Fillable cap closure with a film seal that is opened purely by means of rotation or axial pressing

A closure, axial technology, applied in the direction of capping with aids, closures with aids, closing, etc., capable of solving problems that do not function correctly, solutions that do not fit well enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

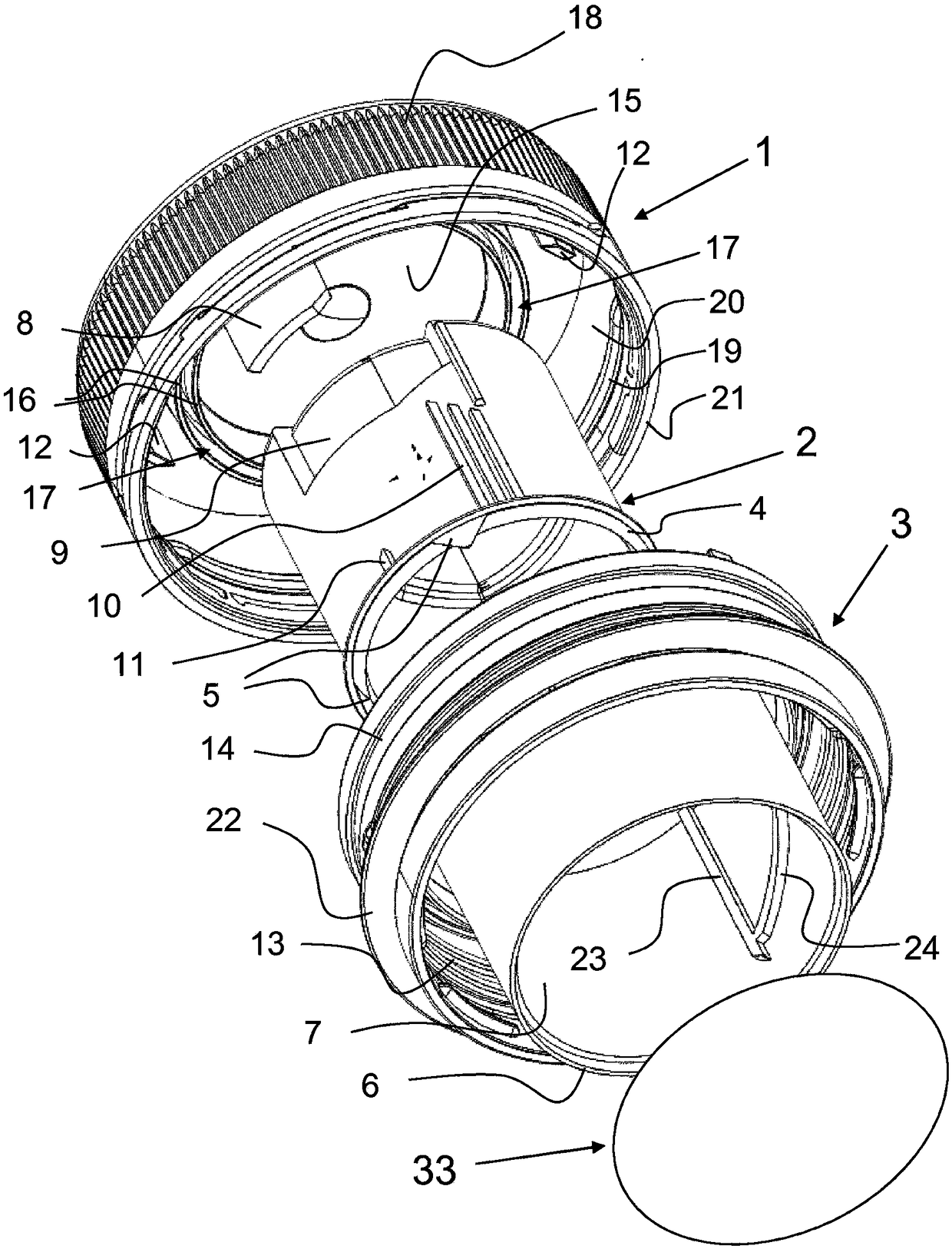

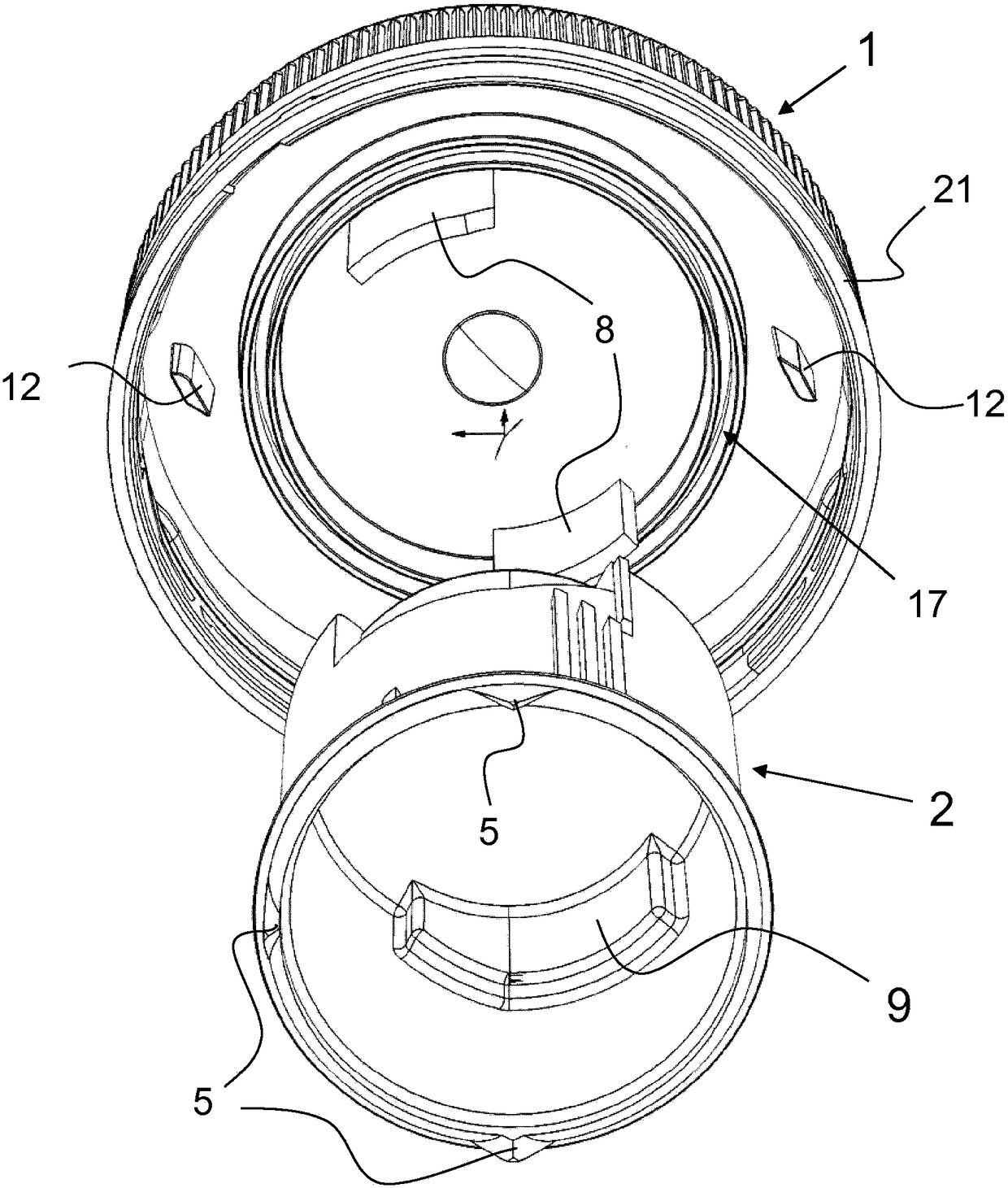

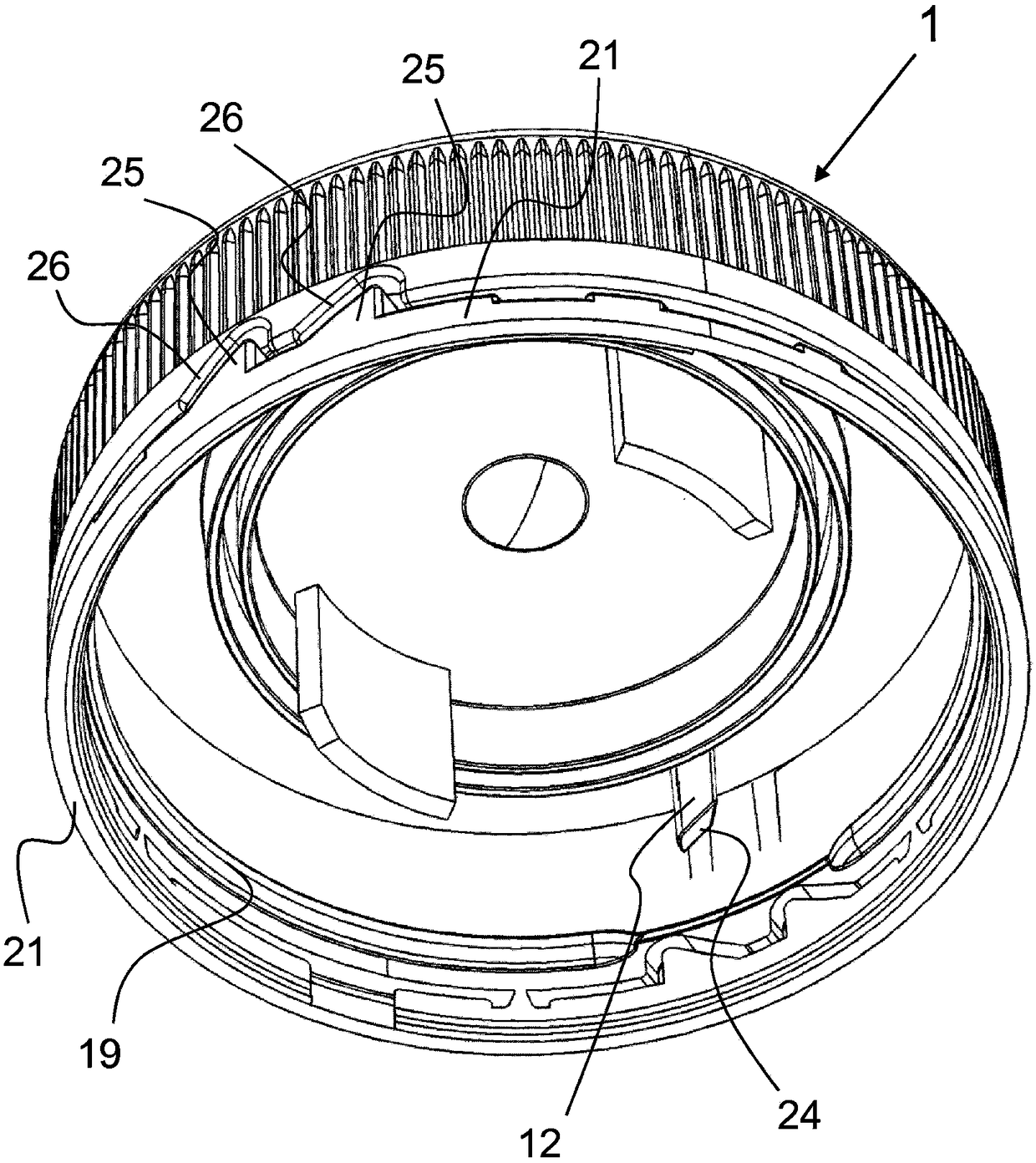

[0015] In the first embodiment, the lid closure comprises a total of four parts, in figure 1 Plastic parts 1 , 2 and 3 of these four parts are shown in , in particular in a view in which the three plastic parts are at a distance from each other along their common axis of rotation. The fourth component is a lamination film by means of which the lowest visible edge of the cylinder can be closed.

[0016] Starting from the top, the cap closure here configured as a twist cap closure comprises: a twist cap 1, then a fillable cup 2 below the twist cap and finally at the bottom most a receiving part 3, the cup 2 can Insert the receiving part. When the cup-shaped body 2 is inserted into the containing part 3, the piercing and cutting teeth 5 integrally formed under said cup-shaped body on its edge 4 and protruding downward beyond the edge do not extend all the way into the interior of the containing part 3 The lower edge 6 of the cylinder 7 . This cylinder 7 is connected at the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com