Amorphous alloy oil immersion type distribution transformer body structure and manufacturing method thereof

A technology for distribution transformers and amorphous alloys, which is applied in the manufacture of inductors/transformers/magnets, transformers/inductor coils/windings/connections, circuits, etc. Cost-effectiveness and other issues, to achieve constant good magnetic properties, low mass density, and eliminate the effect of coil extrusion of amorphous alloy core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

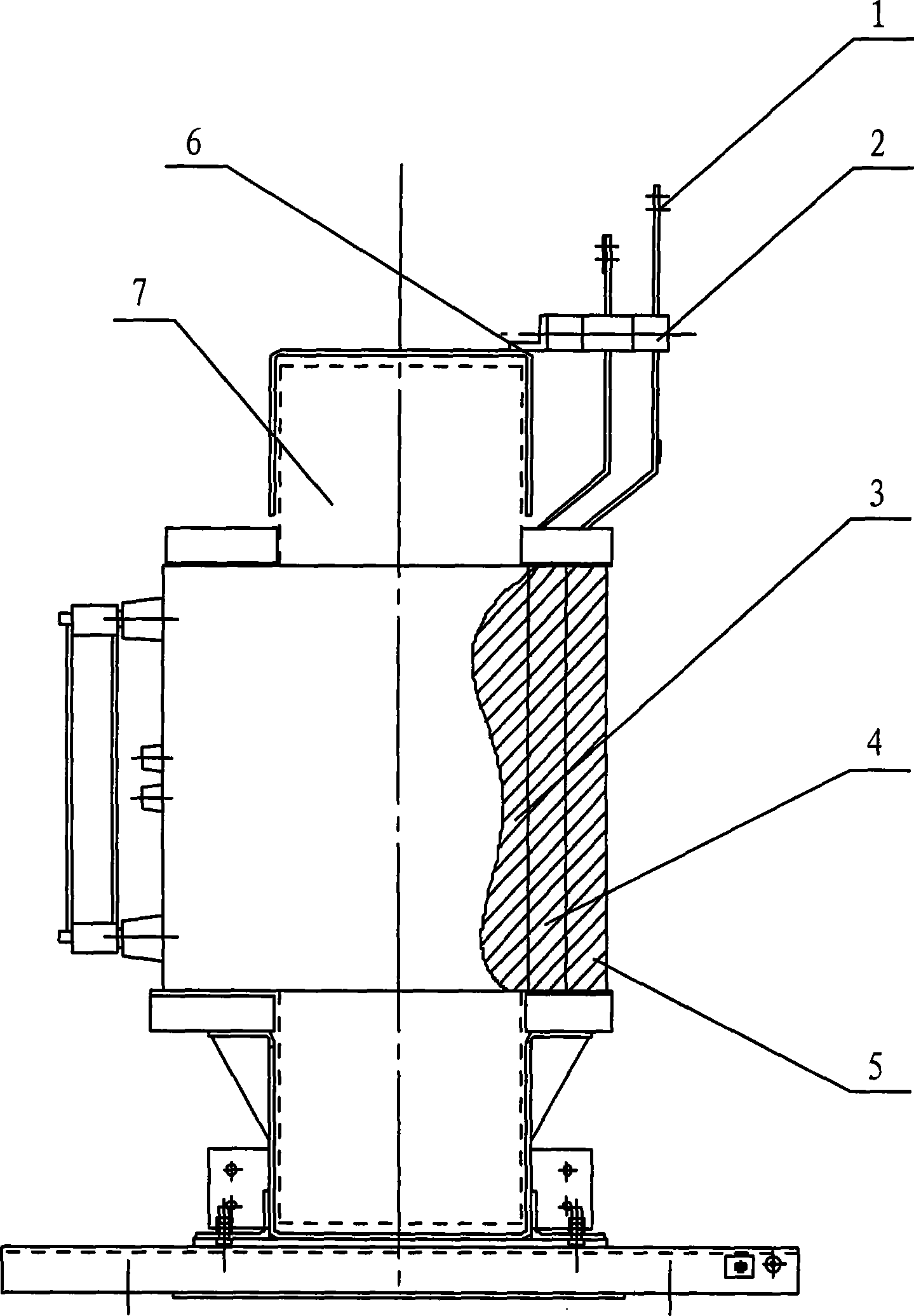

[0022] see figure 1 , and combined with figure 2 , image 3 , a method for manufacturing an amorphous alloy dry-type distribution transformer according to one of the present invention, comprising the following steps:

[0023] The first step is to manufacture the three-phase iron core 7 by winding. The three-phase iron core 7 is a four-frame five-column or three-frame three-column structure with a rectangular cross-section, which can be composed of one row or two rows of amorphous alloy cores stacked side by side. ;

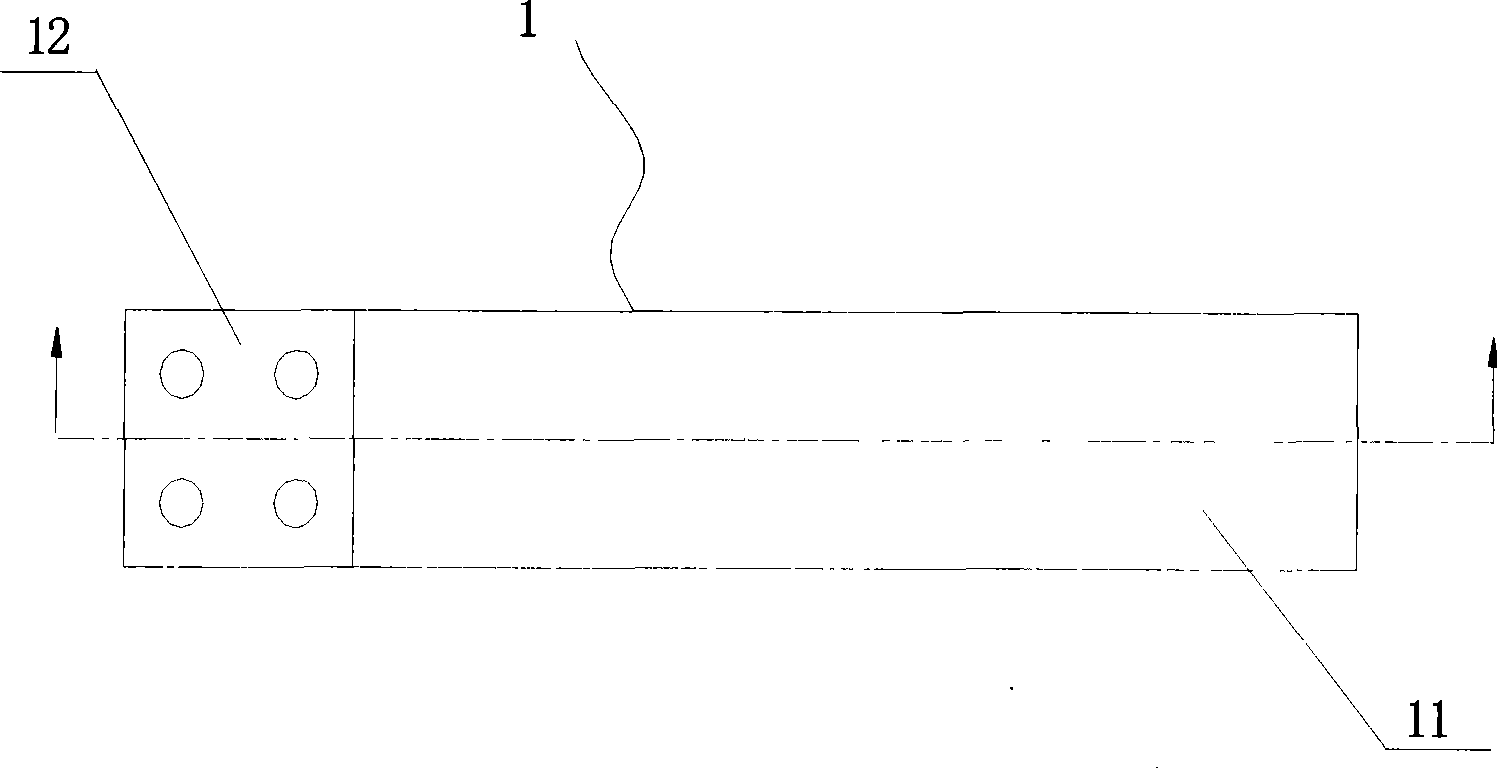

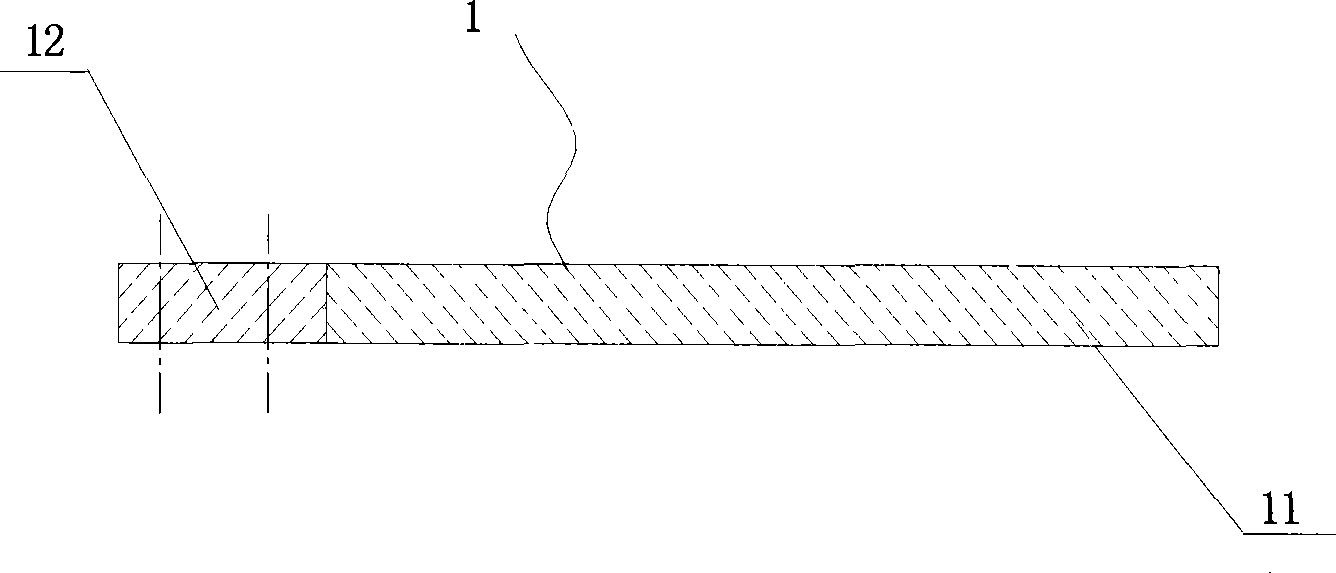

[0024] The second step is to manufacture the combined clamps and insulating framework 3 composed of the end clamps arranged at the left and right ends of the high-voltage coil 5 and the upper and lower clamps 6 arranged at the outer ends of the low-voltage coil 4 at the upper and lower ends by machining. and an aluminum-copper transition joint 1, wherein the insulating skeleton 3 is a rectangular cylinder whose inner diameter matches the section of the three-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com