Fabric layer, flat material, filter element, filter and method for producing a fabric layer

A filter element and fabric layer technology, applied in the field of fabric layers, can solve the problems of fabric layer detachment, low flow resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

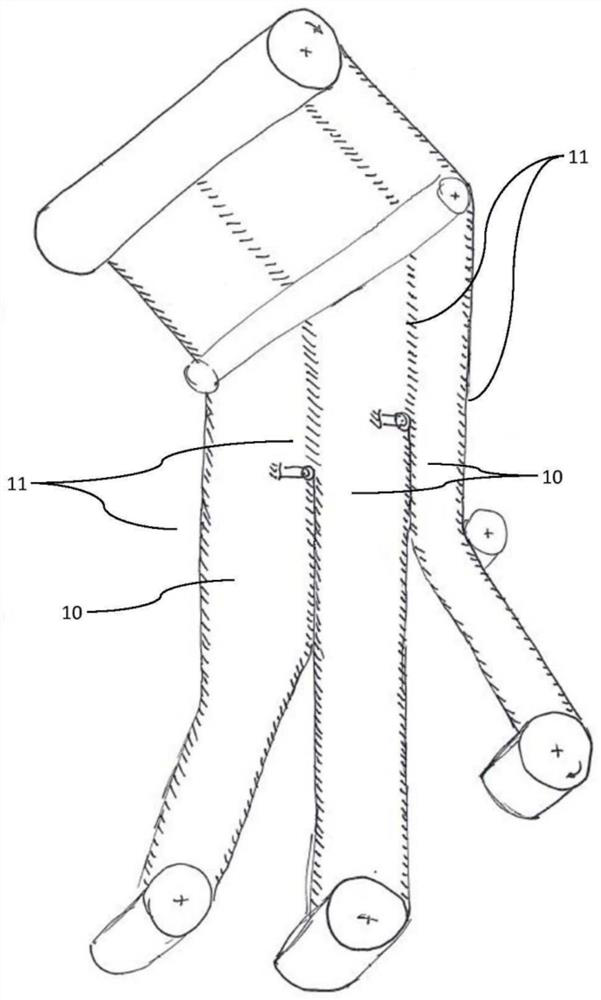

Image

Examples

Embodiment Construction

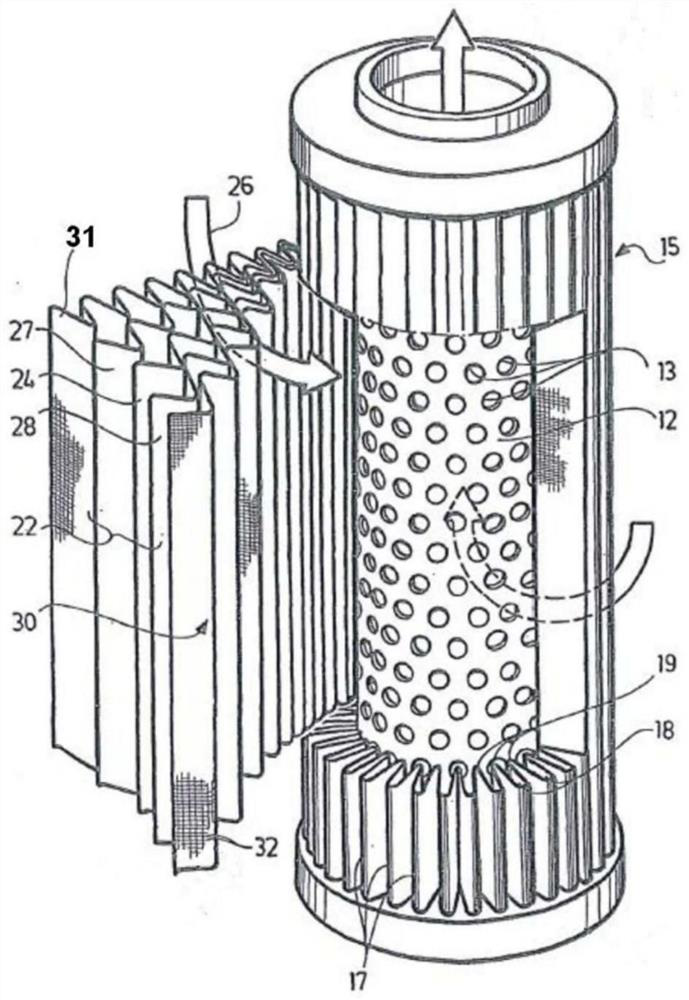

[0052] figure 1 A filter element is schematically shown, which is used, for example, in a hydraulic filter. Use in hydraulic filters is particularly preferred. The filter element can be used in other filters. It comprises a perforated sleeve or cylindrical support tube 12 through which a plurality of flow openings 13 pass in radial direction. In the circumferential direction, the support tube 12 is surrounded by a multilayer filter bellows 15, which is partly shown in an exploded view for illustration figure 1 shown in . The filter bellows 15 can also be referred to as a corrugated or corrugated flat material. The filter bellows 15 is pleated in a star-shaped fashion with pleats 17 extending parallel to the longitudinal axis of the support tube 12 such that radially outer pleat peaks 18 and radially inner pleat bases 19 follow each other alternately along its circumference.

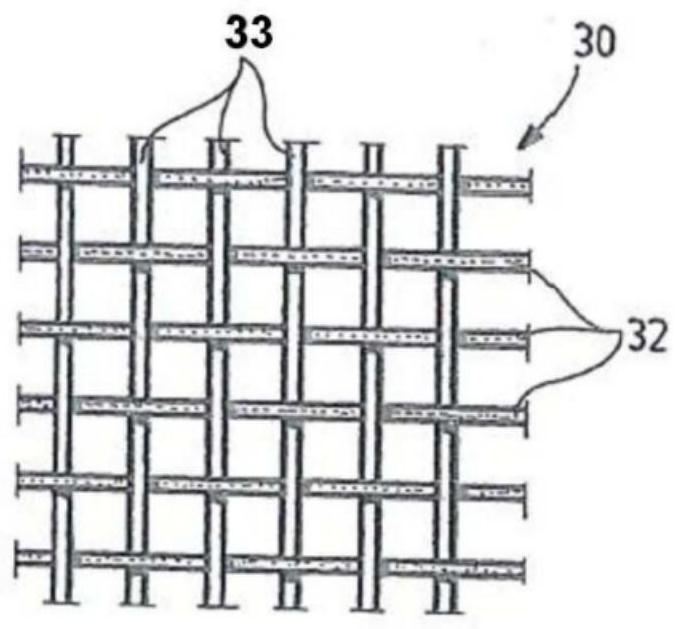

[0053] The filter bellows 15 comprises in particular three layers of filter material 22 with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com