Crimping tool for wire end ferrules

一种压接工具、压接模具的技术,应用在制造工具、线路/集电器零部件、连接等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

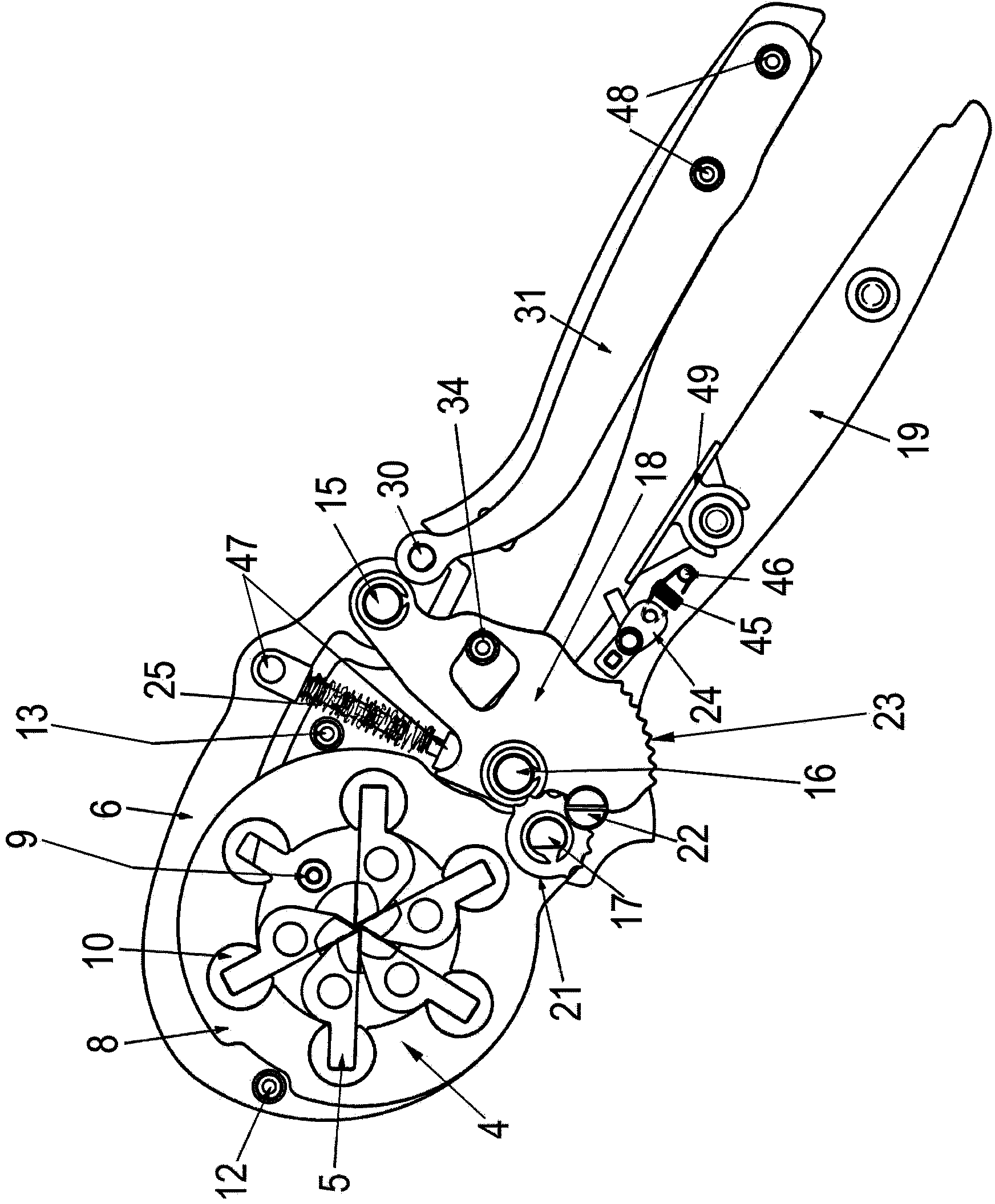

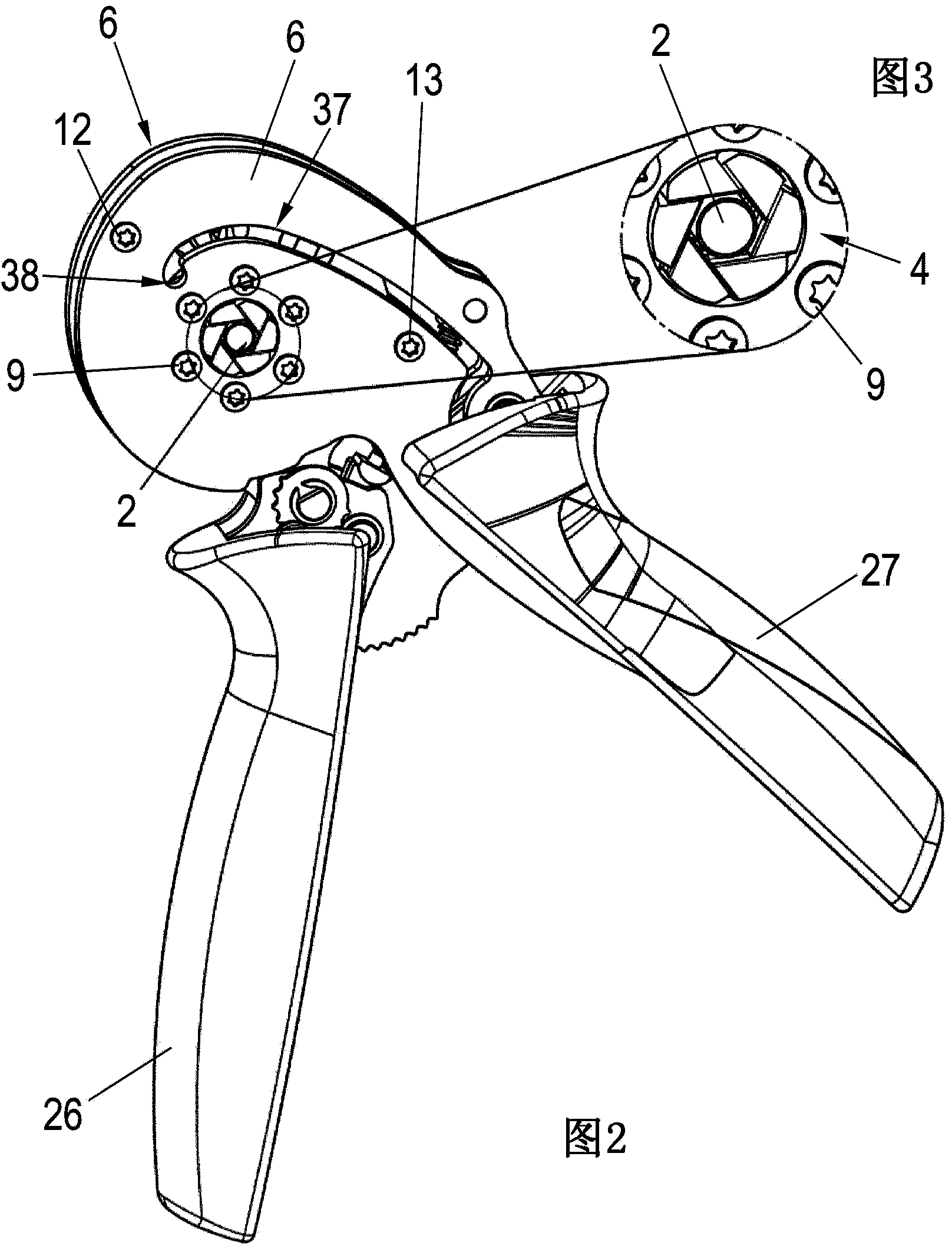

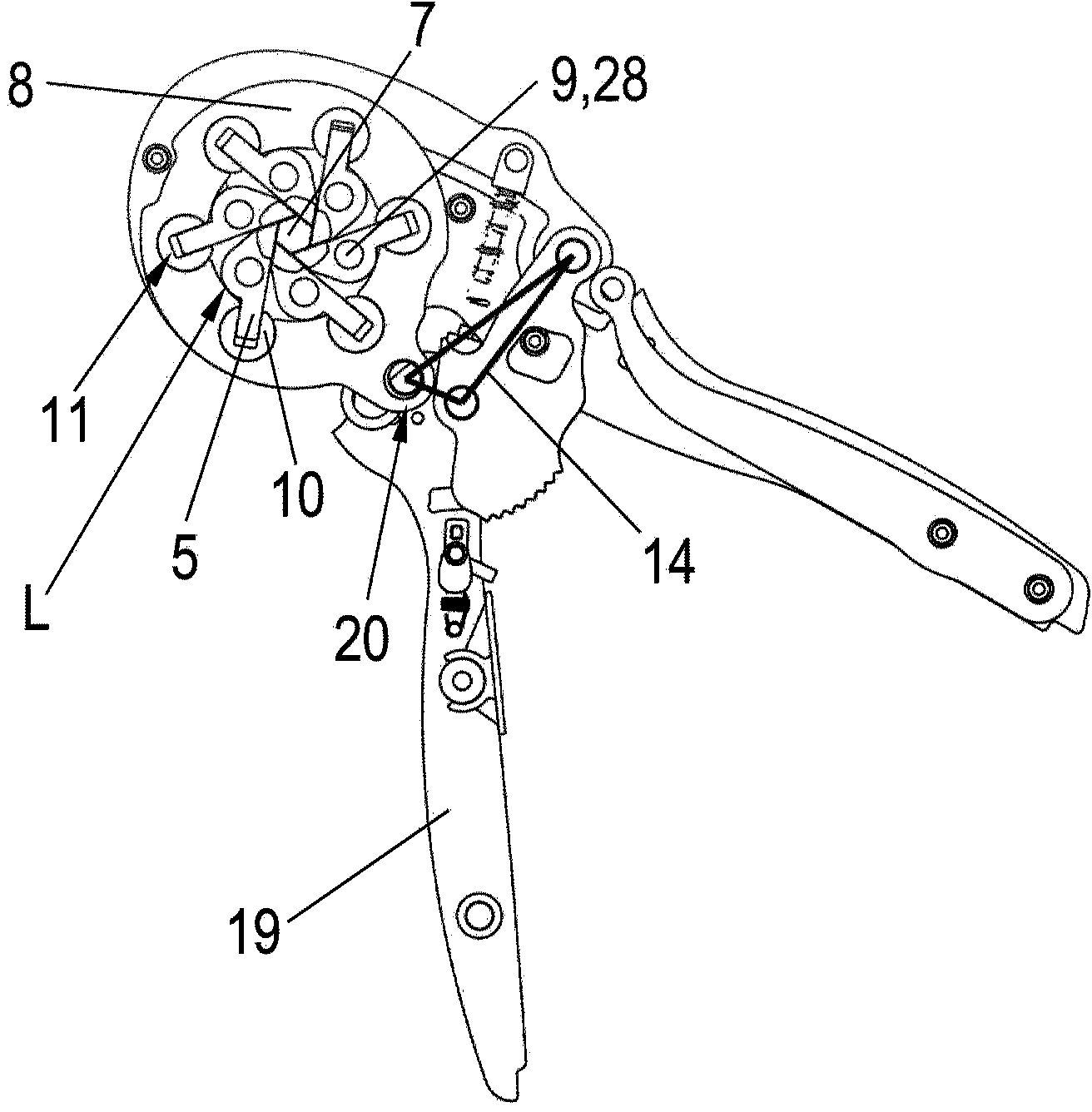

[0030] figure 1 A crimping tool 1 according to the invention is shown for crimping wire end sleeves 2 (not shown), contact bushings, cable lugs or the like on electrical conductors 3 (not shown). The manually operated crimping tool 1 in the form of pliers comprises a crimping die 4 with automatic adjustment according to the crimping sleeve and conductor cross-section to be processed, which crimping die 4 is formed by a plurality of crimping punches 5 . The extruded wire end sleeve 2 can in particular be embodied hexagonally or quadrilaterally.

[0031] The crimping tool 1 has two base plates 6 between which the main components of the crimping tool 1 are mounted. Between the two base plates 6 there is a slider plate 8 coaxially with a circular opening 7 (not shown) in the base plate 6 for guiding the wire end sleeve 2 or the like. The crimped conductor 3 passes through. Slider board 8 accommodates by four ( Figure 14 ) or the crimping die 4 formed by six crimping punches 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com