Component for assembly on a wall with expanded foam behind the same and refrigerator provided with the same

A technology of structural parts and foaming materials, which is applied in the direction of connecting components, household appliances, mechanical equipment, etc., and can solve the problems of heat insulation material discharge and skirt sealing guarantee, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

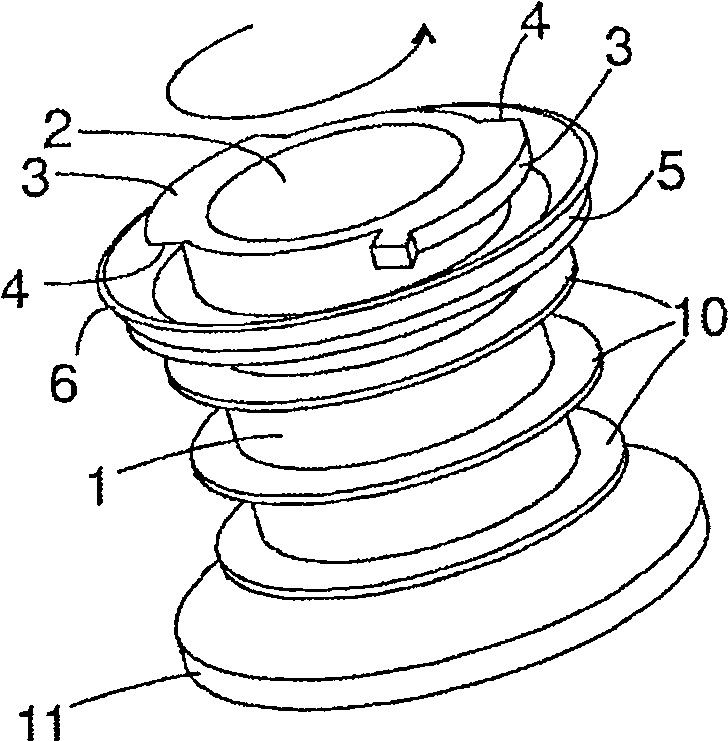

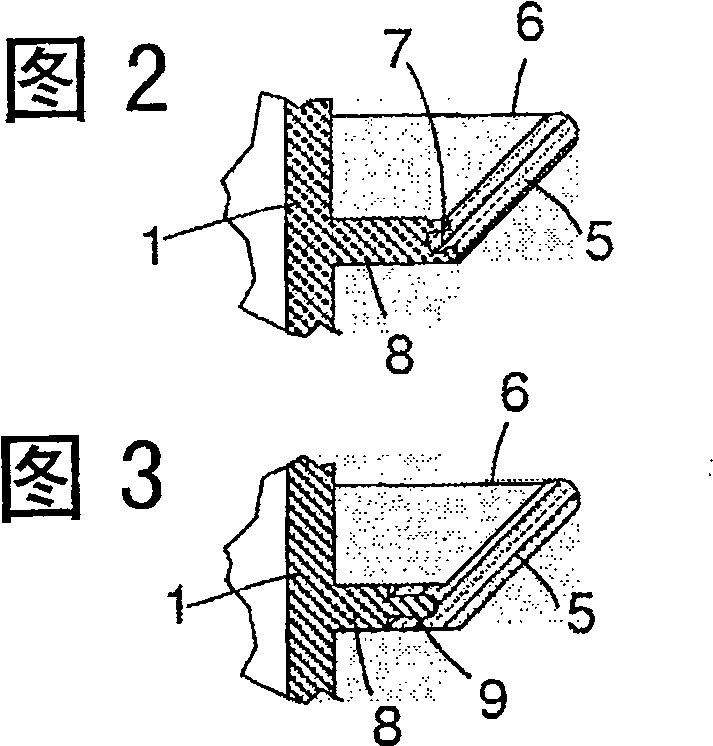

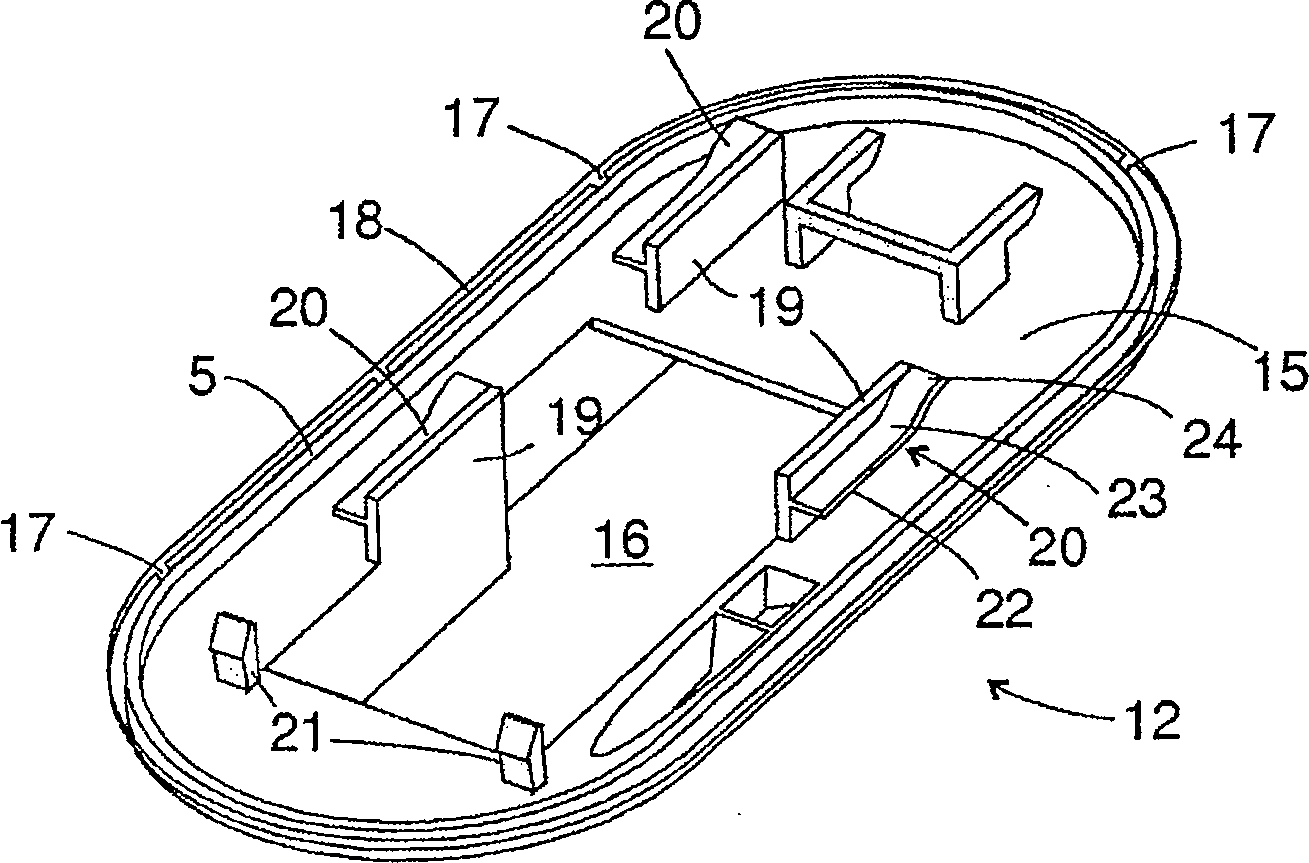

[0023] figure 1 The suction tube threading device shown in has a substantially tubular body 1 formed of solid plastic material, through which a hole 2 extends. On the end side of the bore 2 , the body 1 carries two ribs 3 extending radially over part of the circumference of the body. This end side is correspondingly provided for passing through the complementary shaped opening of the outer wall of the refrigerating appliance housing (not shown) from the foam material side and is then rotated in the direction of the arrow, thereby bringing the ribs 3 in their The beveled narrow sides 4 first slide over the edge regions of the outer wall surrounding the opening and finally clamp these edge regions only between the ribs themselves and an elastic skirt 5 . The substantially conical-shaped elastic skirt 5 has an outer diameter that is larger than the outer diameter of the opening in the outer wall, whereby the outer edge 6 of the skirt 5 rests continuously against the outer wall a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com