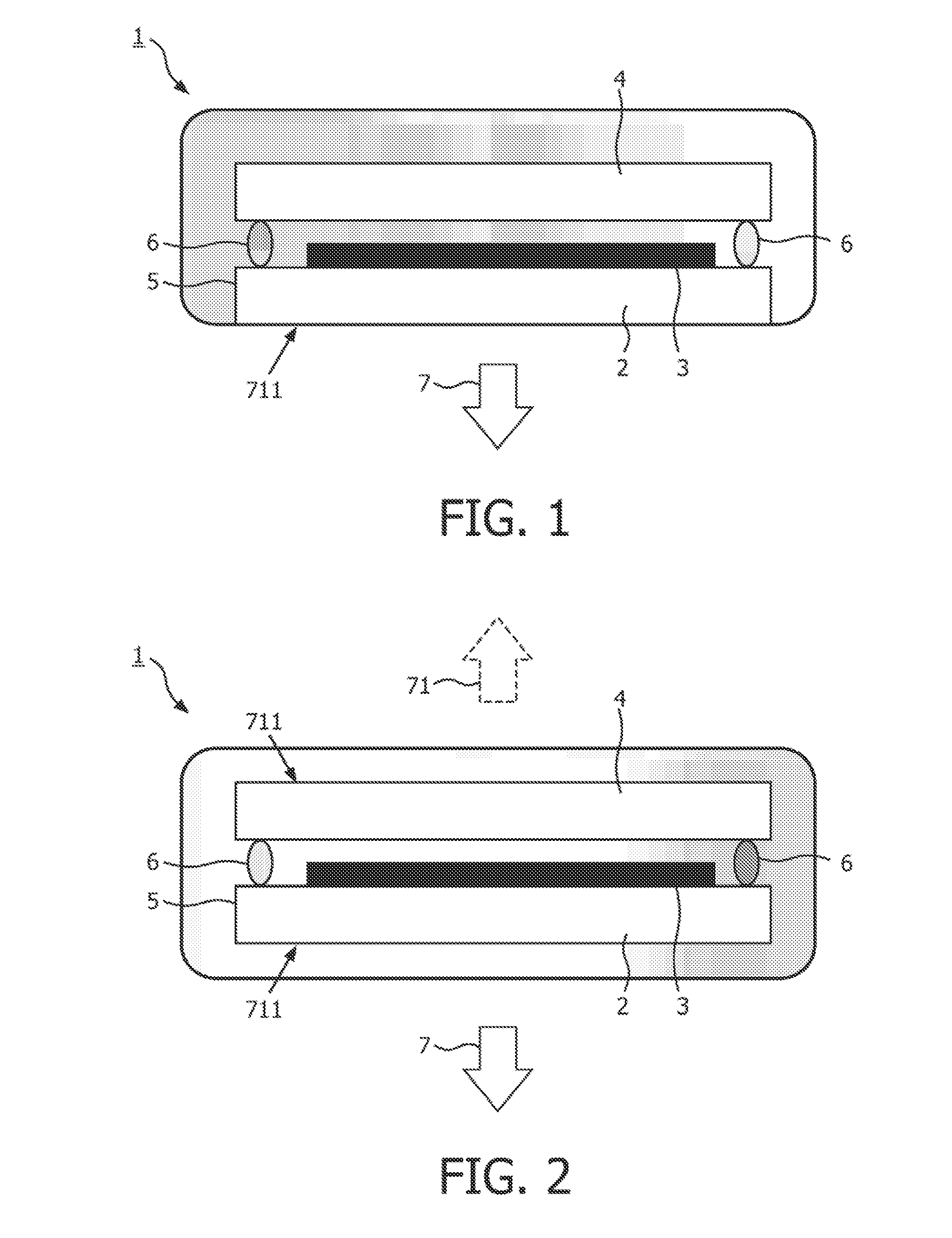

OLED devices with protection cover

ActiveUS8525397B2Increased mechanical load capacityReduce riskIncadescent screens/filtersDischarge tube luminescnet screensEngineeringElectronic board

Owner:KONINK PHILIPS ELECTRONICS NV

Piston pump for a high-pressure cleaning device

ActiveCN103998778AReduce investmentEasy to assemblePositive displacement pump componentsCleaning using liquidsPump chamberHigh pressure

The invention relates to a piston pump (10) for a high-pressure cleaning device, having a plurality of pump chambers (22), into which in each case one piston (24) which can move to and fro dips and which are flow-connected in each case via an upstroke valve (26) to a suction inlet (14) and via a delivery valve (28) to a pressure outlet (16), wherein the pistons (24) are surrounded in each case by a seal ring (46) which is supported in the radial direction by a ring wall (50) and in the axial direction by a supporting ring (56). In order to develop the piston pump in such a way that it can be produced and assembled less expensively, it is proposed according to the invention that the piston pump (10) comprises a single-piece supporting plate (54) which forms the supporting rings (56) and surrounds the ring walls (50) in the circumferential direction.

Owner:ALFRED KARCHER GMBH & CO KG

Retainer and method for attaching lines to lightweight elements of means of transport, in particular to sandwich panels of aircraft

InactiveUS20060174553A1Fast and simple attachmentQuickly and easily attachedElectrical apparatusFoundation engineeringSandwich panelAirplane

A retainer for attaching lines to lightweight elements of means of transport, in particular to sandwich panels of aircraft, with at least one base plate comprising at least one retaining stud. The retaining stud or studs can be cemented into a borehole within a lightweight element. The retaining studs are designed to be free of any undercut, and are connected in one piece to the base plate. A method is also provided for attaching lines to lightweight elements of means of transport, in particular to sandwich panels of aircraft, by means of a retainer comprising at least one retaining stud and a base plate.

Owner:AIRBUS OPERATIONS GMBH

Rotor Support and Method for Producing a Rotor Support

InactiveUS20150115759A1Save materialHigh strengthMagnetic circuit rotating partsManufacturing dynamo-electric machinesDrive shaftEngineering

A rotor arm for an electrical machine includes a support pot for mounting a magnetic element. The support pot has a hub bearing a drive shaft. An inner peripheral surface of the rotor arm has, in an axial direction from the hub, an end stop for a supporting element of the rotor arm for the further bearing of the drive shaft.

Owner:DAIMLER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com