Anti-seepage system suitable for landfill and paving method thereof

A technology of landfill and anti-seepage layer, which is applied in protection devices, buildings, infrastructure engineering, etc. It can solve the problems of pumping inclined pipes and anti-seepage system damage, so as to ensure anti-seepage performance and prevent floating and sideslip , the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

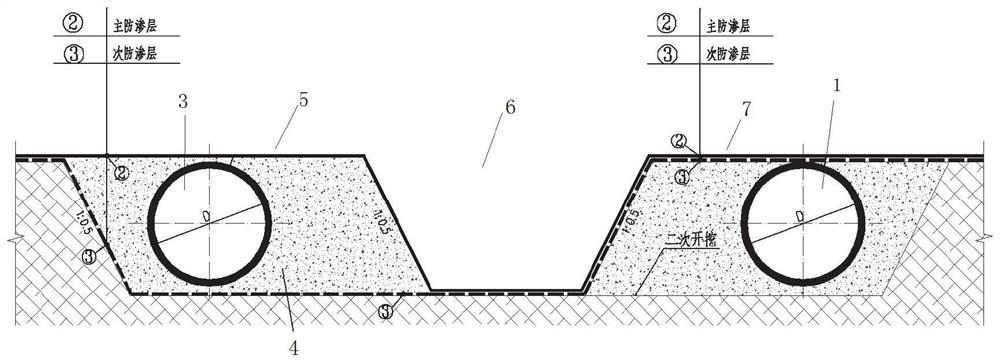

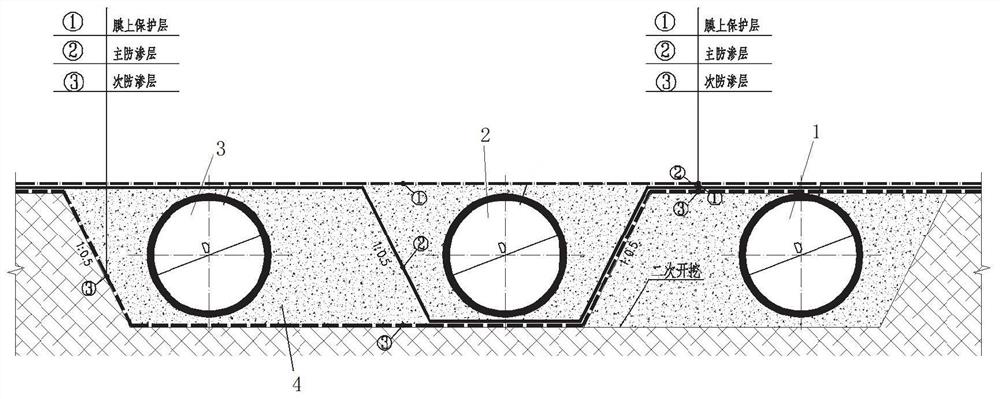

[0028] Such as Figure 1-Figure 2 As shown, the embodiment of the present disclosure provides an anti-seepage system suitable for multi-functional suction and drainage inclined pipes in landfills. The anti-seepage system mainly includes longitudinal grooves arranged on the internal slope of the landfill and arranged The groundwater pumping and discharging inclined pipe 1, the secondary leachate leak detection inclined pipe 3 and the main leachate pumping inclined pipe 2 in the longitudinal groove are described.

[0029] What needs to be explained is that the longitudinal groove is set upward along the side slope, specifically, an inverted trapezoidal groove is dug inward on the side slope.

[0030] Specifically, the three pipes, the groundwater pumping inclined pipe 1, the secondary leachate leak detection inclined pipe 3 and the main leachate pumping inclined pipe 2, are arranged in the longitudinal groove at intervals, and each pipe The surrounding area is filled with plain...

Embodiment 2

[0034] The embodiment of the present disclosure provides a pavement method for an anti-seepage system suitable for multi-functional suction and drainage inclined pipes in landfills, such as figure 1 As shown, before the method is implemented, an inverted trapezoidal groove is pre-dug on the side wall slope of the landfill. The pre-dug trapezoidal groove is pre-divided into the left area, the middle area and the right area in the internal length direction, and the main leachate pumping inclined pipe, the secondary leachate leak detection inclined pipe and the groundwater pumping inclined pipe are placed in these three areas. within an area.

[0035] Step 1: First place the inclined pipe for pumping and discharging groundwater in the right area of the trapezoidal groove. During the installation process, ensure the verticality of the inclined pipe for pumping and discharging groundwater. After installing the inclined pipe for pumping and discharging groundwater, fill around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com