A concrete anti-crack construction method and its aggregate blowing cooler

A construction method and concrete technology, which can be applied in basic structure engineering, building material processing, construction, etc., can solve the problems of short timeliness of anti-aging protection, etc., and achieve the effect of improving timeliness, slowing down aging, and uniform cooling of aggregates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

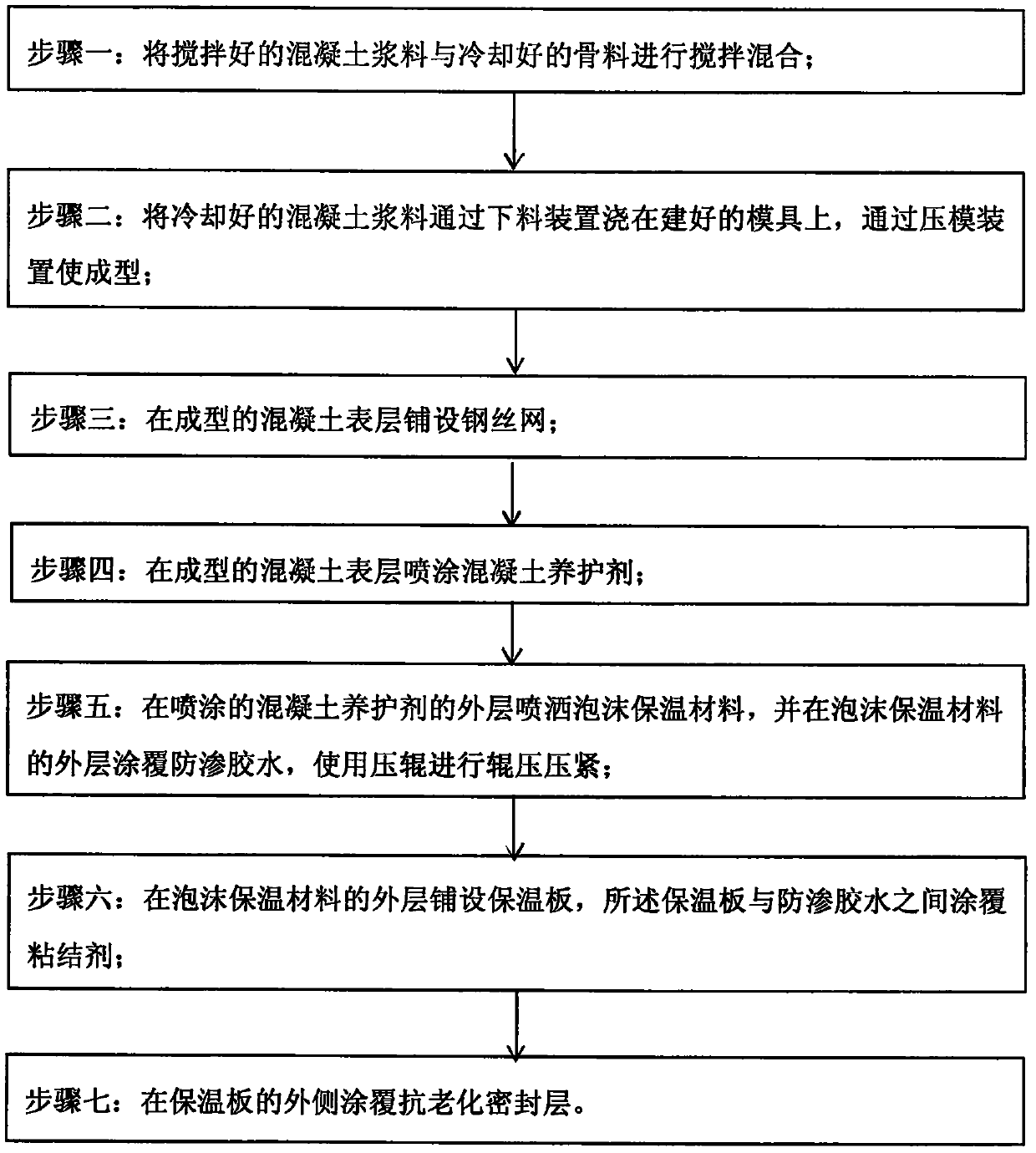

[0039] A concrete anti-cracking construction method, comprising the steps of:

[0040] Step 1: Stir and mix the stirred concrete slurry with the aggregate cooled by the aggregate blower; preferably, the mixing of the concrete slurry and the mixing with the aggregate is carried out by a concrete mixing station, and the concrete mixing The station includes 5 major systems including mixing host, material weighing system, material conveying system, material storage system and control system and other necessary auxiliary facilities. Concrete mixing plant adopts floor aggregate measurement. Compared with station aggregate measurement, its measurement method reduces four intermediate links, and it is vertical feeding measurement, which saves measurement time and greatly improves production efficiency. The cooling of the aggregates is carried out by an aggregate blowing cooler, and the cooling in the form of blowing cooling can make the aggregates of the inner layer and the outer laye...

Embodiment 2

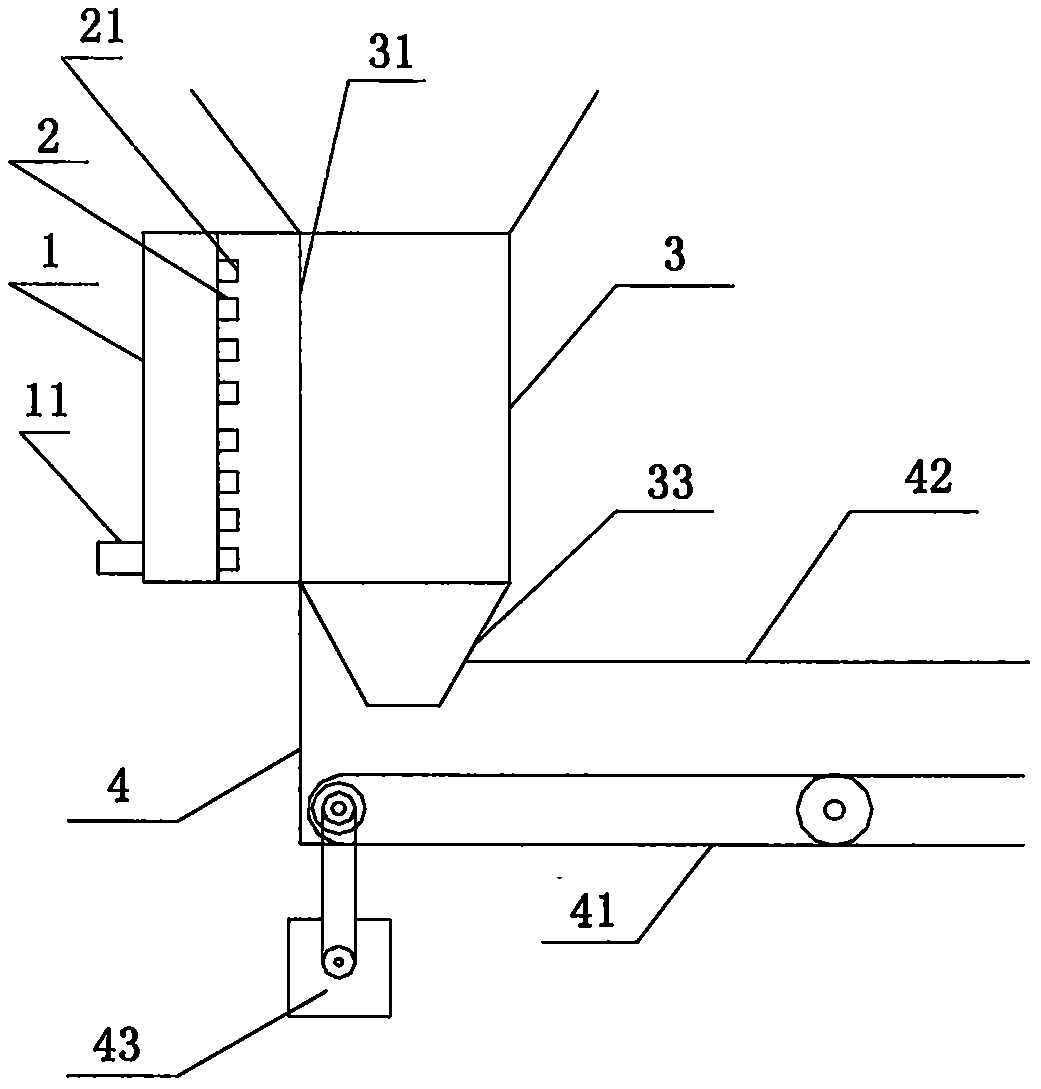

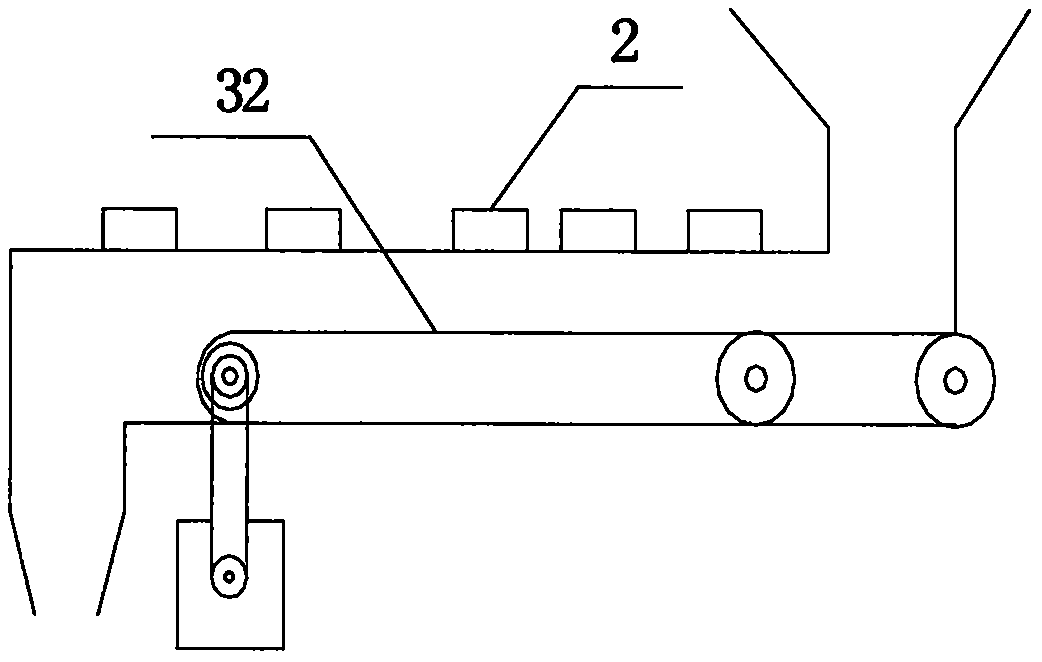

[0054] refer to figure 2 As shown, this specific embodiment discloses an aggregate blowing cooler, including a cooling compressor 1 , a blower 2 , a feeding barrel 3 and a conveyor 4 . Among them, the cooling compressor 1 is used to cool the air sucked by the blower, the blower 2 is used to blow cold air to the aggregate, the feeding barrel 3 is used to store the aggregate and feed it to the conveyor 4, and the conveyor 4 is used to transfer the aggregate The material is transported to the concrete mixing plant.

[0055] Specifically, the cooling compressor 1 and the blower 2 are fixedly connected by bolts or other fixed connection methods. The cooling compressor 1 and the blower 2 are located at the side of the lower material barrel 3, and the blower 2 and the side of the lower material barrel 3 are fixedly connected by screws and nuts. In another embodiment of the present invention, the blower 2 and the lower material barrel 3 The side of the side can also be fixed by oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com