Water distributor for an internal combustion engine

A distributor, internal combustion engine technology, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of expensive manufacturing, heavy stainless steel, etc., achieve simple design and manufacturing, and achieve the effect of pressure measurement and accurate pressure measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

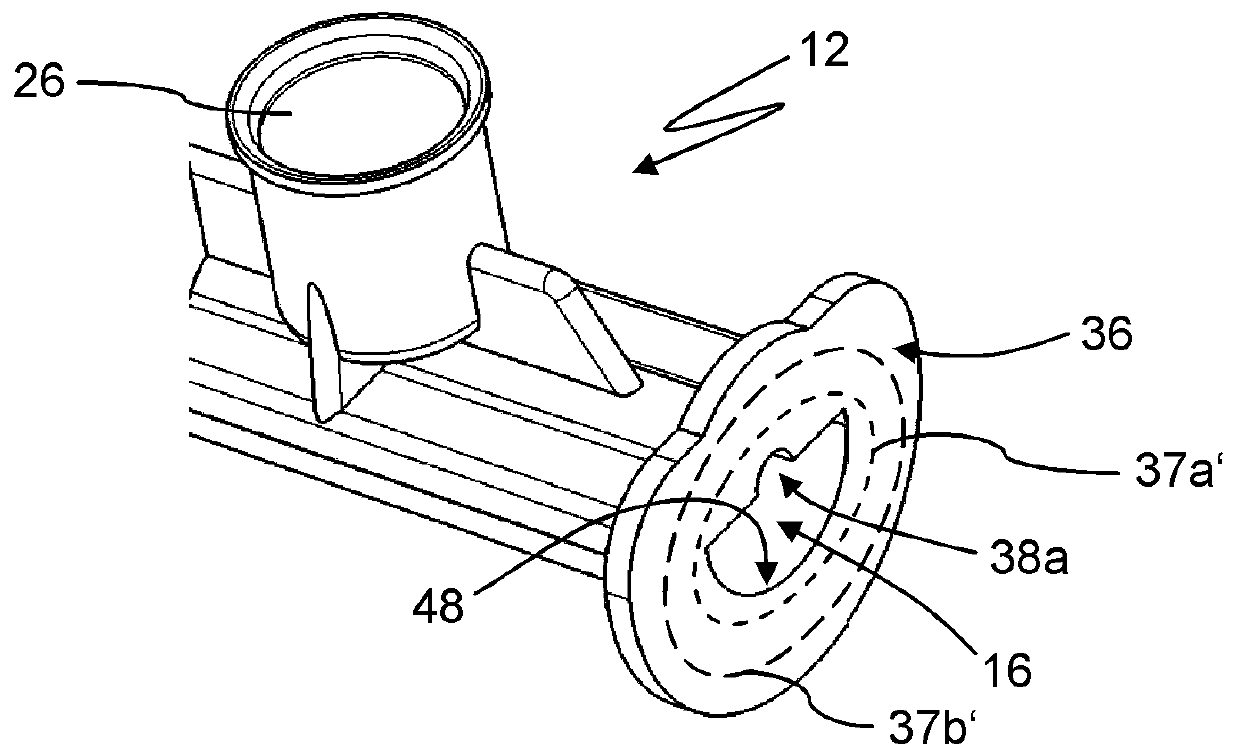

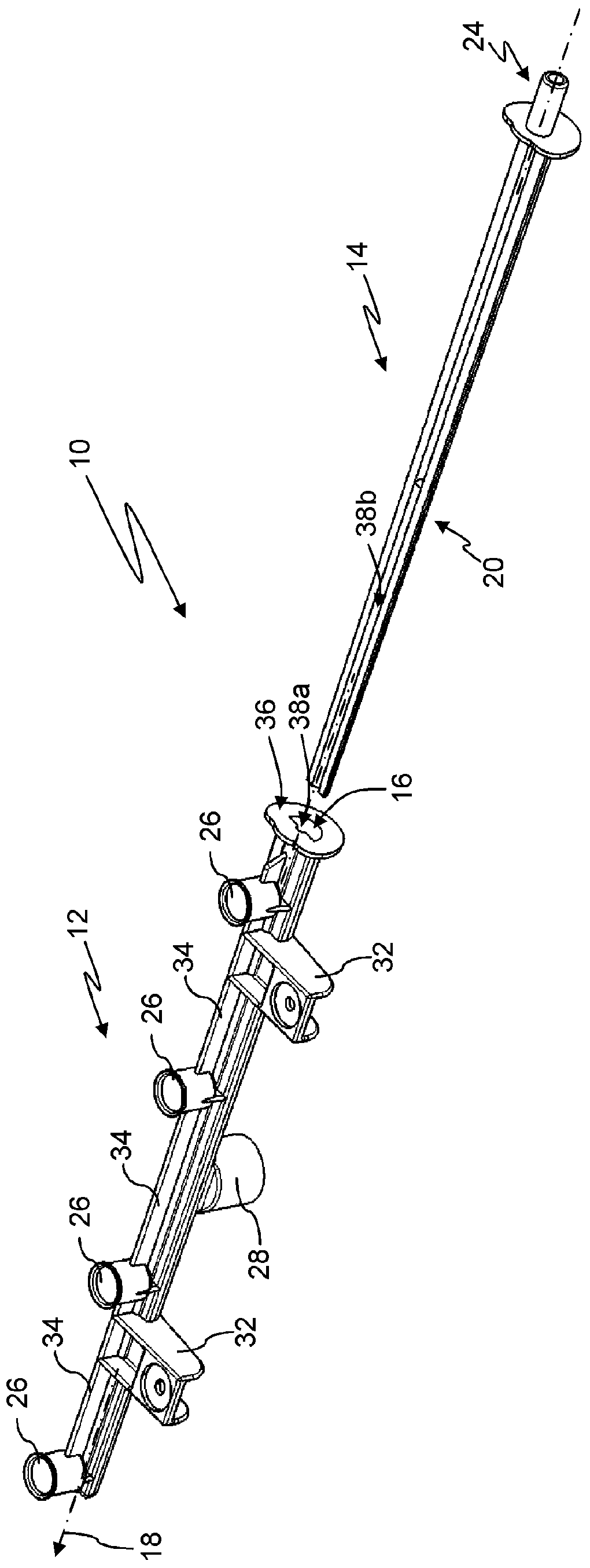

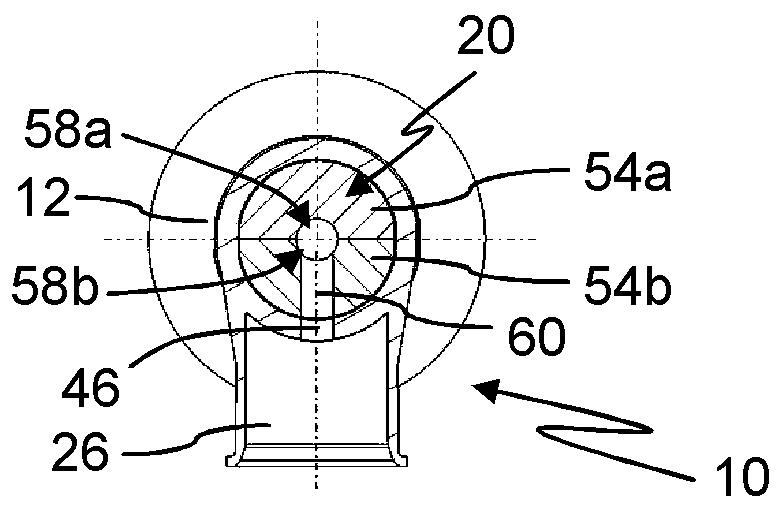

[0040] figure 1 The water dispenser 10 according to the invention in a first embodiment is shown in a perspective view obliquely from above. figure 2 The water dispenser 10 is shown in longitudinal section.

[0041] The water dispenser 10 includes a housing 12 and a push-in element 14 . The housing 12 and the push-in element 14 are made here from the same plastic material, ie glass-fiber-reinforced polypropylene. A receiving chamber 16 is formed in the housing 10 . The receiving chamber 16 tapers in the longitudinal direction 18 . Here, the receiving chamber 16 tapers uniformly along the longitudinal direction 18 , that is to say with a constant rate of reduction of its clear width. The insertion element 14 has an insertion section 20 . The insertion section 20 is accommodated in the receiving chamber 16 , that is to say inserted into it. The insertion section 20 tapers in the longitudinal direction corresponding to the receiving chamber 16 , here uniformly.

[0042] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com