A kind of preparation method of nitrogen and phosphorus co-doped flexible carbon fiber membrane negative electrode material

A carbon fiber membrane and anode material technology, applied in the field of nitrogen and phosphorus co-doped carbon fiber membrane flexible anode materials and its preparation, can solve the problems of reducing the electronic conductivity of electrode materials, separating active materials from current collectors, and affecting the electrochemical performance of materials , to achieve the effects of improving transmission and ion diffusion, good mechanical flexibility, increasing energy density and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Nitrogen and phosphorus co-doped flexible carbon fiber membrane anode material I

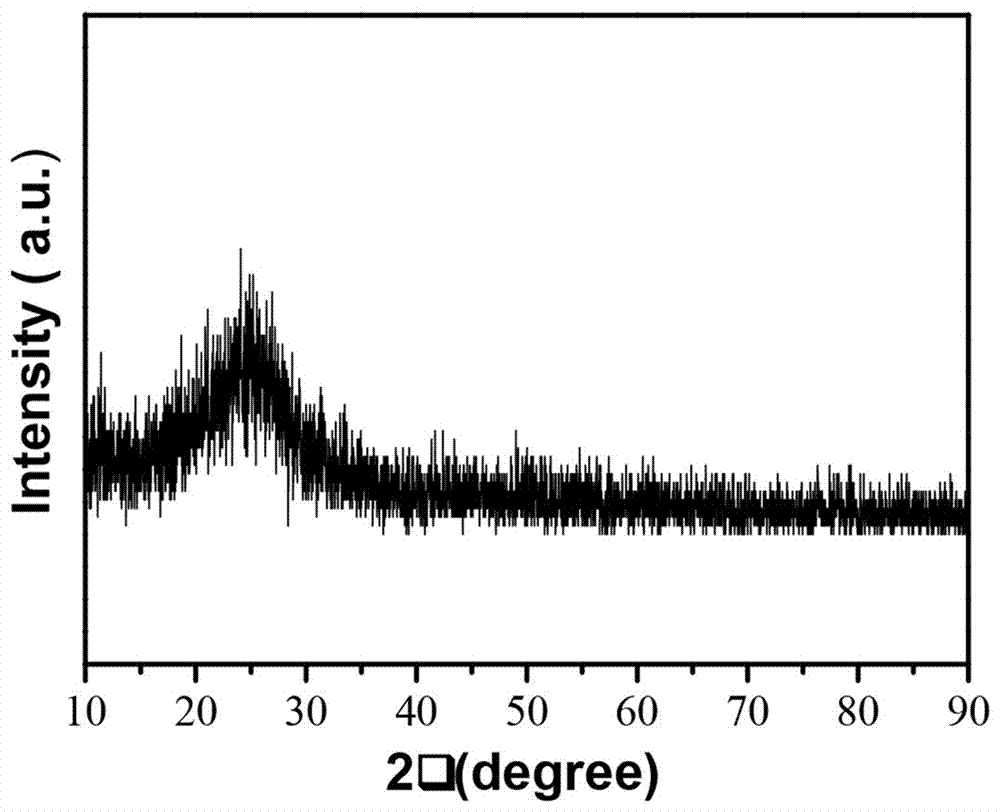

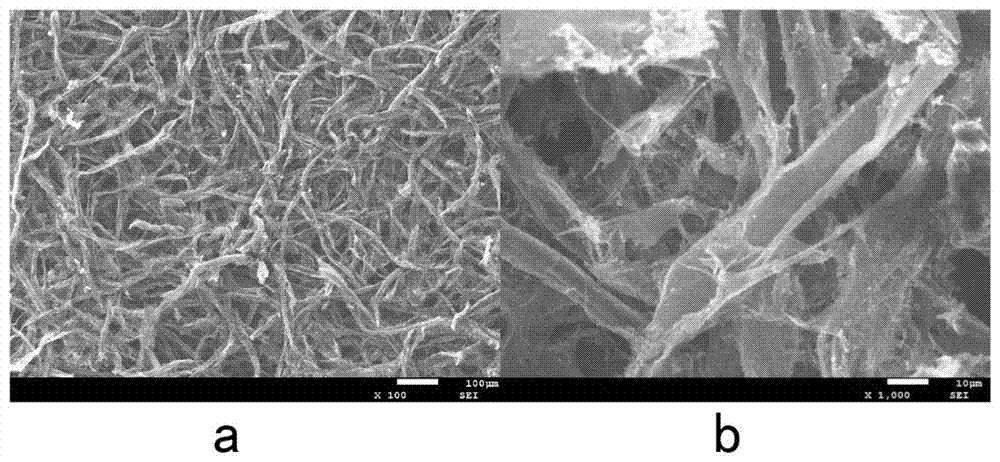

[0027] Put ordinary qualitative filter paper (20 cm 2 , 0.16 g) and hydrazine hydrate (1 mL) were placed in a hydrothermal kettle at 120 °C for 12 hours to obtain nitrogen-doped filter paper, and then the nitrogen-doped filter paper was soaked in pre-configured urea solution (0.5 g mL -1 ), followed by natural drying, and then the nitrogen-containing filter paper filled with urea (the mass ratio of filter paper and urea is 1:16) was calcined in an atmosphere furnace (nitrogen), and the calcination temperature was 550 ° C for 2 hours, and then continued to heat up to 900°C, keep warm for 2 hours. During the calcination process, nitrogen-containing filter paper is carbonized into nitrogen-doped carbon fibers, urea is pyrolyzed into ammonia gas and further doped with nitrogen, and the gas generated by the decomposition of urea strips the carbon paper into an ultra-thin carbon fil...

Embodiment 2

[0028] Example 2 Nitrogen and phosphorus co-doped flexible carbon fiber membrane negative electrode material II

[0029] Put ordinary qualitative filter paper (30 cm 2 , 0.24 g) and hydrazine hydrate (1 mL) were placed in a hydrothermal kettle at 100°C for 4 hours to obtain a nitrogen-doped filter paper, and then the nitrogen-doped filter paper was soaked in a pre-configured urea solution (0.4 g mL -1 ), followed by natural drying, and then the nitrogen-containing filter paper filled with urea (the mass ratio of filter paper and urea is 1:12) was calcined in an atmosphere furnace (nitrogen) at a temperature of 1000°C and kept for 3 hours to obtain nitrogen Phosphorus co-doped flexible carbon fiber membrane. The electrode material test conditions are as described in Example 1, as lithium ion battery negative electrode material, with 1 A g -1 The current density is charged and discharged, and the first reversible capacity is 620 mAh g -1 , with a reversible capacity of 730 mA...

Embodiment 3

[0030] Example 3 Nitrogen and phosphorus co-doped flexible carbon fiber membrane negative electrode material III

[0031] Put ordinary qualitative filter paper (40 cm 2 , 0.32 g) and hydrazine hydrate (2 mL) were placed in a hydrothermal kettle at 110°C for 3 hours to obtain nitrogen-doped filter paper, and then soaked in pre-configured urea solution (0.3 g mL -1 ), followed by natural drying, and then the nitrogen-containing filter paper filled with urea (the mass ratio of filter paper and urea is 1:10) was calcined in an atmosphere furnace (nitrogen) at a calcination temperature of 900°C and kept for 4 hours to obtain nitrogen Phosphorus co-doped flexible carbon fiber membrane. The electrode material test conditions are as described in Example 1, as lithium ion battery negative electrode material, with 1 A g -1 The current density is charged and discharged, and the first reversible capacity is 600 mAh g -1 , with a reversible capacity of 710 mAh g after 200 cycles -1 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com