sealing profile

A profile and elastic material technology, applied in the direction of engine seals, aircraft accessories, engine components, etc., to ensure the effect of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described below based on the drawings explained above.

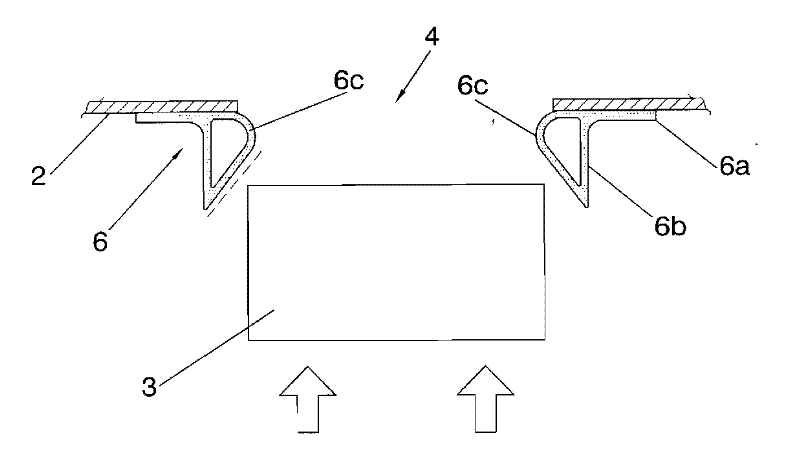

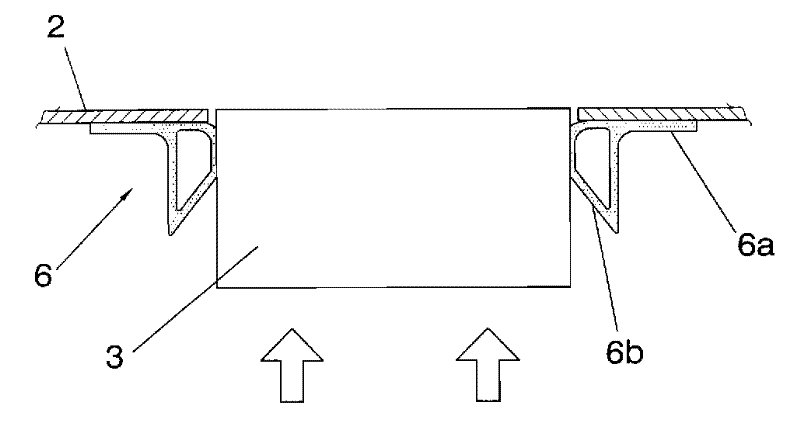

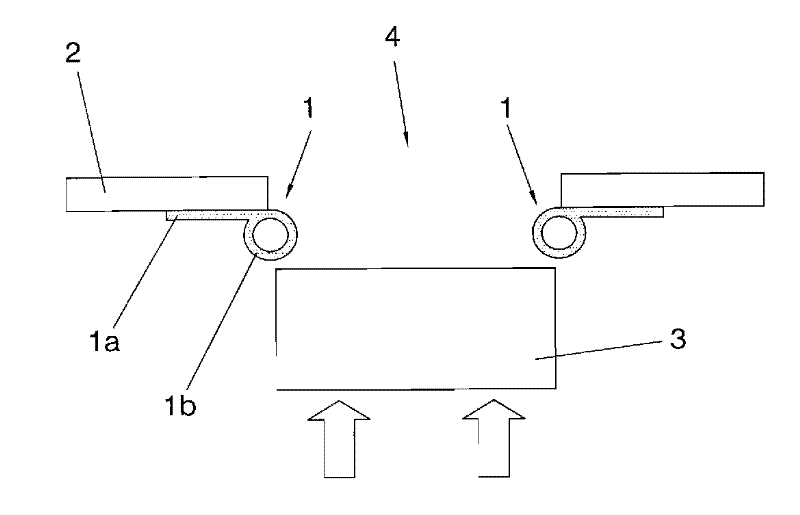

[0021] pass figure 1 and 2 , first describe the sealing profile 1 conventionally used to connect the first element 2 and the second element 3, for example in the embodiment the first element 2 comprises an aerodynamic lining 2 equipped with openings 4, with which the sealing profile 1 consisting of the device 3 The second element 3 fits and seals in the opening.

[0022] Thus, the sealing profile is provided with a rectilinear portion, which is fixed on the aerodynamic lining 2 of the first element. The first section 1a terminates in a circular tubular section 1b protruding relative to the first element 2, the tubular section occupying part of the opening 4, as in figure 1 shown in .

[0023] For example, the device 3 may be a device, usually included in the aircraft, that ventilates the APU when the aircraft is stationary on the ground and the APU is activated. Thus, the ventilation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com