Patents

Literature

35results about How to "Chance of damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

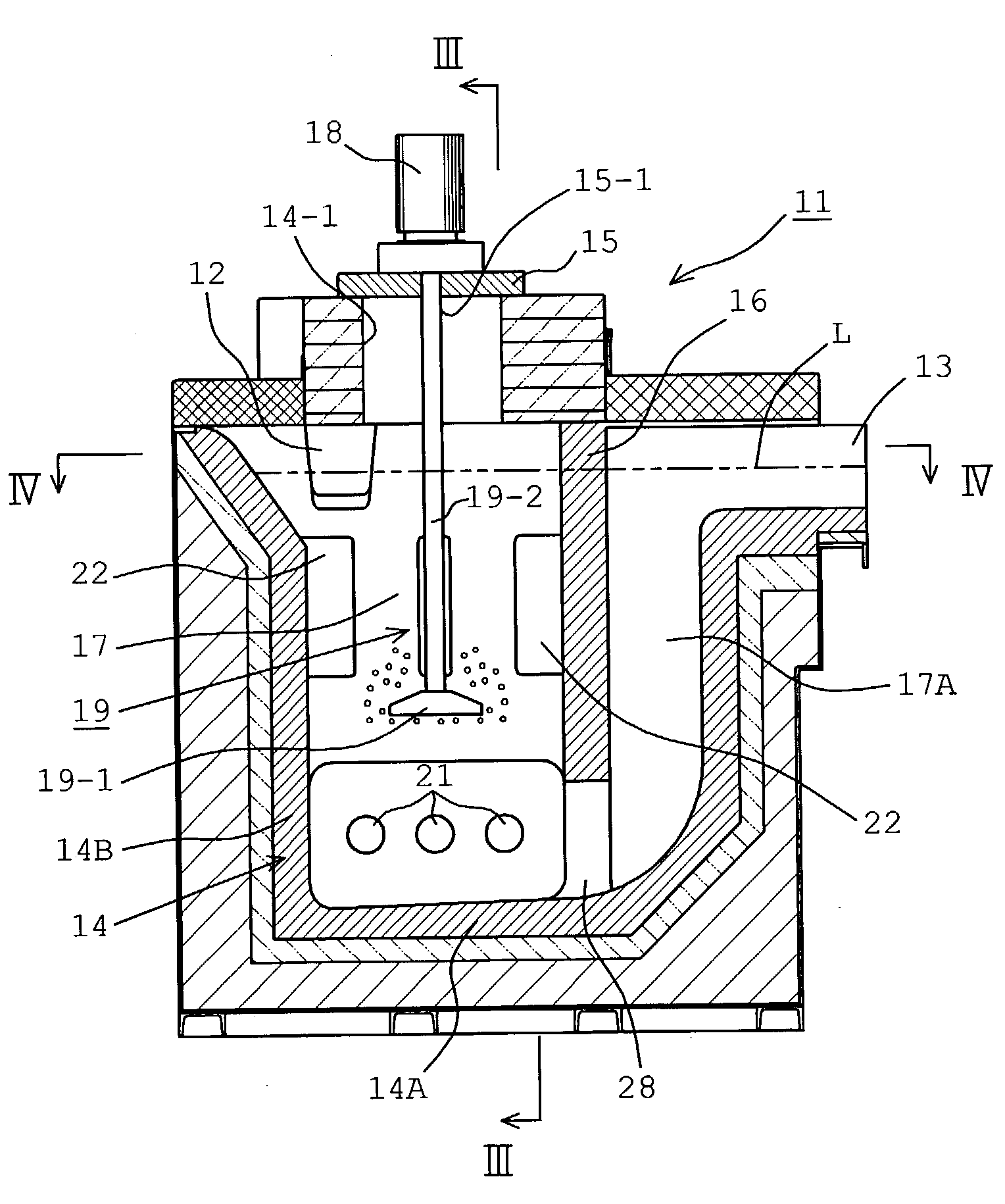

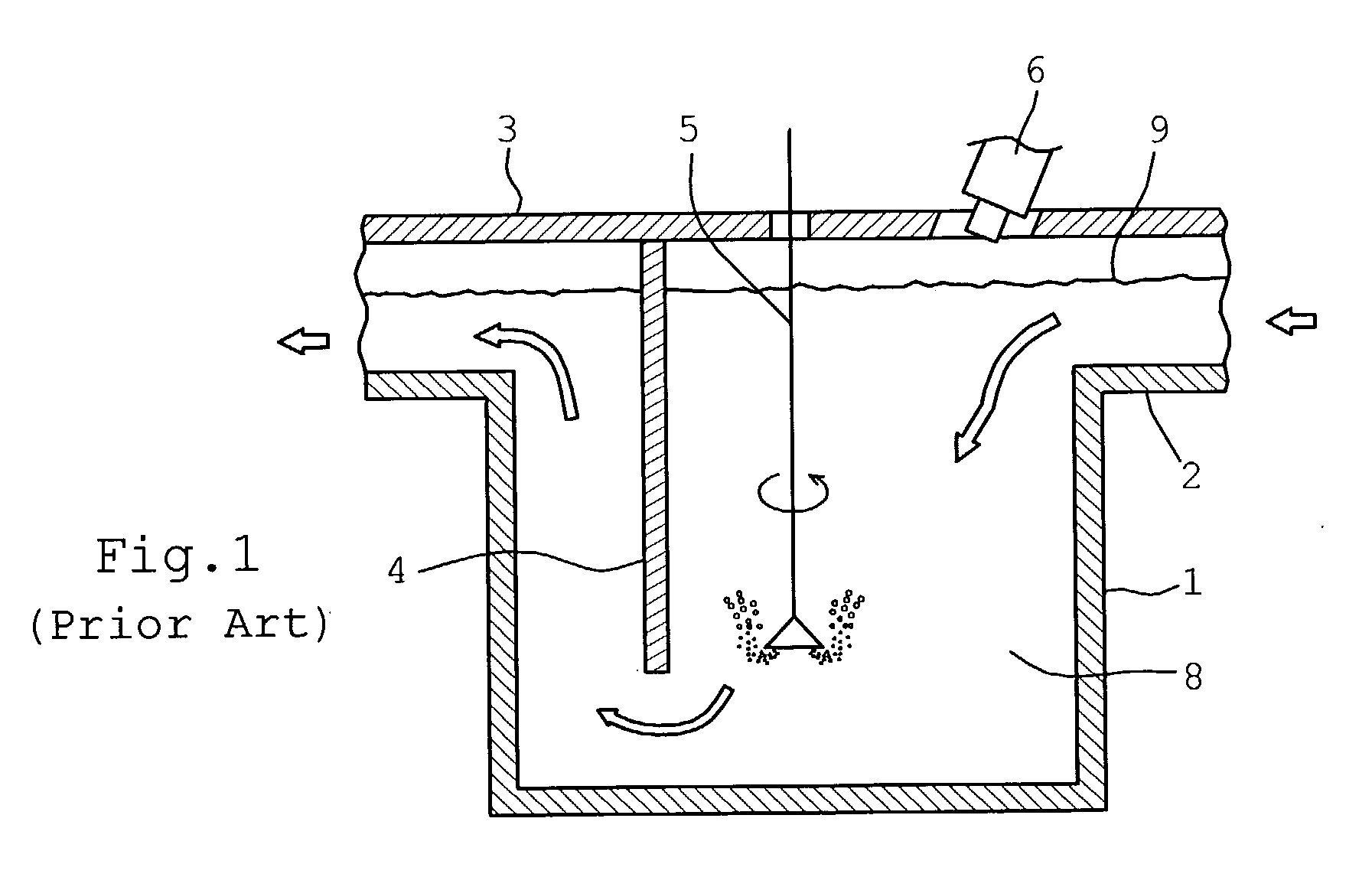

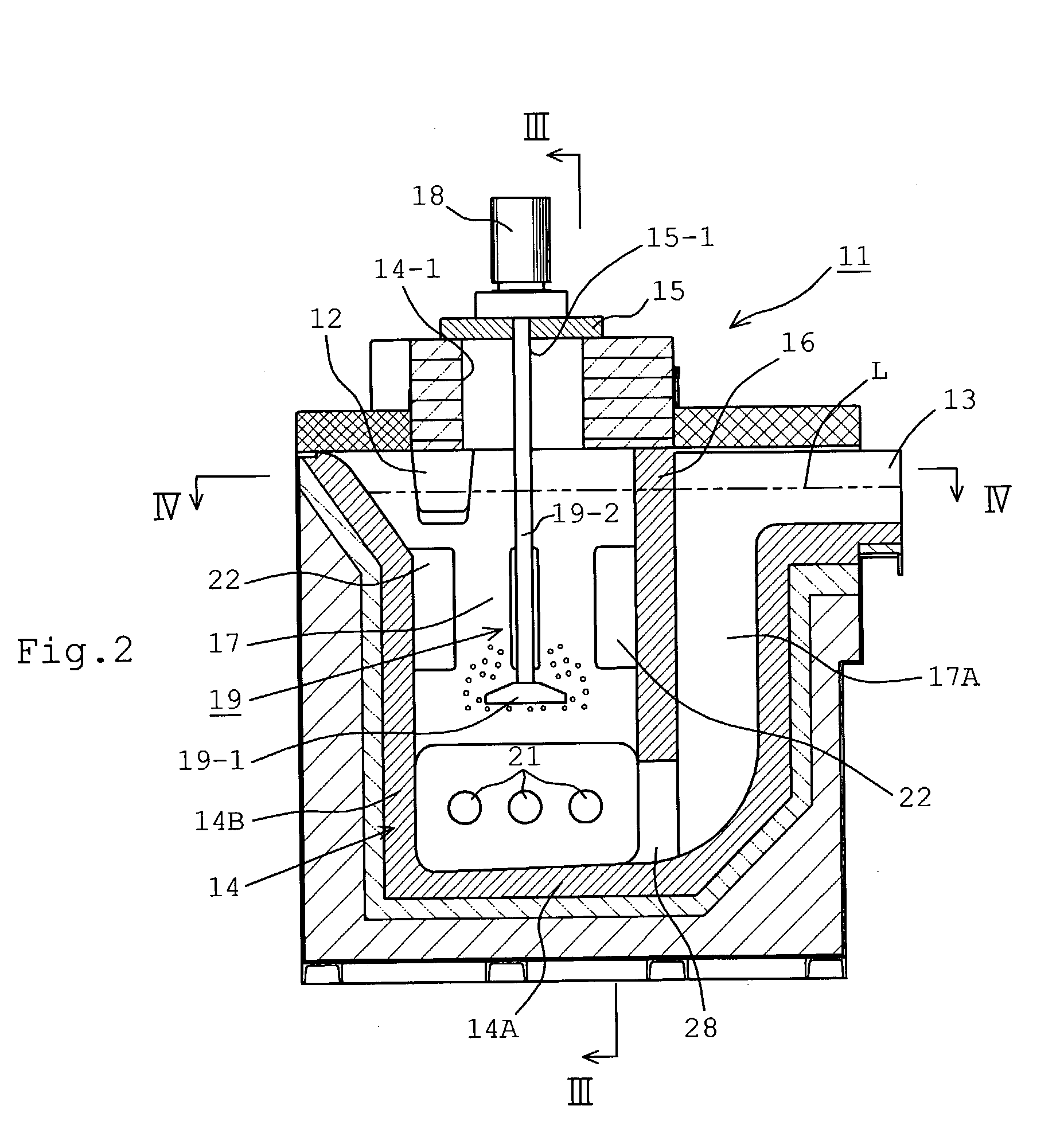

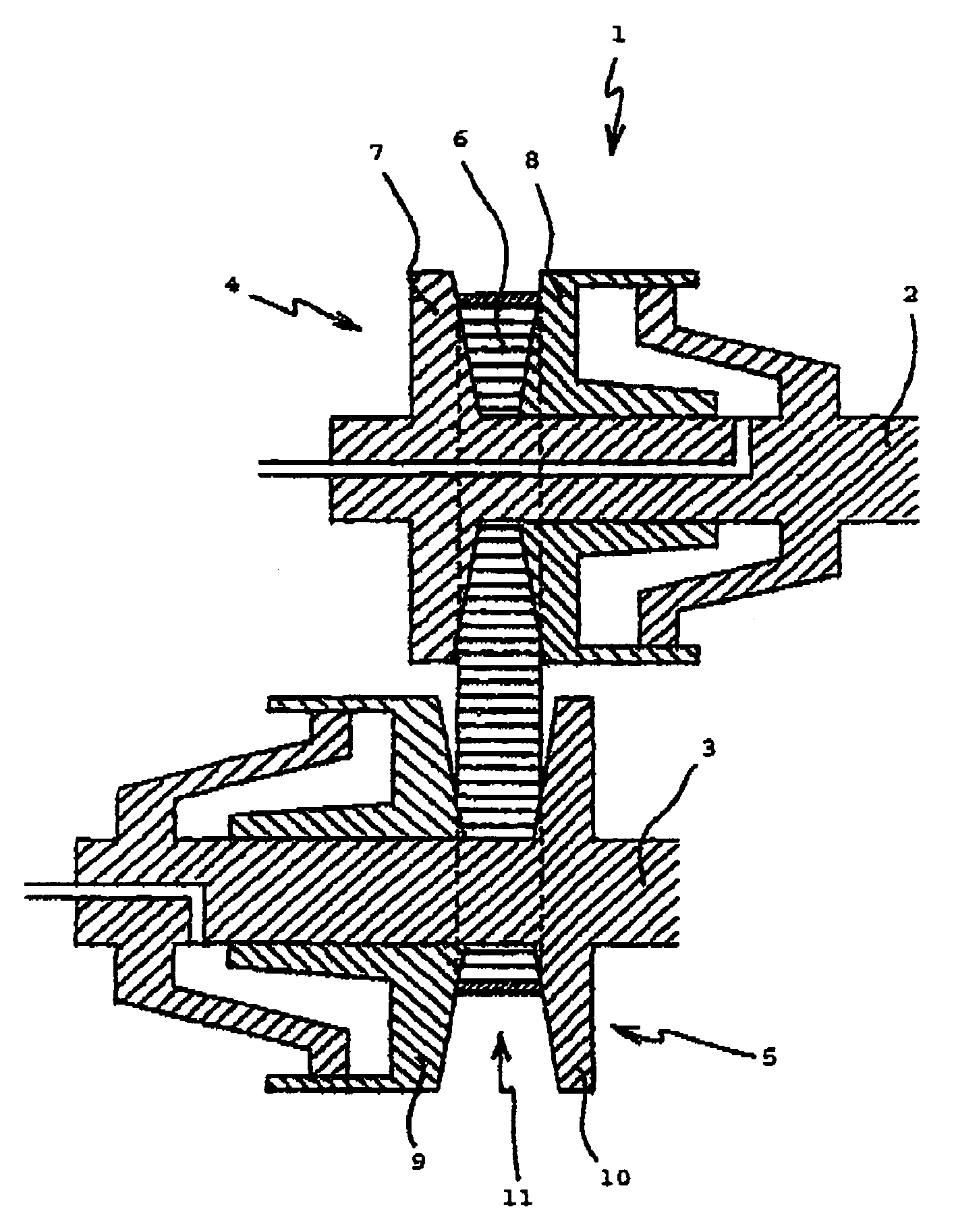

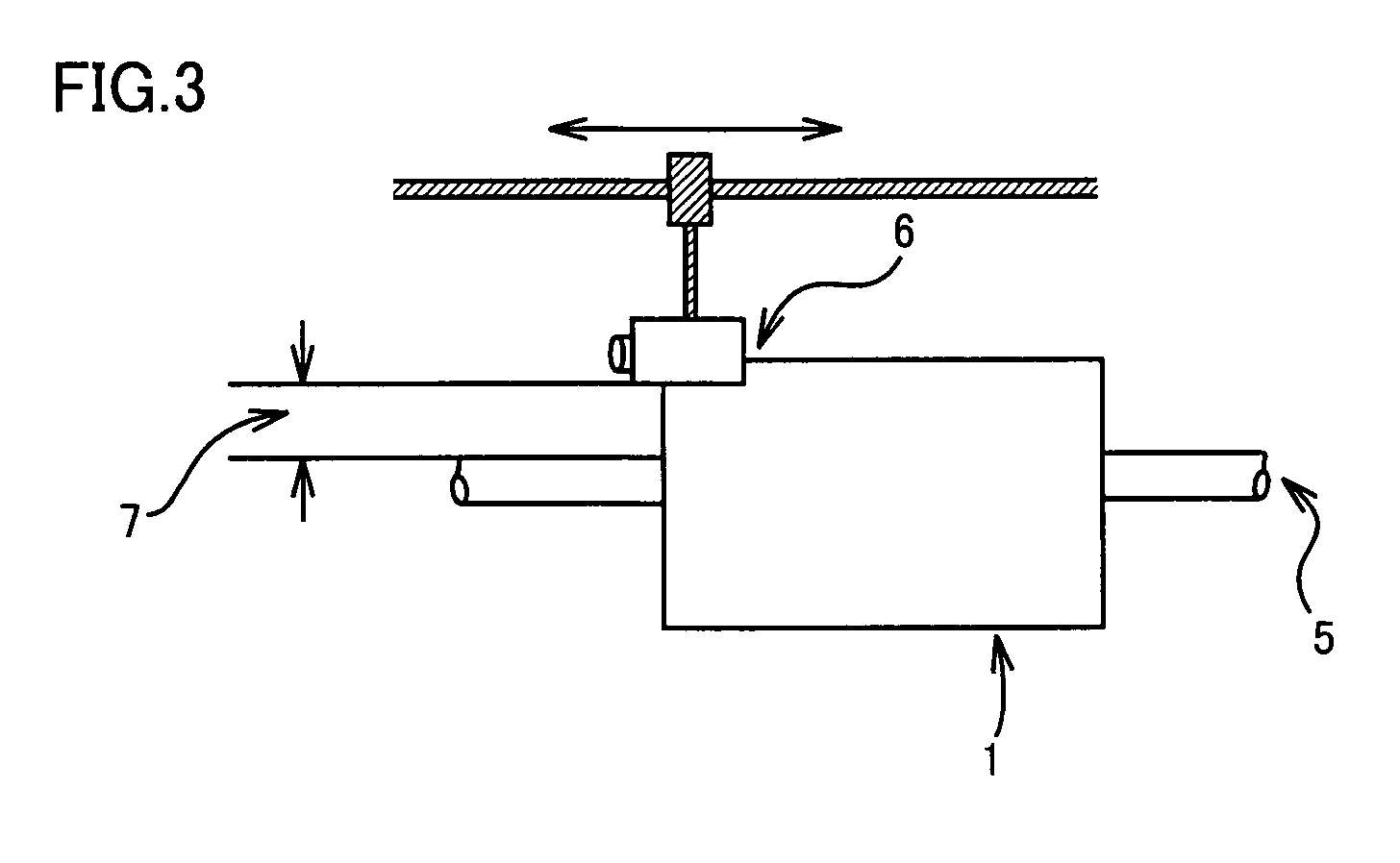

Inline degassing apparatus

InactiveUS20030151176A1Chance of damageExtended service periodMelt-holding vesselsStirring devicesNon-metallic inclusionsProduct gas

An inline degassing apparatus for removing solid solution gases as well as nonmetallic inclusions from molten metal in a degassing container, to which the molten metal is continuously introduced for degassing operation and from which the degassed molten metal is continuously removed. A rotary diffusing device is arranged in the degassing container for generating bubbles of inert gas diffused into the molten metal, thereby entrapping solid solution gases as well as nonmetallic inclusions into the bubbles, which are then floated and separated. Heaters are provided, which extend, in a cantilever fashion, from a side wall of container at a position adjacent the bottom wall of the container substantially parallel to the bottom wall.

Owner:PYROTEK JAPAN +1

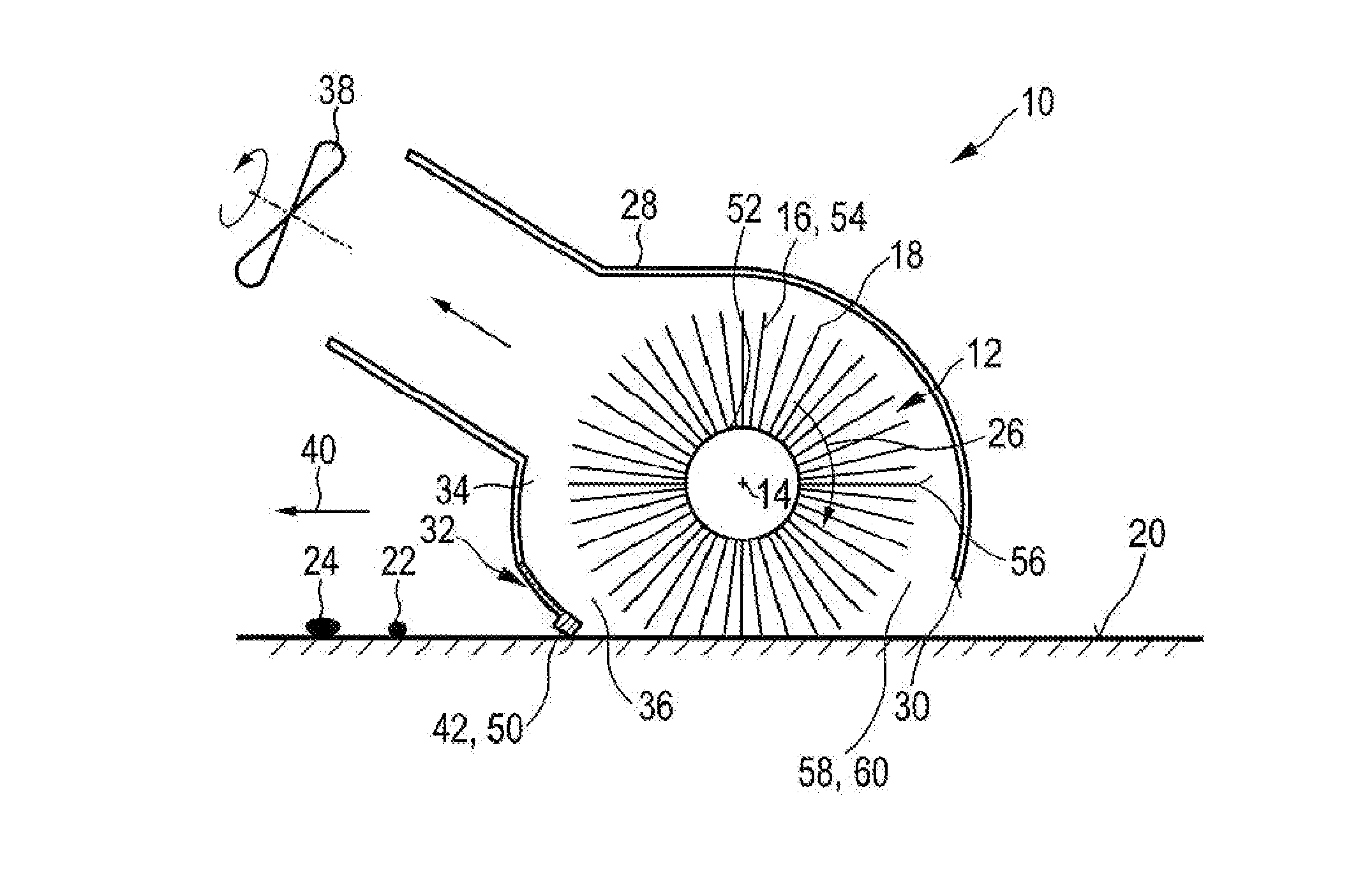

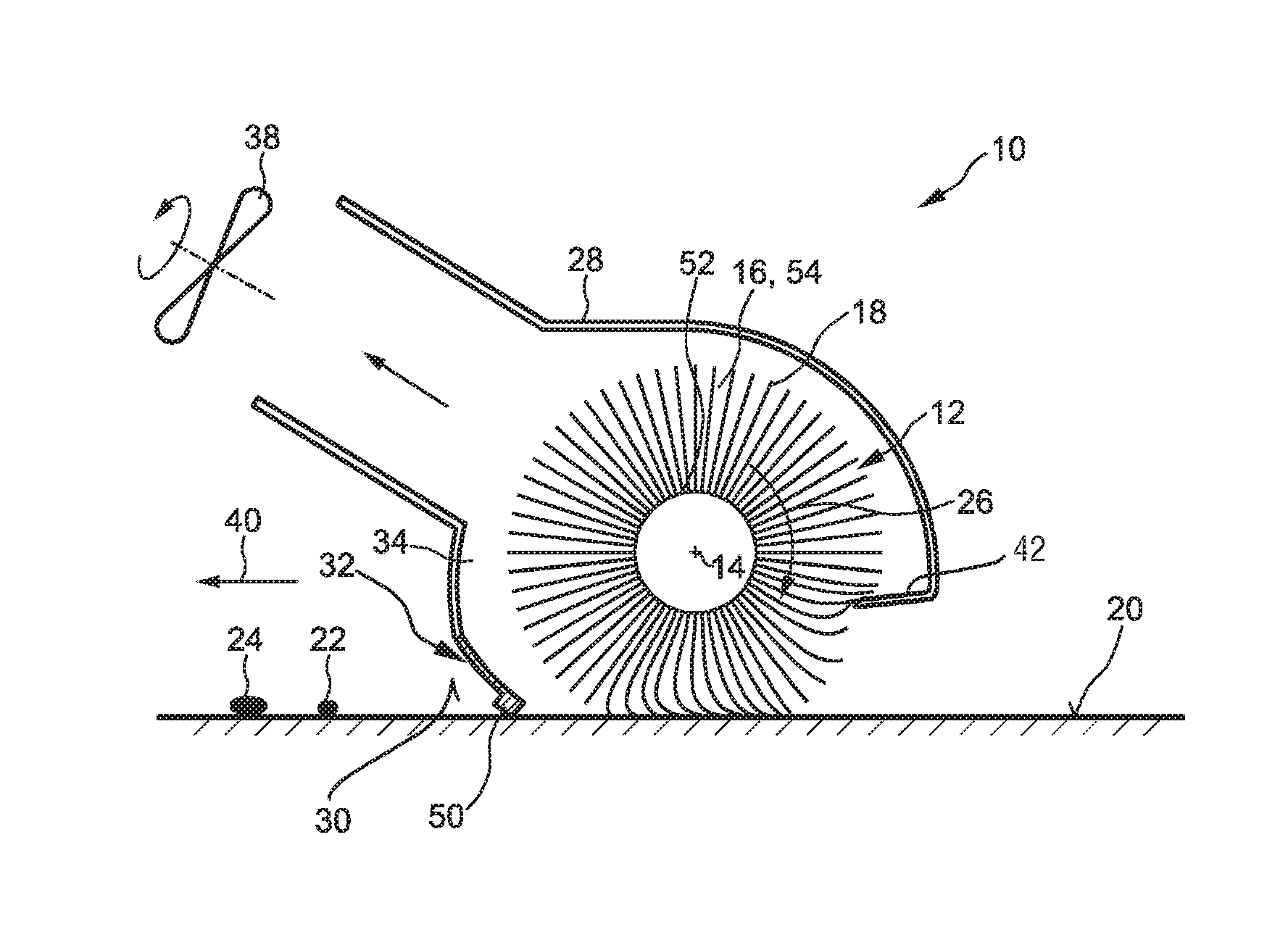

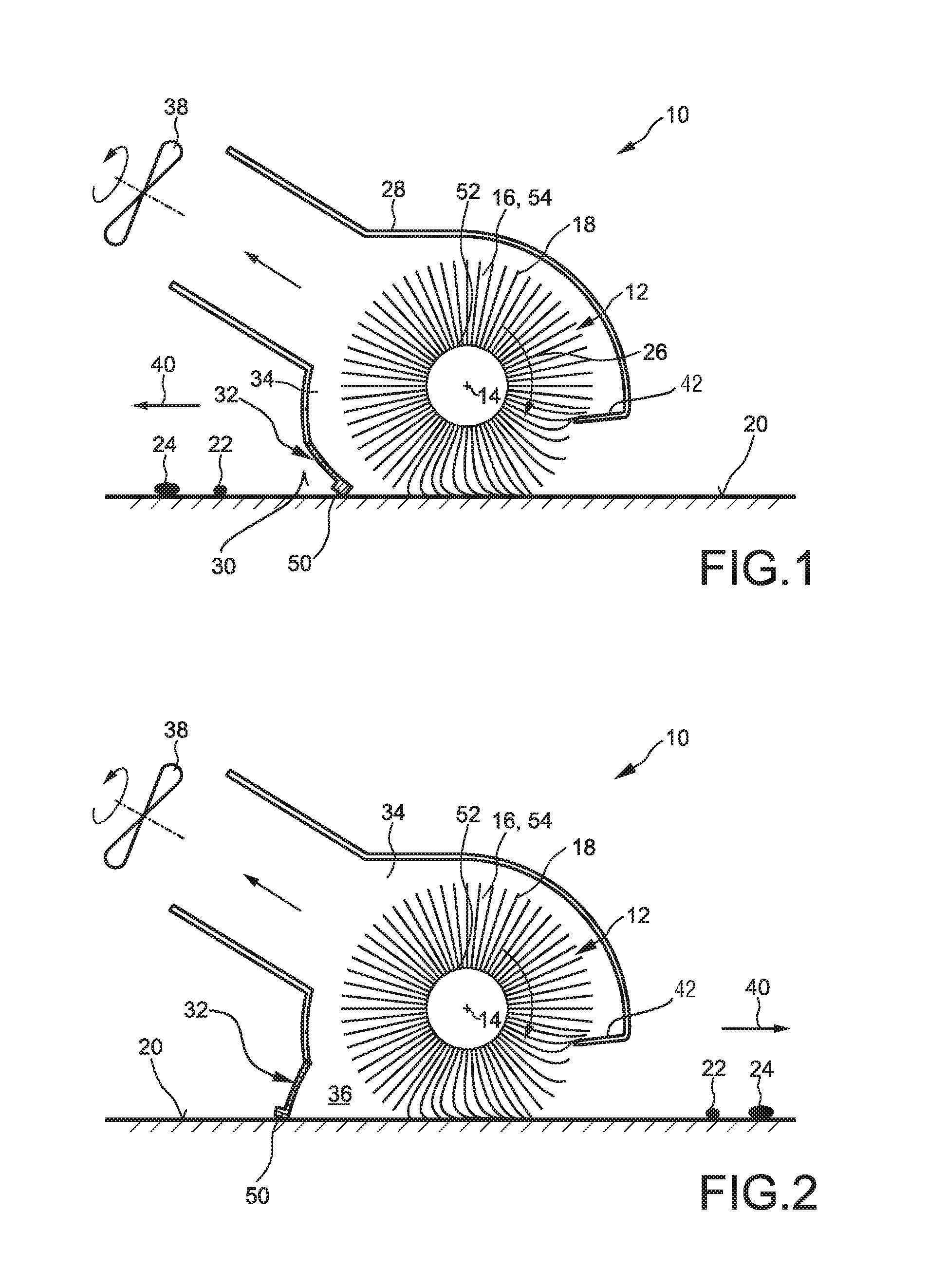

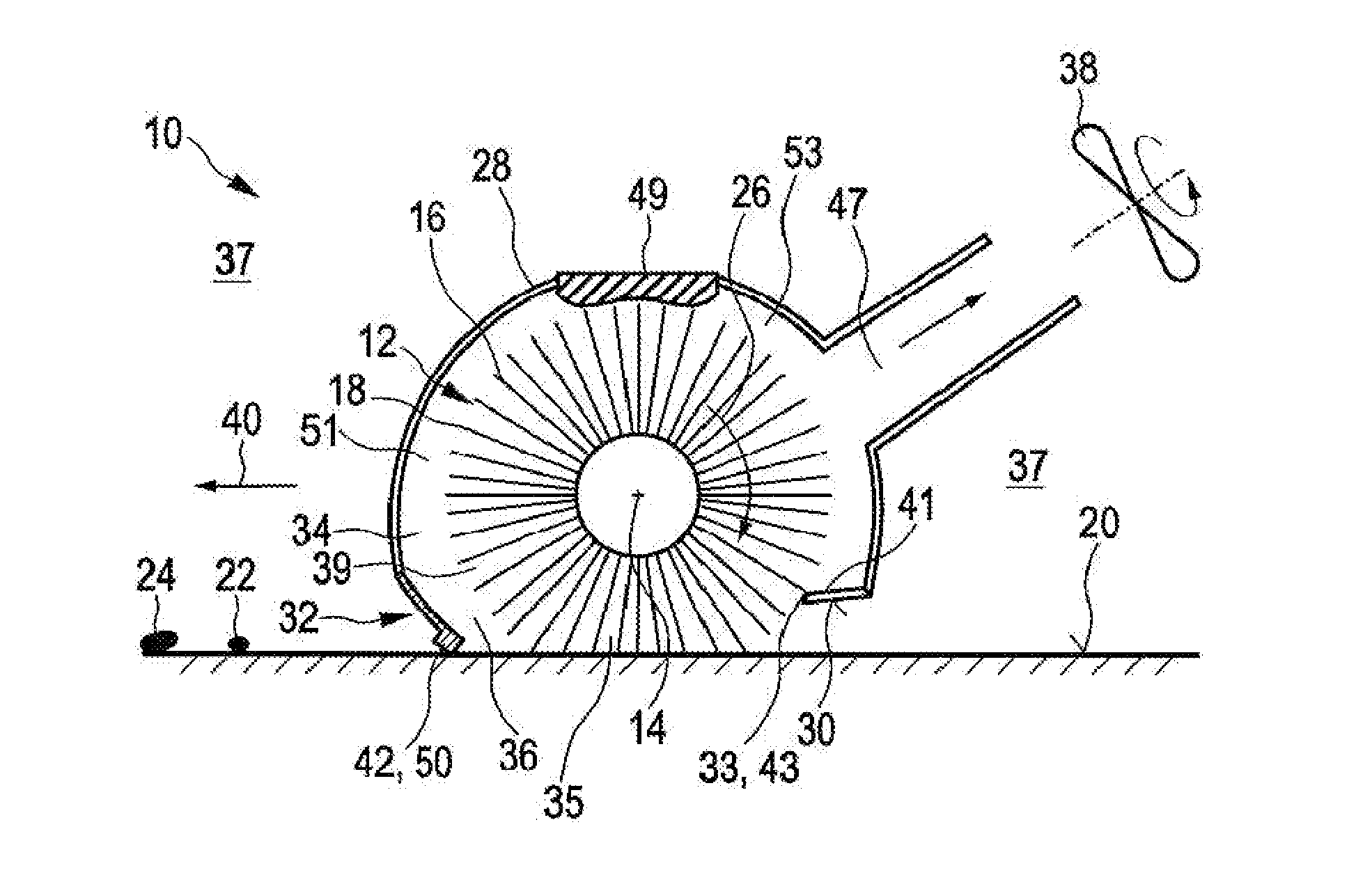

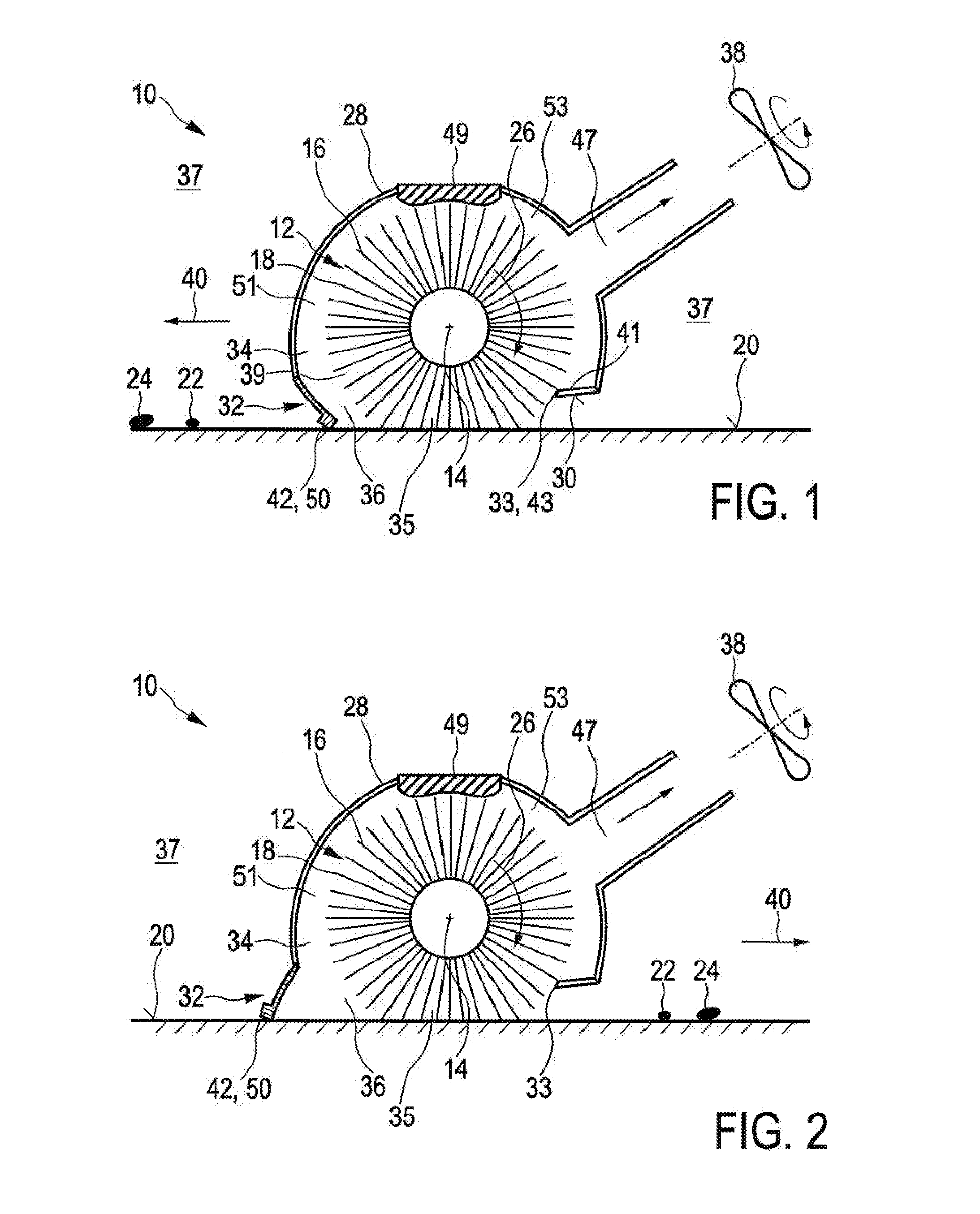

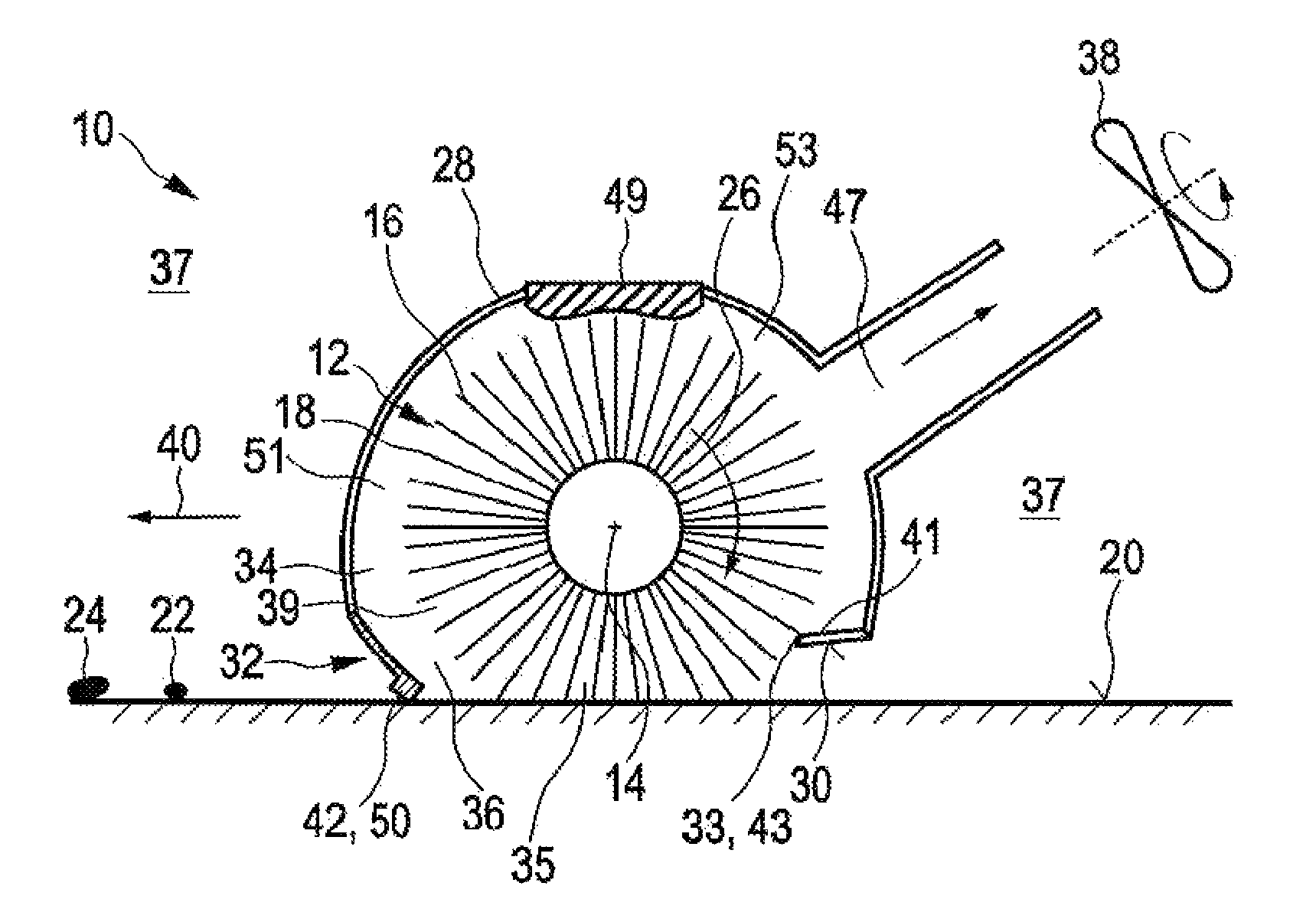

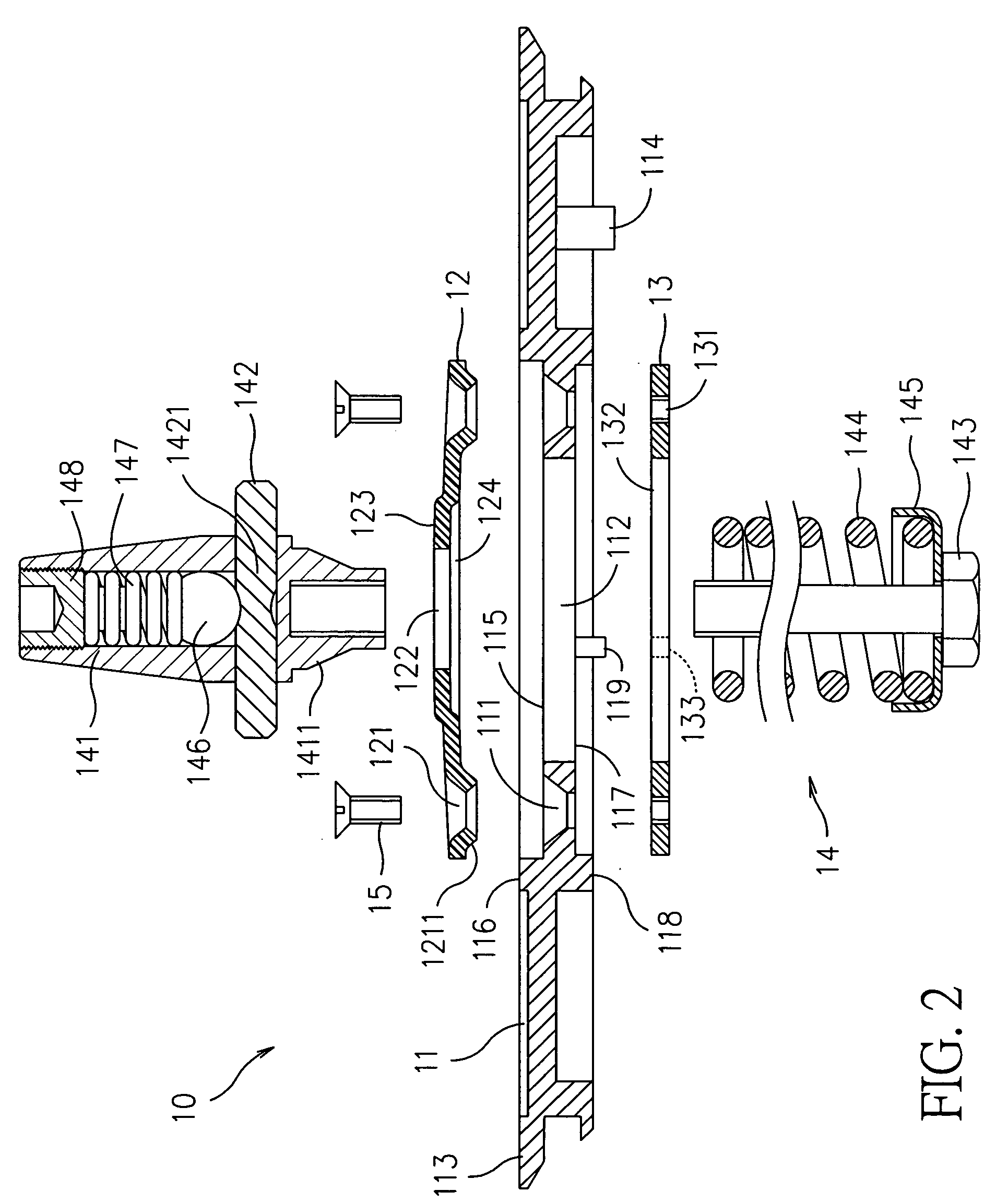

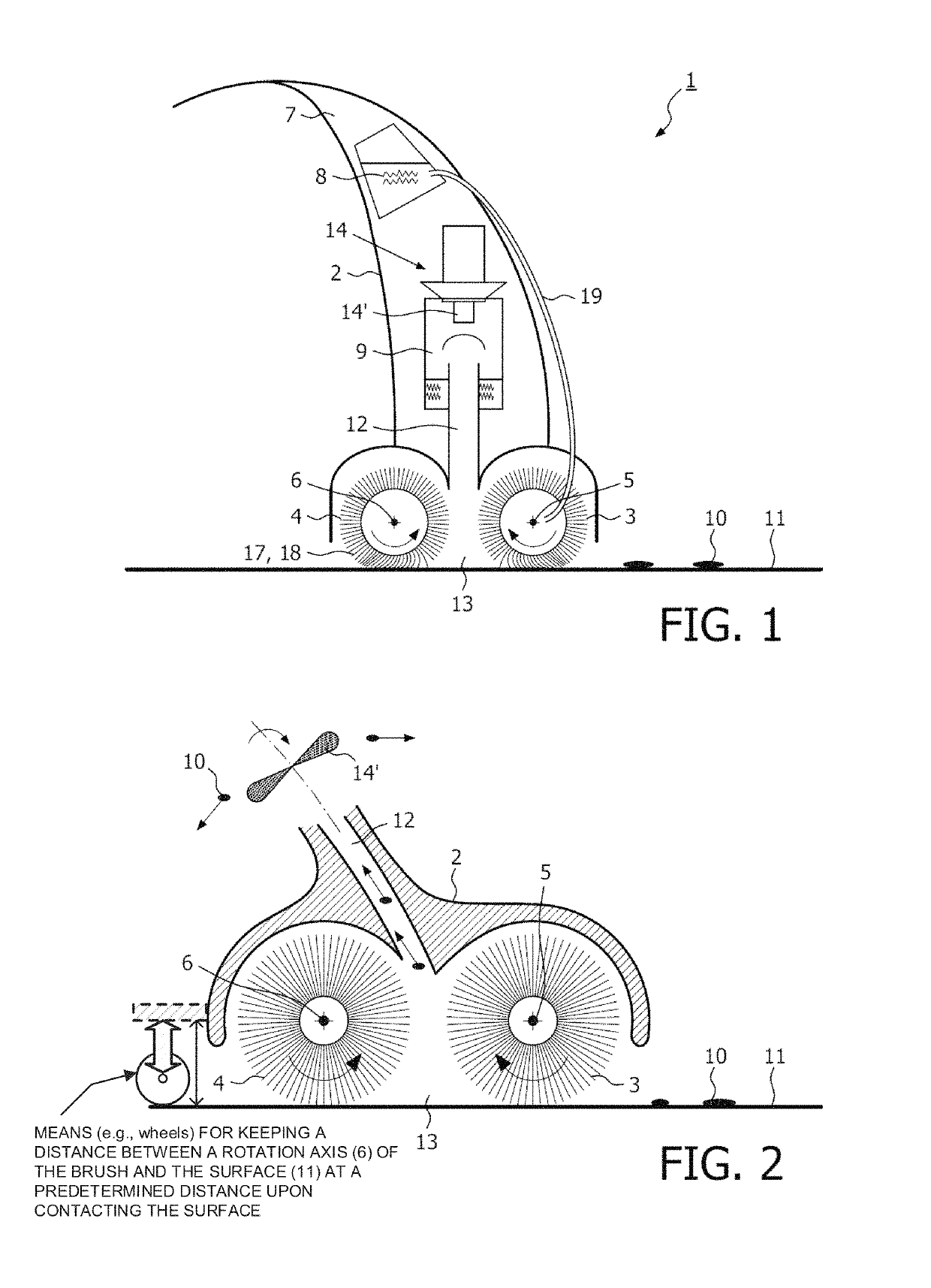

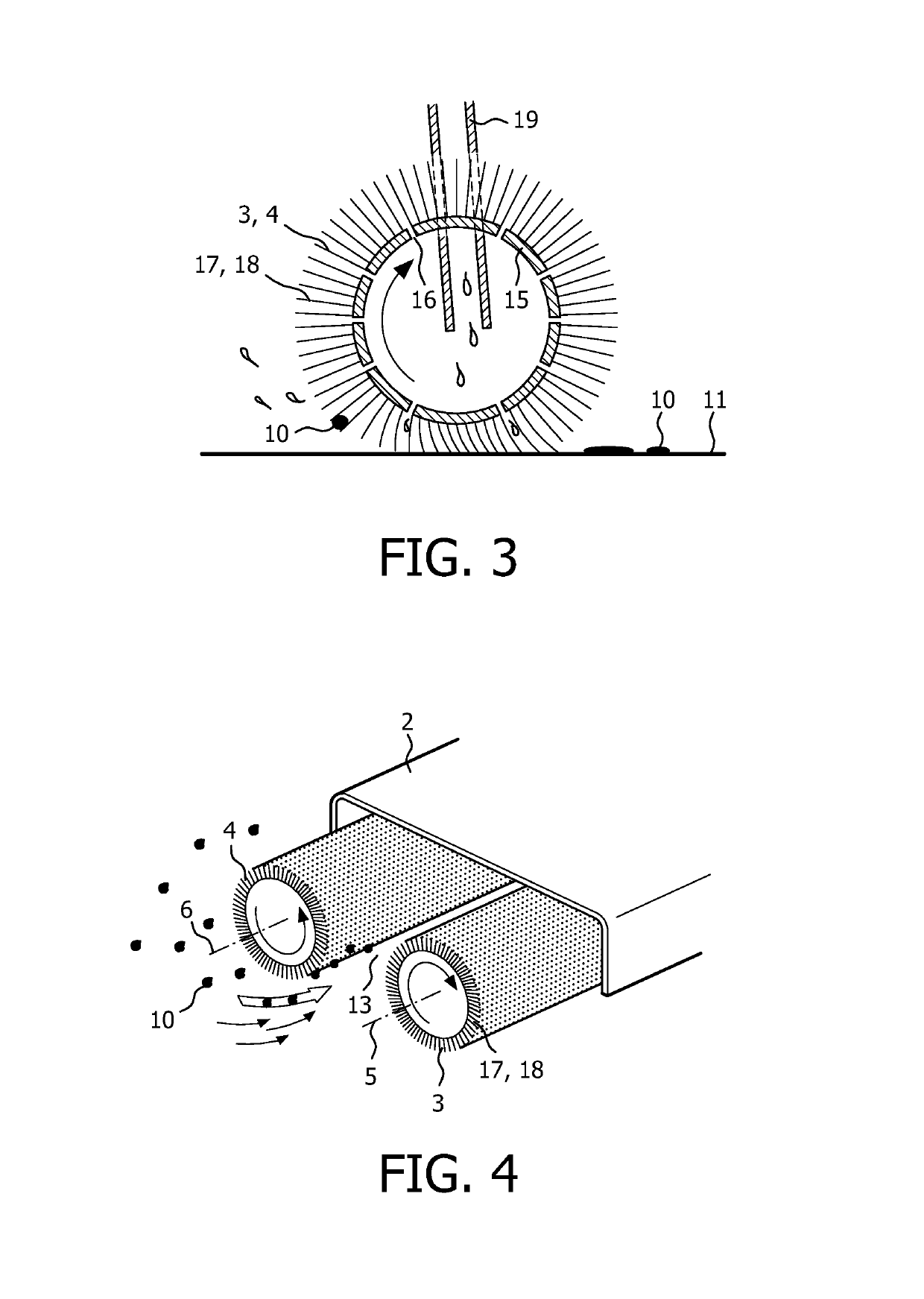

Cleaning device for cleaning a surface comprising a brush and a squeegee element

PendingUS20140182079A1Increase heightHigh strengthCarpet cleanersFloor cleanersEngineeringVolumetric Mass Density

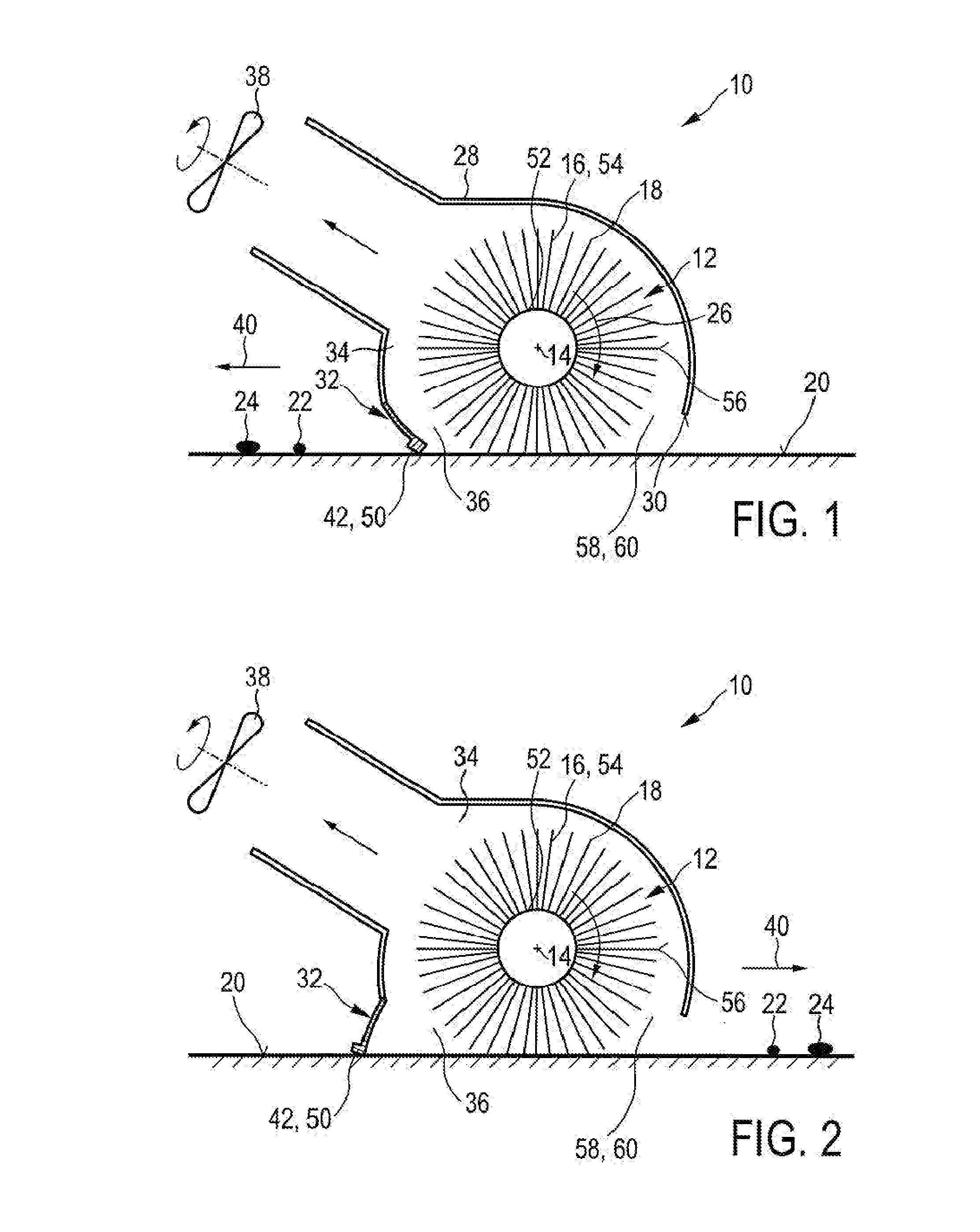

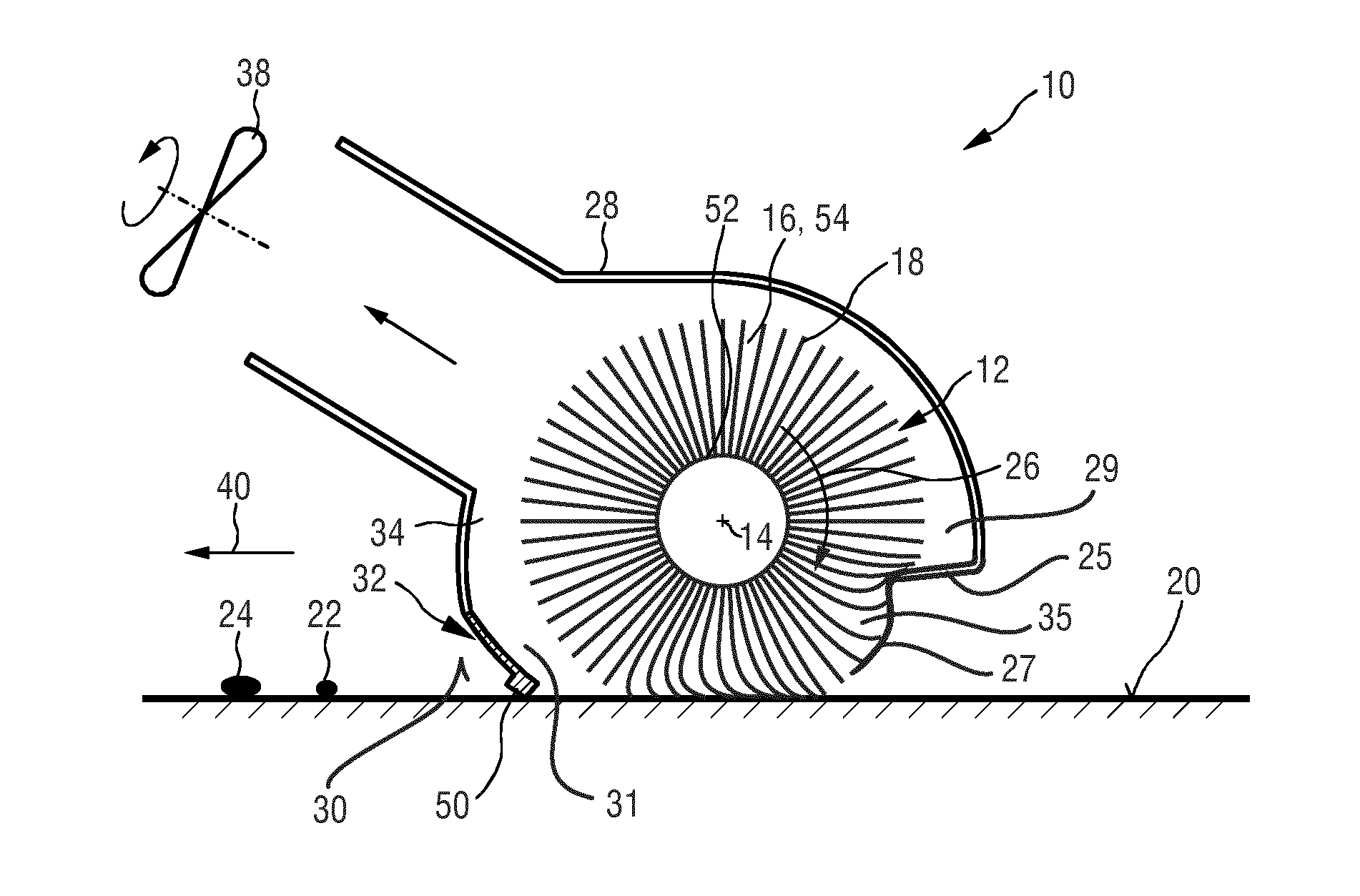

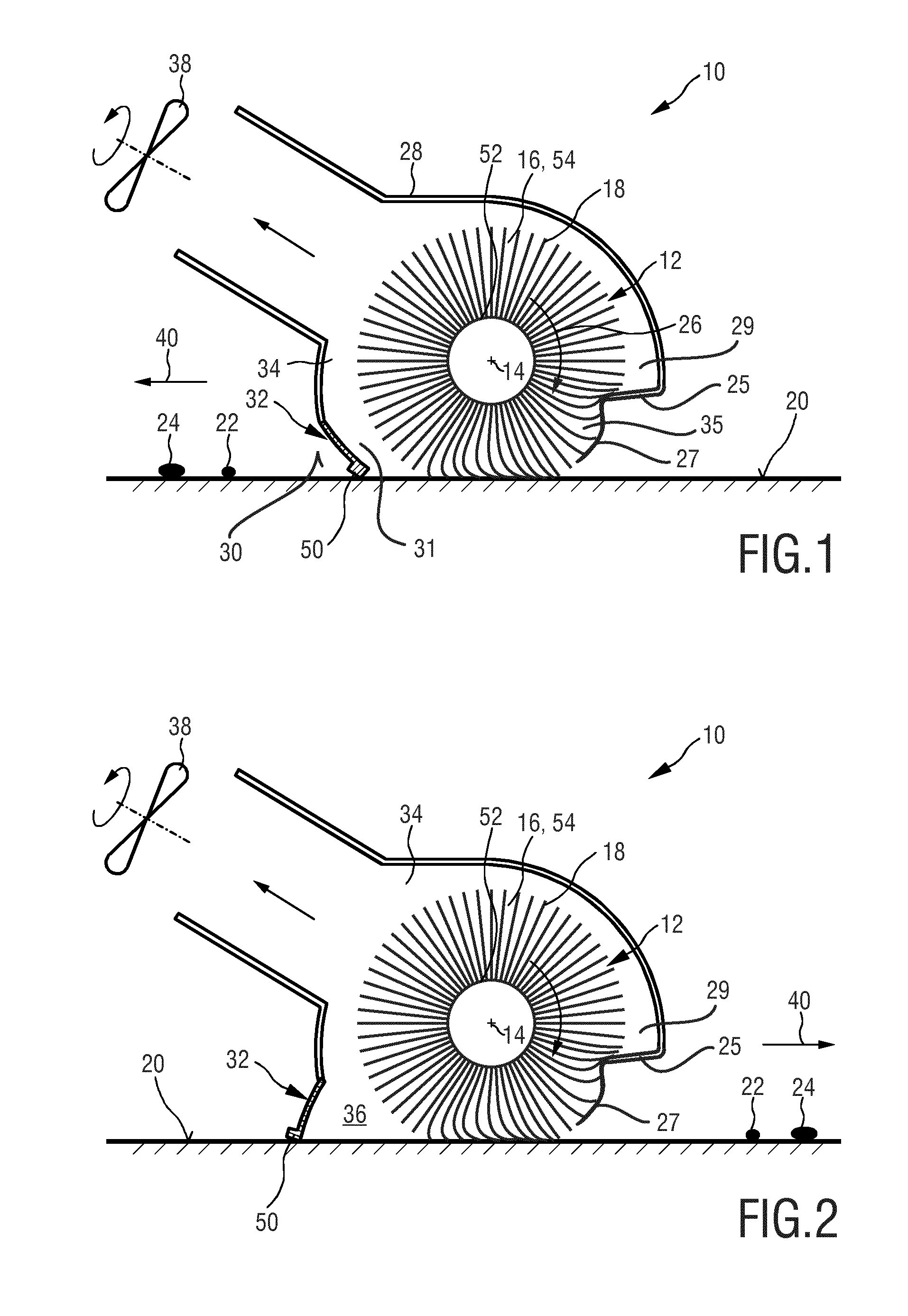

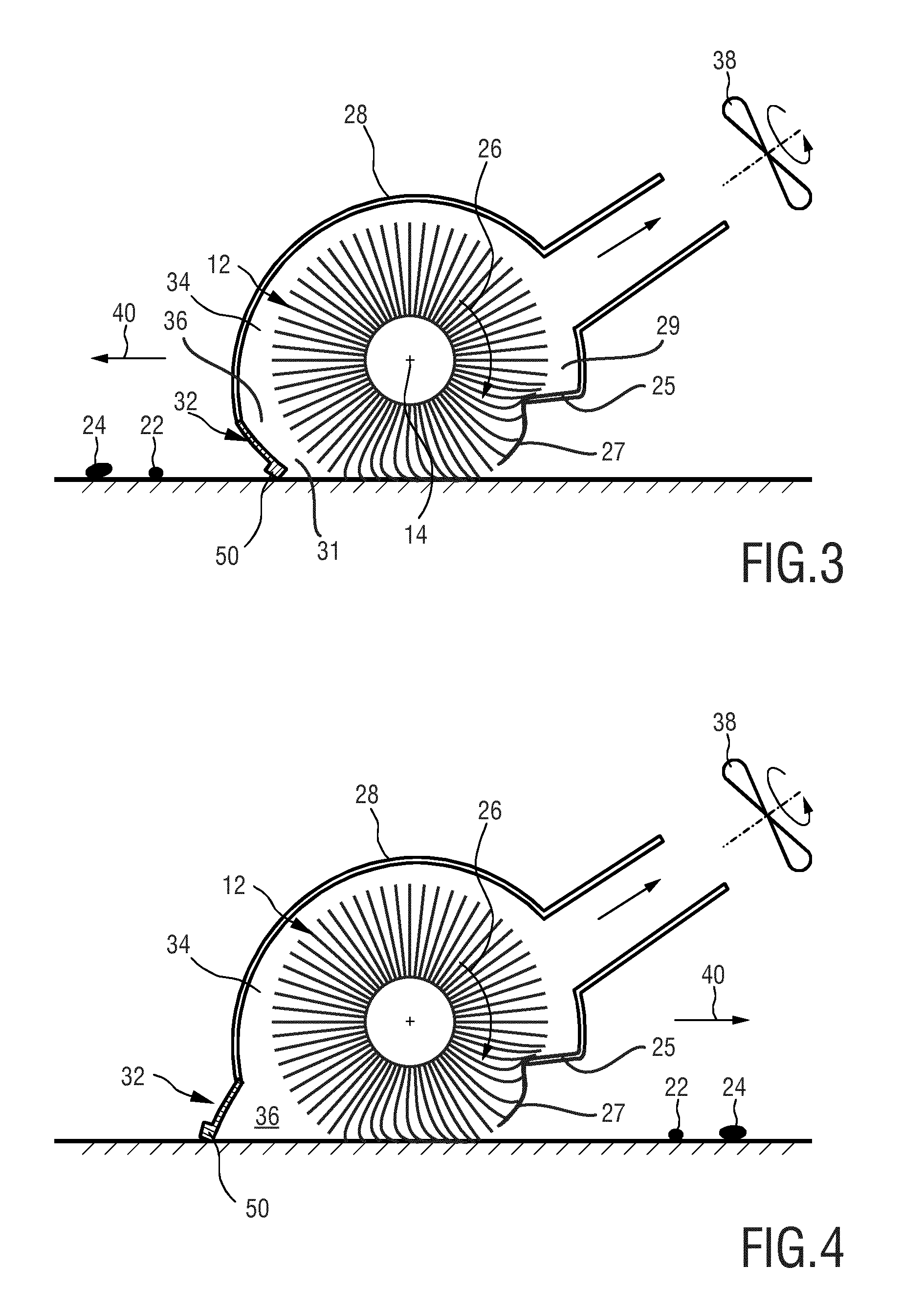

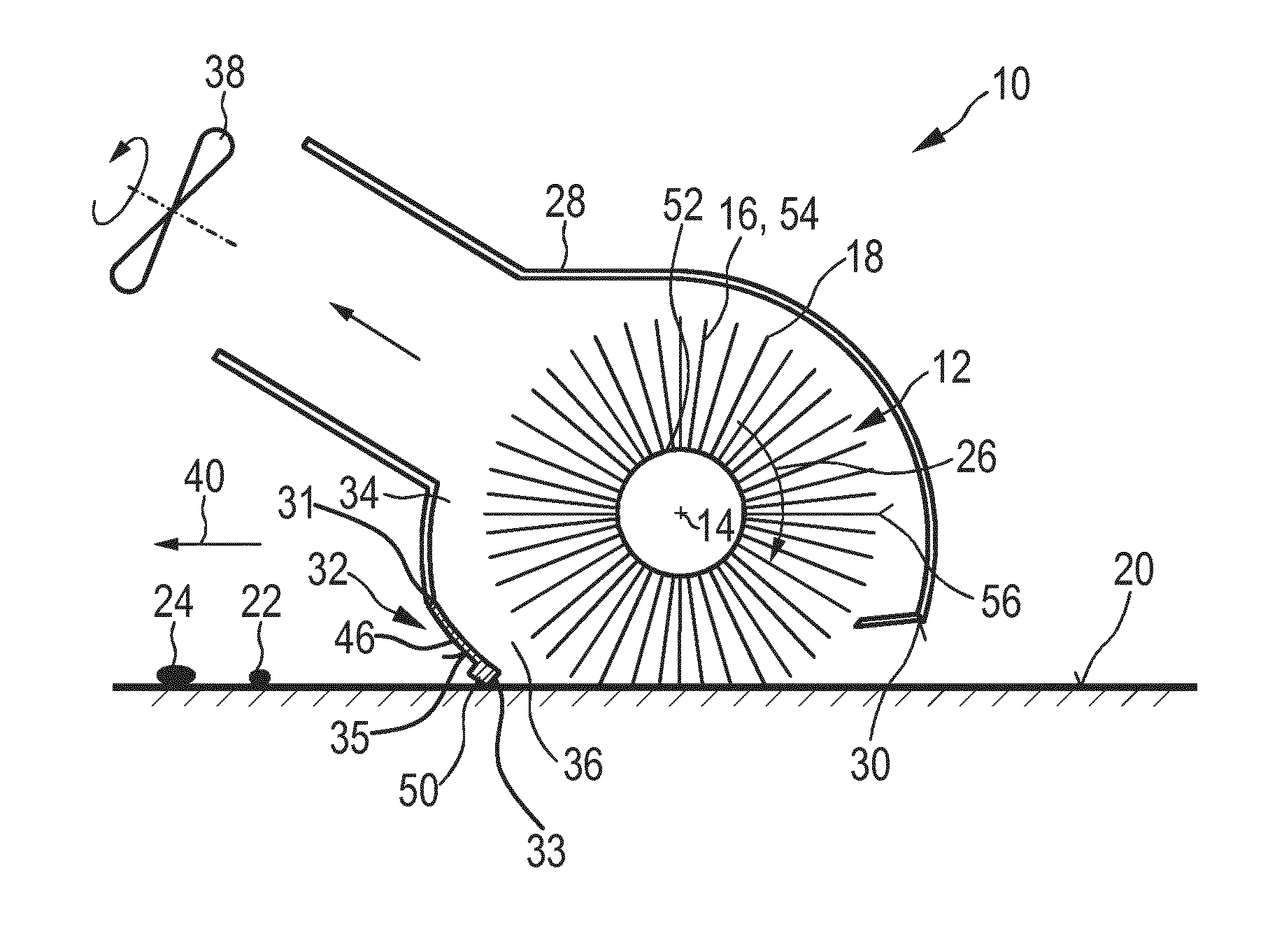

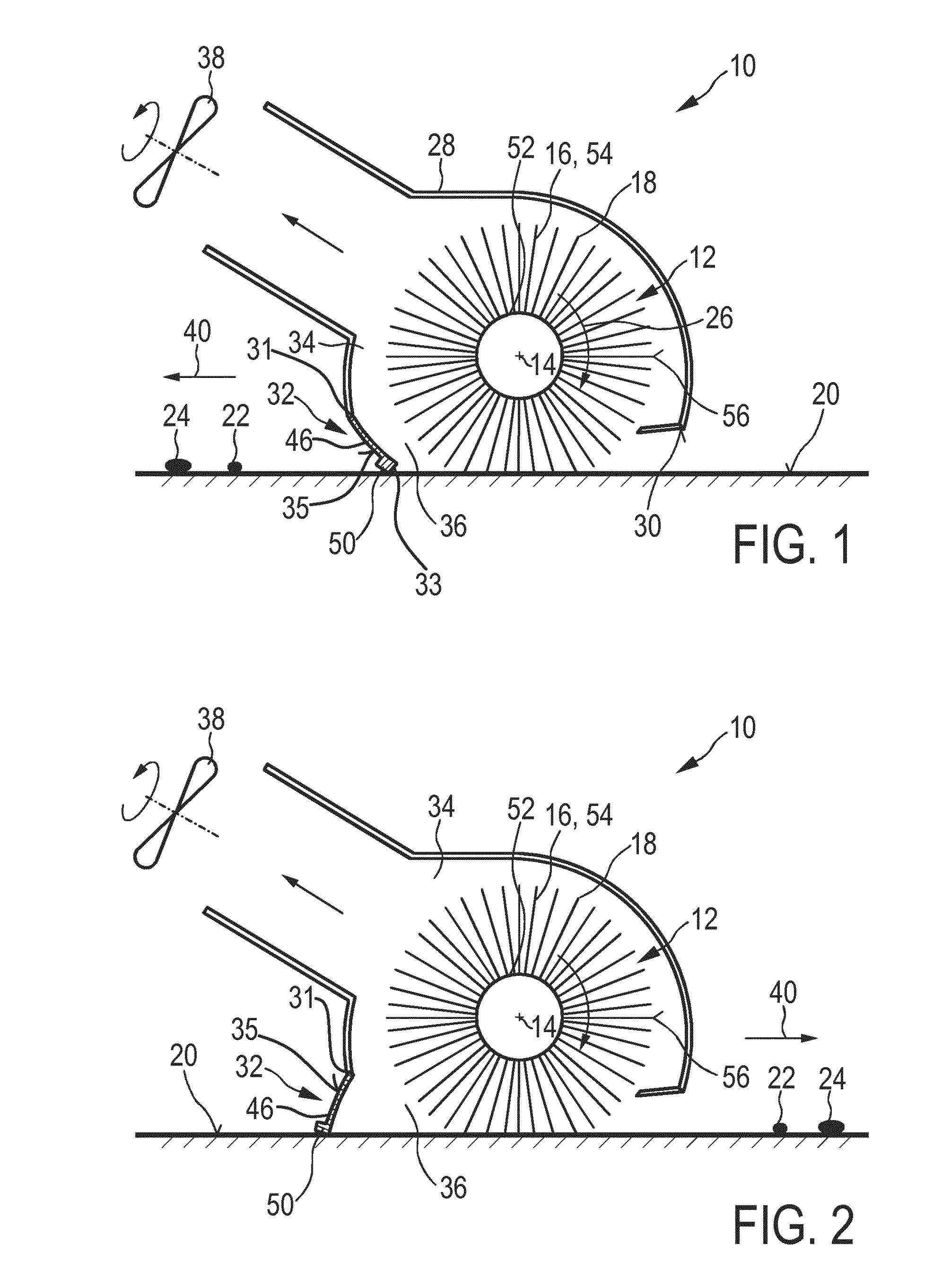

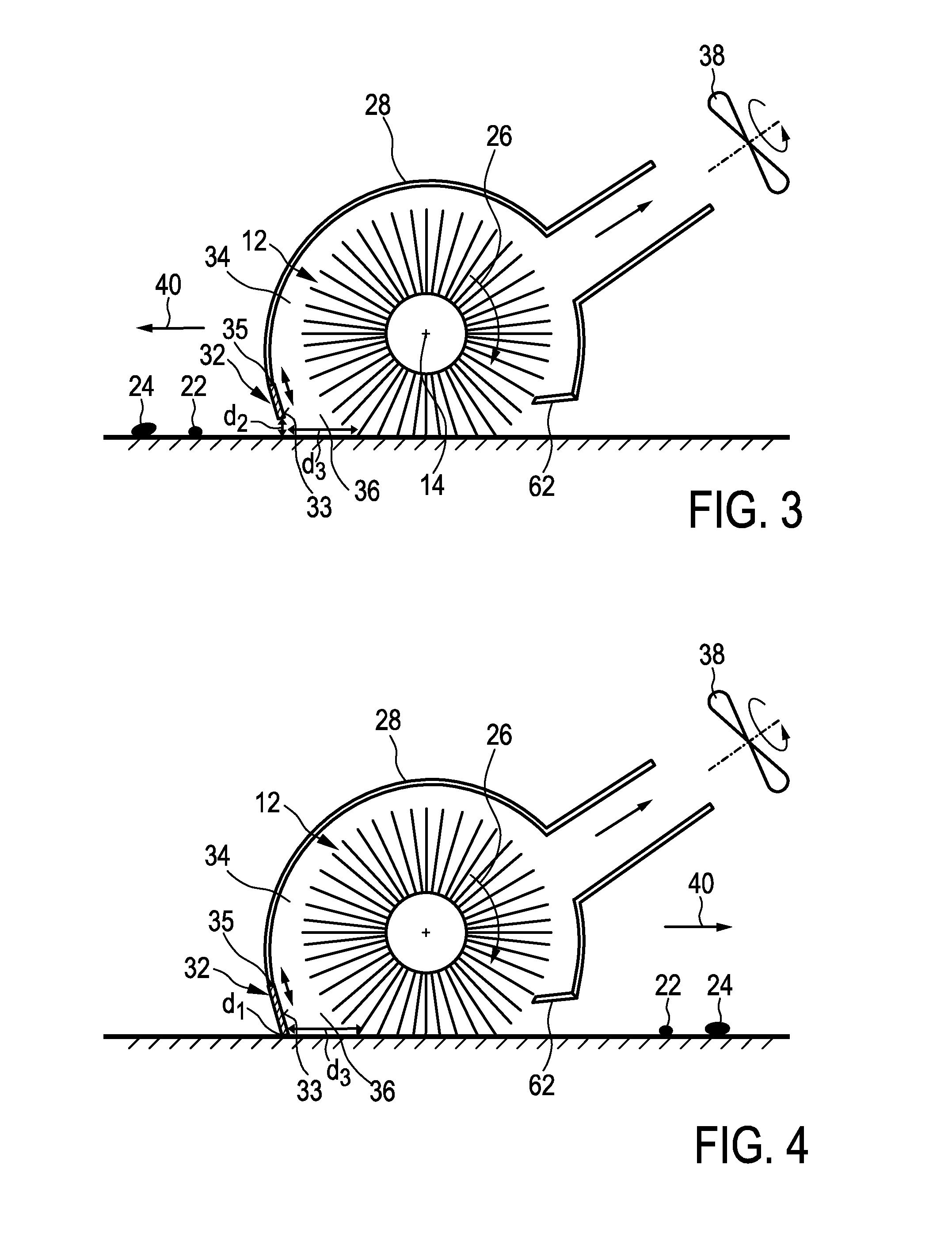

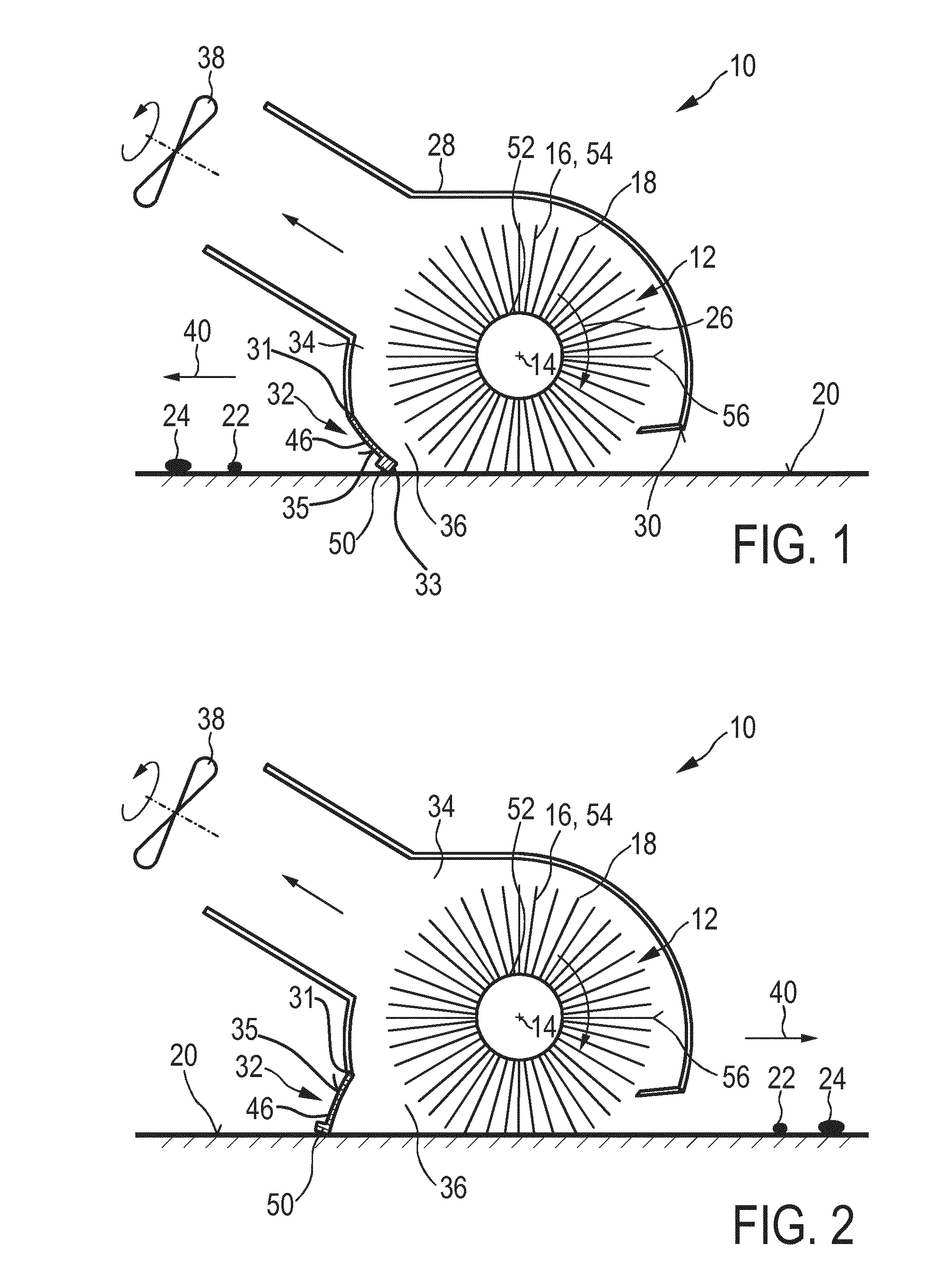

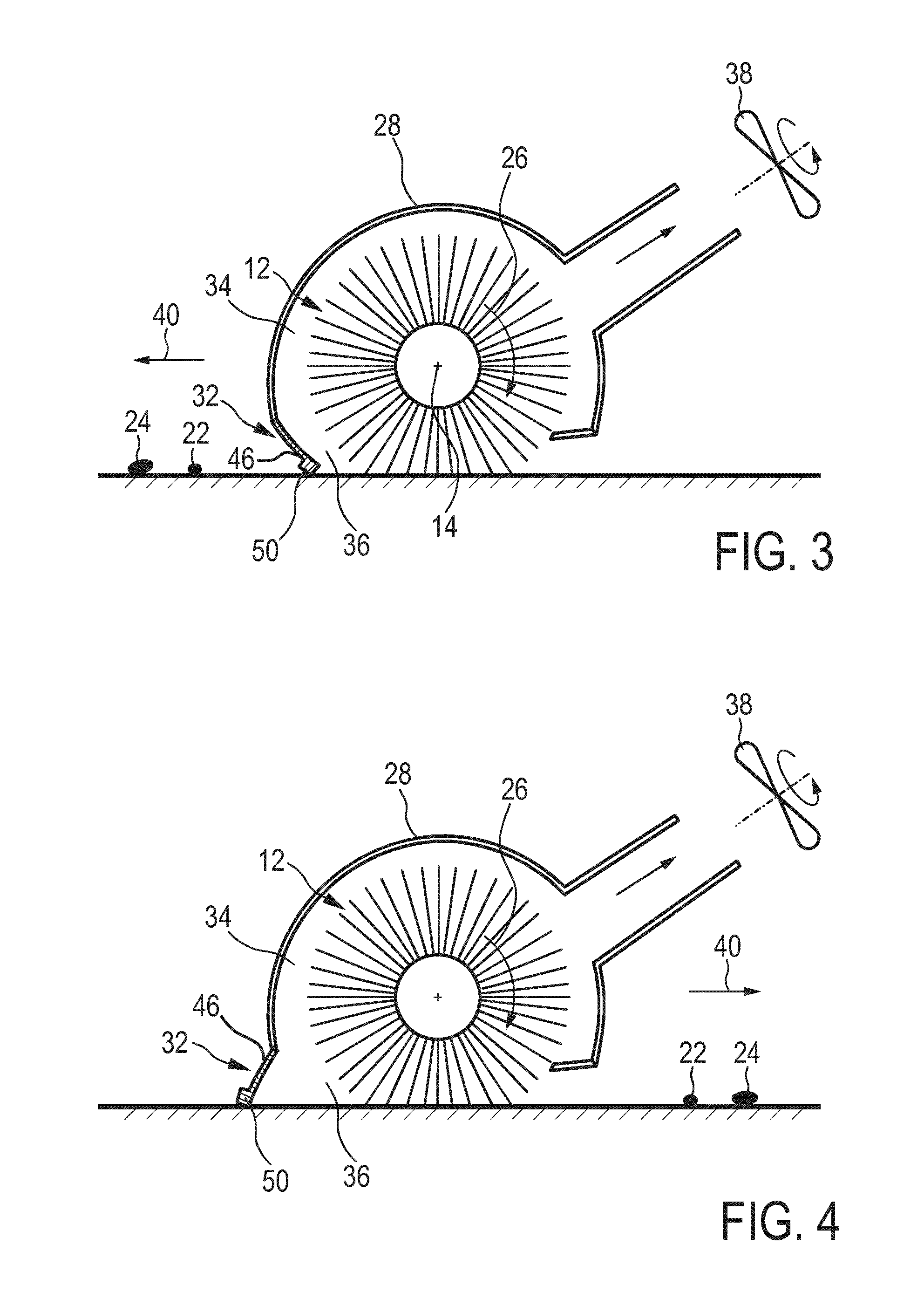

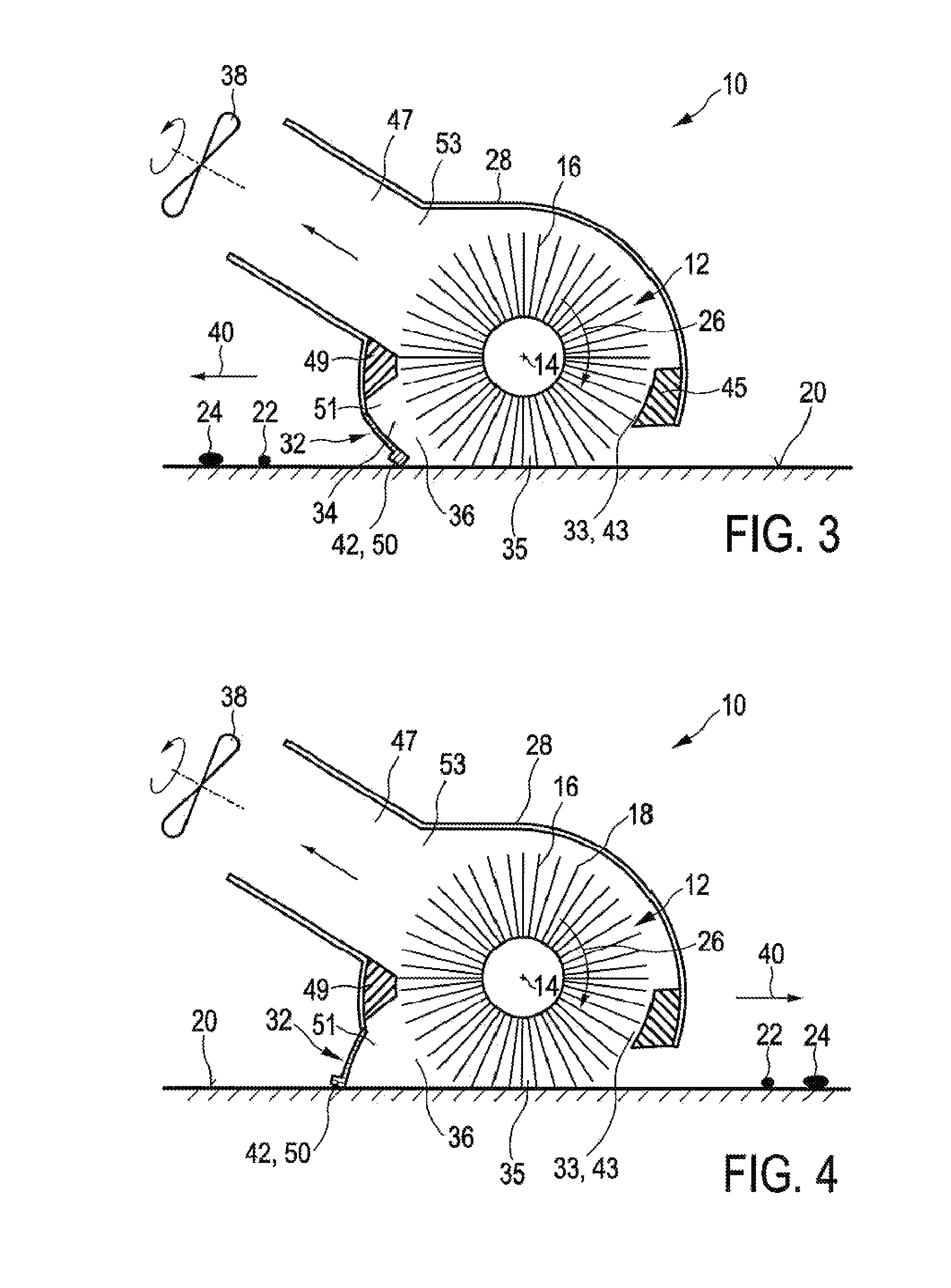

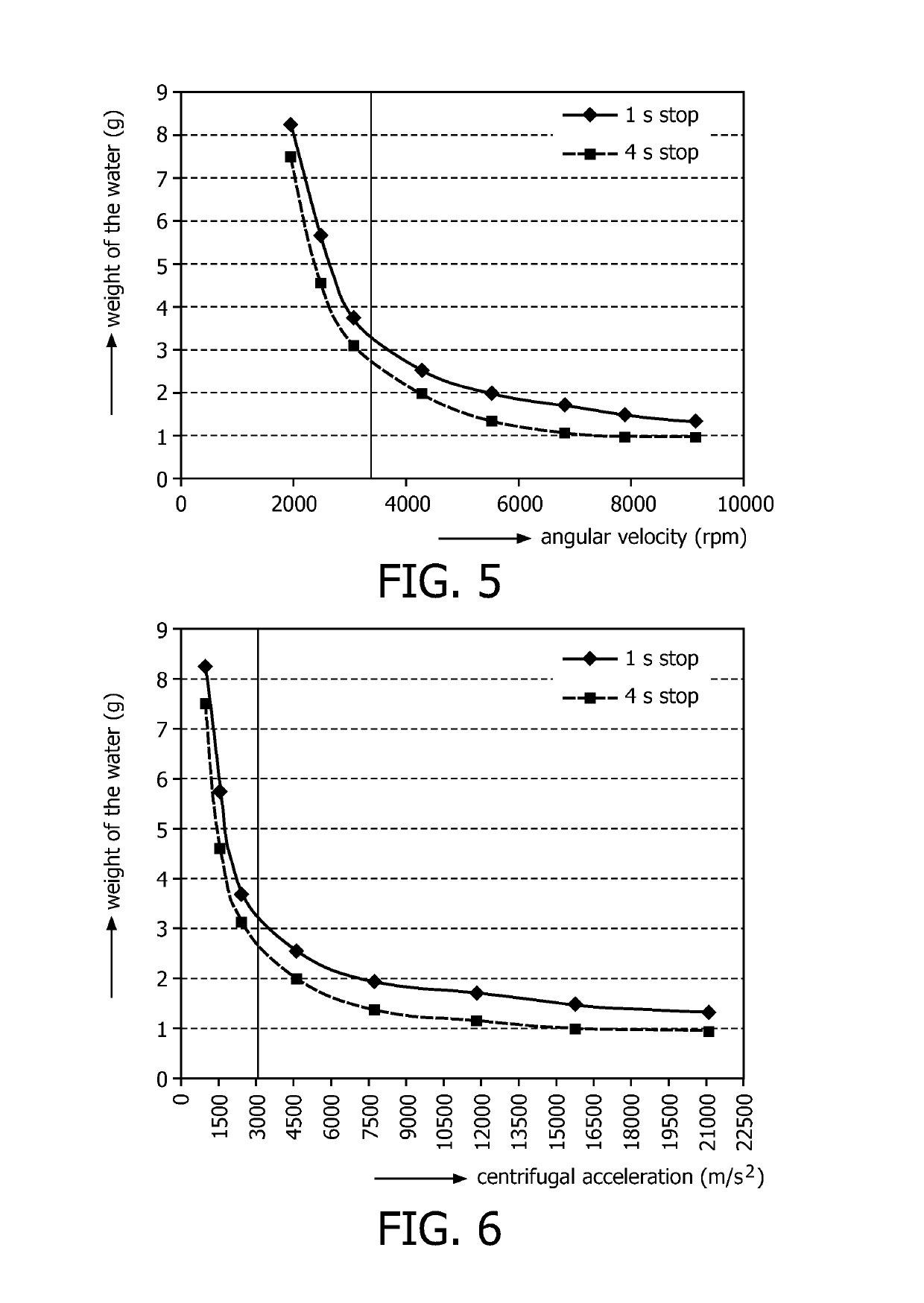

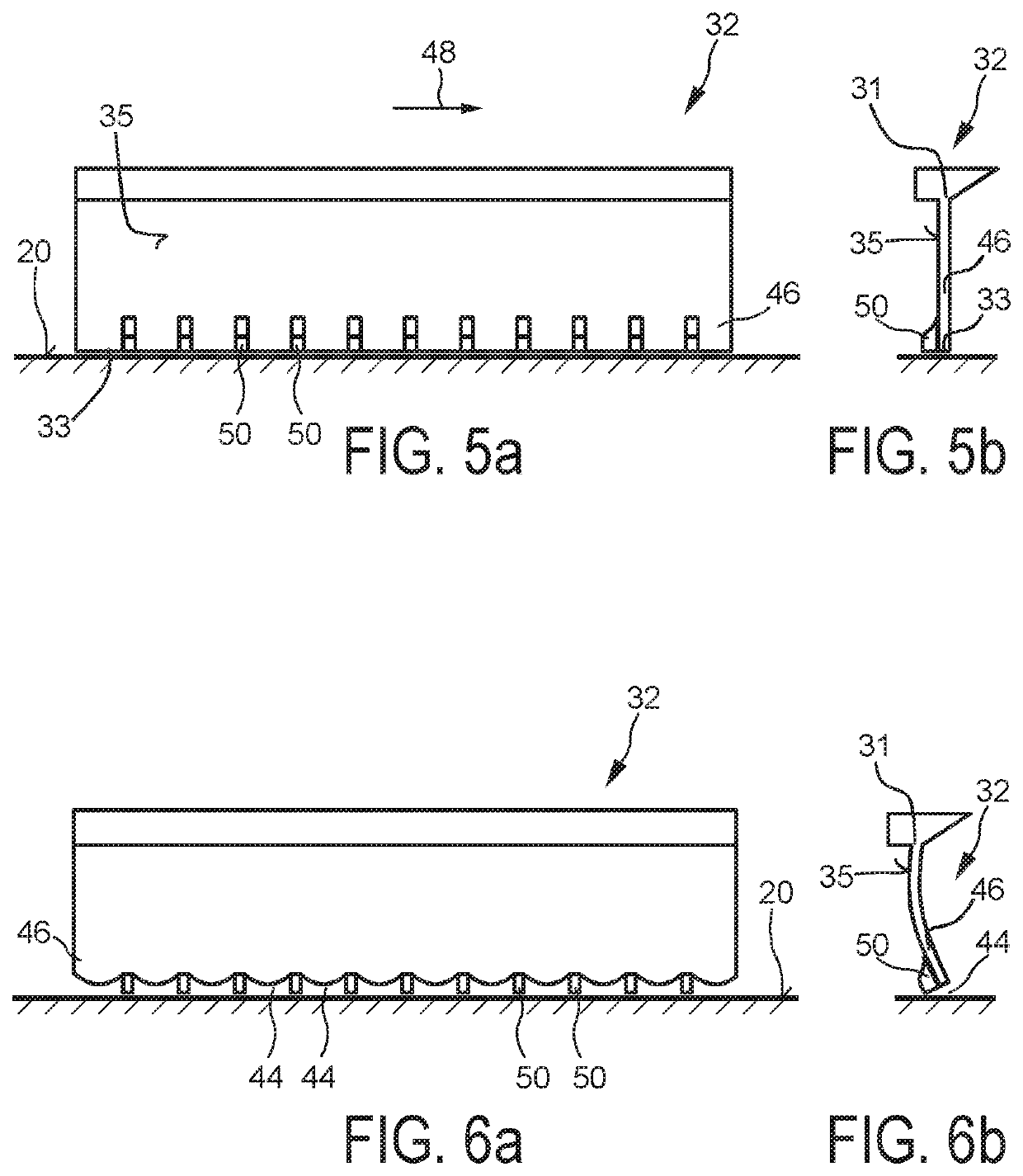

The present invention relates to a cleaning device for cleaning a surface (20), comprising: —a nozzle arrangement (10) that comprises i) a brush (12) rotatable about a brush axis (14), said brush (12) being provided with flexible brush elements (16) having tip portions (18) for contacting the surface to be cleaned (20) and picking up dirt particles (22) and liquid (24) from the surface (20) during a pick-up period when the brush elements (16) contact the surface (20) during the rotation of the brush (12), wherein a linear mass density of a plurality of the brush elements (16) is, at least at the tip portions (18), lower than 150 g per 10 km, and ii) a single squeegee element (32) for pushing or wiping dirt particles (22) and liquid (24) across or off the surface to be cleaned (20) during movement of the cleaning device (100), said squeegee element (32) being spaced apart from the brush (12) and extending substantially along a longitudinal direction (48) being substantially parallel to the brush axis (14), wherein a suction area (34) is defined within the nozzle arrangement (10) between the squeegee element (32) and the brush (12), —a drive means for driving the brush (12) in rotation, wherein the drive means are adapted to realize a centrifugal acceleration at the tip portions (18) which is, in particular during a dirt release period when the brush elements (16) are free from contact to the surface (20) during rotation of the brush (12), at least 3,000 m / s 2, and —a vacuum aggregate (38) for generating an under-pressure in the suction area (34) for ingesting dirt particles (22) and liquid (24).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

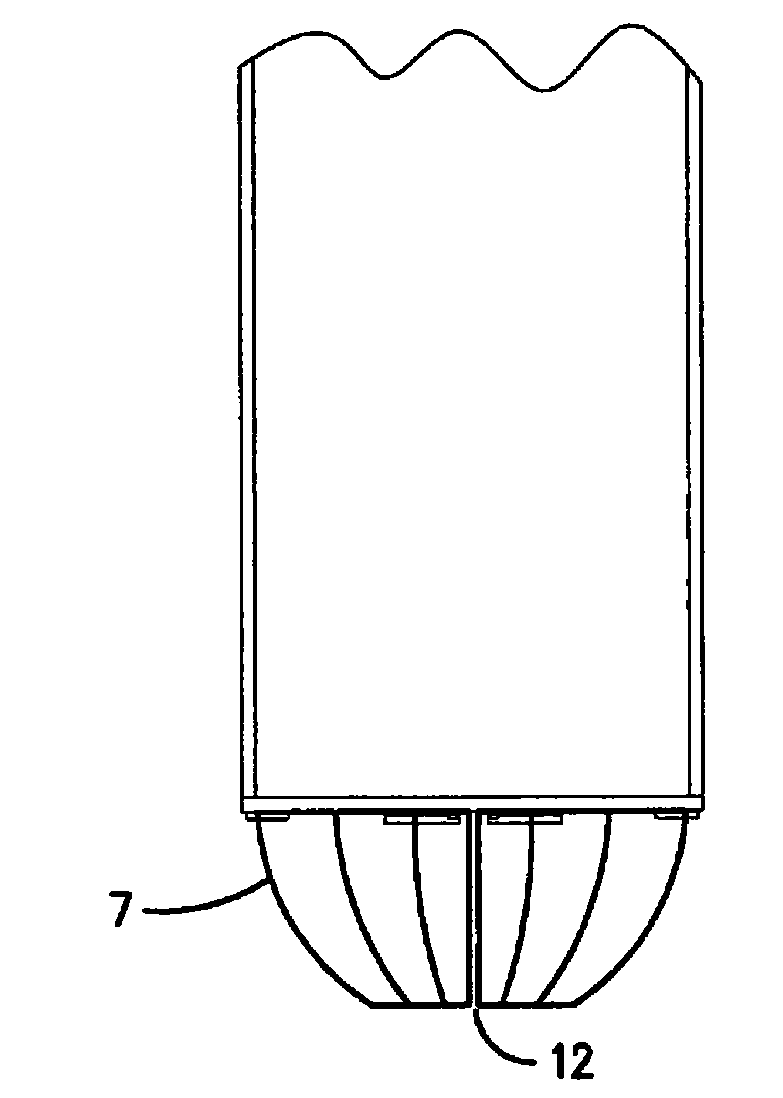

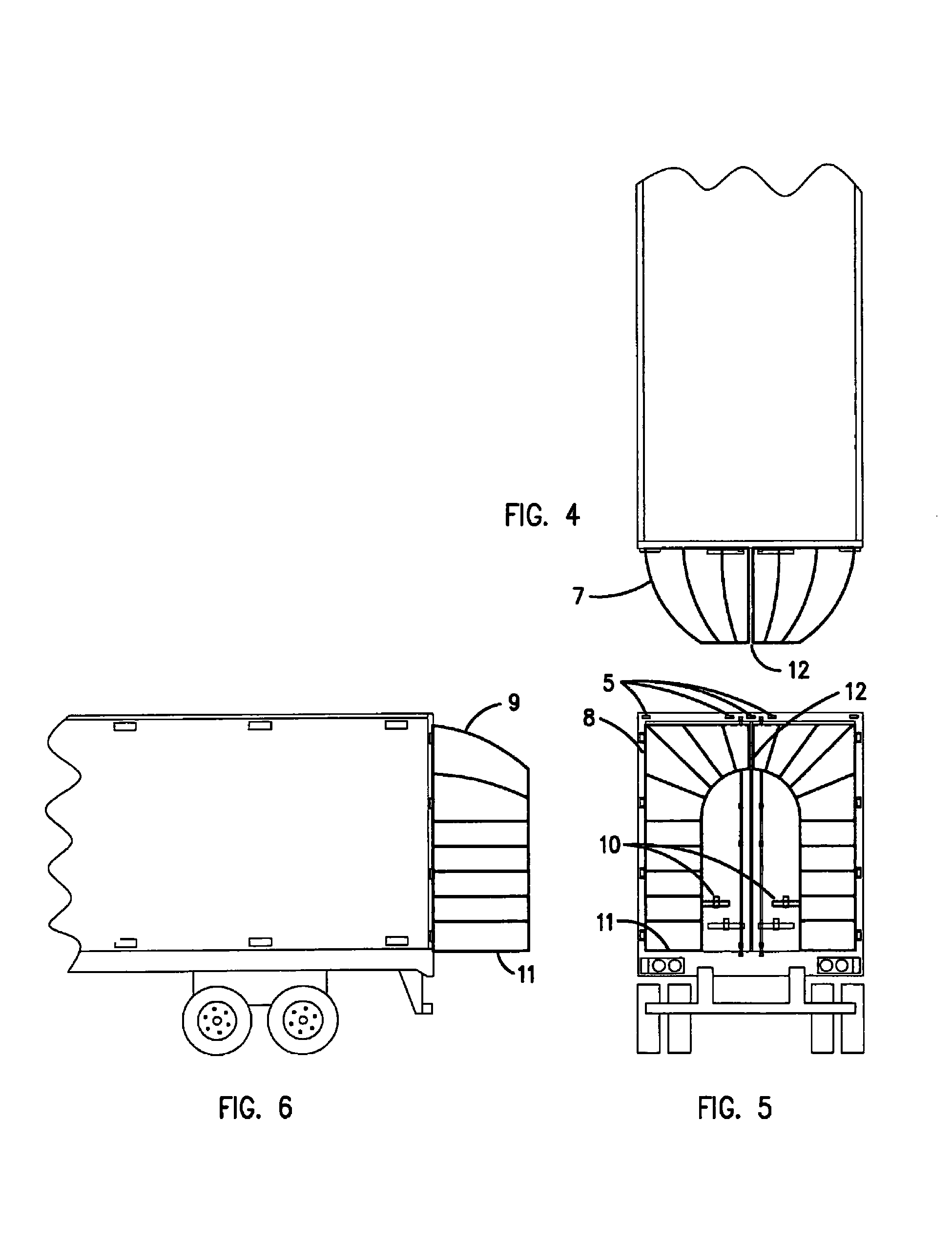

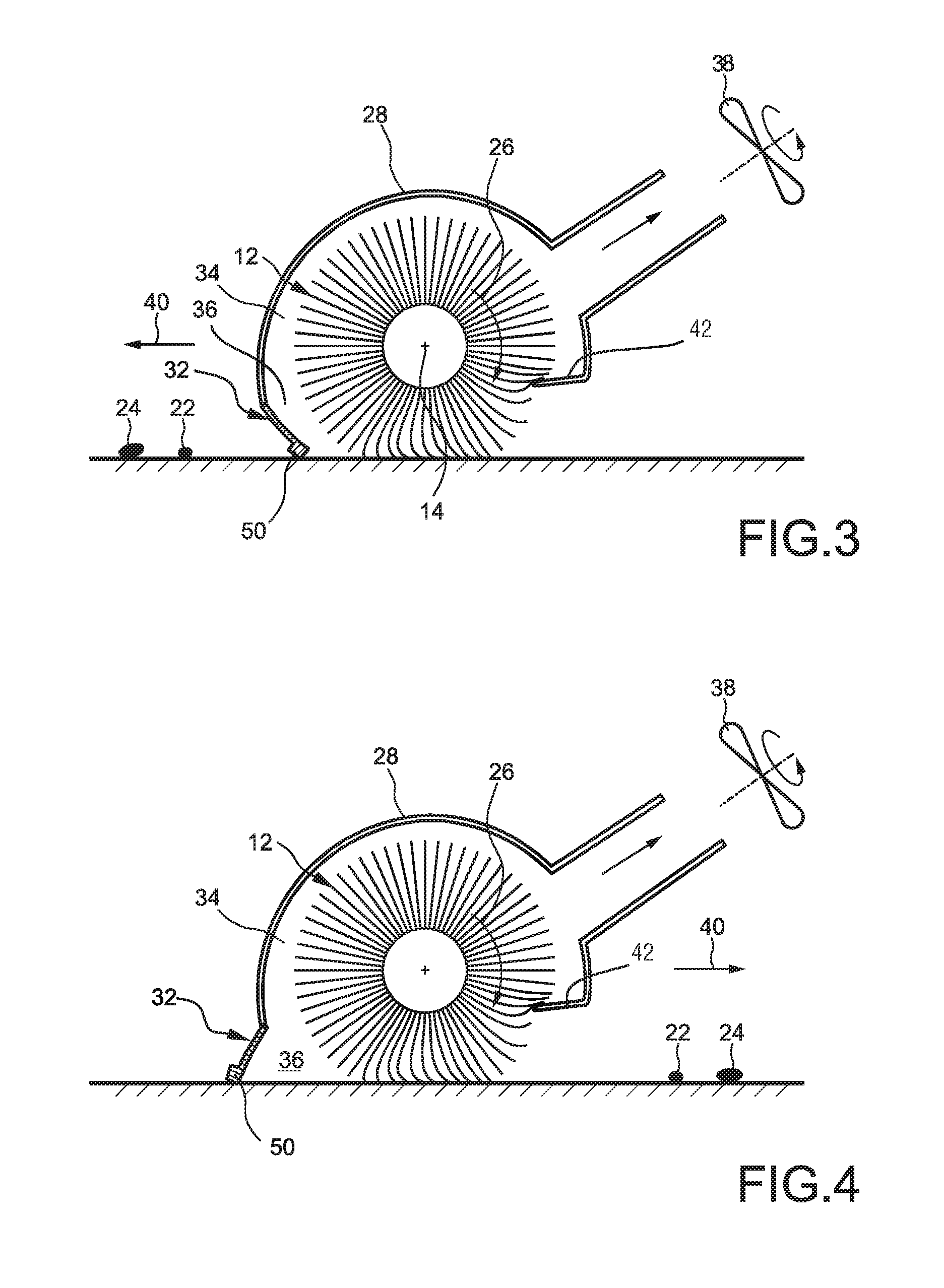

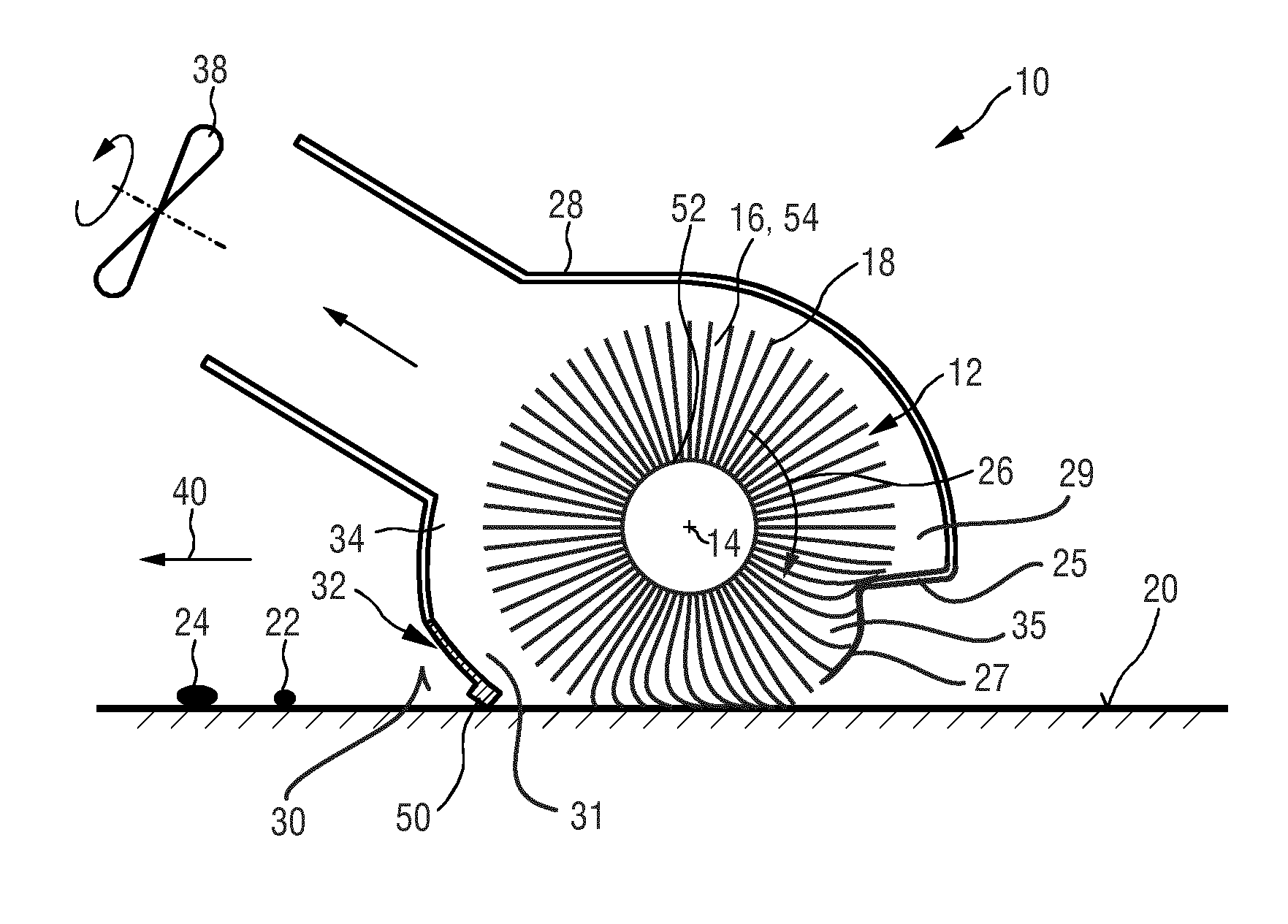

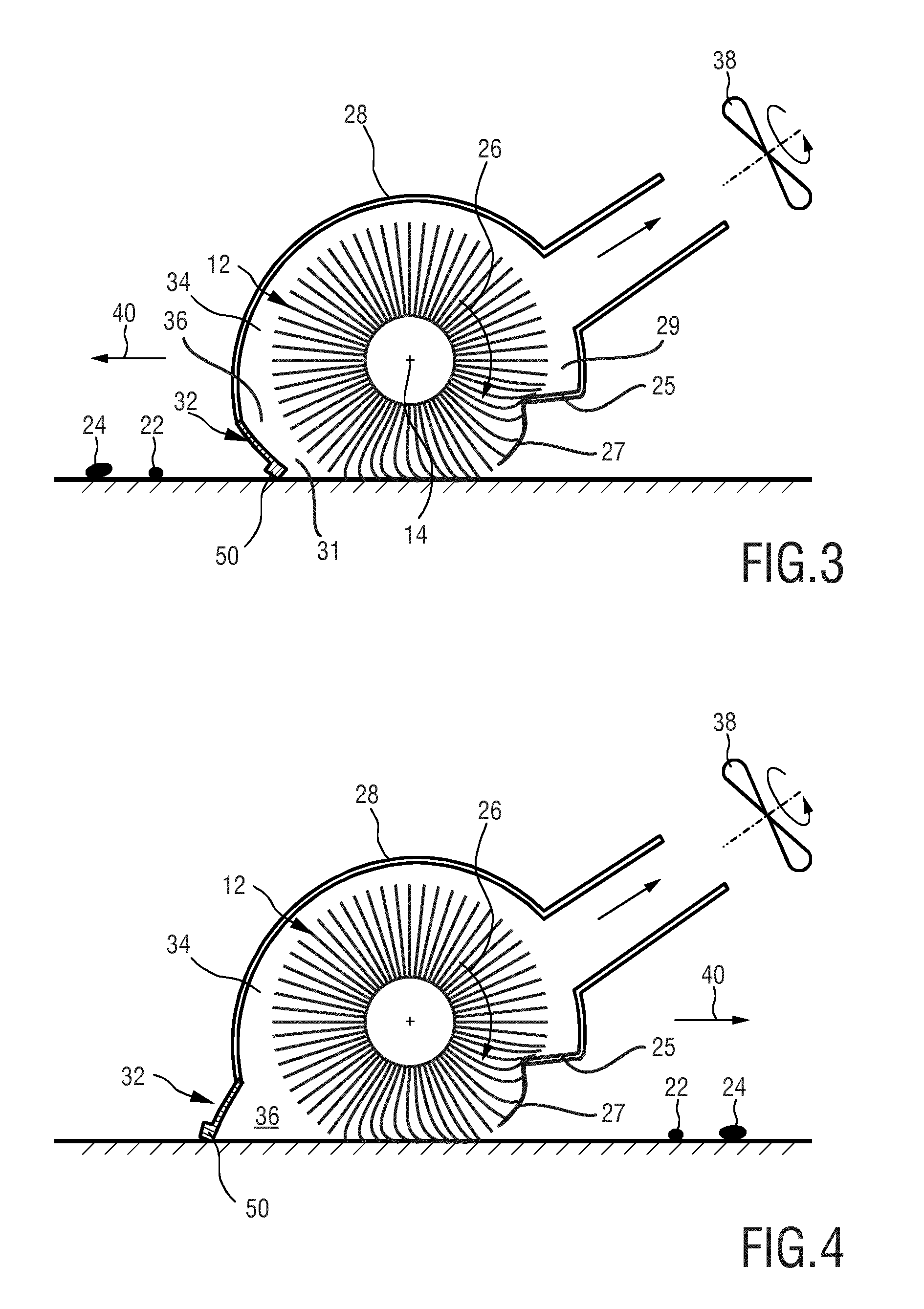

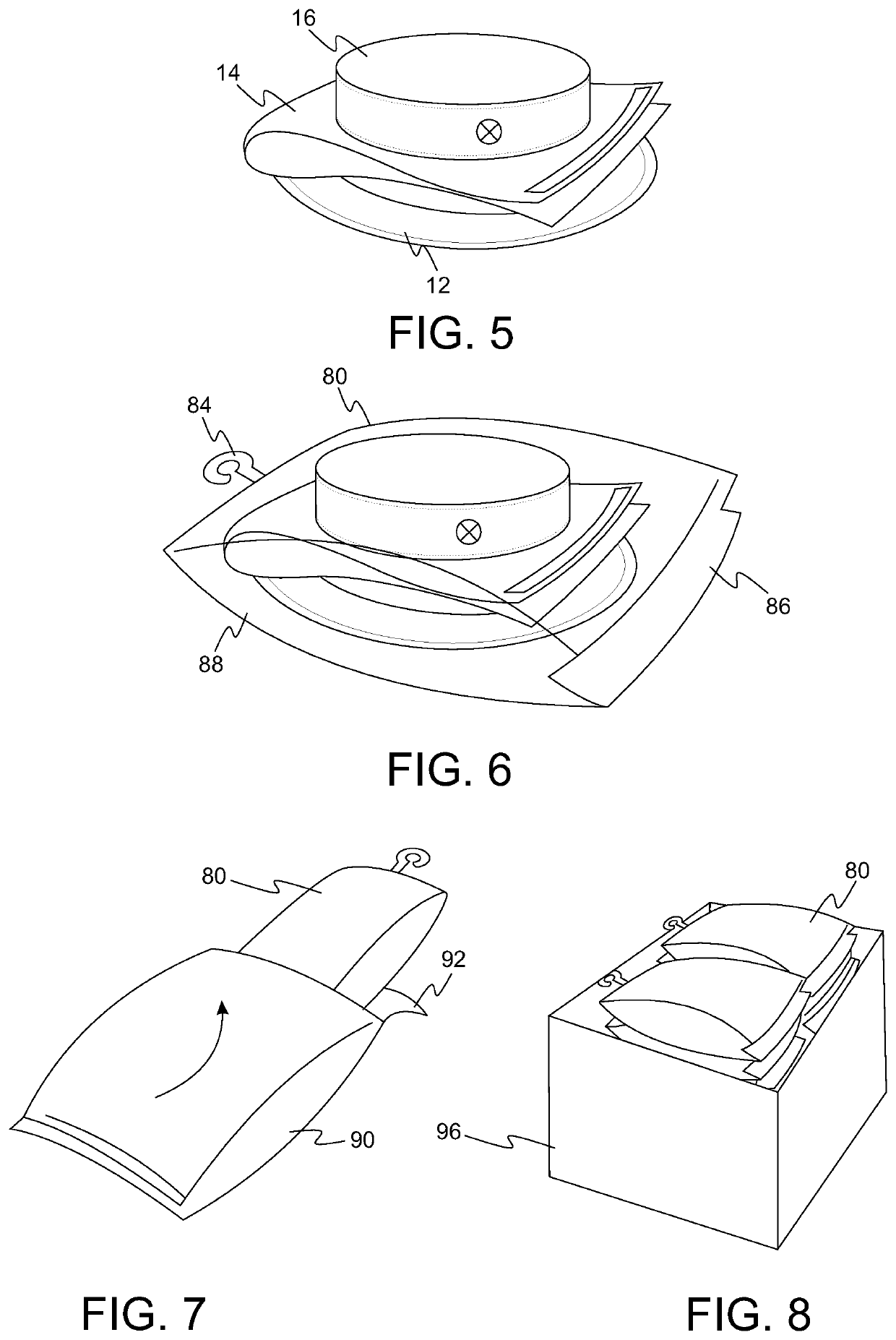

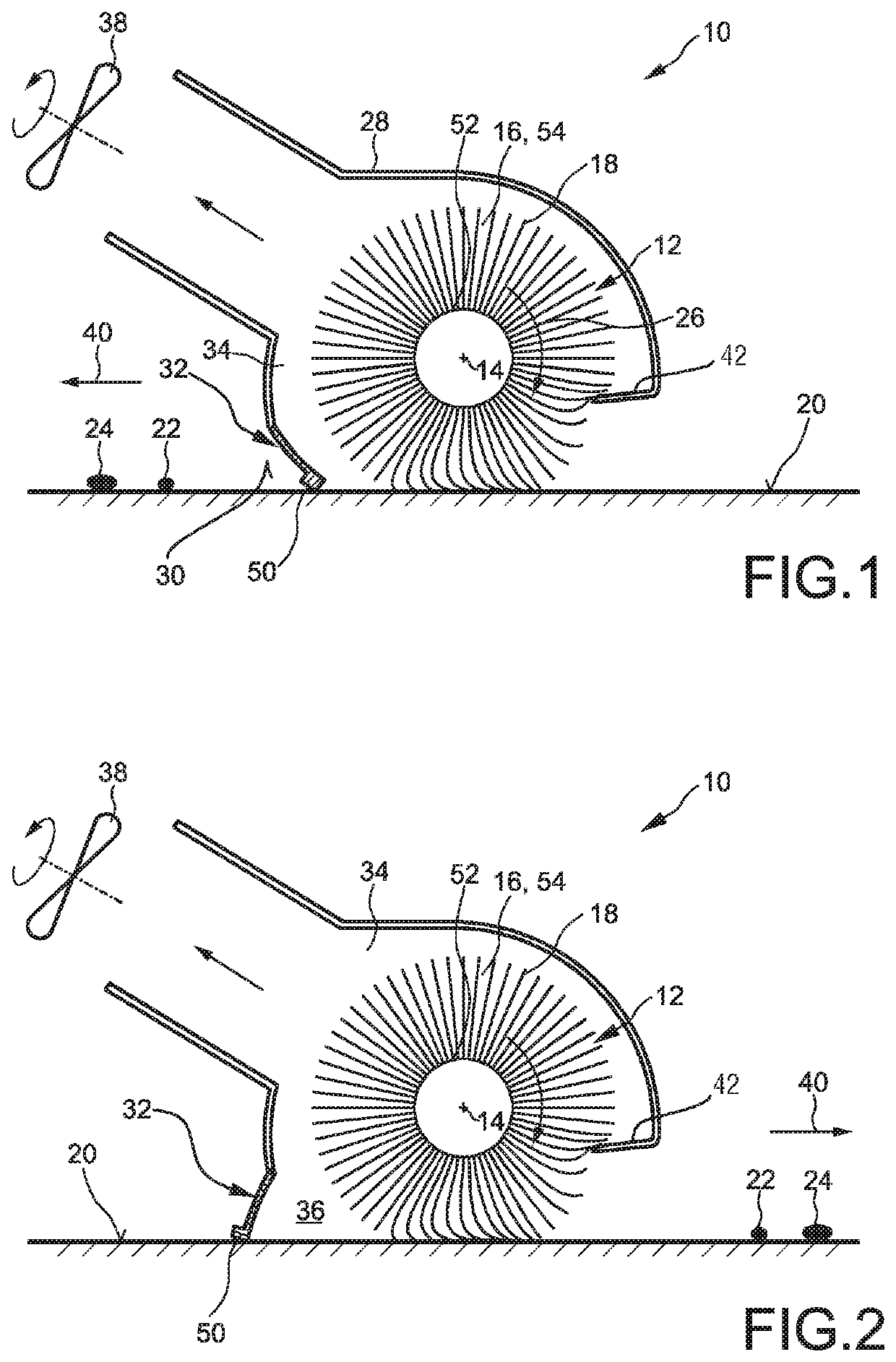

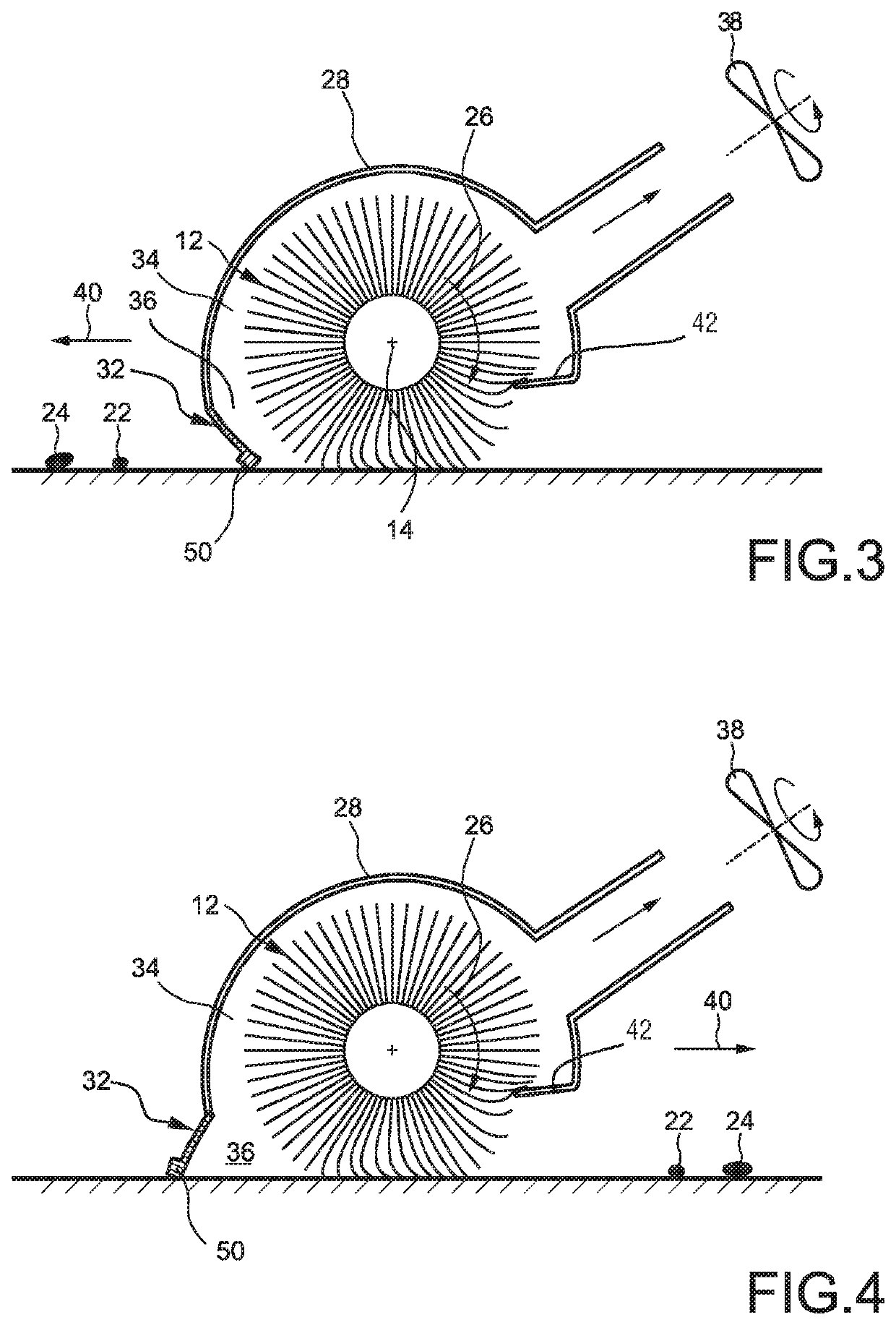

Umbrella semi-trailer drag reducer

InactiveUS7740304B1Degraded aerodynamic performanceChance of damageVehicle seatsWindowsAerodynamic dragRoad surface

The Umbrella Semi-Trailer Drag Reducer is a device that reduces tractor-trailer aerodynamic drag, saving energy and reducing fuel consumption. The design includes a number of features similar to an umbrella, including flexible skin, metal ribs, quick-acting deployment, and compact stowage. The Umbrella Semi-Trailer Drag Reducer is designed to minimize installed cost, be robust and vandal resistant, and reduce the time needed for deployment to only a few seconds. The design includes two independent, paraboloid, mirrored halves, one mounted to each door. The bottom of each mirrored half is open, with a profile similar to one quadrant of an umbrella. Wide-throw hinges accommodate the collapsed stowed drag reducer. Turnbuckles maintain taught skin. The design allows easy retrofit for most existing semi-trailers. The drag reducer is mounted high above the road surface, with no part protruding beyond the top or sides of the semi-trailer.

Owner:BREU THOMAS JAMES

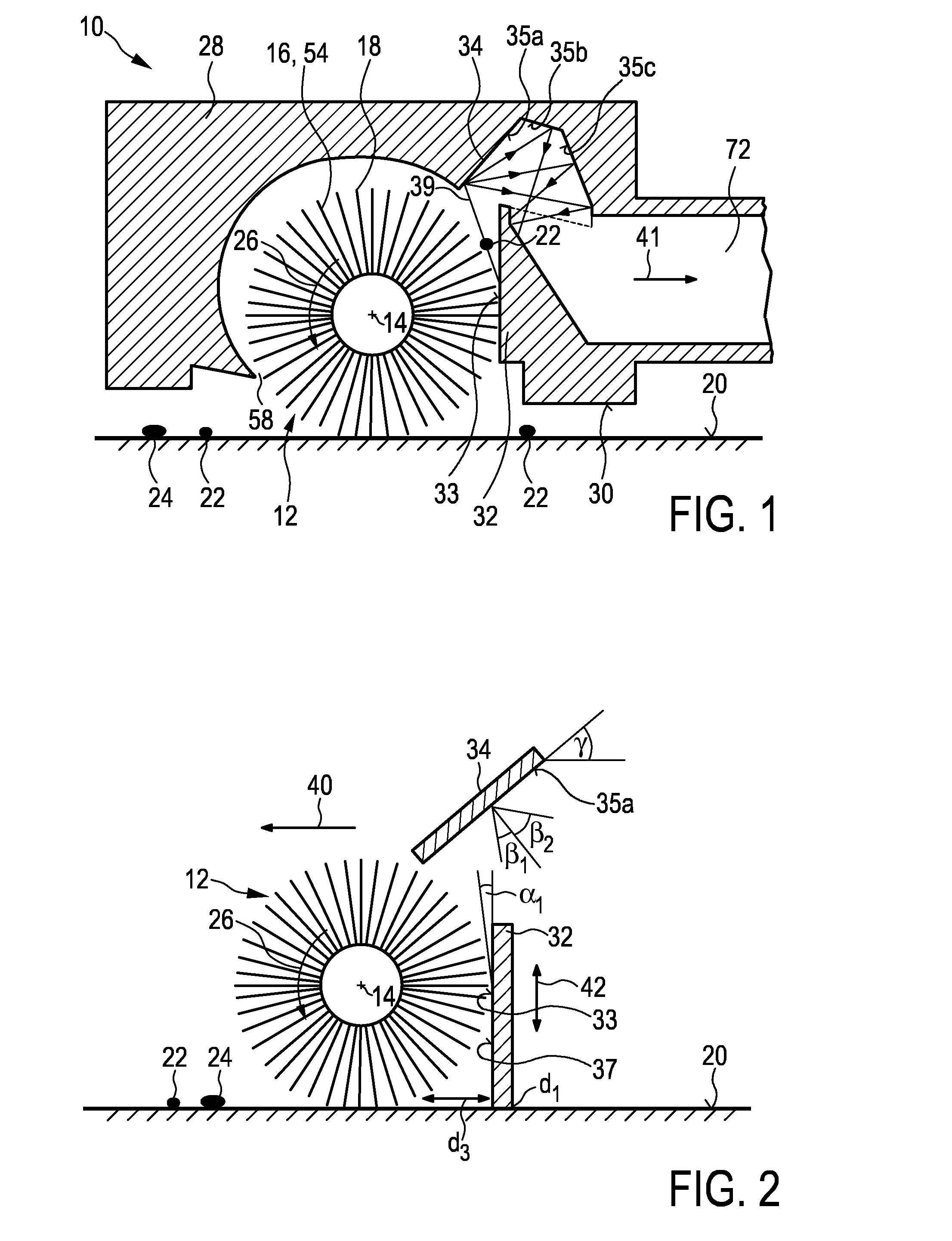

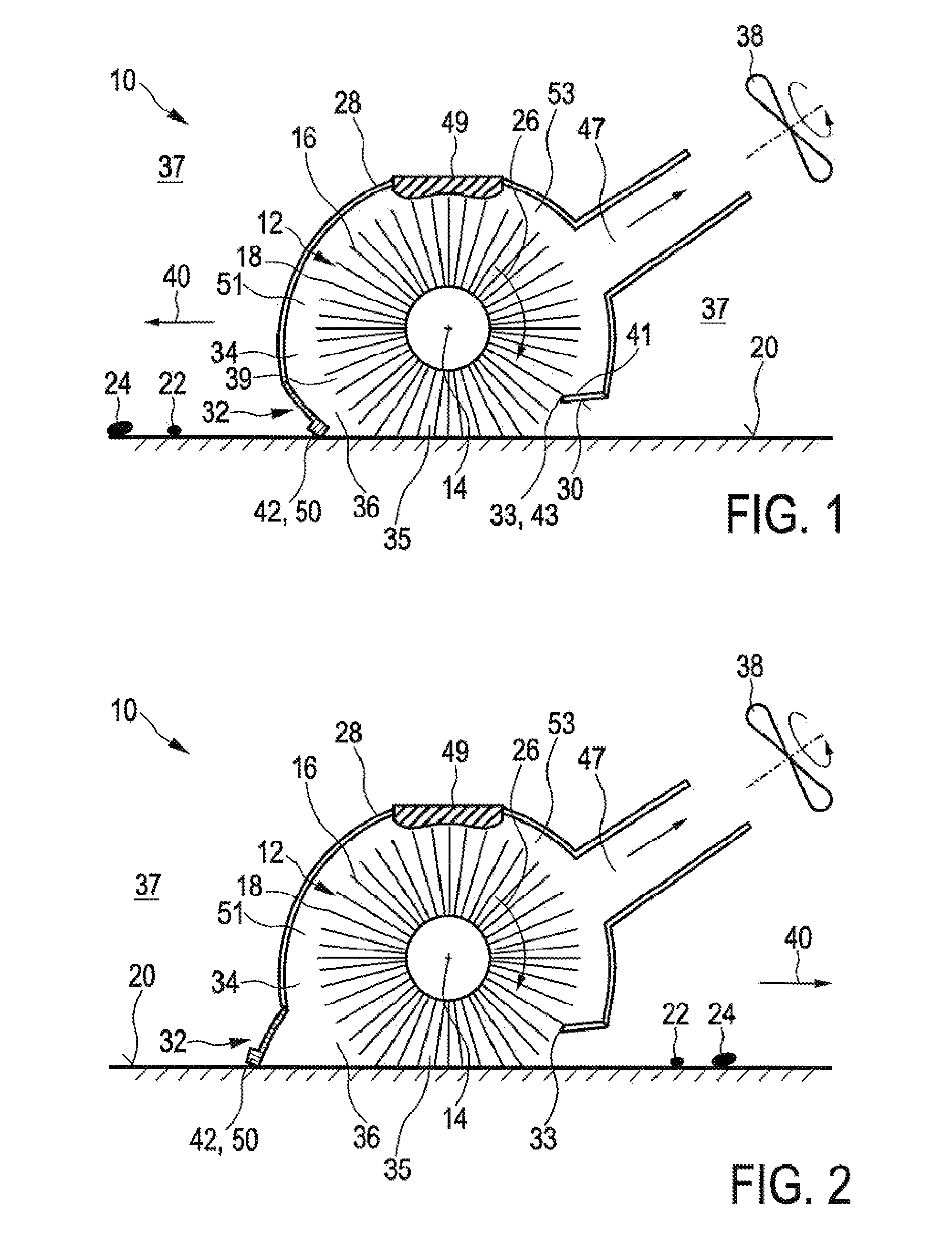

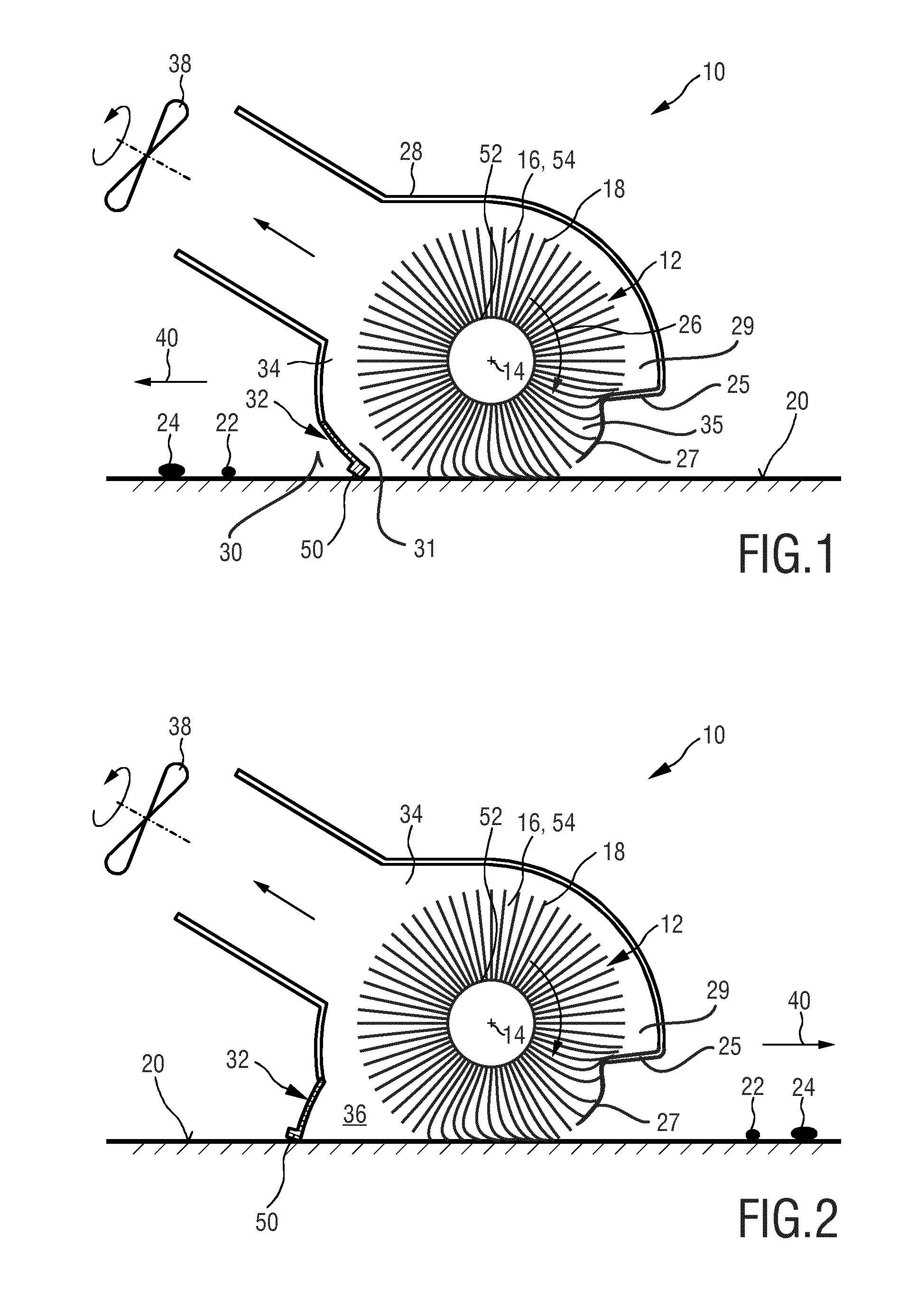

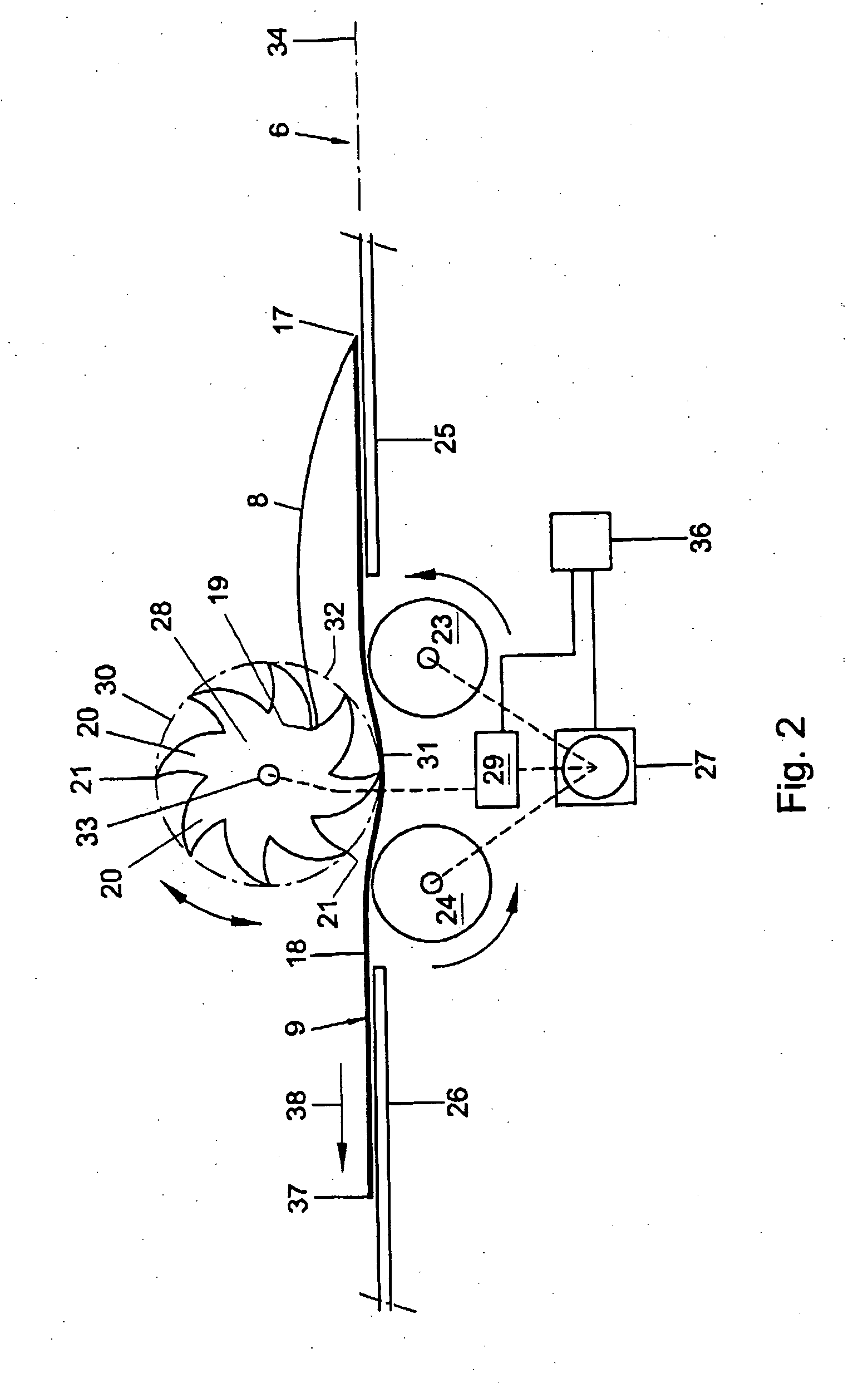

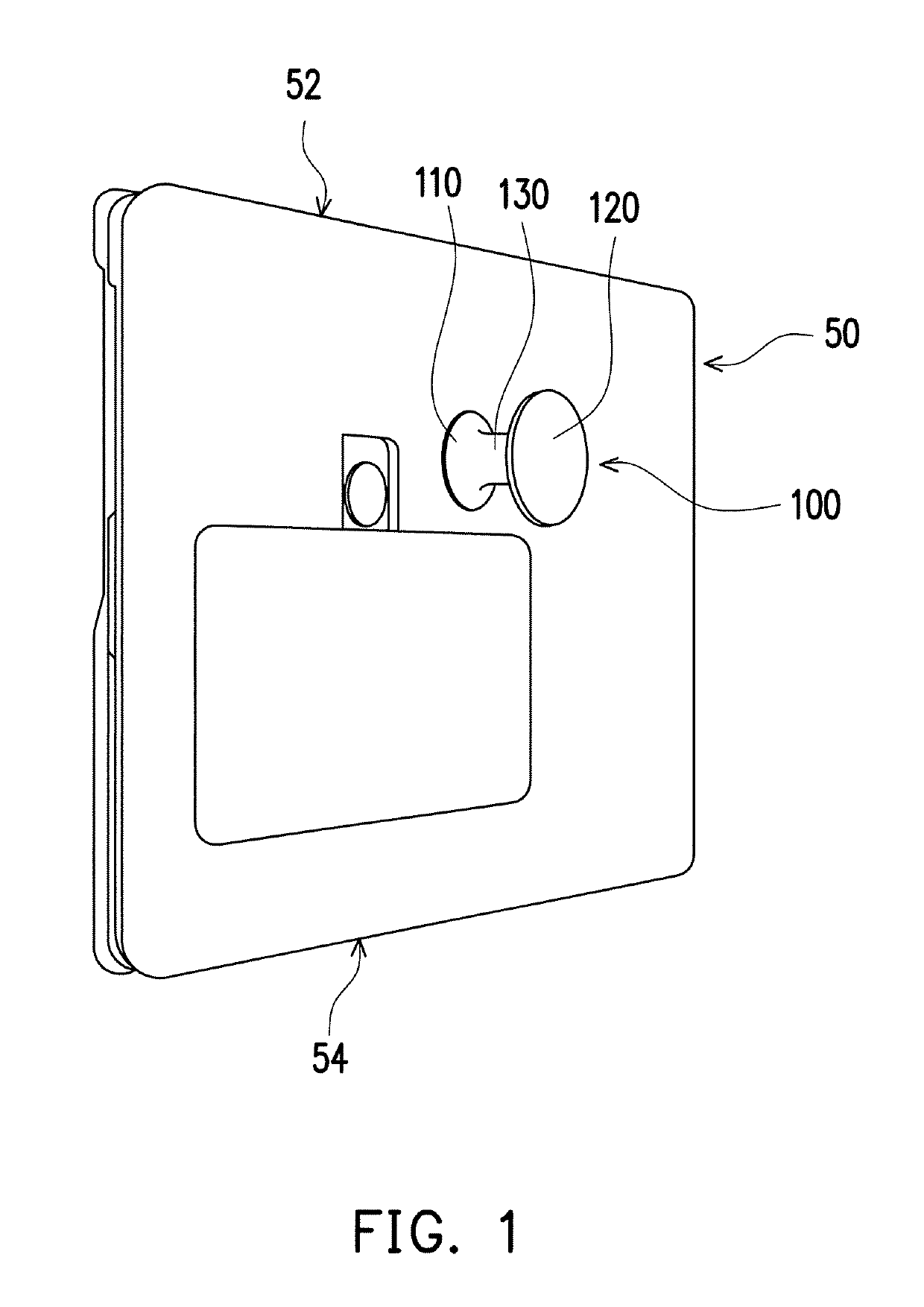

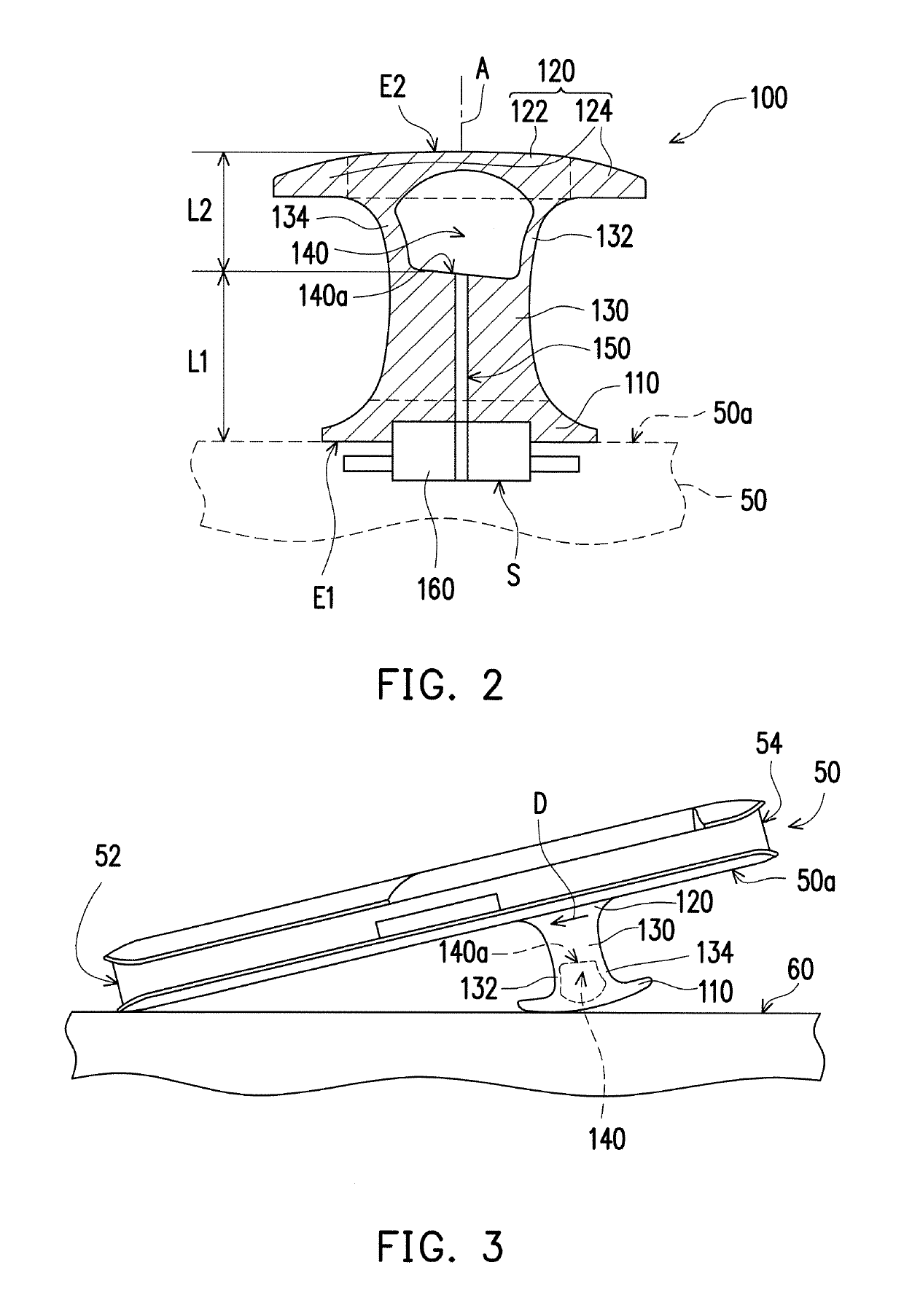

Cleaning device for cleaning a surface

ActiveUS20150297047A1Enhance fast removal of liquidIncrease capillary forceCarpet cleanersBrush bodiesEngineeringNozzle

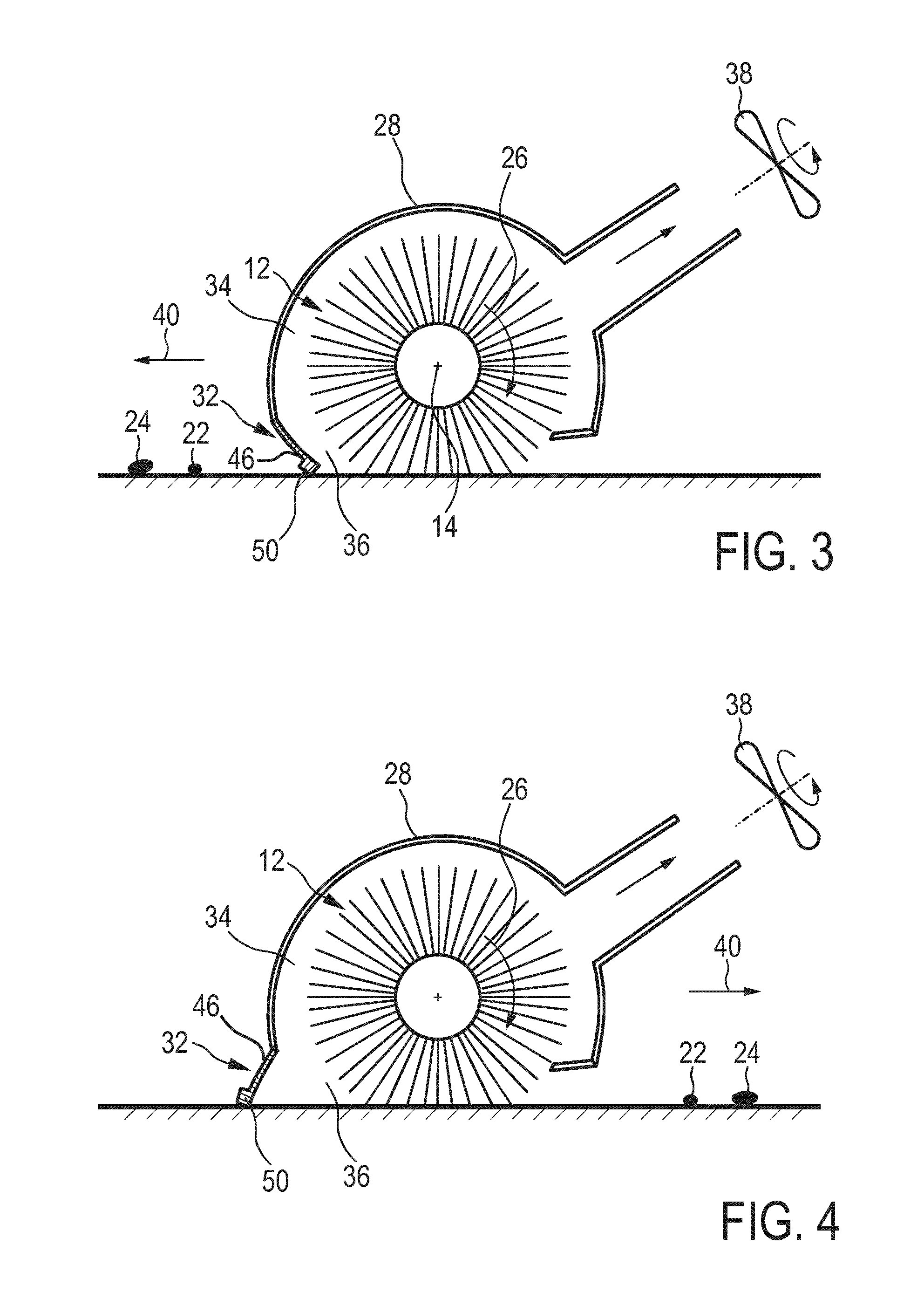

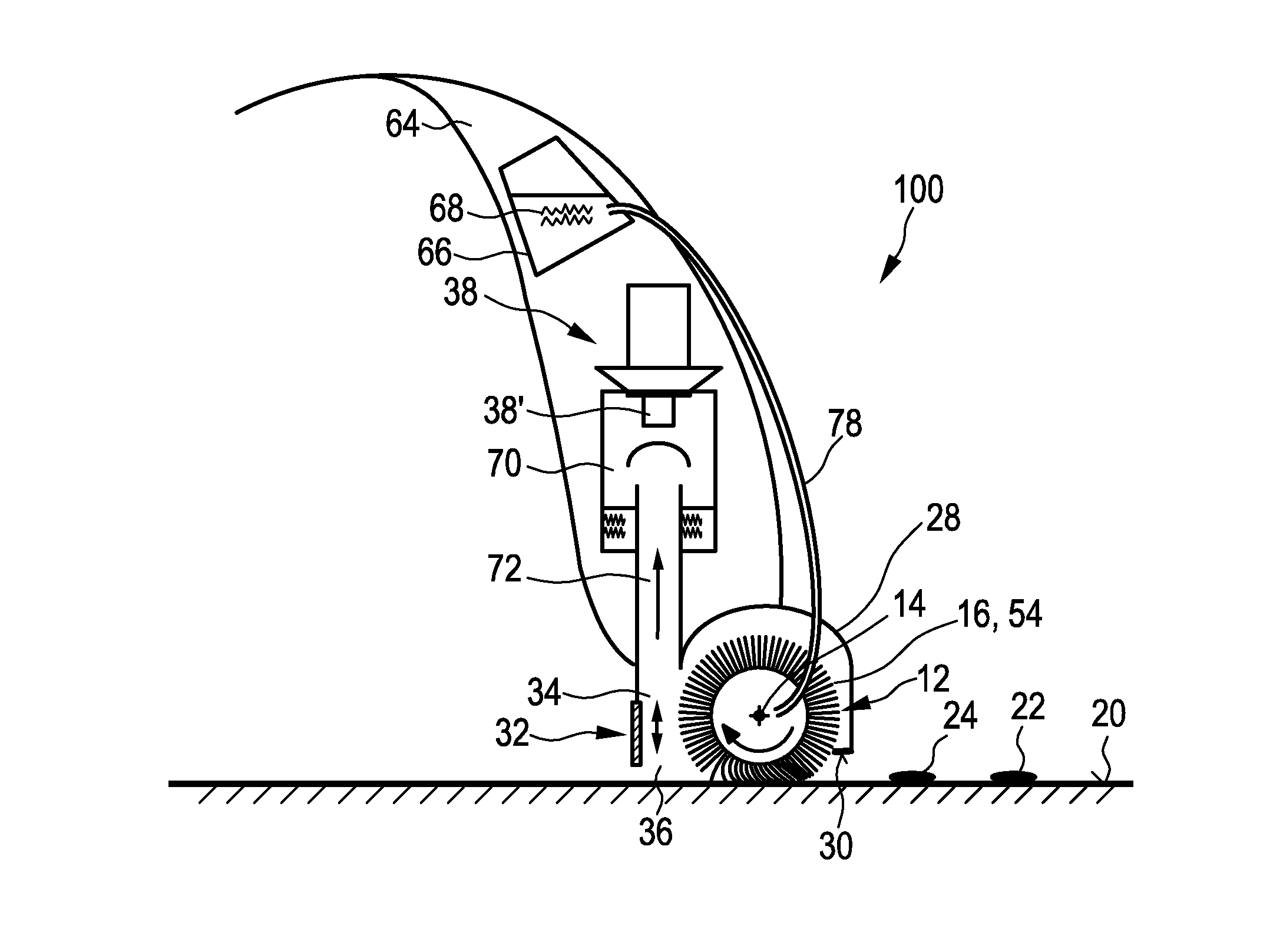

The present invention relates to a nozzle arrangement (10) for a cleaning device (100) for cleaning a surface, the nozzle arrangement comprising: —a brush (12) rotatable about a brush axis (14), the brush being provided with flexible brush elements (16) having tip portions (18) for contacting the surface to be cleaned (20) and picking up dirt and / or liquid particles (22, 24) from the surface (20) during the rotation of the brush (12), wherein the brush (12) is at least partly surrounded by a nozzle housing (28) and protrudes at least partly from a bottom side (30) of the nozzle housing (28), —a squeegee element (32) which is spaced apart from the brush (12) and attached to the bottom side (30) of the nozzle housing (28) on a first side (31) of the brush (12) where the brush elements (16) enter the nozzle housing (28) during the rotation of the brush (12), wherein the squeegee element (32) is configured for wiping dirt and / or liquid particles (22, 24) across or off the surface to be cleaned (20) during a movement of the cleaning device (100)—a deflector (150) for contacting the brush (12) and deflecting the brush elements (16) during the rotation of the brush (12), and—a restriction element (27) for at least partly restricting air from getting sucked into the nozzle housing (28) at a second side (29) of the brush (12) where the brush elements (16) leave the nozzle housing (28), wherein the restriction element (27) is, seen in a rotation direction (26) of the brush (12), arranged behind the deflector (25), such that the brush elements (16), during the rotation of the brush (12), contact the deflector (25) before passing the restriction element (27) and then leaving the nozzle housing (28) at the bottom side (30), and the restriction element (27) comprises a mechanically flexible element that is, due to its flexibility, configured to follow an outer surface of the brush (12) and to contact the tip portions (18) during the rotation of the brush (12).

Owner:KONINKLJIJKE PHILIPS NV

Nozzle arrangement with brush and squeegee

ActiveUS20150250367A1Enhance fast removal of liquidIncrease capillary forceCarpet cleanersFloor cleanersEngineeringMicrofiber

Nozzle arrangement (10) of a vacuum cleaning device (100) for cleaning a surface (20), comprising: —a nozzle housing (28); —a brush (12) rotatable about a brush axis (14), said brush (12) being provided with flexible microfiber brush elements (16) having tip portions (18) for contacting the surface to be cleaned (20) and picking up dirt and liquid particles (22, 24) from the surface to be cleaned (20) during the rotation of the brush (12); —a drive means for rotating the brush (12); —a single squeegee element (32) for wiping dirt and liquid particles (22, 24) across or off the surface to be cleaned (20) by contacting said surface (20) with its free end (33), wherein said squeegee element (32) extends along a longitudinal direction (48), which is arranged substantially parallel to the brush axis (14), and is attached with its fixed end (33) to the bottom side (30) of the nozzle housing (28) on a side of the brush (12) where the brush elements (16) enter the nozzle housing (28) during the rotation of the brush (12).

Owner:VERSUNI HLDG BV

Floor nozzle for vacuum cleaner

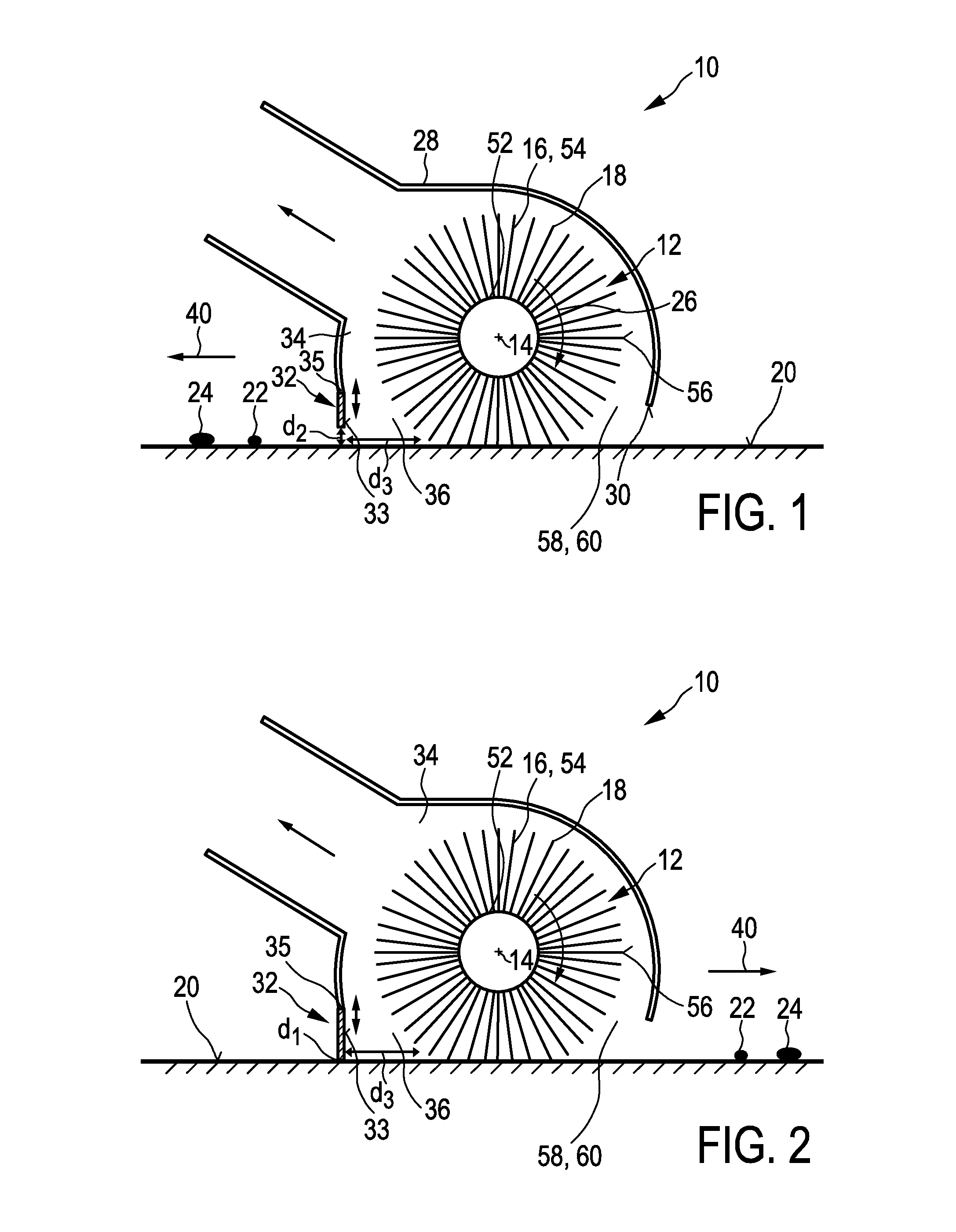

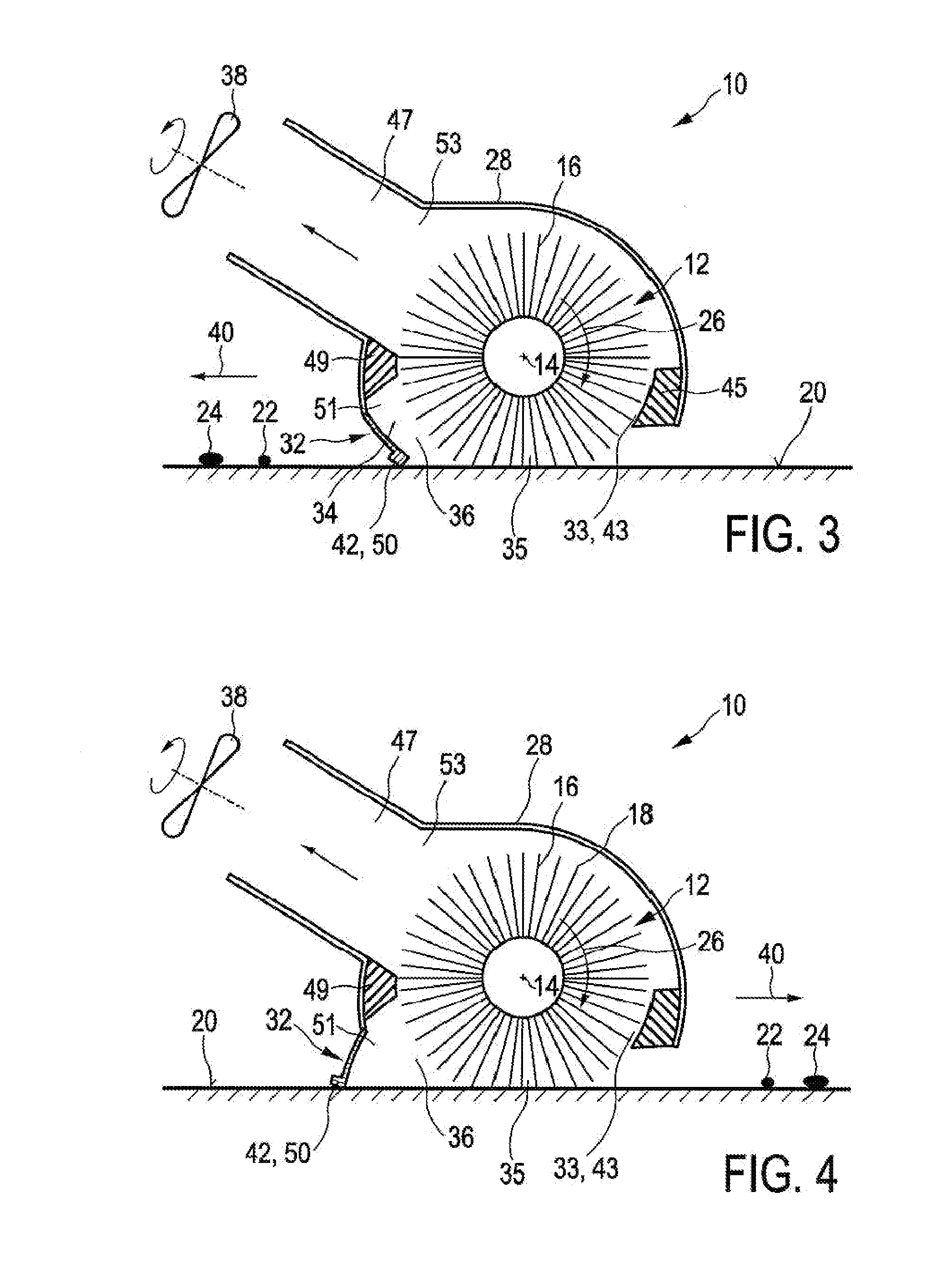

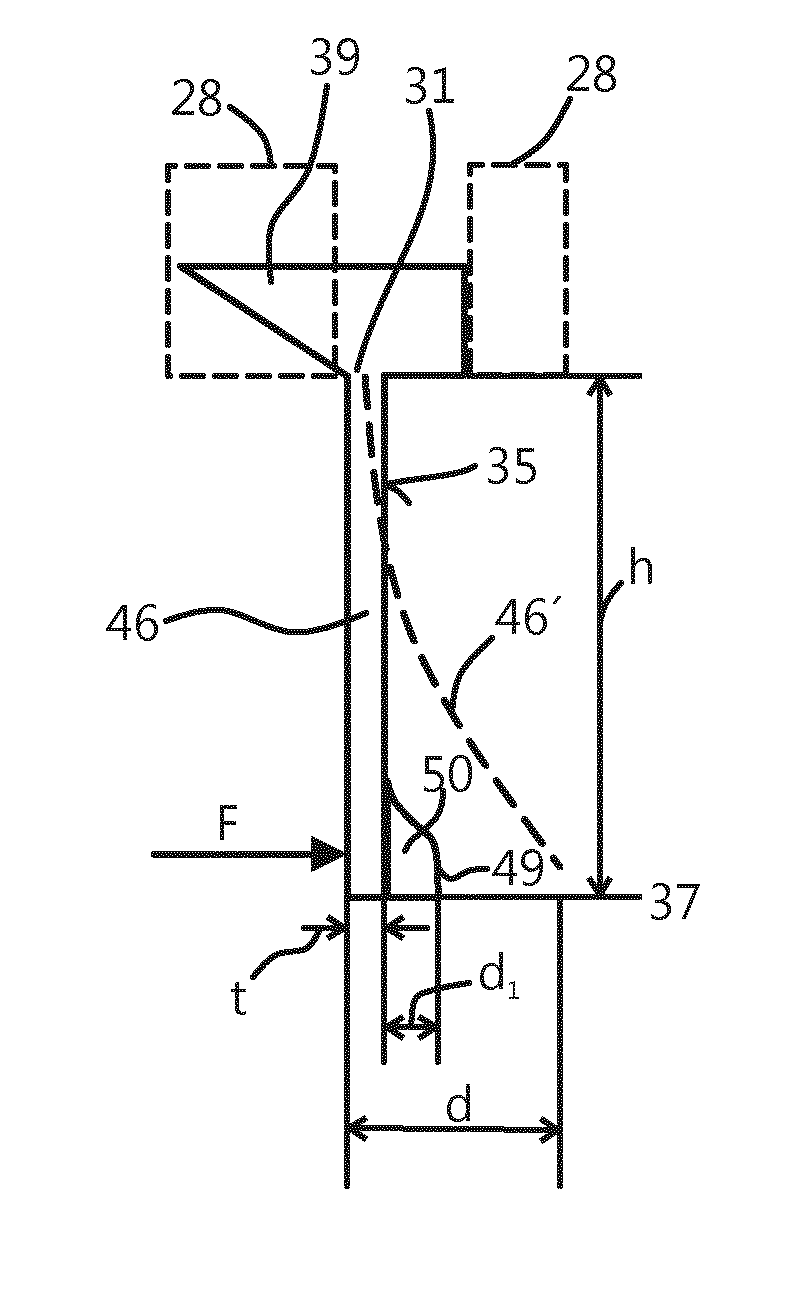

The present invention relates to a cleaning device for cleaning a surface, with a nozzle arrangement (10) comprising: —a brush (12) rotatable about a brush axis (14), said brush (12) being provided with brush elements (16) having tip portions (18) for contacting the surface to be cleaned (20) and picking up dirt particles (22) and / or liquid (24) from the surface (20) during the rotation of the brush (12), —a drive means for driving the brush (12) in rotation, —a bouncing element (32) comprising a bouncing surface (33) that is configured to let the dirt particles (22) and / or liquid (24), that are released from the brush (12) during rotation, rebound to the brush (12), said bouncing surface (33) being spaced apart from the brush (12) and extending substantially parallel to the brush axis (14), and —an adjustment means (35) for adjusting the position of the bouncing element (32) relative to the surface (20) depending on a direction of movement (40) of the device, wherein the adjustment means (35) is adapted to arrange the bouncing element (32) in a first position in which the bouncing element (32) has a first distance d1 to the surface (20), when the cleaning device is moved in a forward direction, in which the bouncing element (32) is, seen in the direction of movement of the device (40), located behind the brush (12), and to arrange the bouncing element (32) in a second position in which the bouncing element (32) has a second distance d2 to the surface, when the cleaning device is moved in an opposite backward direction, wherein d2 is greater than d1 and equal to d3*tan(α), d3 being the distance between the bouncing surface (33) and the position of the brush (12) where the tip portions (18) lose contact from the surface to be cleaned (20) during the rotation of the brush (12), and α being an angle that is equal to or smaller than 20°.

Owner:VERSUNI HLDG BV

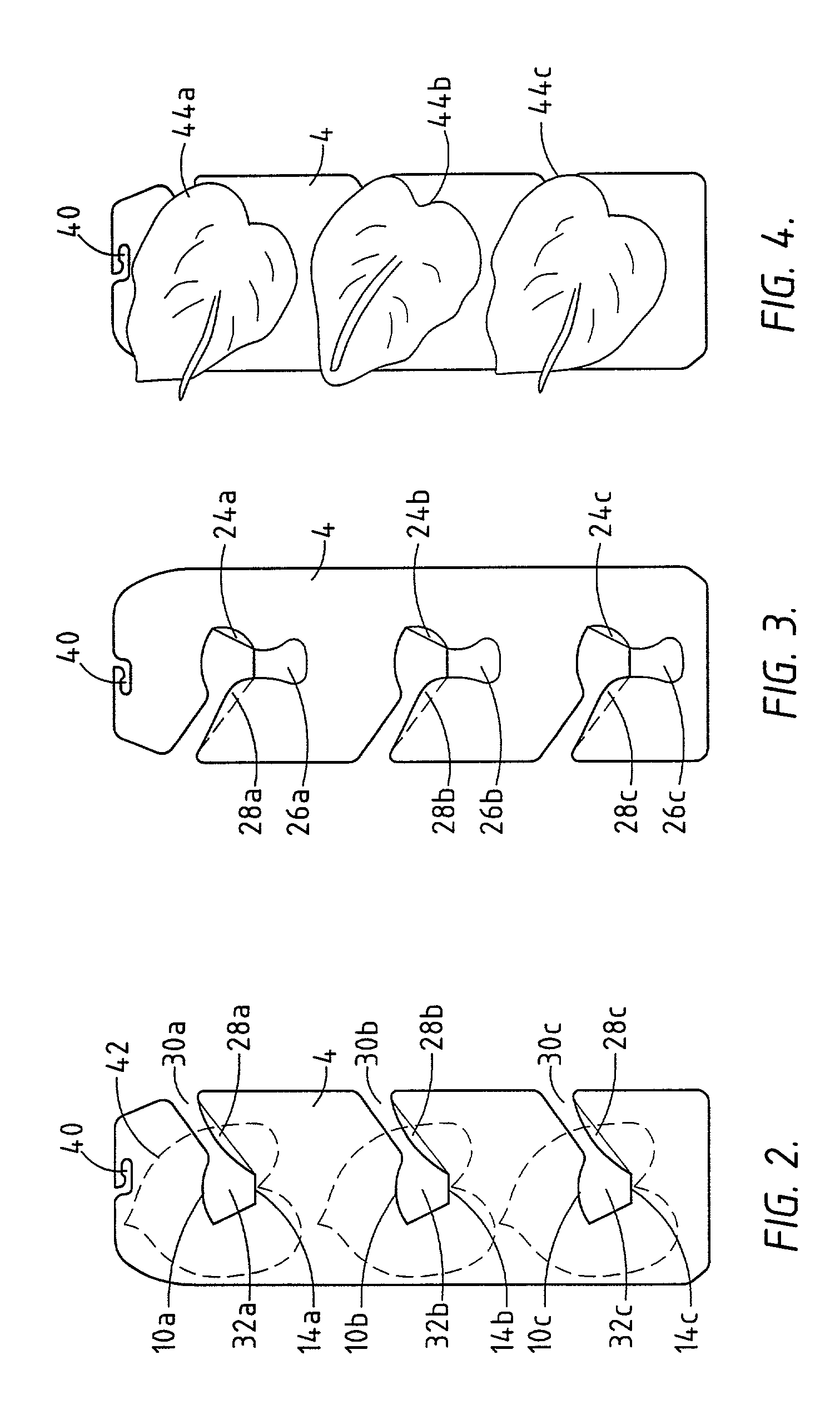

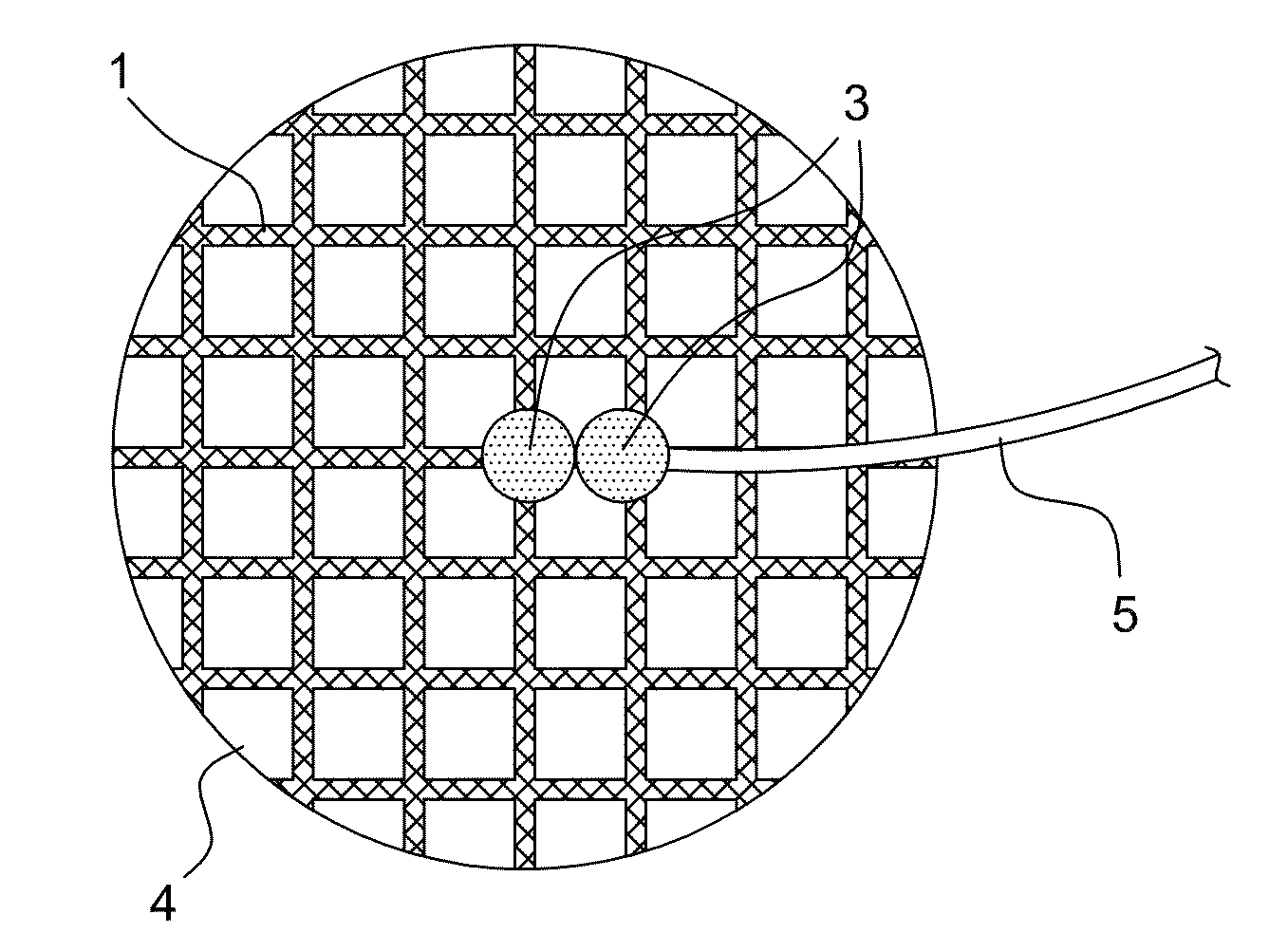

Plate-shaped flower carrier

InactiveUS20020014427A1More accuratelyLess actionLiving organism packagingOther accessoriesAcute angleEngineering

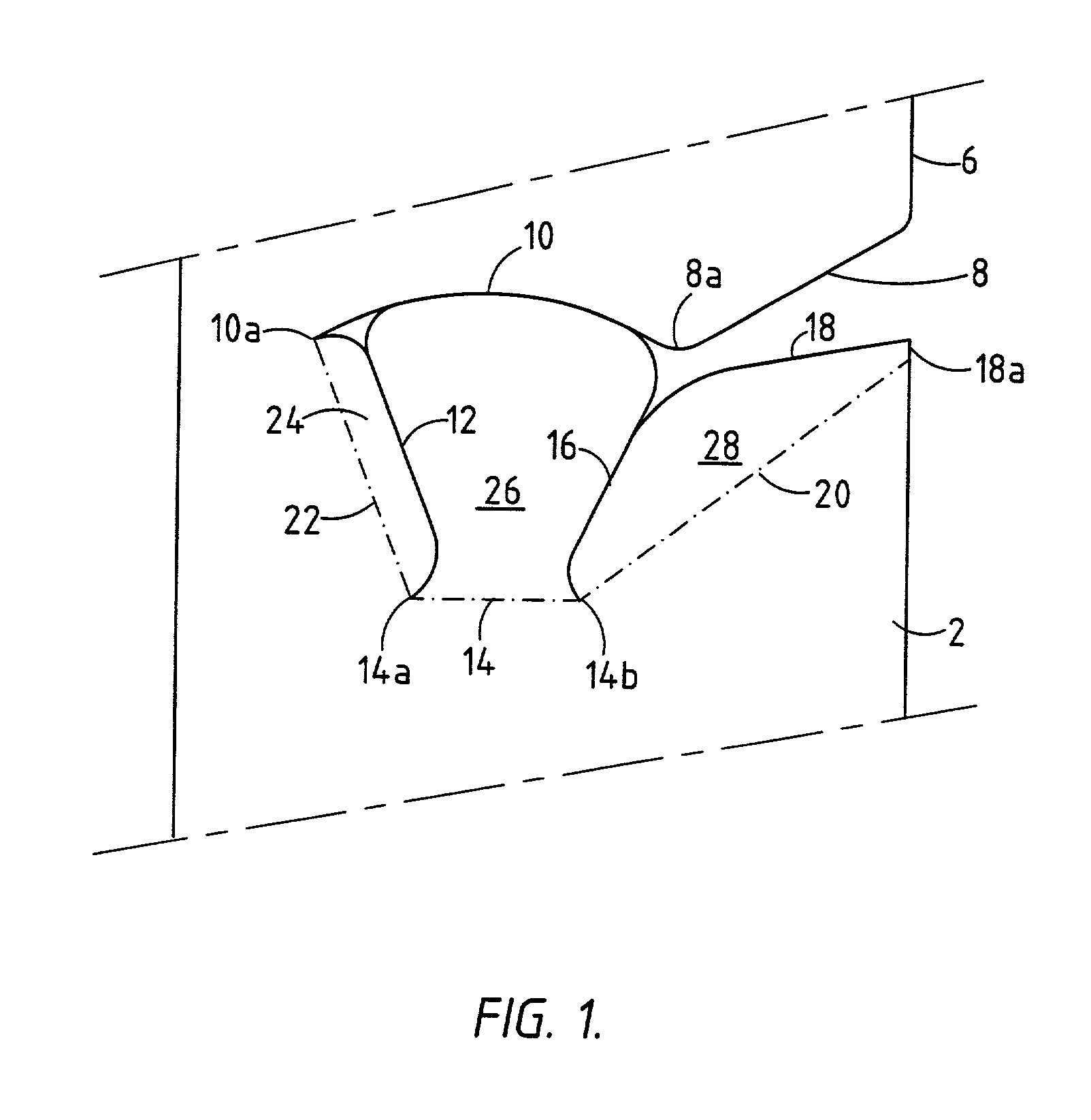

The invention relates to a plate-shaped carrier for flowers, having in its plane a number of accommodating openings for the respective flower stems, comprising, for easing the insertion of the respective flower stems in an accommodating opening, a flower stem infeed slot, starting from a longitudinal edge of the carrier and running downwardly under an acute angle with this edge into the accommodating opening.

Owner:UNIRES PARTICIPATIES +1

Nozzle arrangement of a cleaning device for cleaning a surface

ActiveUS20150327743A1Reduce quality problemsIncrease flexibilityCarpet cleanersBrush bodiesEngineeringNozzle

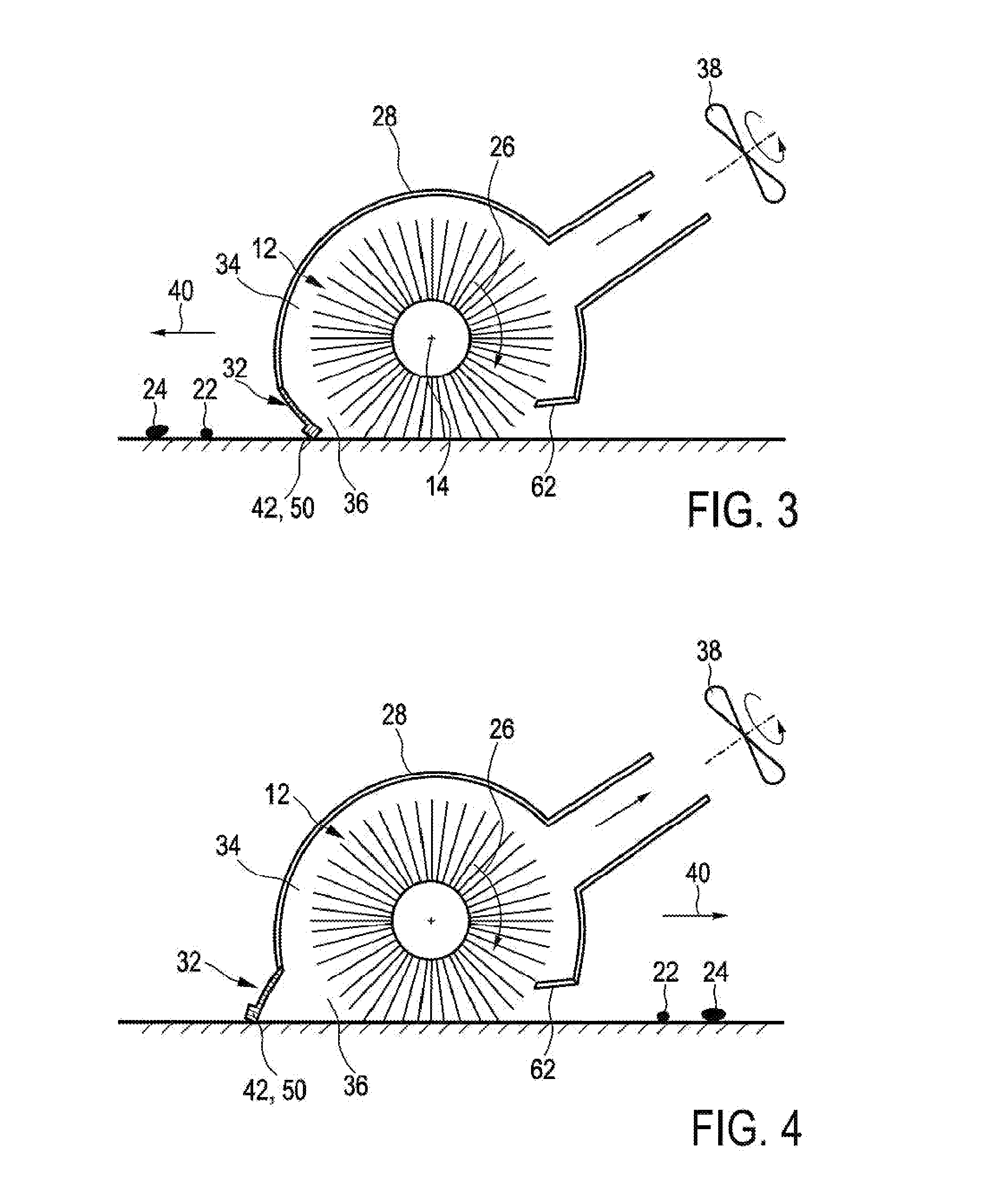

The present invention relates to a nozzle arrangement (10) of a cleaning device (100) for cleaning a surface (20), comprising: a nozzle housing (28); a rotating brush (12) that is rotatable about a brush axis (14) and comprises a substantially cylindrical core element (52) with flexible brush elements (16) that are arranged on a circumferential surface (56) of the core element (52), wherein said brush elements (16) are configured to contact the surface to be cleaned (20) and pick up dirt and liquid particles (22, 24) from the surface to be cleaned (20) during a rotation of the rotating brush (12); a drive for driving the rotating brush (12); a liquid supplying arrangement (58) for supplying a cleansing liquid (68) to the rotating brush (12); a wiping element (32) for wiping dirt and liquid particles (22, 24) across or off the surface to be cleaned (20), wherein said wiping element (32) extends along a longitudinal direction (48), which is arranged substantially parallel to the brush axis (14), and wherein said wiping element (32) is arranged on a first longitudinal side (27) of the rotating brush (12) where the brush elements (16) enter the nozzle housing (28) during the rotation of the rotating brush (12); and at least one side sealing element (62a, b) for sealing a lateral side (82a, b) of the nozzle housing (28), wherein the at least one side sealing element (62a, b) is spaced apart from a transverse side (80a, b) of the core element (52) that is transverse to the circumferential surface (56)

Owner:VERSUNI HLDG BV

Cleaning device for cleaning a surface comprising a brush and a squeegee element

ActiveUS20140189978A1Easy to cleanImprove filtering effectCarpet cleanersFloor cleanersEngineeringNozzle

The present invention relates to a cleaning device for cleaning a surface (20), comprising: —a brush (12) rotatable about a brush axis (14), said brush (12) being provided with flexible brush elements (16) that are substantially uniformly distributed over the periphery of the brush (12), wherein the brush (12) is at least partly surrounded by a nozzle housing (28) and protrudes at least partially from a bottom side (30) of said nozzle housing (28), which, during use of the device (100), faces the surface to be cleaned (20), wherein the brush elements (16), during the rotation of the brush (12), substantially form a sealing with the housing (28) at a first position (33) where the brush elements (16) leave the housing (28) during the rotation of the brush (12), and contact the surface to be cleaned (20) during the rotation of the brush (12) at a second position (35) for picking up dirt particles (22) and liquid (24) from said surface (20), thereby defining a suction area (34) in a space between the brush (12), said housing (28) and said surface to be cleaned (20) which is at least partly sealed at said first and second positions (33, 35), —a single squeegee element (32) which is spaced apart from the brush (12) and attached to the bottom side (30) of the nozzle housing (28) on a side of the brush (12), where the brush elements (16) enter the housing (28) during the rotation of the brush (12), wherein said squeegee element (32) is adapted for pushing or wiping dirt particles and liquid across or off the surface to be cleaned (20) during movement of the cleaning device (100), thereby defining a suction inlet (36) between the squeegee element (32) and the brush (12) that opens into the suction area (34), —a drive means for driving the brush (12) in rotation, and —a vacuum aggregate (38) which is arranged at a suction outlet (47) of the suction area (34) for generating an under-pressure in said suction area (34) for ingesting dirt particles (22) and liquid (24) from the suction inlet (36).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

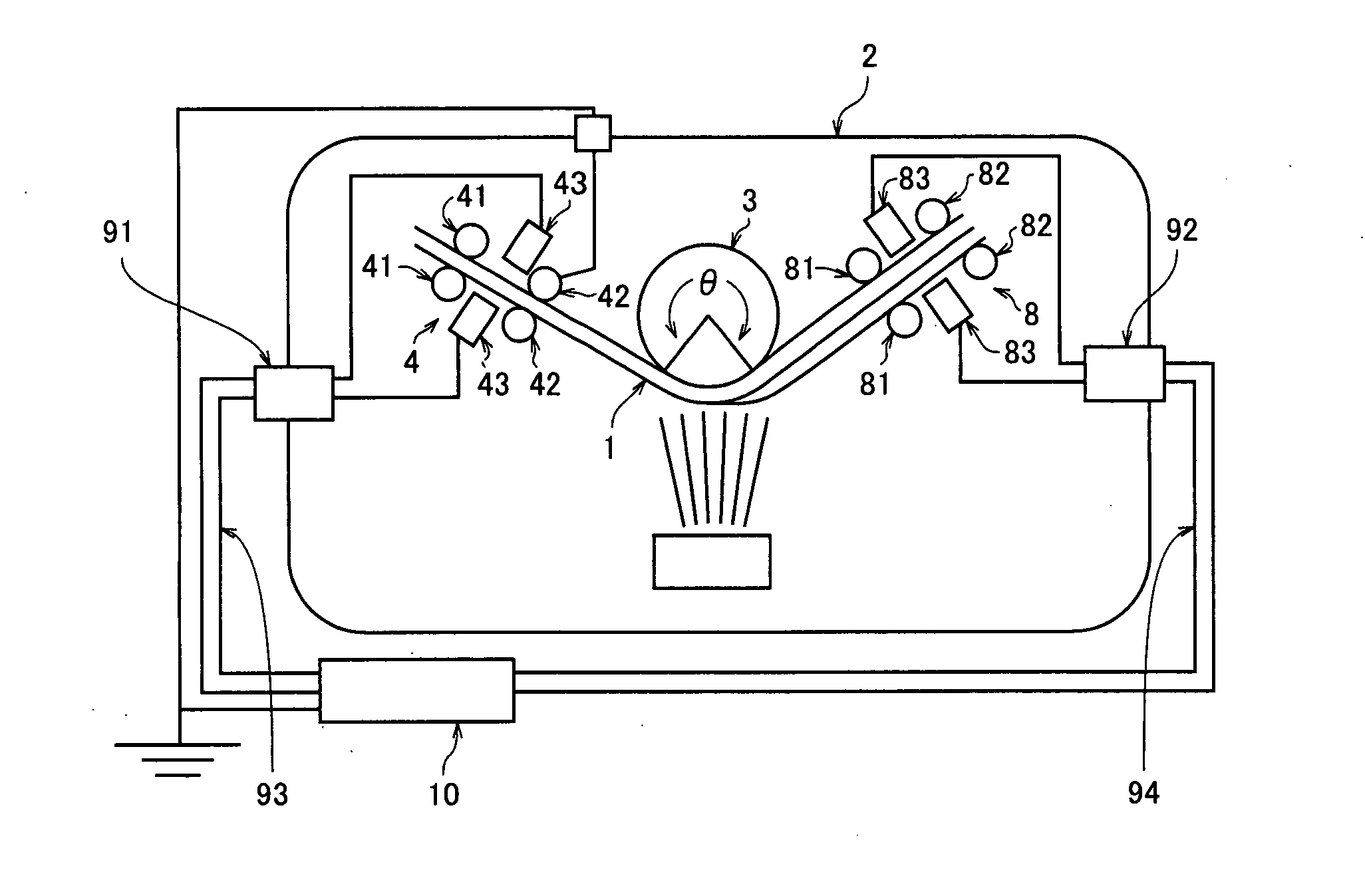

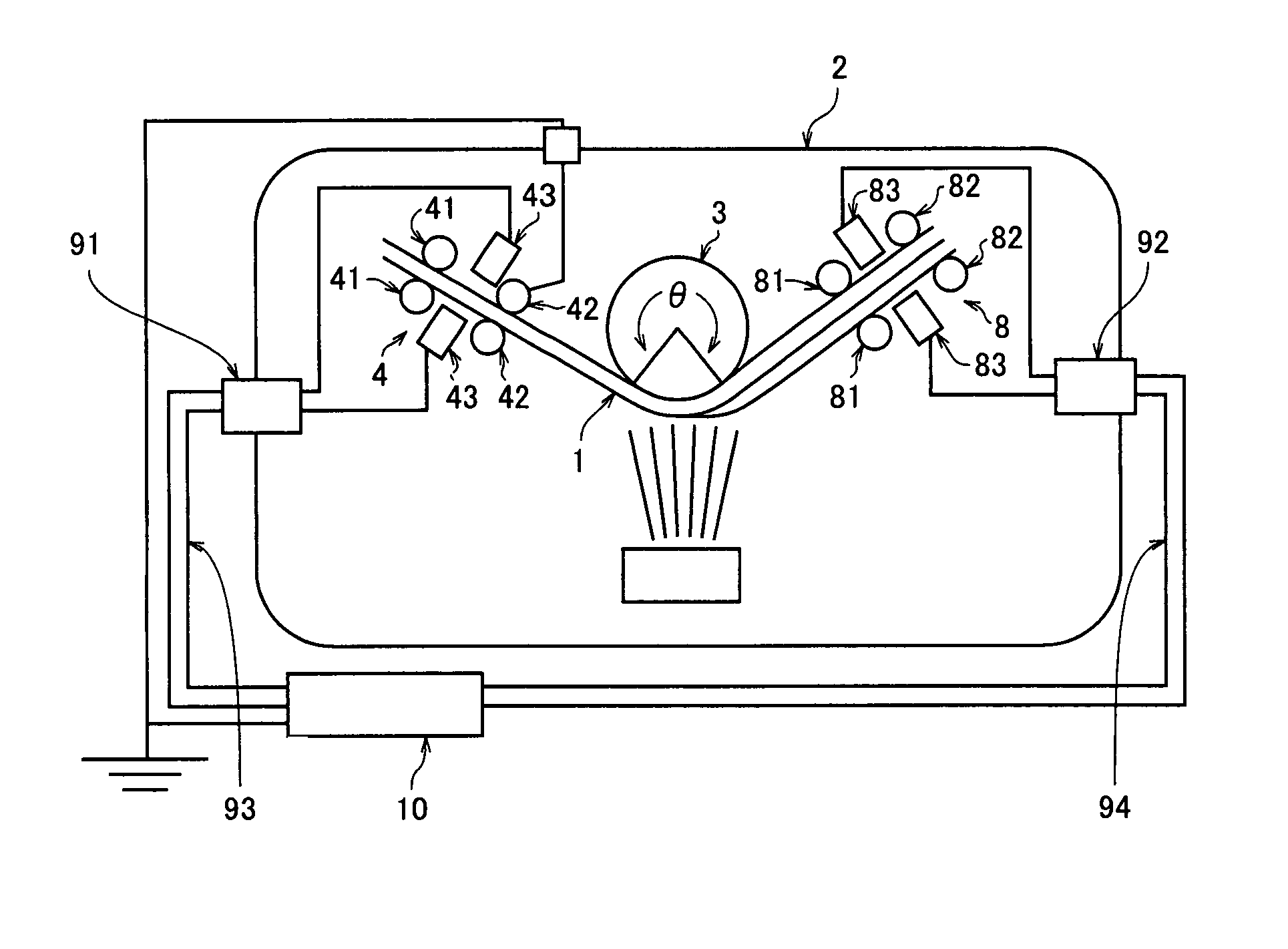

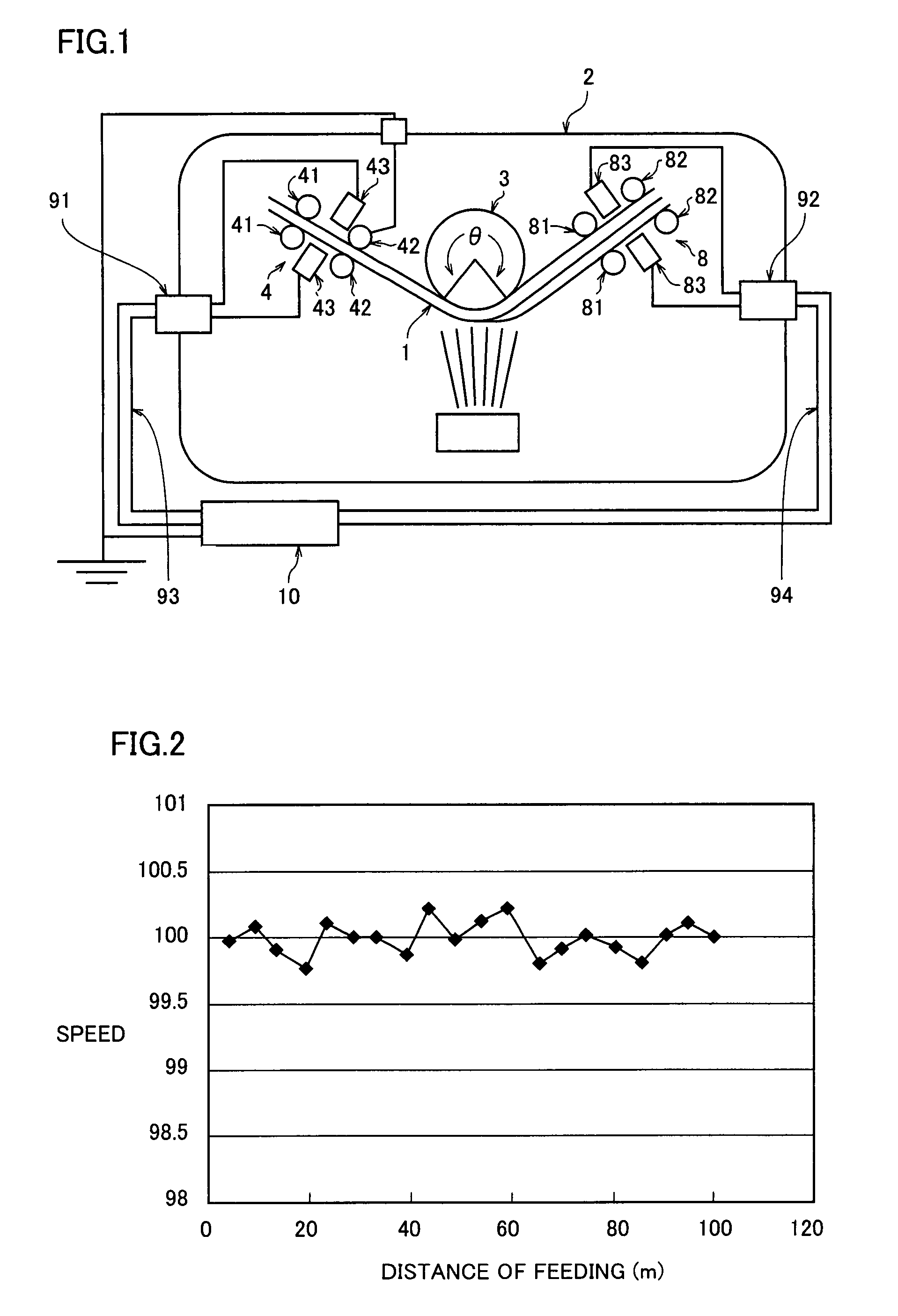

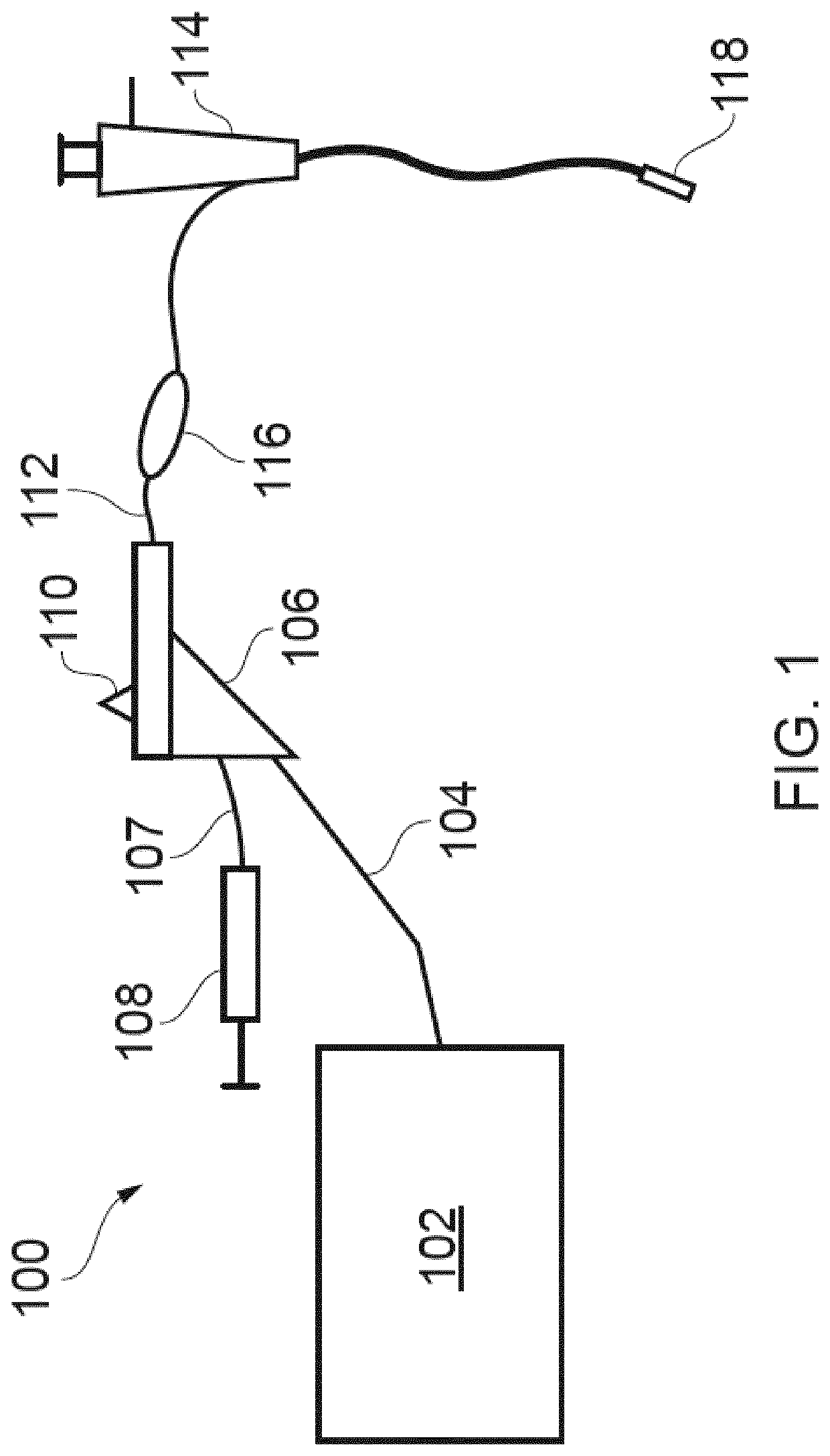

Coating layer thickness measurement mechanism and coating layer forming apparatus using the same

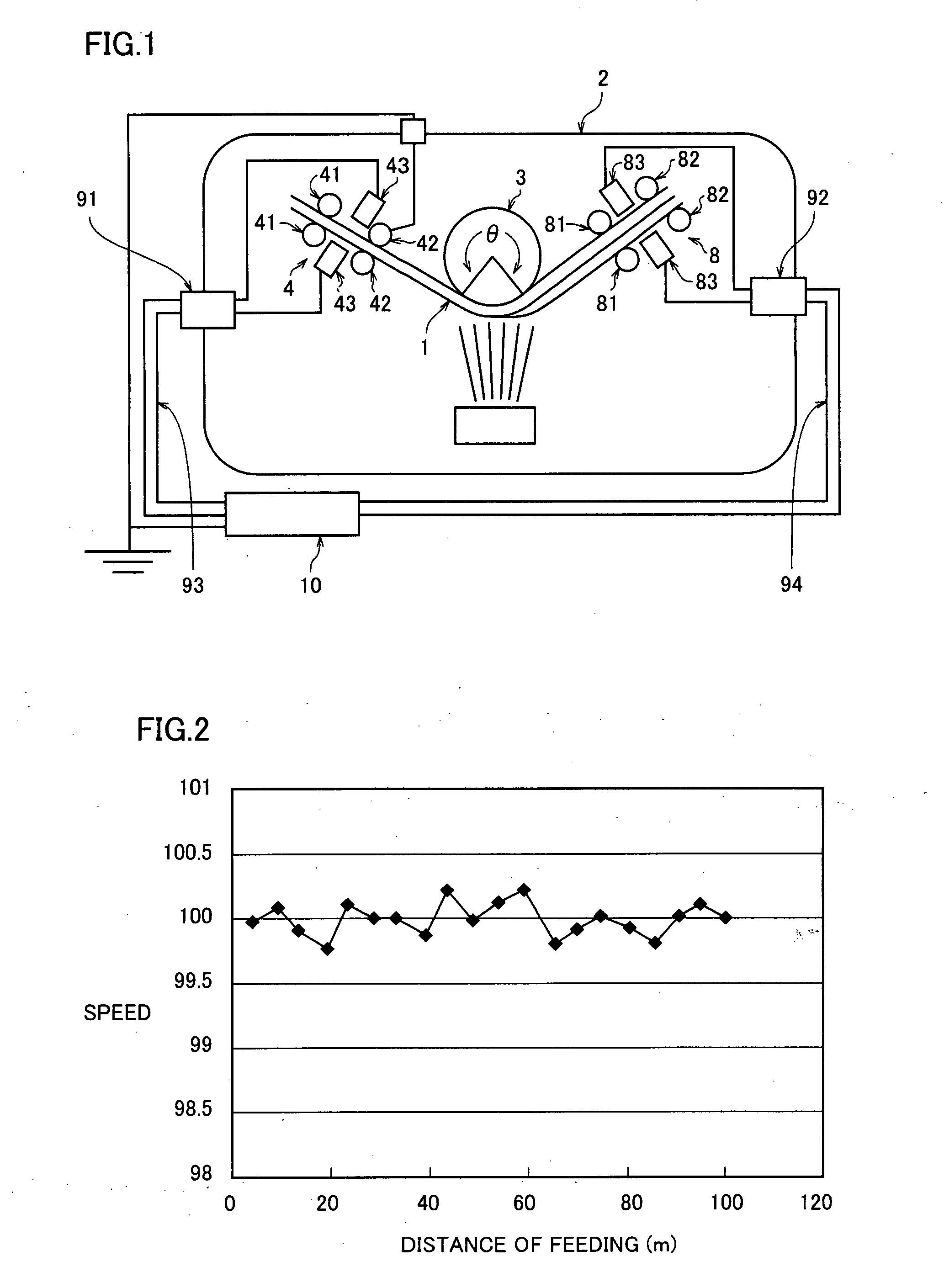

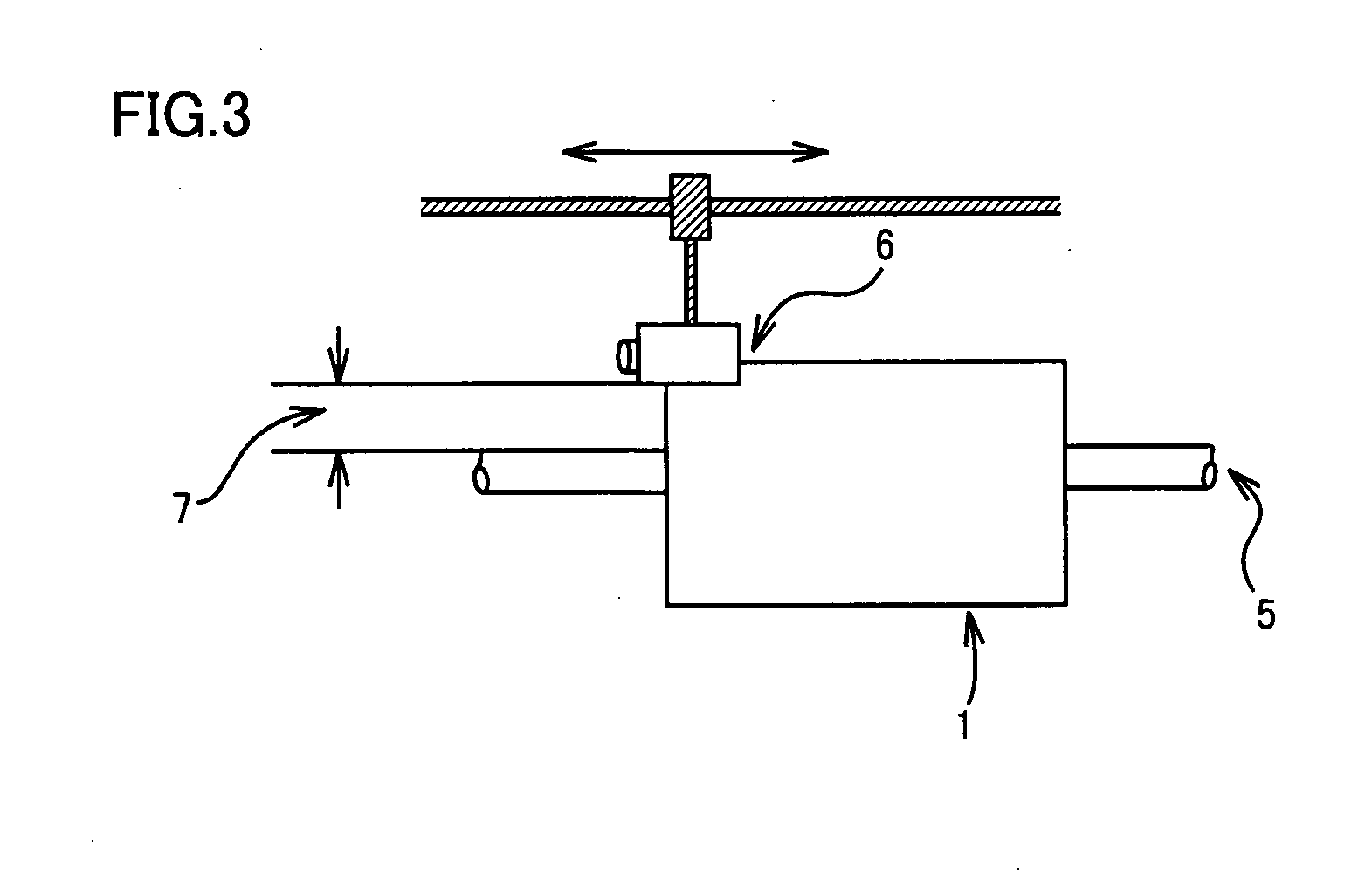

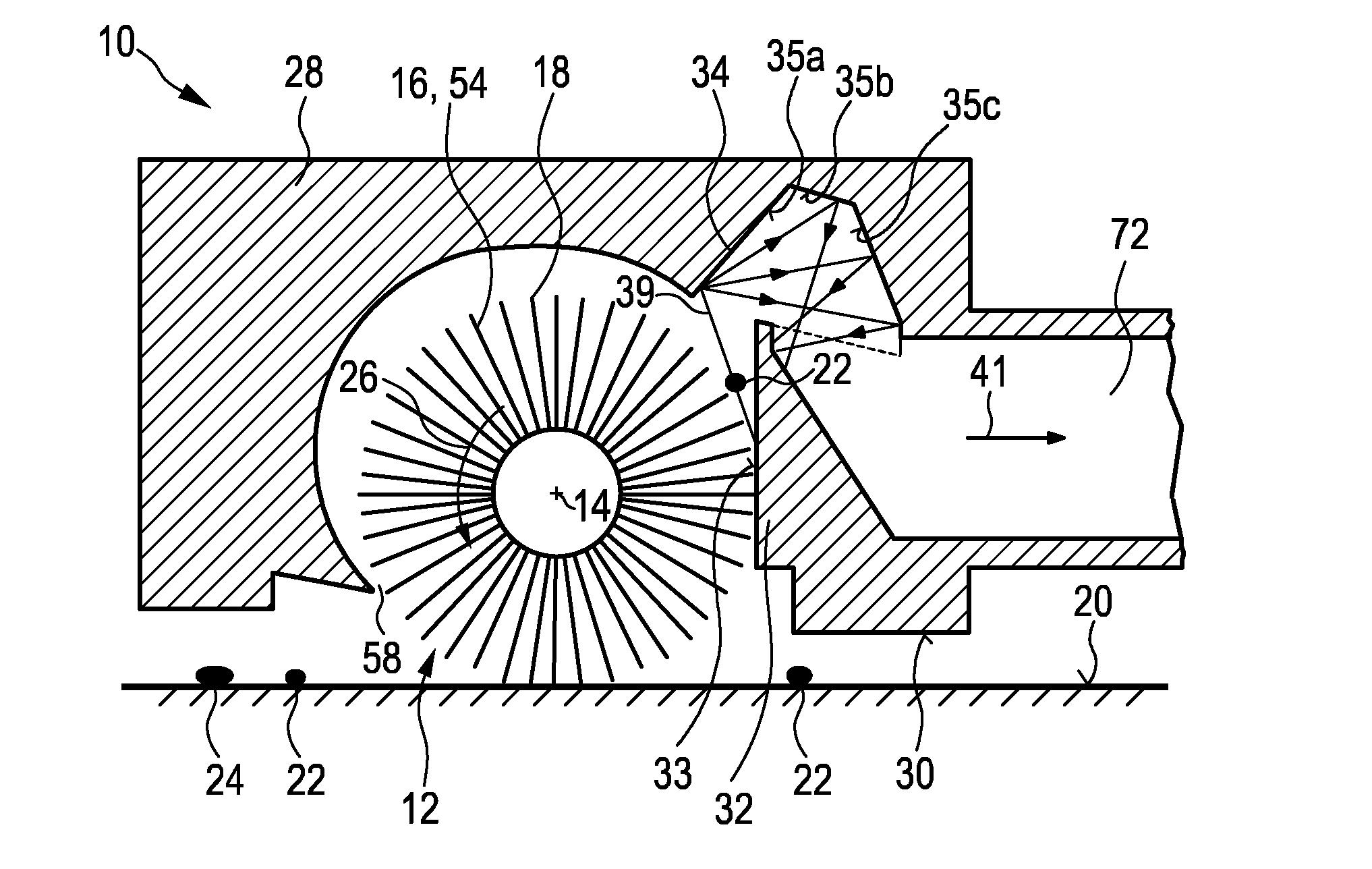

InactiveUS20070261638A1Suppressing variation in a speed of feeding a base materialMinimize impactLiquid surface applicatorsVacuum evaporation coatingCapacitanceEngineering

In a measurement mechanism for continuously measuring a thickness of a coating layer, provided in an apparatus for forming the coating layer on a conductive elongate base material in a coating treatment base station while the base material is fed, a sensing portion for measuring a capacitance value of the coating layer is arranged before and after the base station, and tension applied to the base material at the sensing portion is set to be greater than tension applied to the base material at the base station. Thus, in forming the coating layer on the elongate base material while the base material is continuously fed, variation in a feeding speed is suppressed, influence of sway of a measurement surface in a direction of thickness at the thickness sensing portion during feeding is minimized, and a thickness of the coating layer can be measured with higher accuracy.

Owner:SUMITOMO ELECTRIC IND LTD

Cleaning device having a nozzle for cleaning a surface

ActiveUS20160256025A1Speed at which deformationReduce quality problemsCarpet cleanersFloor cleanersEngineeringNozzle

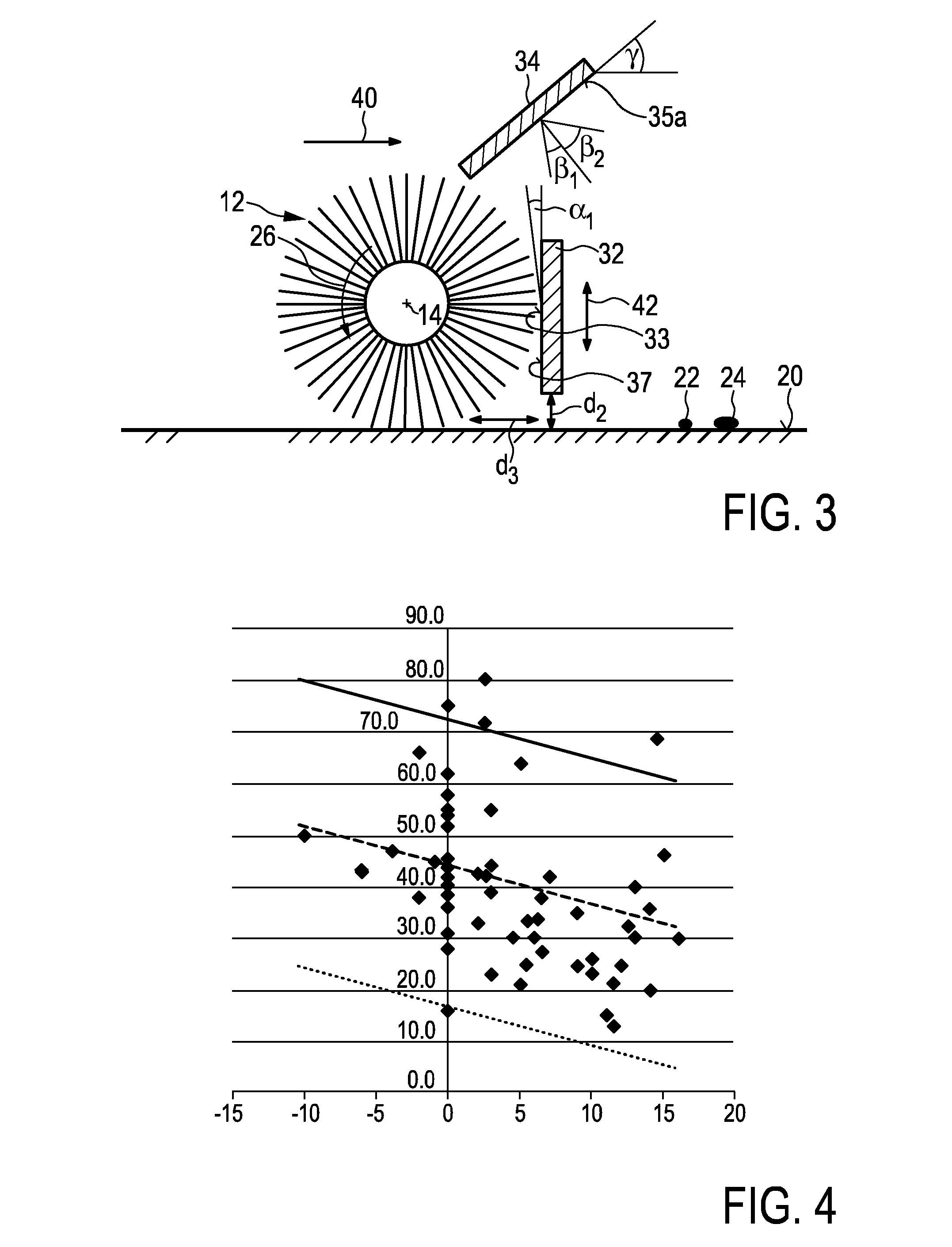

Cleaning device for cleaning a surface (20), the cleaning device having a nozzle arrangement (10) comprising: —a brush (12) rotatable about a brush axis (14), said brush (12) being provided with brush elements (16) having tip portions (18) for contacting the surface to be cleaned (20) and picking up dirt and / or liquid particles (22, 24) from the surface (20) during the rotation of the brush (12), —a drive means for rotating the brush (12), —a first deflector element (32) with a first deflector surface (33) that extends substantially parallel to the brush axis (14), wherein the first deflector surface (33) is configured to interact with the brush (12) during the rotation of the brush (12) for releasing the picked-up dirt and / or the liquid particles (22, 24) from the brush (12), and —a second deflector element (34) that is spaced apart from the brush (12) and the first deflector element (32), the second deflector element (34) comprising a second deflector surface (35a) that is oriented transverse to the first deflector surface (33), wherein the second deflector surface (35a) is configured to deflect the dirt and / or liquid particles (22, 24), which are released from the brush (12) at the first deflector surface (33), into an exhaust channel (41) that begins between the first and second deflector elements.

Owner:VERSUNI HLDG BV

Nozzle arrangement with brush and squeegee

ActiveUS9265394B2Reduce quality problemsIncrease flexibilityCarpet cleanersFloor cleanersEngineeringMicrofiber

Owner:VERSUNI HLDG BV

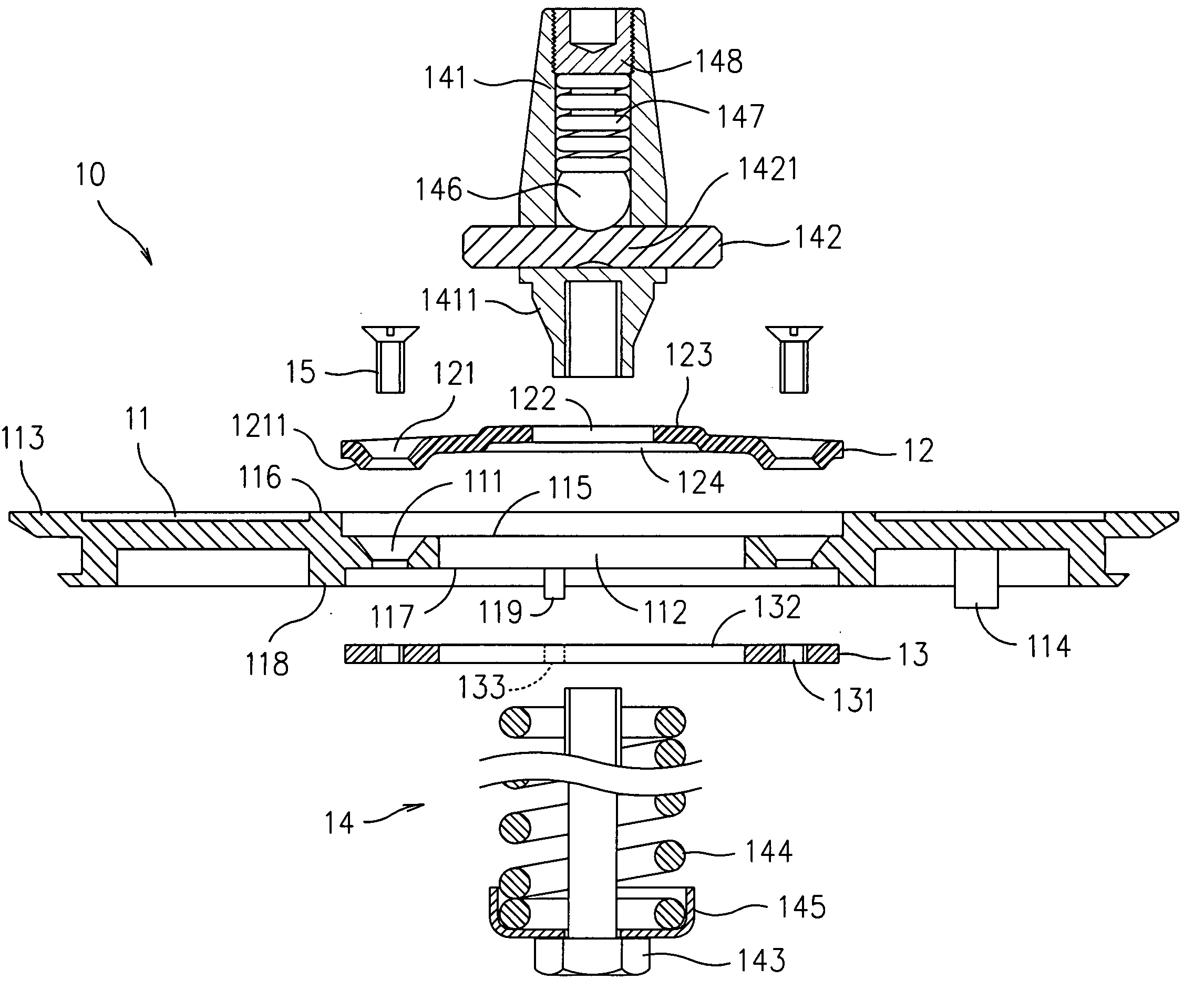

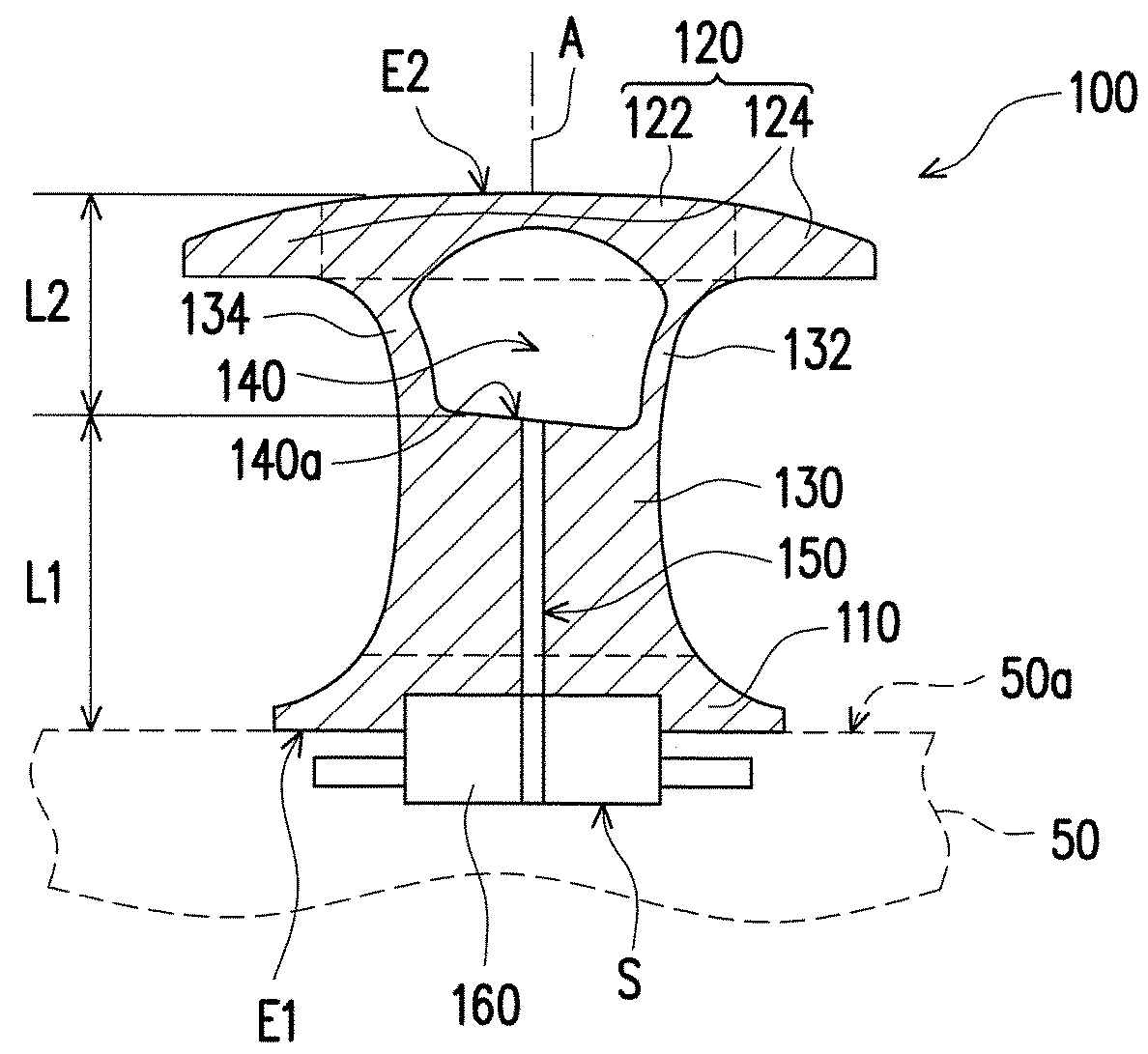

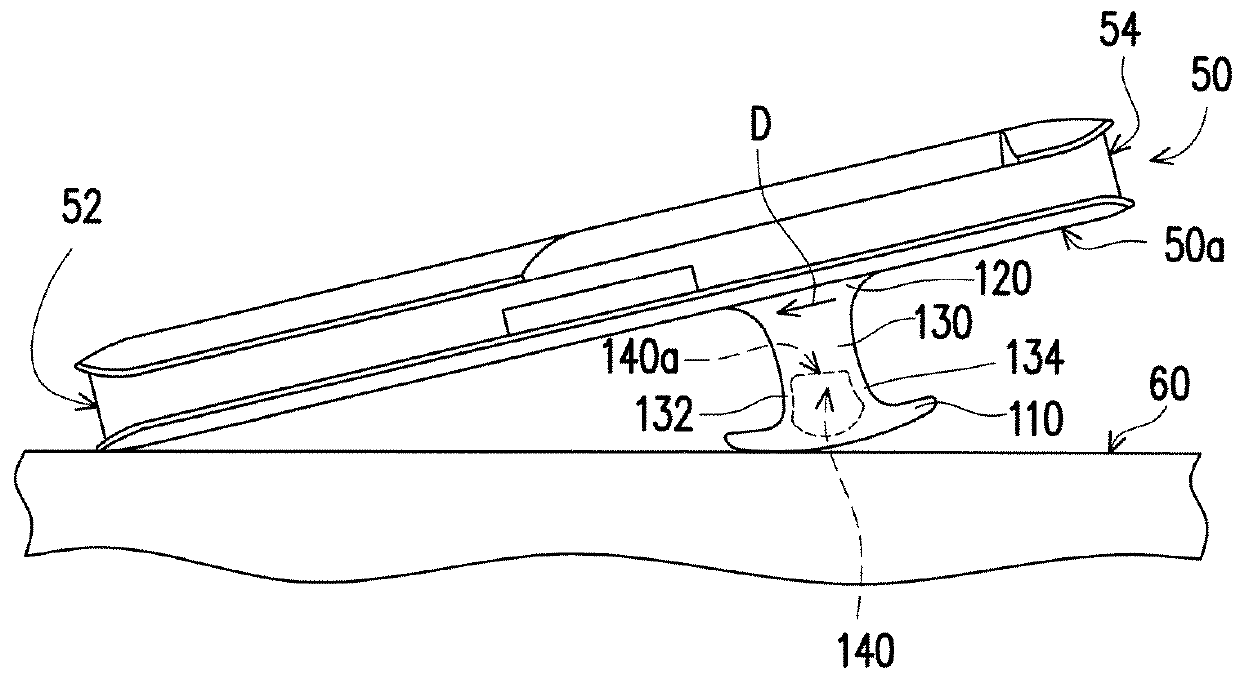

Transverse element for a drive belt for a continuously variable transmission

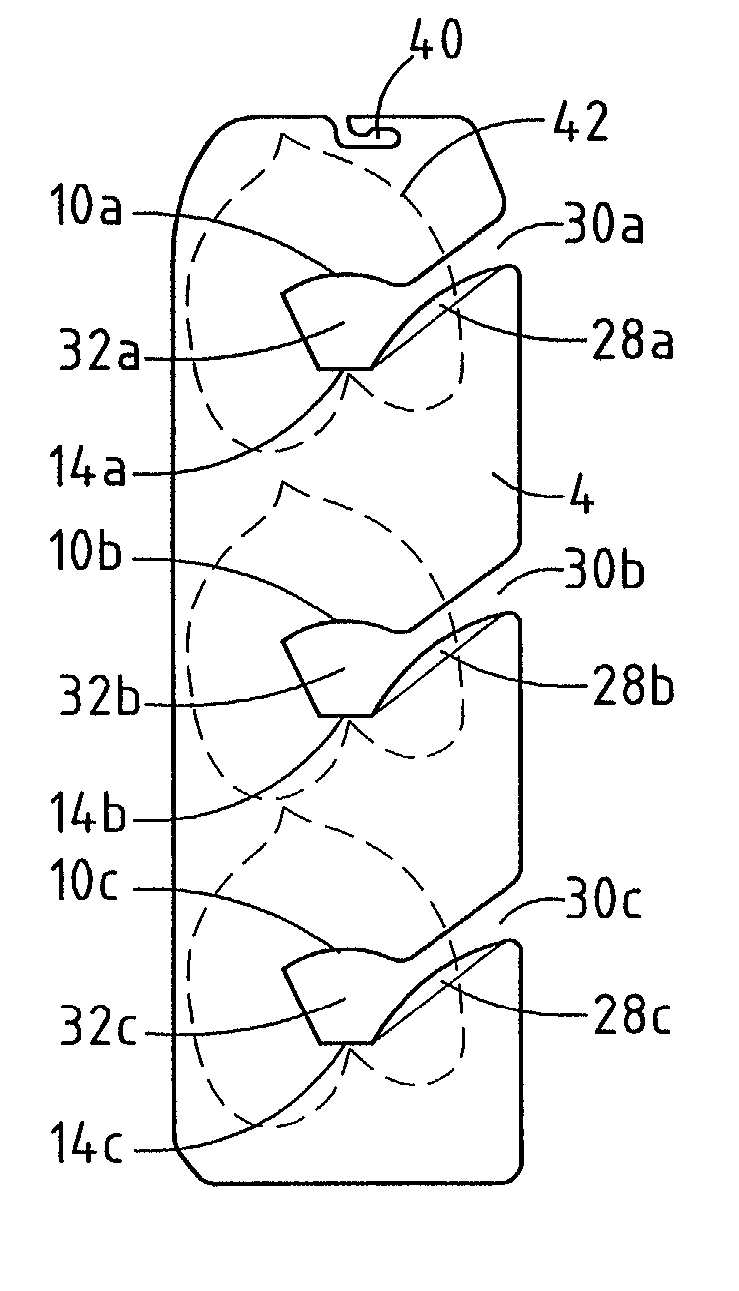

The present invention is a transverse element for a drive belt for a continuously variable transmission. The drive belt includes two endless carriers, wherein transverse elements are continuously arranged along the entire length of the carriers. The transverse elements are on both sides provided with recesses for at least partially receiving the carriers. Furthermore, the transverse elements include supporting surfaces for supporting the carriers, as well as pulley sheave contact surfaces for the purpose of contact between the transverse elements and pulley sheaves of the continuously variable transmission. A convex transition region which has two parts having different curvature radii is situated between a supporting surface and a pulley sheave contact surface, wherein a first curvature radius of a first part at the side of the supporting surface is larger than a second curvature radius of a second part at the side of the pulley sheave contact surface.

Owner:BOSCH TRANSMISSION TECH

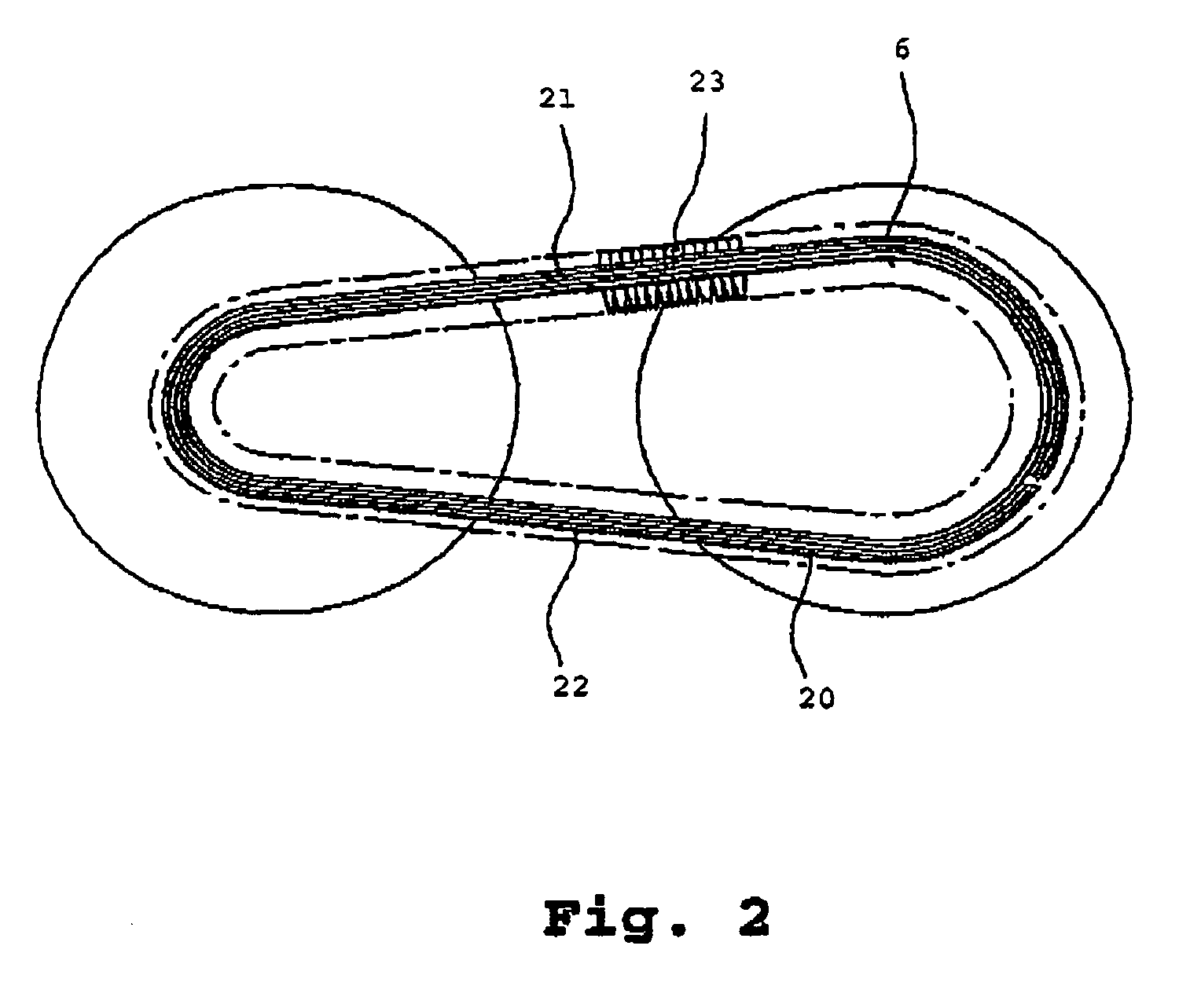

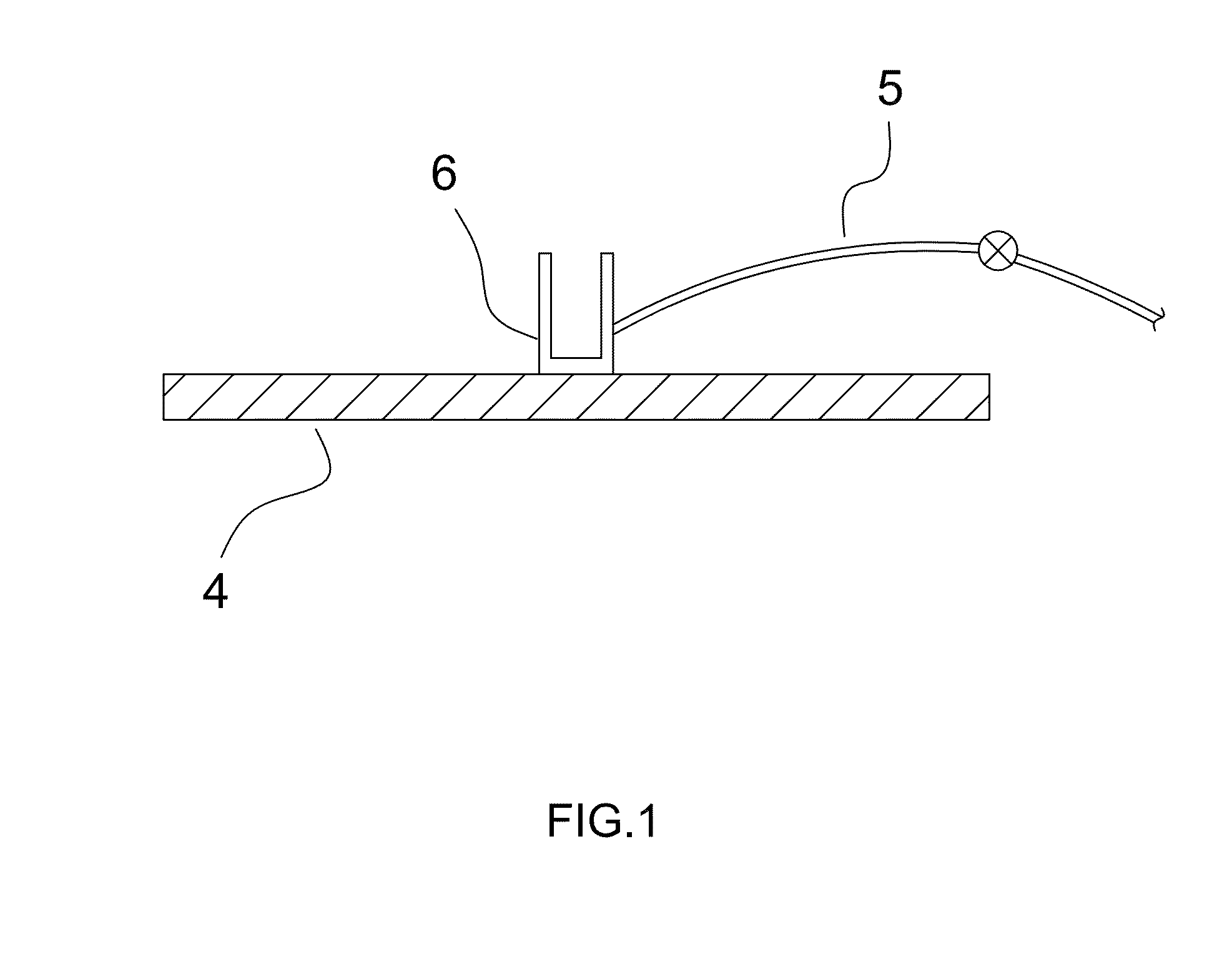

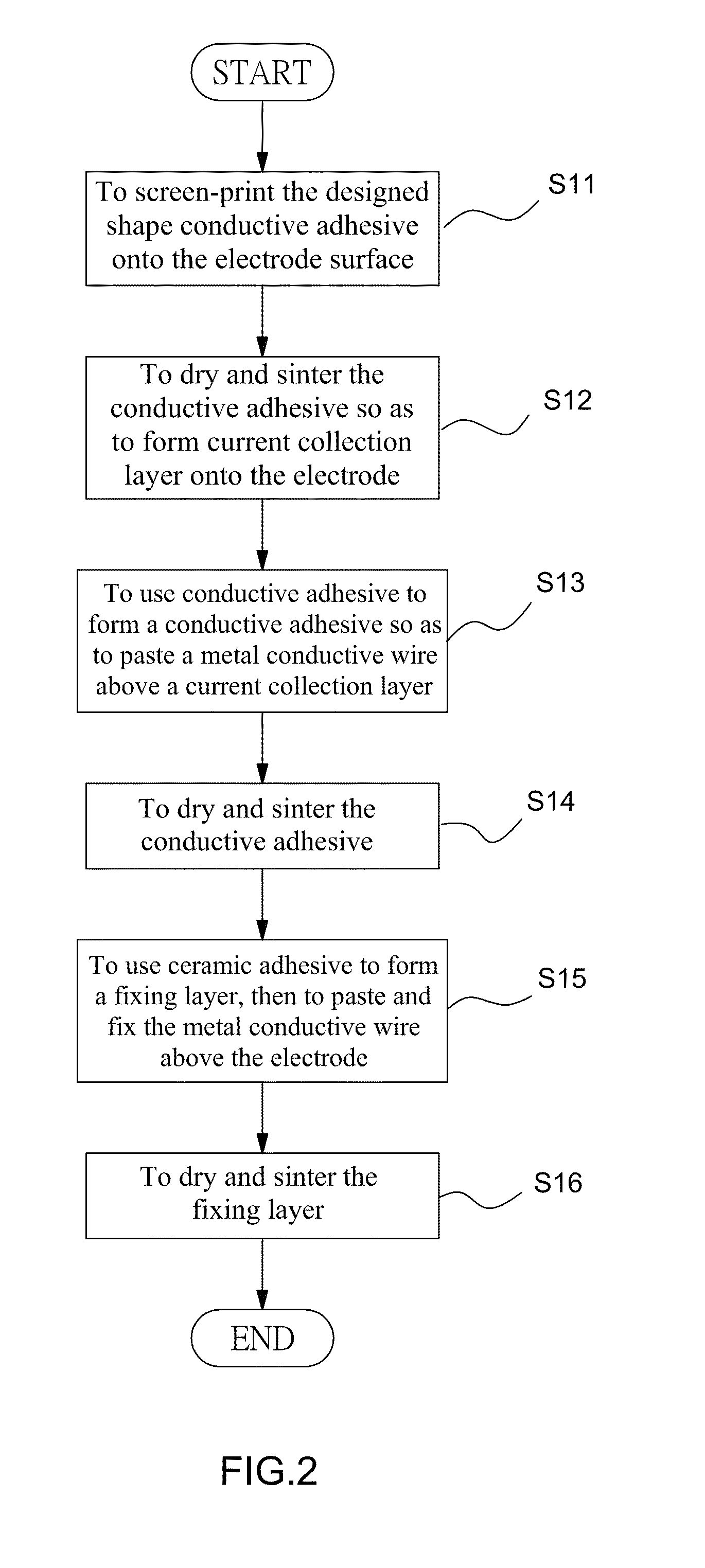

Current collection apparatus and method of processing for a solid oxide fuel cell thereof

InactiveUS20130230791A1Enhance effectively current conduction efficiencyLow contact resistanceLamination ancillary operationsLaminationPhysicsEngineering

A current collection apparatus and its method of processing for a solid oxide fuel cell, which mainly includes using screen printing process to print conductive adhesive onto the surface of the electrode of solid oxide fuel cell (SOFC), forming a current collection layer with drying process, using an appropriate amount of conductive adhesive to paste a conductive wire onto the current collection layer, forming an adhesion layer through drying, fixing the conductive wire on the electrode surface with an appropriate amount of ceramic adhesive, and forming a fixing layer after baking. A good connection is hence made between metal conductive wire and electrode through current collection layer, not only the interface impedance between electrode and current collection layer can be reduced effectively, but also the output power density of the SOFC unit cell can be enhanced, and stable as well as long term power output can be provided.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Cleaning device for cleaning a surface comprising a brush and a squeegee element

Owner:VERSUNI HLDG BV

Dechlorinator

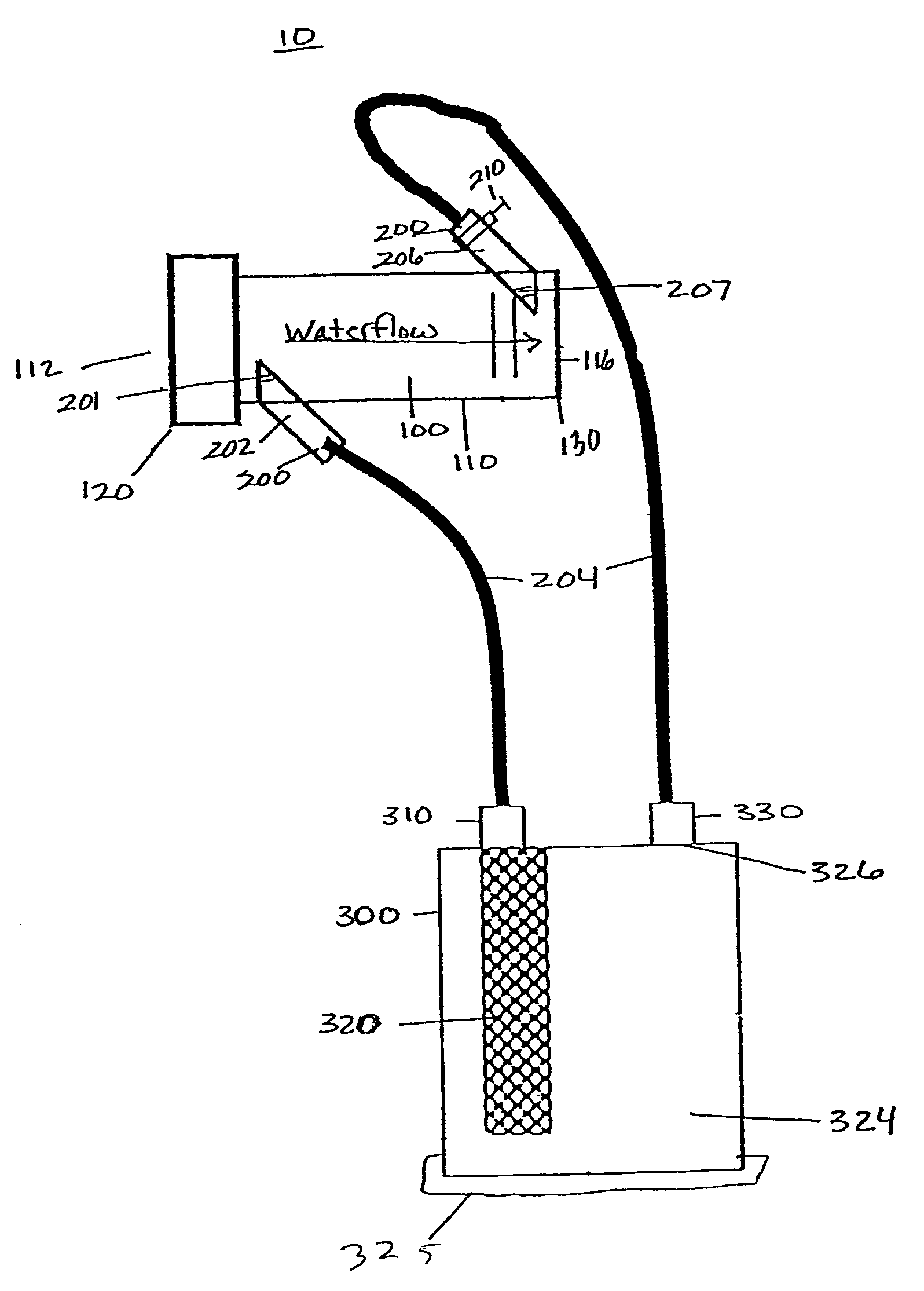

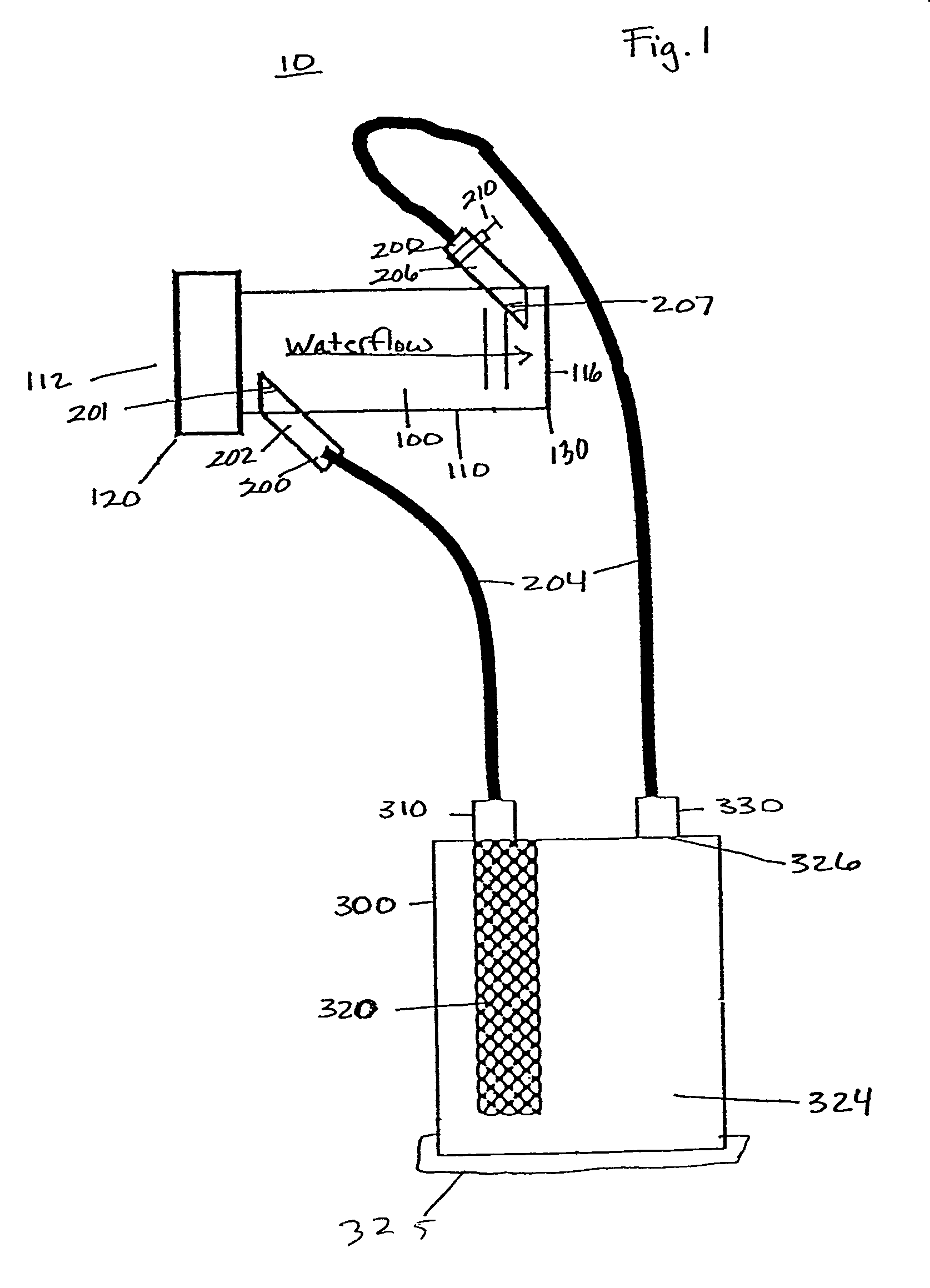

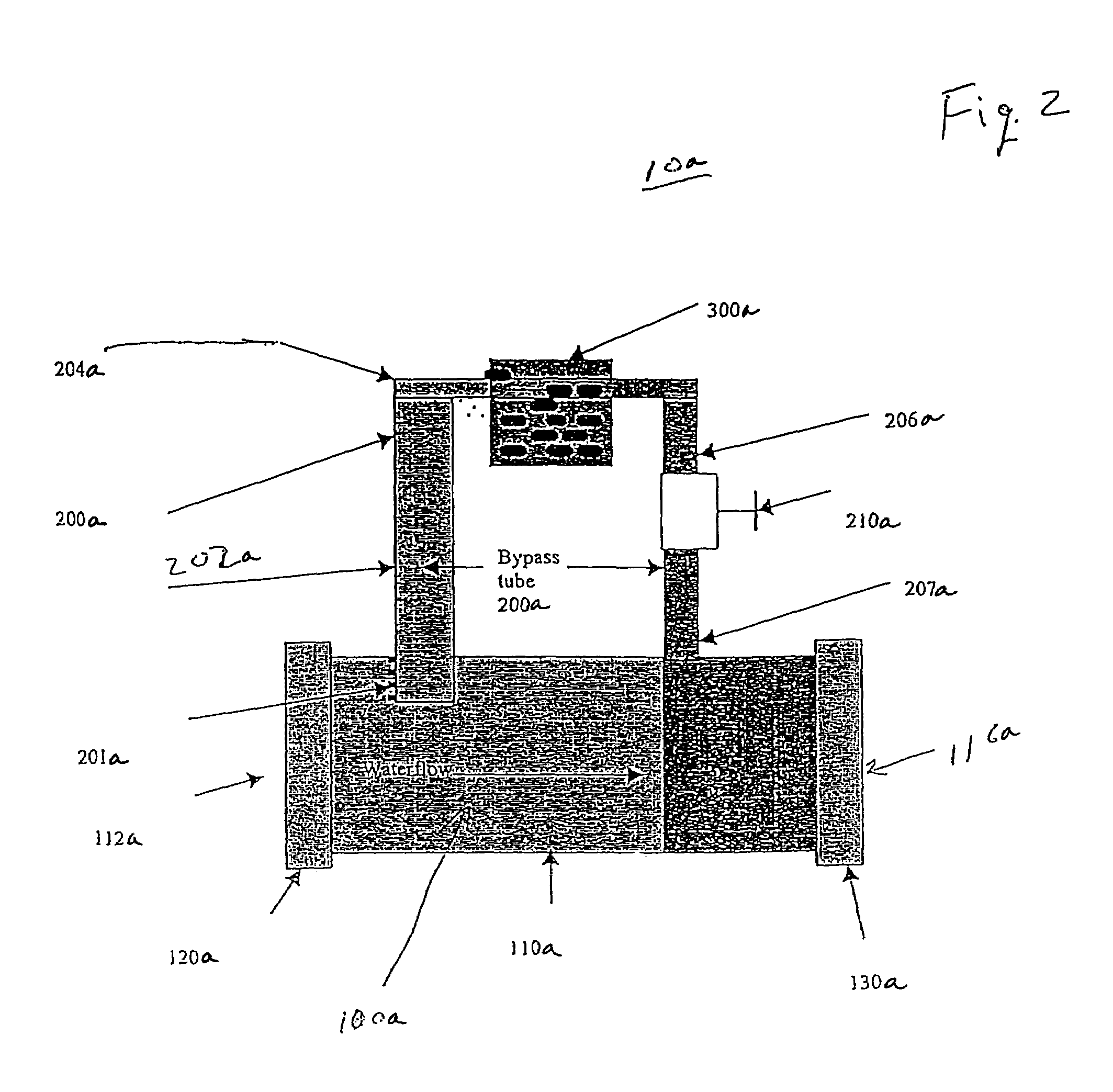

InactiveUS7150827B1Easy to transportGood adhesionSpecific water treatment objectivesWater contaminantsDechlorinatorEngineering

A portable apparatus for adding a dechlorination agent into a fluid stream prior to discharge and a method for treatment of chlorinated water. The portable apparatus can connect in any part of a fluid flow system. A bypass is provided such that a controlled portion of the fluid stream is diverted to a dechlorination agent. The dechlorination agent dissolves in the bypassed fluid flow. The bypassed, dechlorination agent enriched fluid re-enters and mixes with the fluid flow that was not bypassed. As the two streams mix, the total flow receives the required amount of dechlorination before being discharged into the environment. A valve controls proportional flow of the fluid stream through the bypass.

Owner:GRENNING FREDERICK H

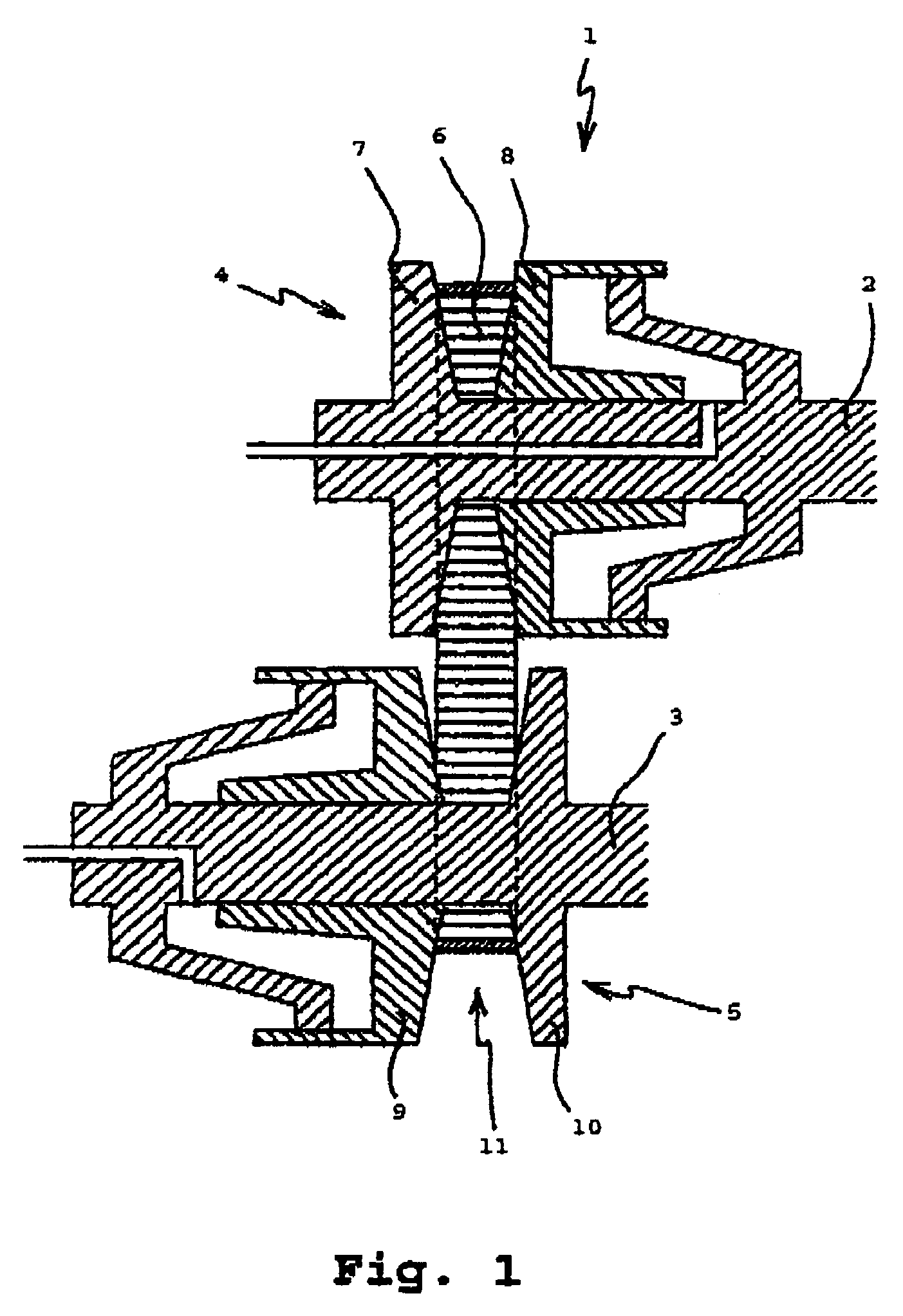

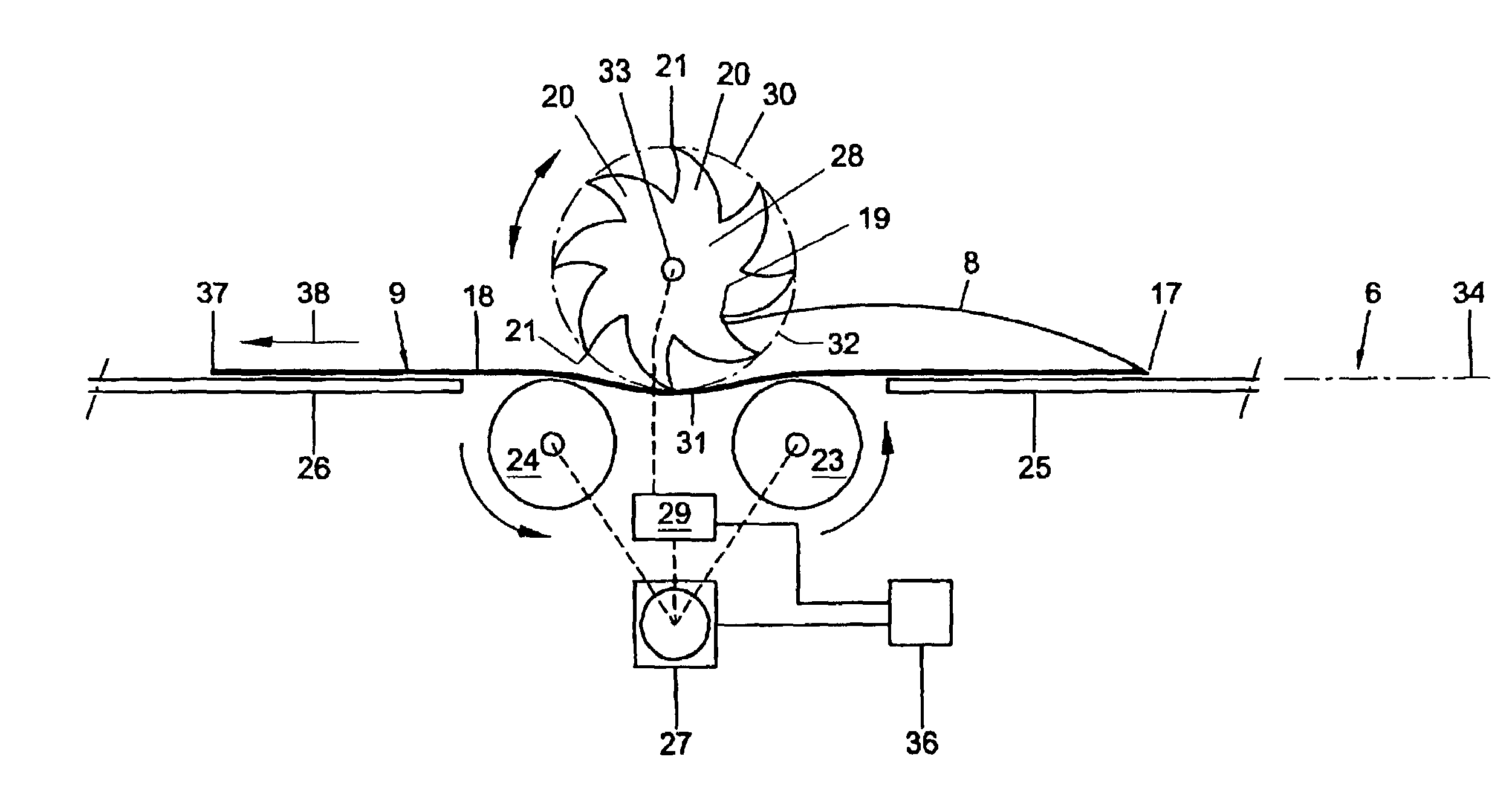

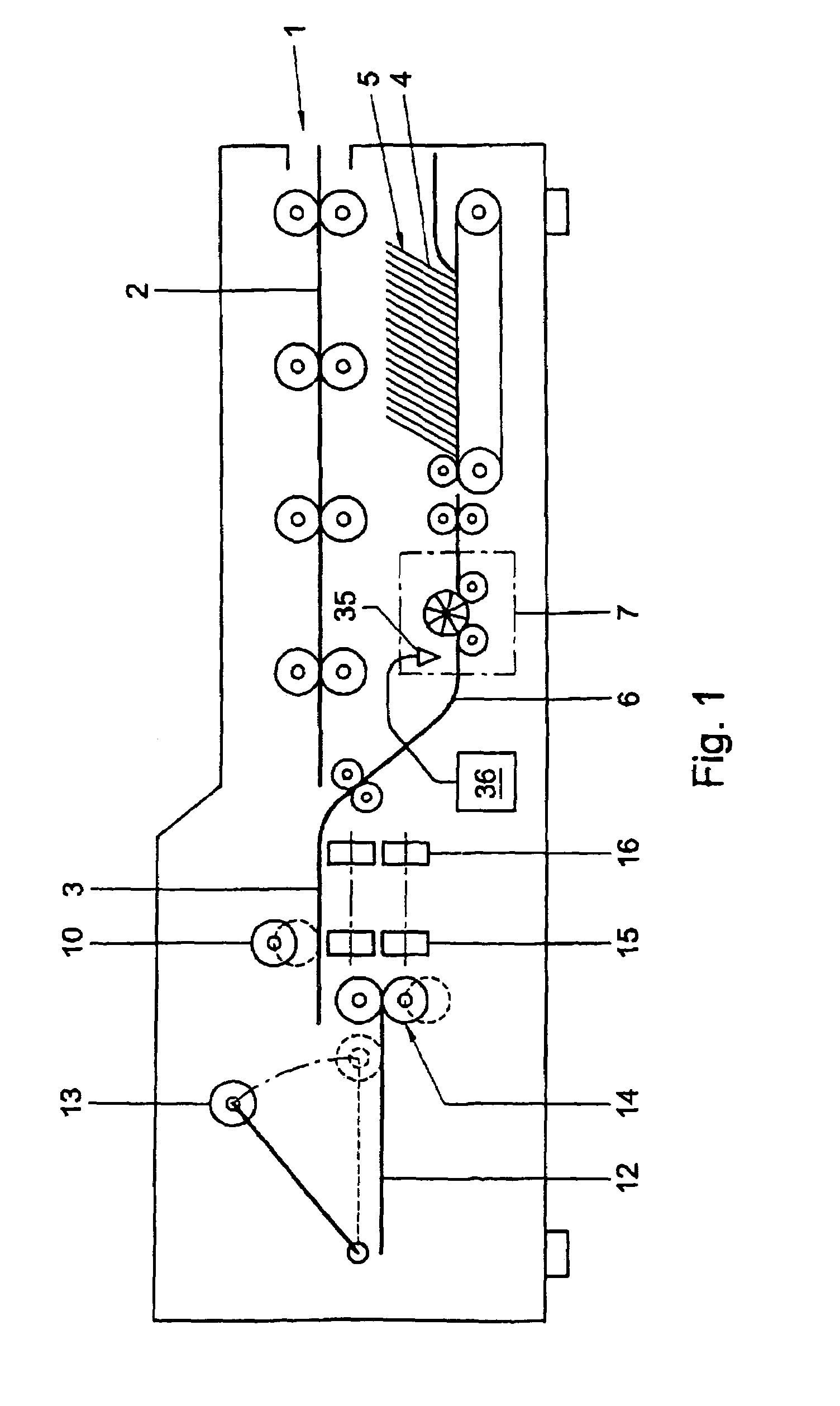

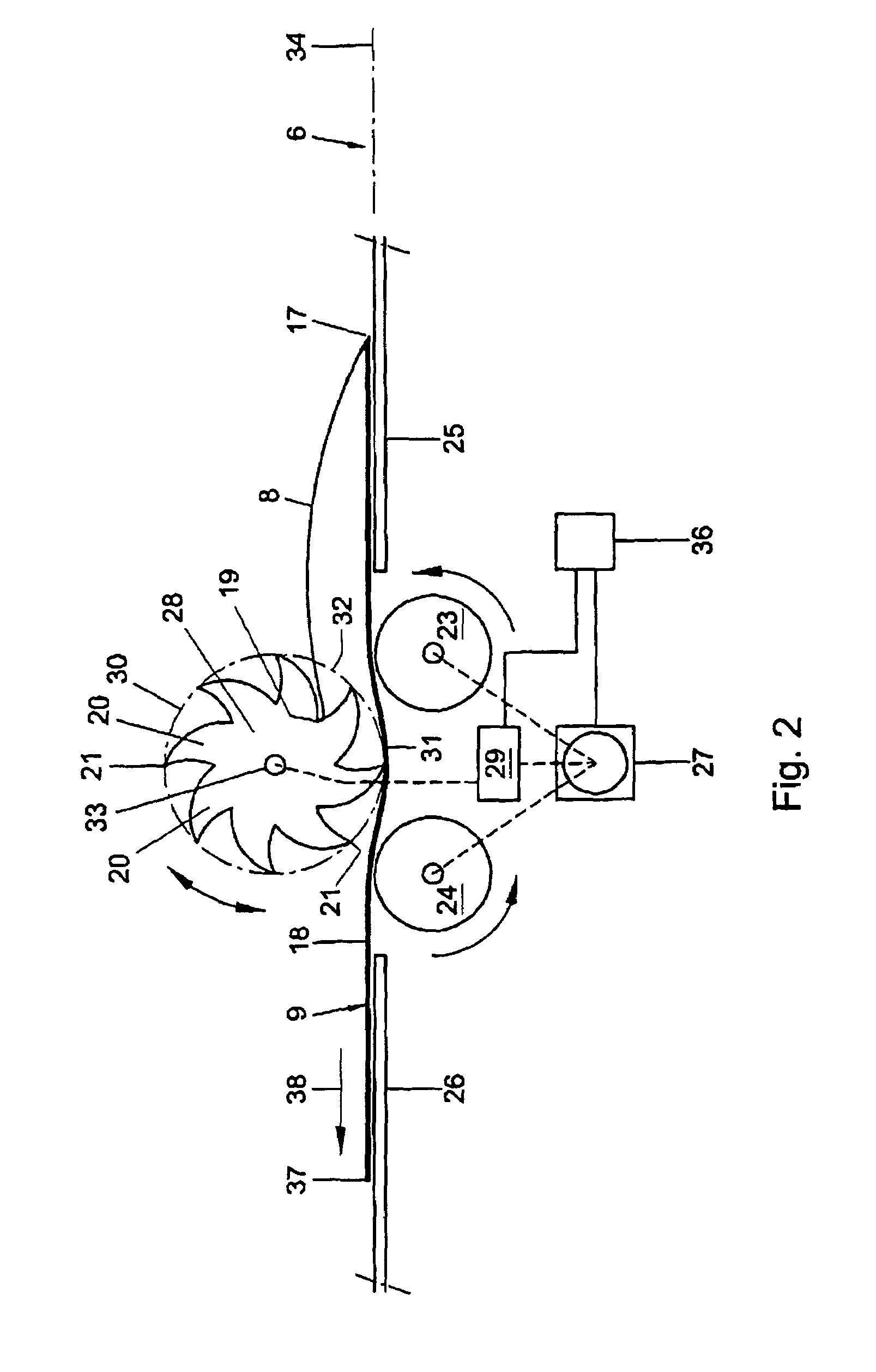

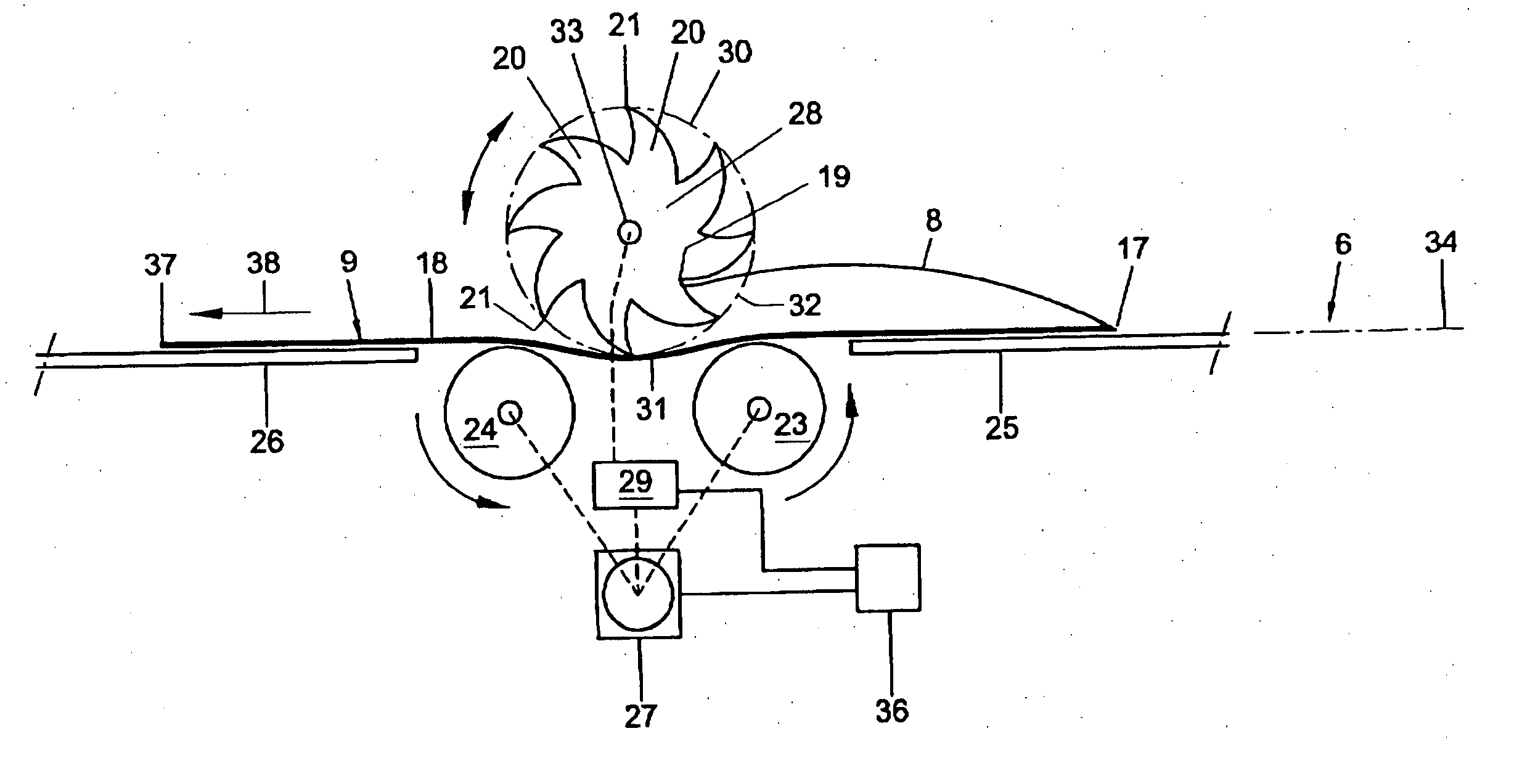

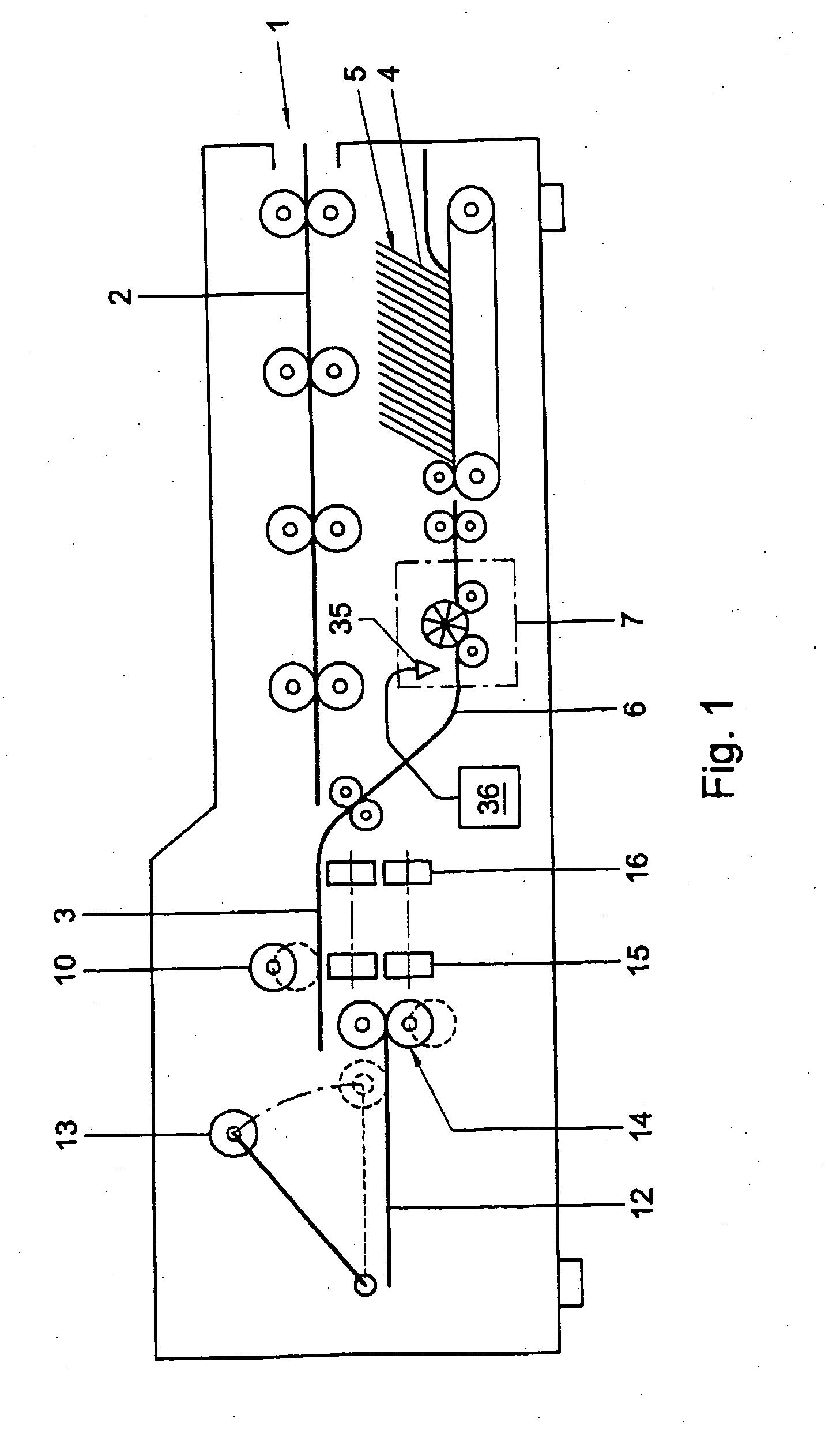

Machine and method for inserting sheets into envelopes

An inserting machine with an assembly (7) for unfolding a flap (8) of an envelope (9), including: a scraper (20) with a sharp scraping end (21) and an envelope carrier (23-26) as well as a drive (27, 29) for moving the holder portion (18) and the scraper (20) relative to each other, such that the holder portion (18) with the fold edge (17) in trailing position scrapes along the scraping end (21), the scraper (20) scrapes the flap (8) in the area of its free edge (19) off the holder portion (18), and pivots the flap (8) open about the fold edge (17). The scraping end (21) moves along a circulation path (30), of which a first portion (31) extends in a direction towards the fold edge (17) over the holder portion (18) of the envelope (9) and of which a second, contiguous portion (32) diverges from the holder portion (18) of the envelope (9).

Owner:NEOPOST

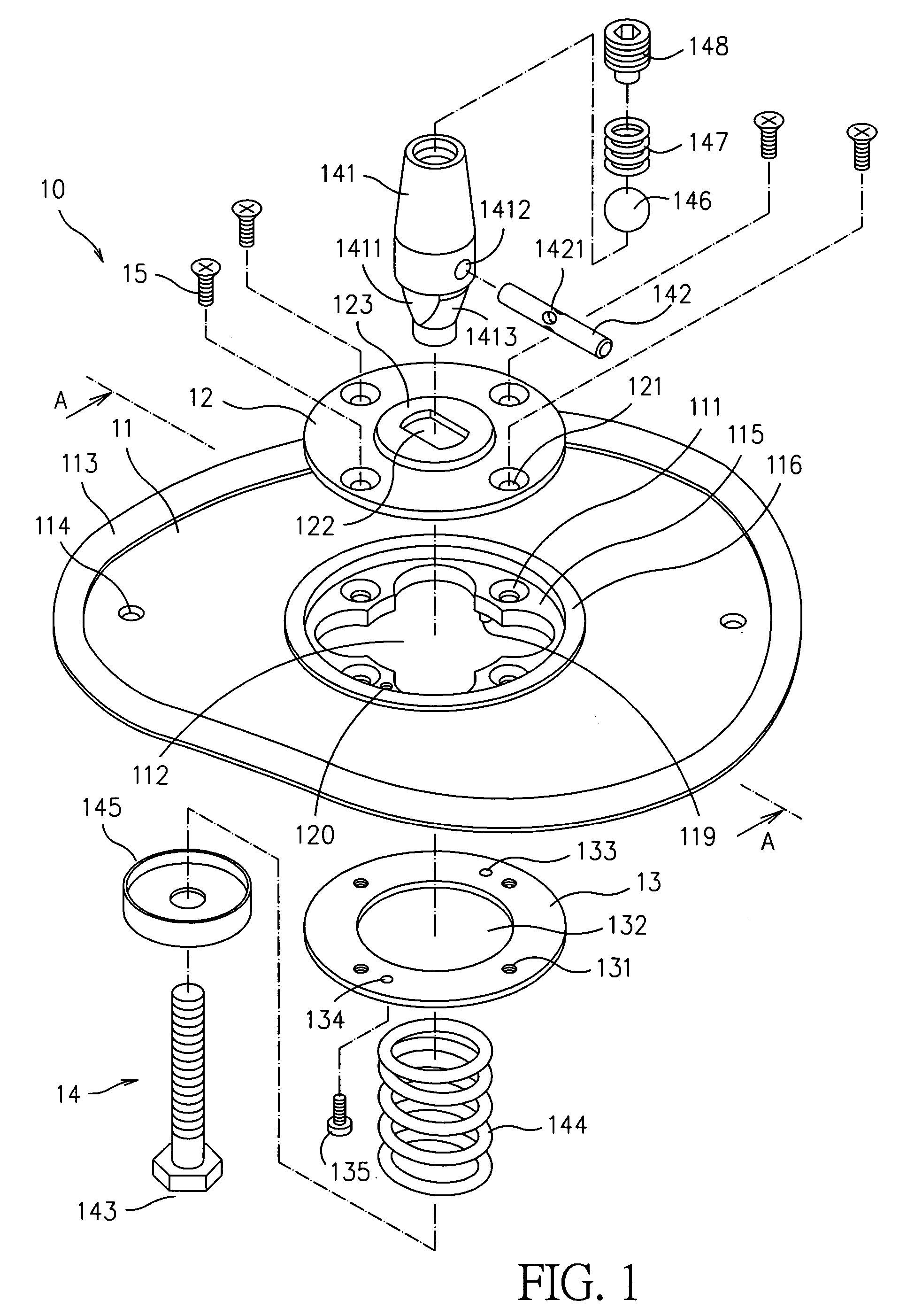

Coupling device for an artificial model

InactiveUS20050105965A1Easy to replaceLittle resistanceSecuring devicesCouplings for rigid shaftsElastomerEngineering

A coupling device for an artificial model includes a male joining part and a female joining part, which is joined to the male joining part tightly. The male joining part has the front positioning plate thereof providing a central circular protrusion, the insertion member thereof is composed of an insert head, a pin, an adjustment bolt, an elastic body and a covering cap with the insert head having a conical shape and an elongated flat part at the bottom thereof with the pin being inserted into the insert head along a radial direction of the insert head and passing through an axis of the insert head to form a shape of cross, and a hollow center thereof has a shape corresponding to the elongated flat part of the insert head such that the elongated flat part of the insert head can fit with the hollow center after being inserted into the hollow center with the adjustment bolt passing through the cap and the elastic body before engaging with the bottom of insert head. The female joining part has the front positioning plate with a center thereof providing a hollow part with a plurality of equidistant radial grooves and two opposite ones of the radial grooves are pierced with the pin; and a radial recess is disposed between two neighboring ones of the radial grooves respectively. Hence, the male joining member and the female joining member can be joined to each other tightly and be inserted into each other for achieving a purpose of positioning.

Owner:CHIANG JUNG CHANG

Cleaning device for cleaning a surface

ActiveUS9414728B2Speed at which deformationReduce quality problemsCarpet cleanersBrush bodiesEngineeringNozzle

The present invention relates to a nozzle arrangement (10) for a cleaning device (100) for cleaning a surface, the nozzle arrangement comprising: —a brush (12) rotatable about a brush axis (14), the brush being provided with flexible brush elements (16) having tip portions (18) for contacting the surface to be cleaned (20) and picking up dirt and / or liquid particles (22, 24) from the surface (20) during the rotation of the brush (12), wherein the brush (12) is at least partly surrounded by a nozzle housing (28) and protrudes at least partly from a bottom side (30) of the nozzle housing (28), —a squeegee element (32) which is spaced apart from the brush (12) and attached to the bottom side (30) of the nozzle housing (28) on a first side (31) of the brush (12) where the brush elements (16) enter the nozzle housing (28) during the rotation of the brush (12), wherein the squeegee element (32) is configured for wiping dirt and / or liquid particles (22, 24) across or off the surface to be cleaned (20) during a movement of the cleaning device (100) —a deflector (150) for contacting the brush (12) and deflecting the brush elements (16) during the rotation of the brush (12), and —a restriction element (27) for at least partly restricting air from getting sucked into the nozzle housing (28) at a second side (29) of the brush (12) where the brush elements (16) leave the nozzle housing (28), wherein the restriction element (27) is, seen in a rotation direction (26) of the brush (12), arranged behind the deflector (25), such that the brush elements (16), during the rotation of the brush (12), contact the deflector (25) before passing the restriction element (27) and then leaving the nozzle housing (28) at the bottom side (30), and the restriction element (27) comprises a mechanically flexible element that is, due to its flexibility, configured to follow an outer surface of the brush (12) and to contact the tip portions (18) during the rotation of the brush (12).

Owner:VERSUNI HLDG BV

Machine and method for inserting sheets into envelopes

InactiveUS20050160703A1Chance being damagedEasy constructionWrappingSolid materialFree edgeMechanical engineering

An inserting machine with an assembly (7) for unfolding a flap (8) of an envelope (9), including: a scraper (20) with a sharp scraping end (21) and an envelope carrier (23-26) as well as a drive (27, 29) for moving the holder portion (18) and the scraper (20) relative to each other, such that the holder portion (18) with the fold edge (17) in trailing position scrapes along the scraping end (21), the scraper (20) scrapes the flap (8) in the area of its free edge (19) off the holder portion (18), and pivots the flap (8) open about the fold edge (17). The scraping end (21) moves along a circulation path (30), of which a first portion (31) extends in a direction towards the fold edge (17) over the holder portion (18) of the envelope (9) and of which a second, contiguous portion (32) diverges from the holder portion (18) of the envelope (9).

Owner:NEOPOST

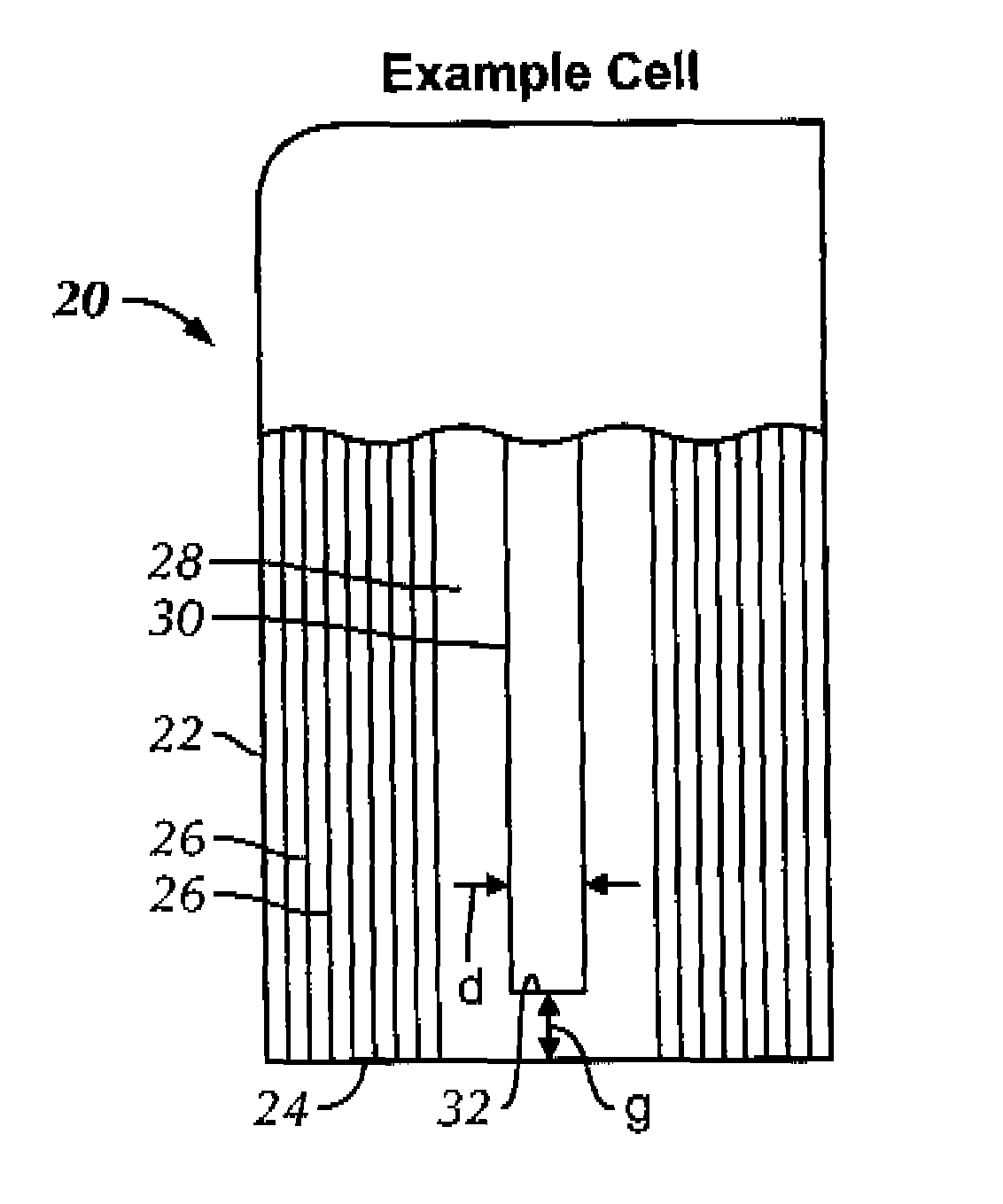

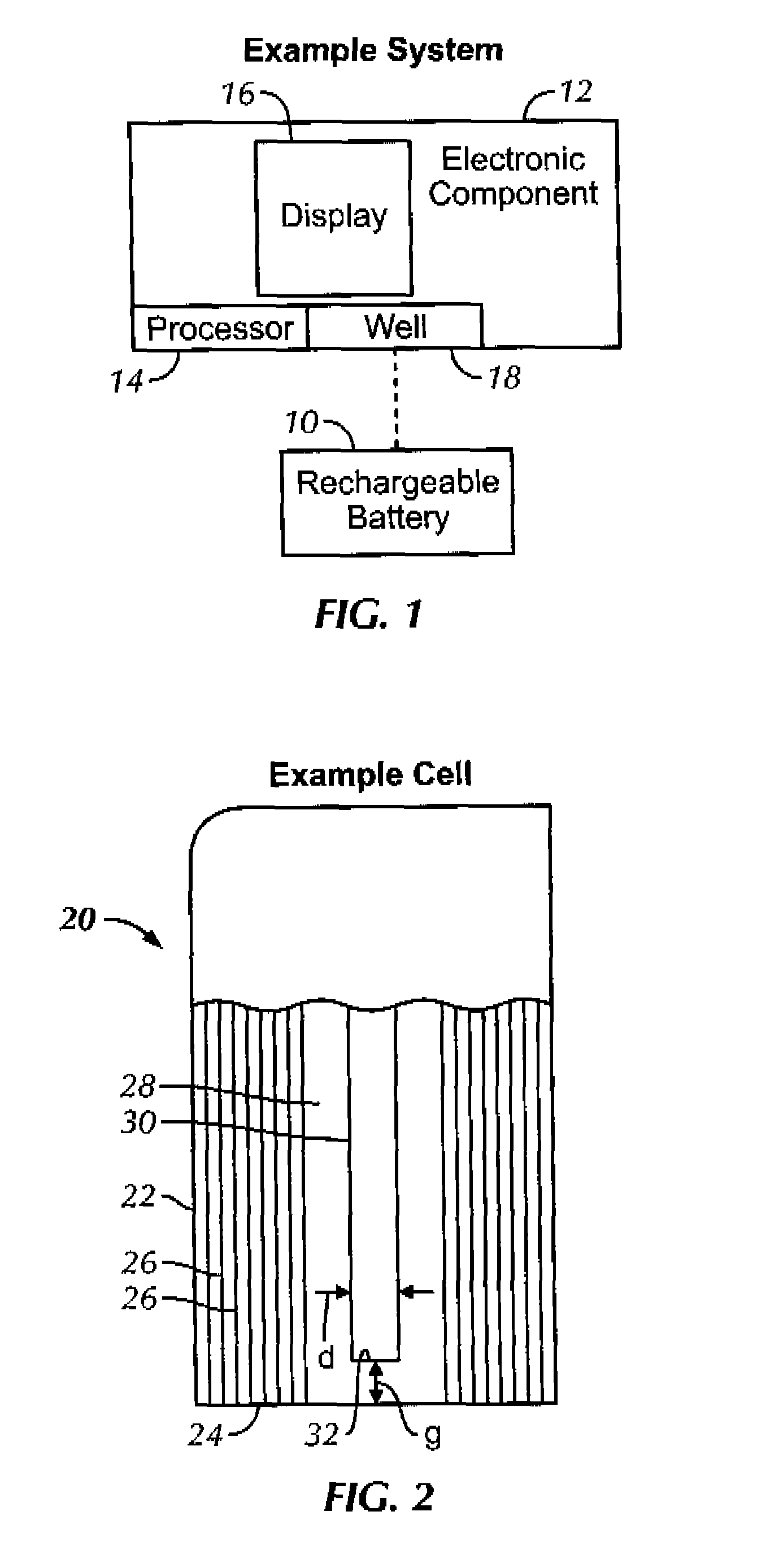

Establishing space between end of center gas pipe in battery and bottom of battery can

ActiveUS8012619B2Reduce riskChance of damageFinal product manufactureCell electrodesEngineeringBattery cell

The gap between the bottom of a center gas vent pipe in a battery cell and the bottom of the cell can is established to be at least a minimum distance to reduce the risk of battery damage from inadequate gas venting.

Owner:LENOVO PC INT

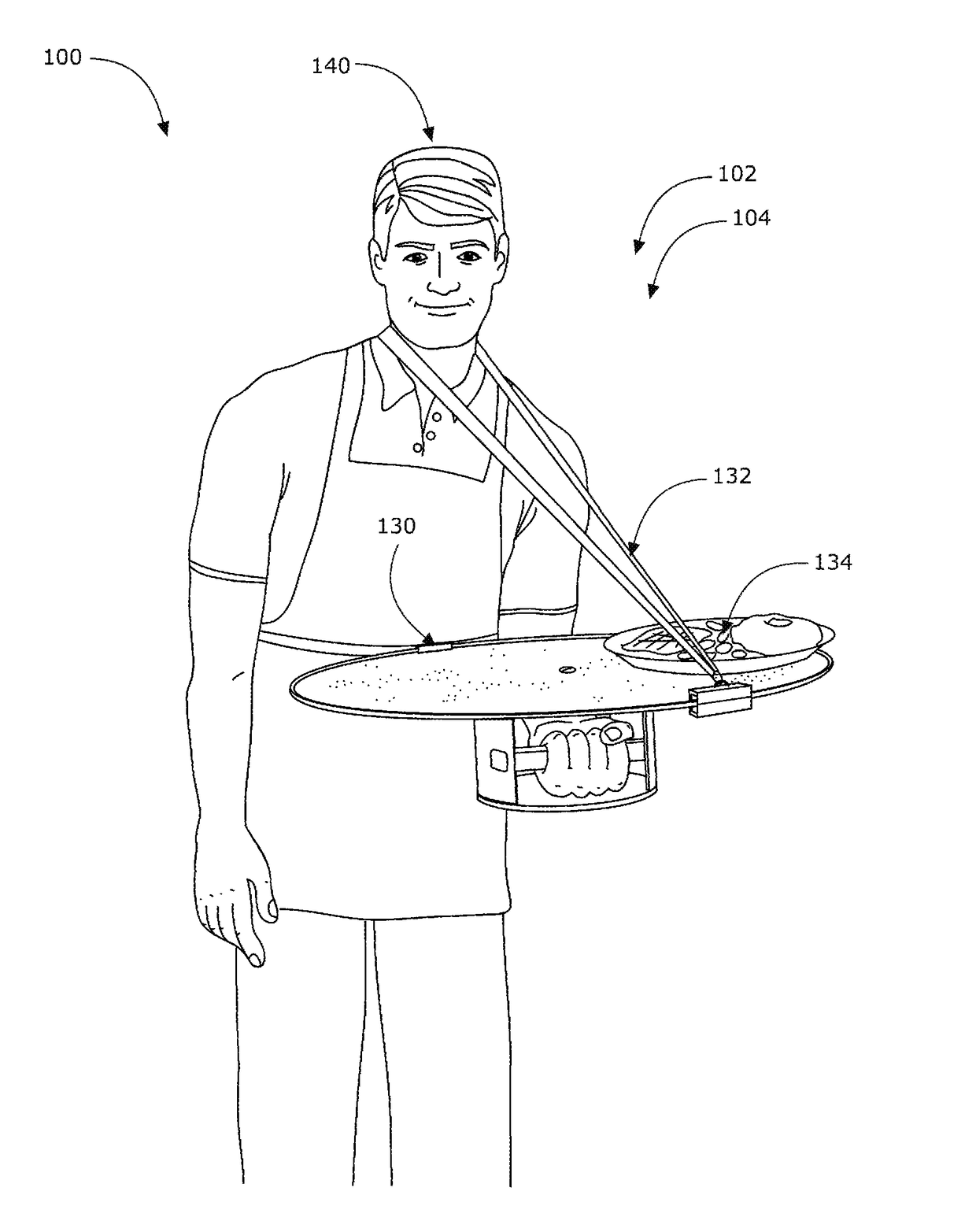

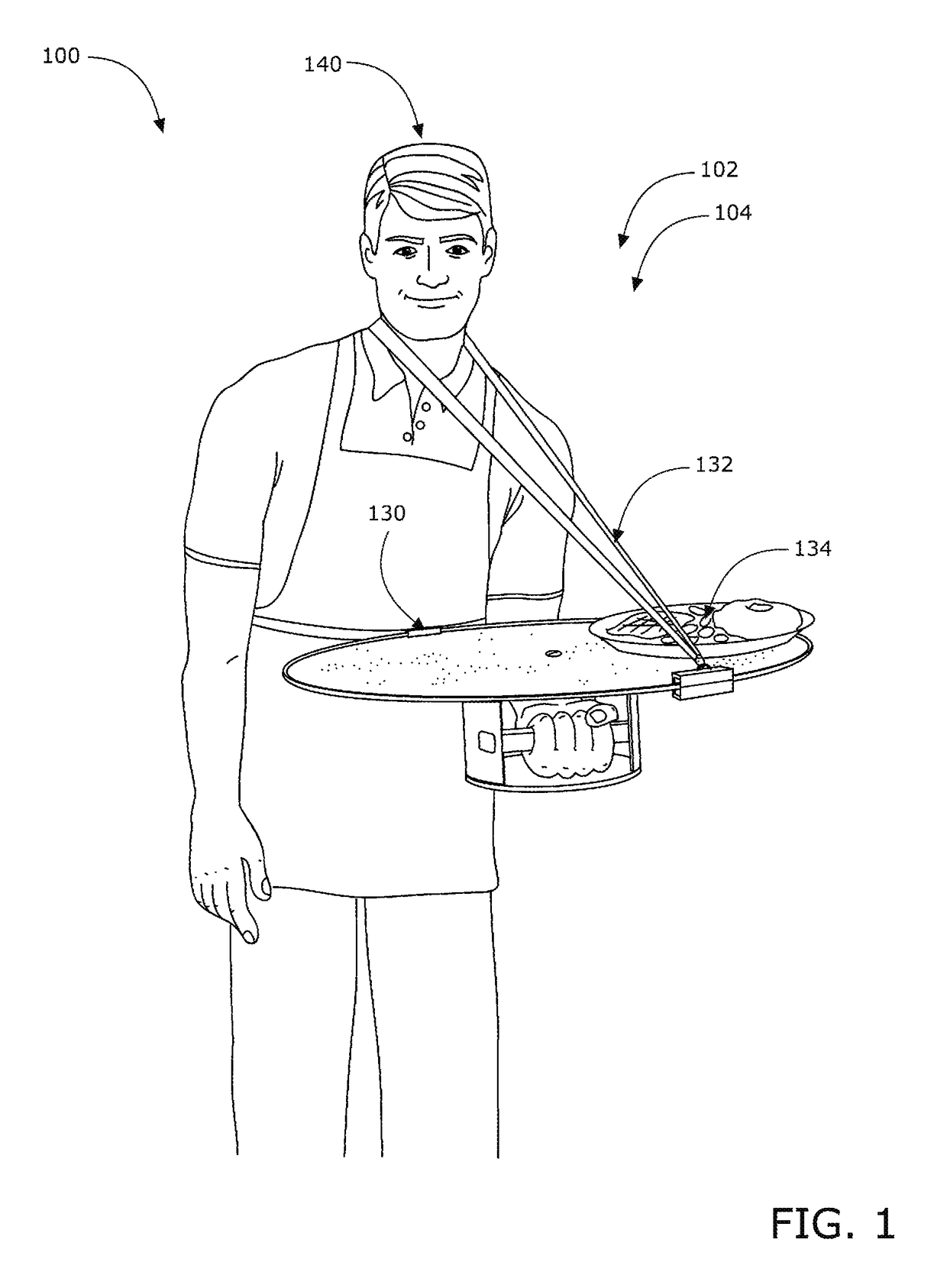

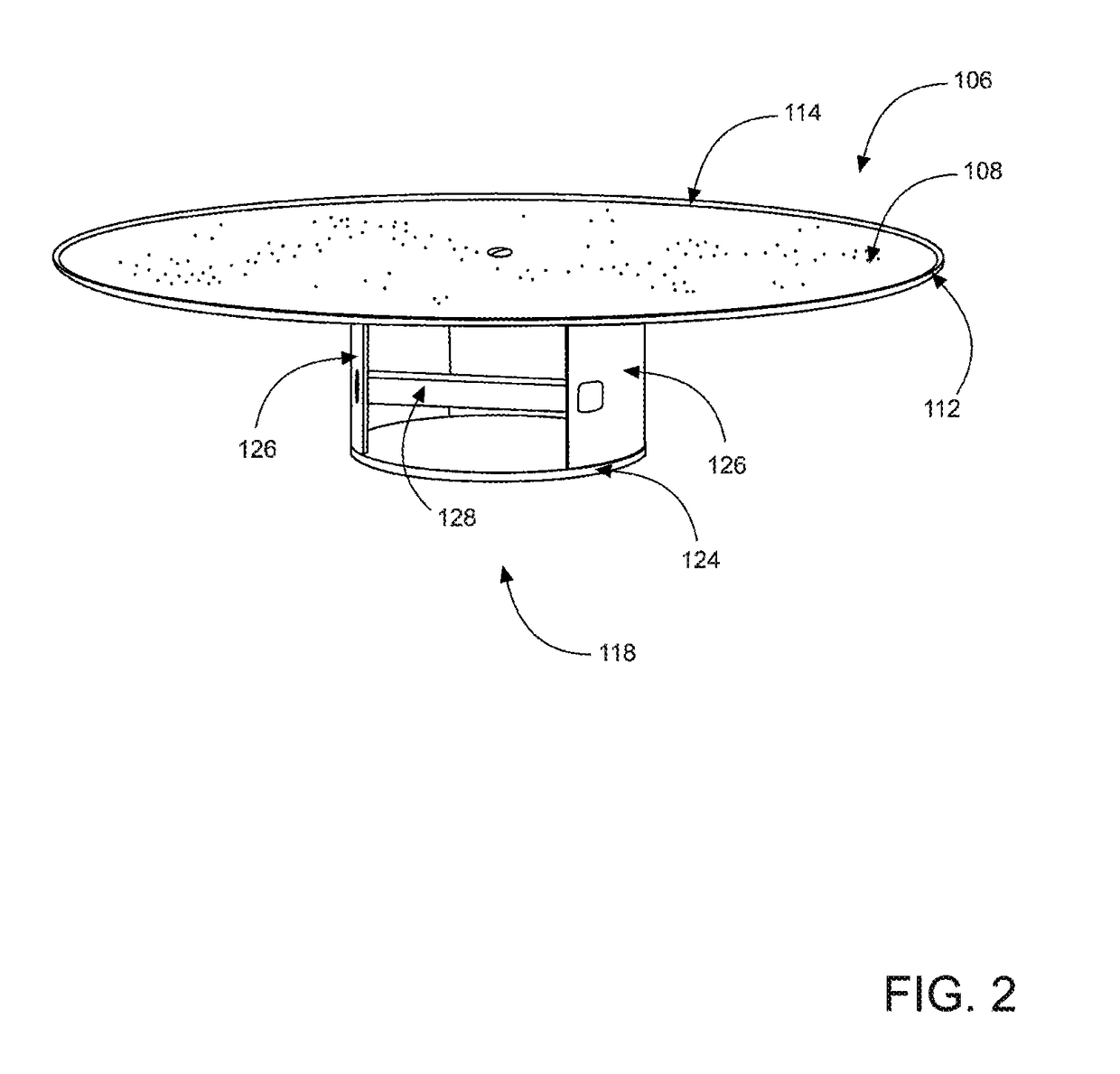

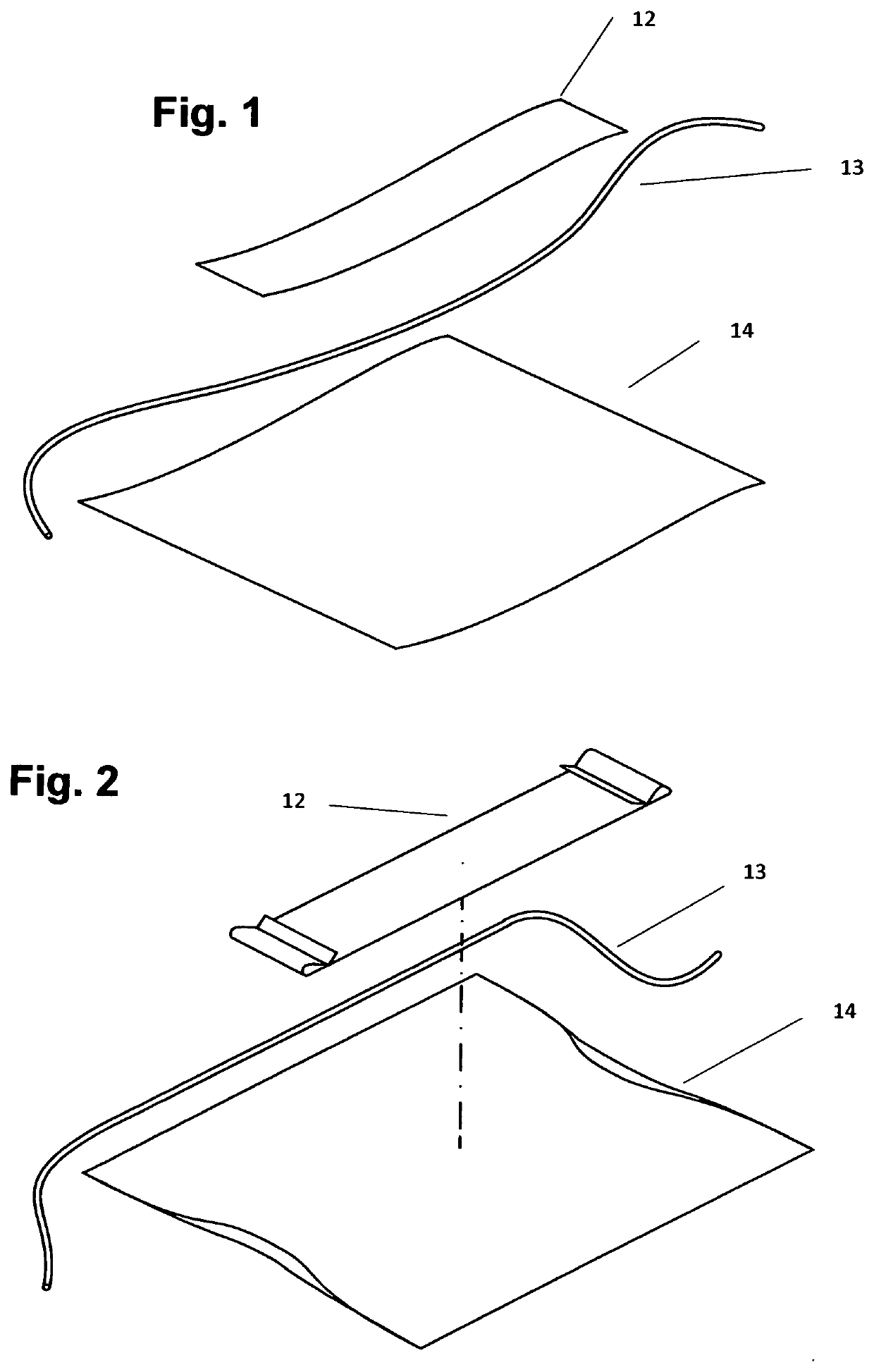

Dining service system

InactiveUS20170172329A1Reducing required effort and subsequent fatigueImprove comfortServing trayTravelling carriersEngineeringService component

A dining service system for aiding a waiter or waitress in carrying meal service implements. The dining service assembly of the dining service system includes a serving tray assembly and a belt-clip. Some versions may additionally include a lanyard-necklace. The serving tray assembly includes a top-tray, a base, at least two vertical members and a handle. The handle is structured and arranged to be held by a user to support at least a partial load of the serving tray assembly and of the meal service implements while using the dining service assembly to serve patrons. The belt-clip is structured and arranged to accept and support the serving tray assembly such that the belt-clip carries part of the weight of the serving tray assembly and the items carried by the tray assembly.

Owner:WICKSTROM VIC

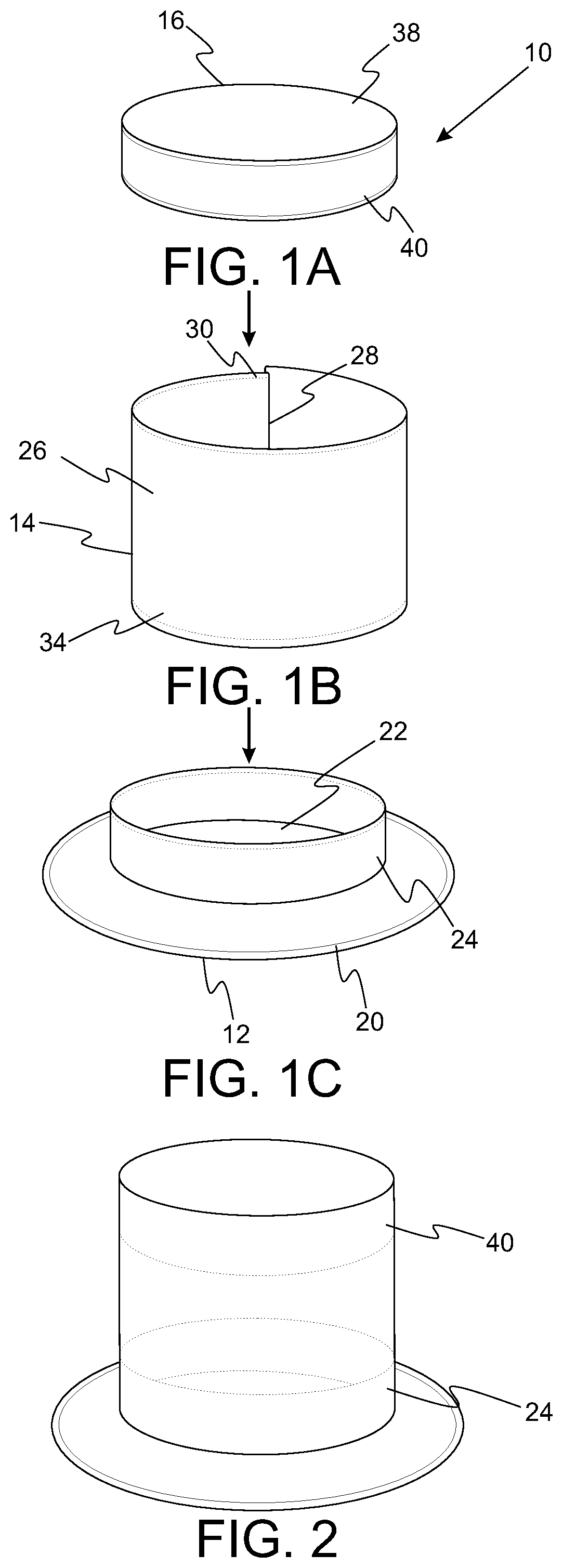

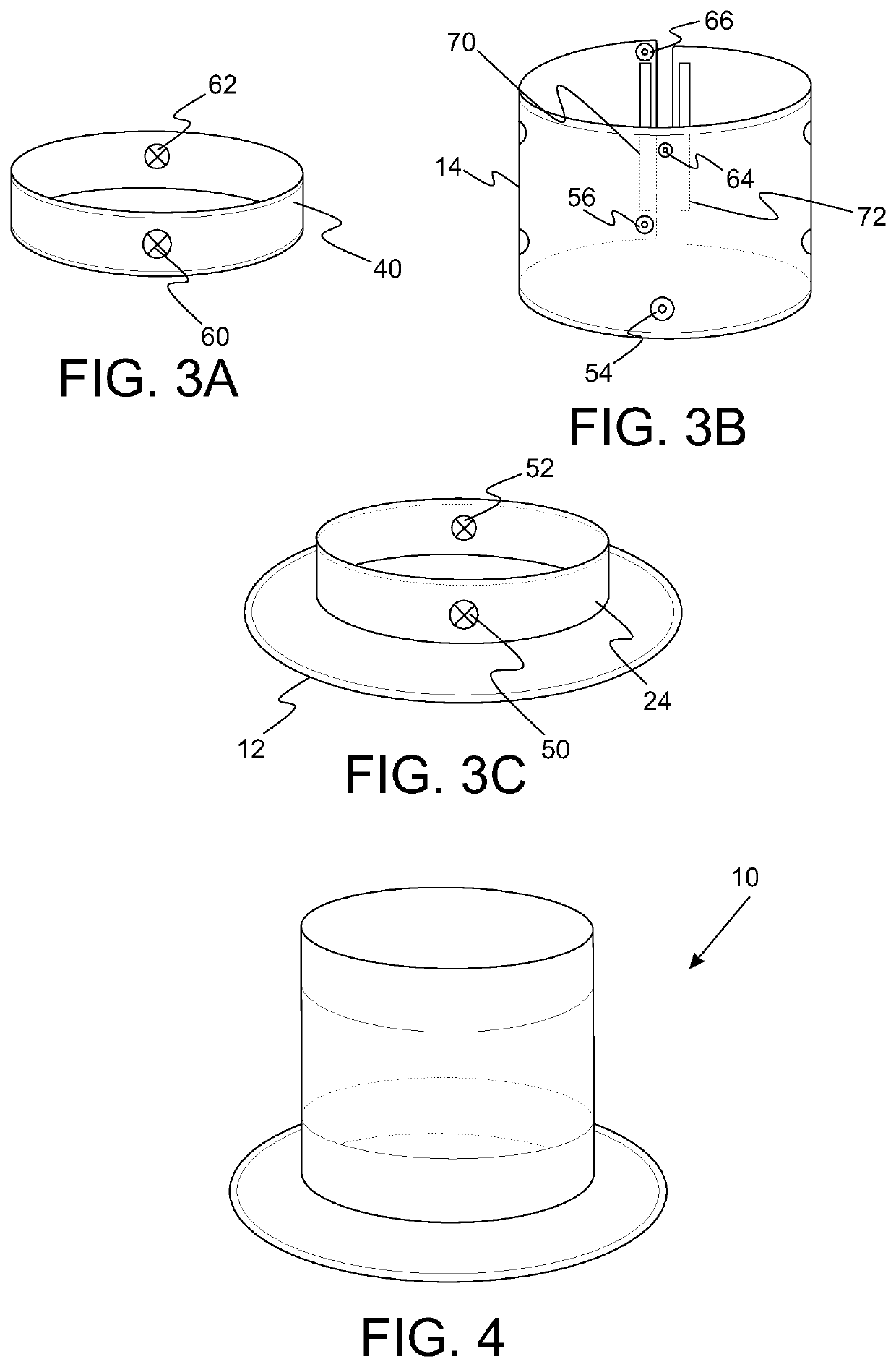

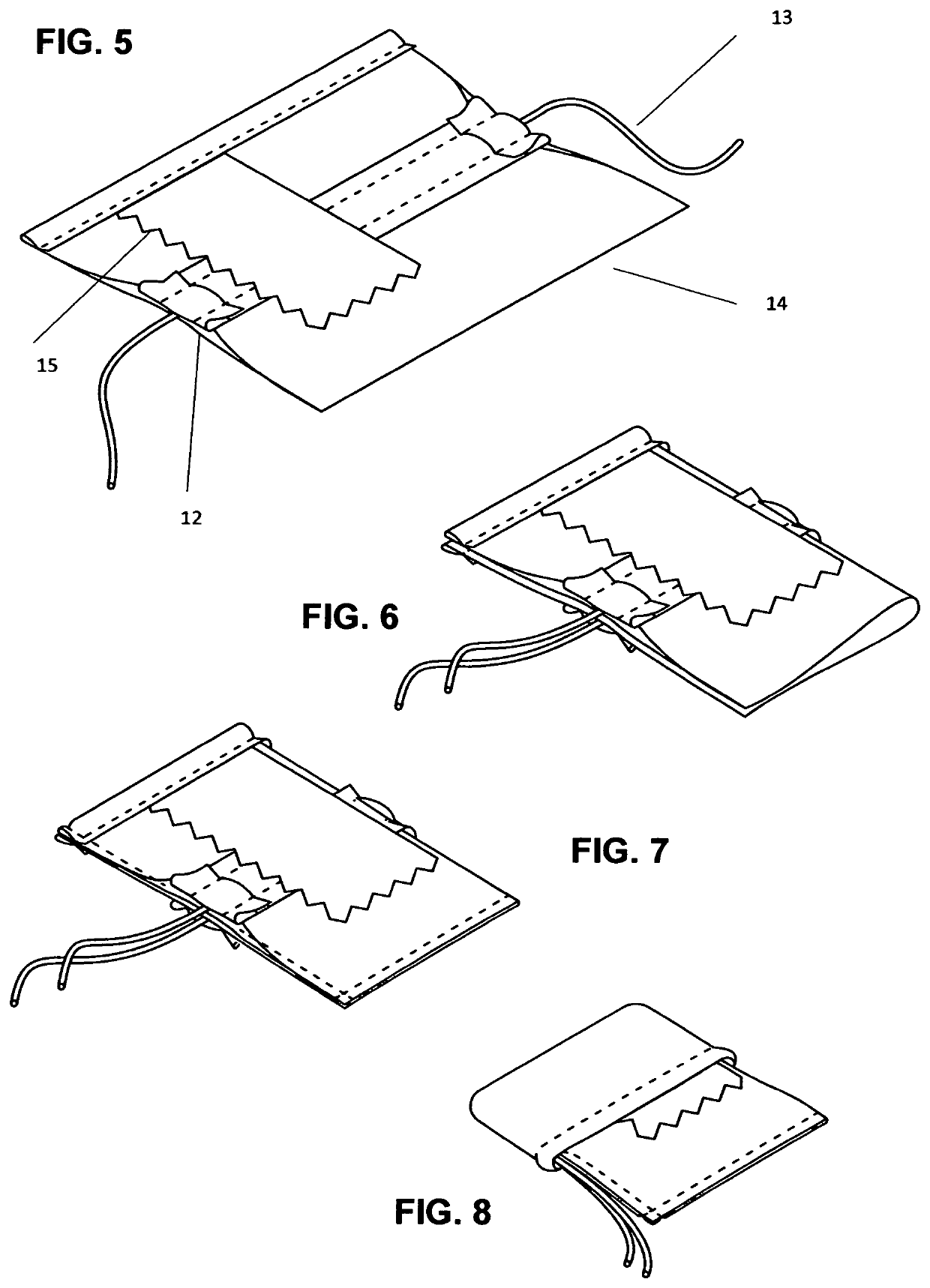

Collapsible modular hat

ActiveUS10645986B1Less spaceEfficient productionHatsHeadwear capsClassical mechanicsStructural engineering

Owner:CALIFORNIA COSTUME COLLECTIONS INC

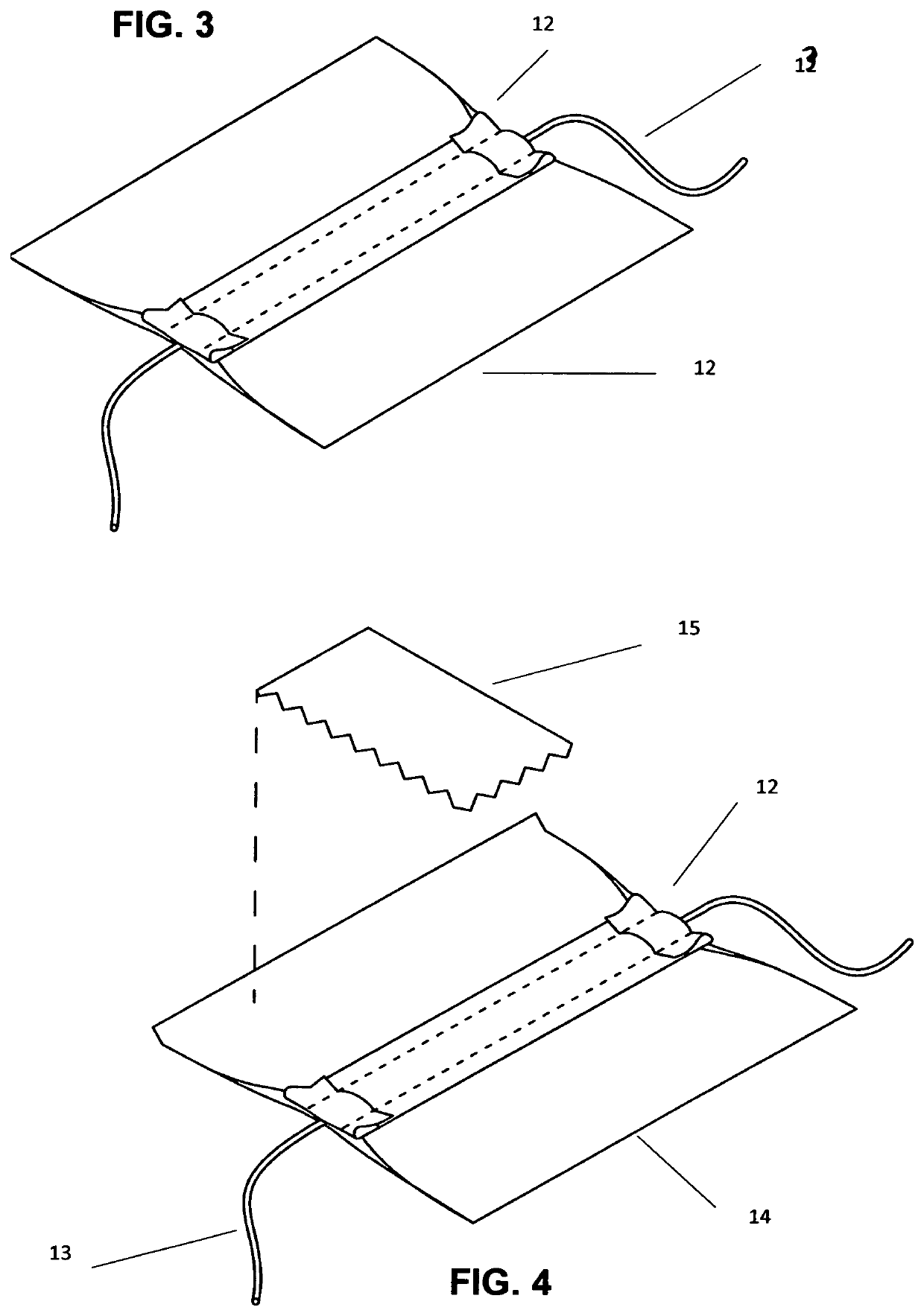

Alternative Cinched Eye Wear Case

An eyewear case to hold eye wear in variations of sizes and designs by focusing on center cinching to constrict the eyewear using tightening around the bridge section of eyewear and a drawstring length to allow extra looping capabilities. The length, width and depth of the body of the case are all catered to holding small to larger more designer frames. The case is flattened when opened using the drawstring technique to allow insertion and when tightened it secures the hold and adds wave patterns which act as a buffer against direct contact of the eyewear with surfaces. The case may be comprised of materials which may be washable or wiped clean and may require interfacing or padding. The present invention being comprised of a case body, drawstring, toggle, a clasp, fasteners are placed on the open end(s) to add security and length of drawstring for extra looping.

Owner:HEAROD KATHLEEN +1

Device for cleaning a surface, comprising at least one rotatable brush

ActiveUS10349796B2Reduce quality problemsIncrease flexibilityBowling gamesCarpet cleanersVolumetric Mass DensityEngineering

A device for cleaning a surface (11) comprises at least one rotatable brush (3,4) which is provided with flexible brush elements (18) for contacting the surface (11) and picking up dirt particles (10) and liquid which are present on the surface (11) during a dirt pick-up period of each revolution of the brush (3, 4), and means for driving the brush (3, 4). A linear mass density of the flexible brush elements (18) is chosen such as to be lower than 50 g per 10 km, at least at tip portions, and an acceleration at tips of the brush elements (18) is set such as to be at least 3,000 m / sec2, at least at some time during another period of each revolution of the brush (3, 4) than the dirt pick-up period, namely a period in which the brush elements (18) are free from contact to the surface (11).

Owner:VERSUNI HLDG BV

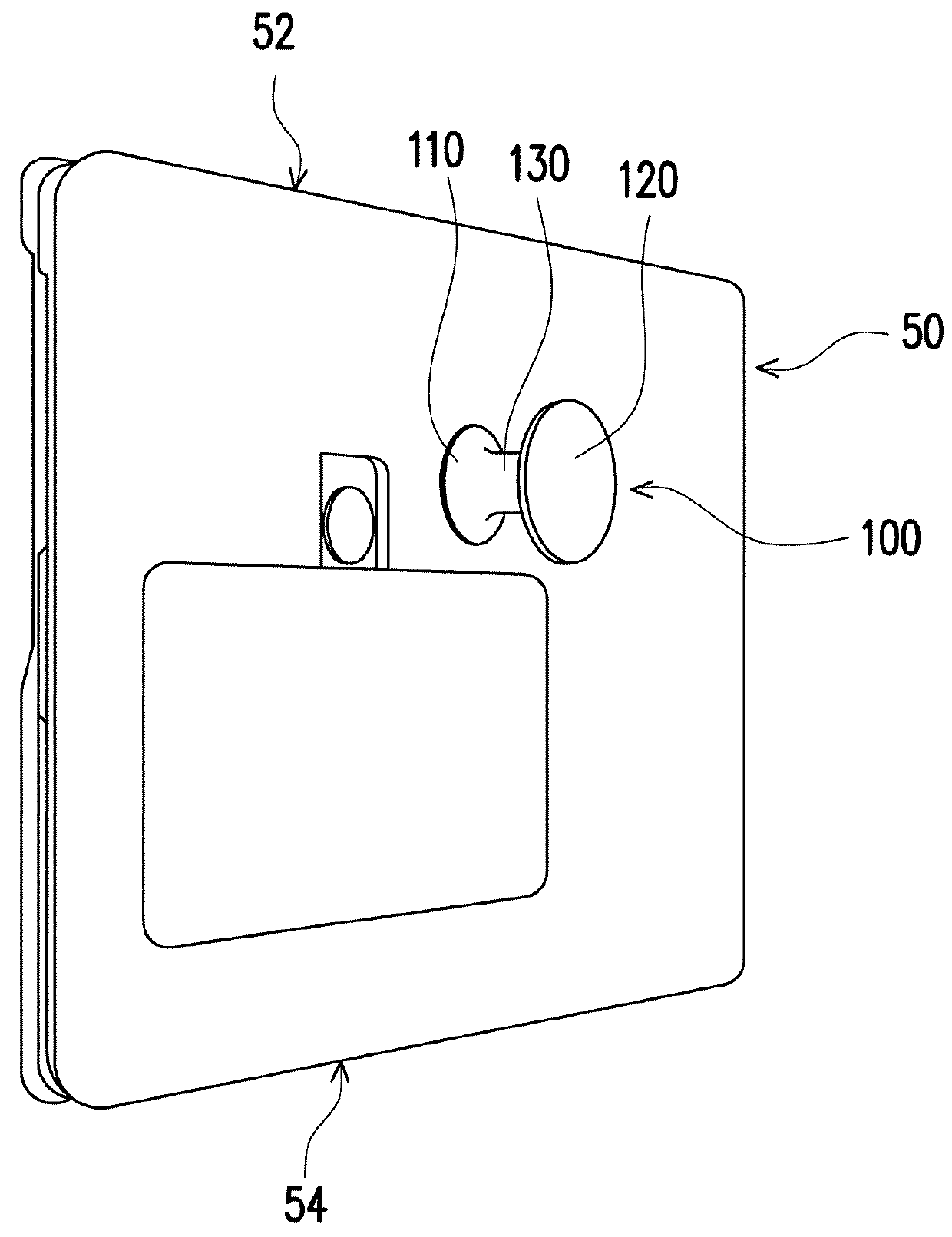

Handle structure

ActiveUS20180275723A1Avoid damageChance of damageDetails for portable computersEngineeringMechanical engineering

A handle structure including a base portion, a stop portion and a grip potion is provided. The grip portion is connected between the base portion and the stop portion. The handle structure has a cavity therein, the cavity has a bottom surface, and the bottom surface of the cavity is inclined to an axial direction of the grip potion.

Owner:COMPAL ELECTRONICS INC

Coating layer thickness measurement mechanism and coating layer forming apparatus using the same

InactiveUS7946247B2Suppressing variation in a speed of feeding a base materialMinimize impactLiquid surface applicatorsVacuum evaporation coatingCapacitanceEngineering

In a measurement mechanism for continuously measuring a thickness of a coating layer, provided in an apparatus for forming the coating layer on a conductive elongate base material in a coating treatment base station while the base material is fed, a sensing portion for measuring a capacitance value of the coating layer is arranged before and after the base station, and tension applied to the base material at the sensing portion is set to be greater than tension applied to the base material at the base station. Thus, in forming the coating layer on the elongate base material while the base material is continuously fed, variation in a feeding speed is suppressed, influence of sway of a measurement surface in a direction of thickness at the thickness sensing portion during feeding is minimized, and a thickness of the coating layer can be measured with higher accuracy.

Owner:SUMITOMO ELECTRIC IND LTD

Handle structure

ActiveUS10303222B2Avoid damageChance of damageDetails for portable computersEngineeringMechanical engineering

A handle structure including a base portion, a stop portion and a grip portion is provided. The grip portion is connected between the base portion and the stop portion. The handle structure has a cavity therein, the cavity has a bottom surface, and the bottom surface of the cavity is inclined to an axial direction of the grip portion.

Owner:COMPAL ELECTRONICS INC

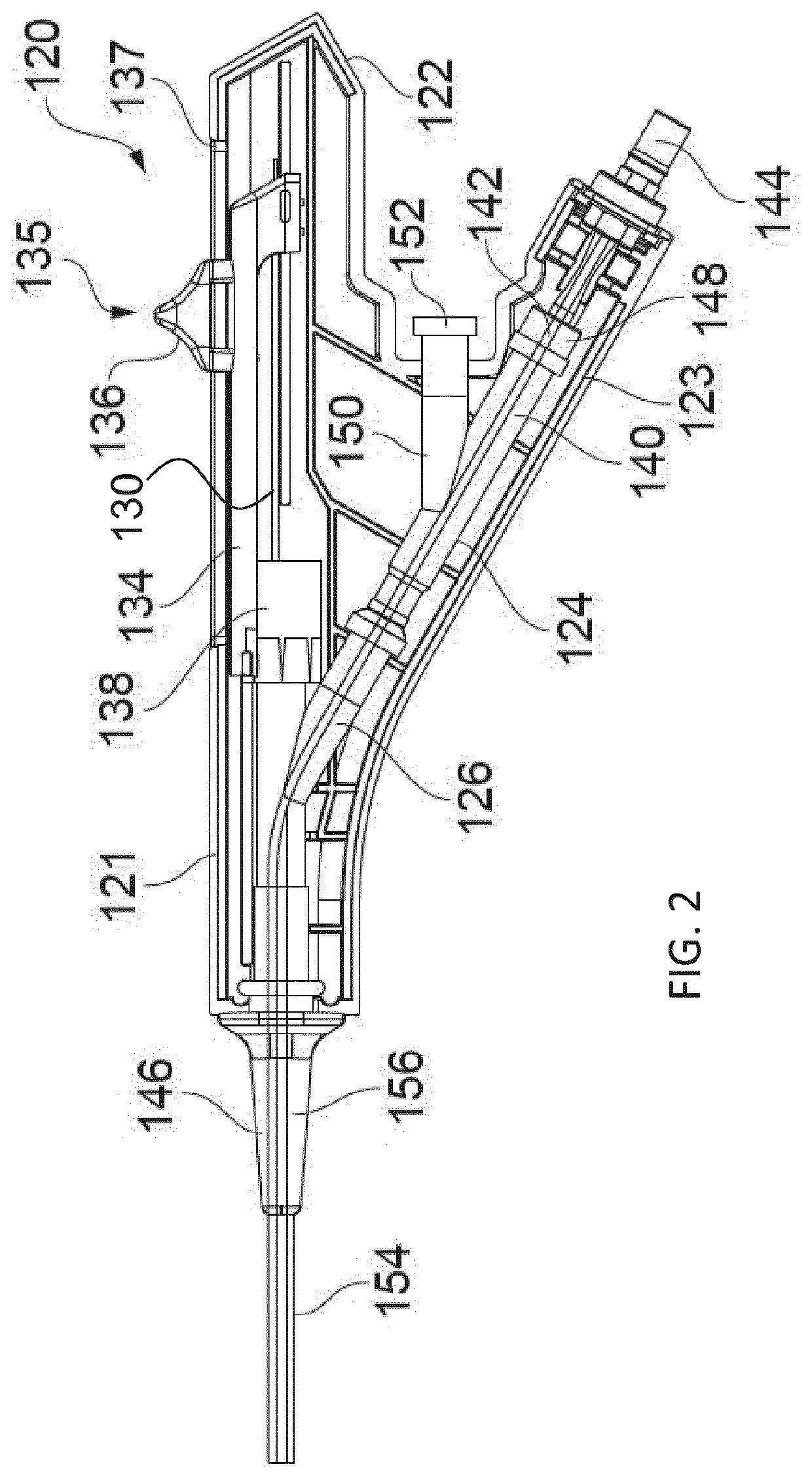

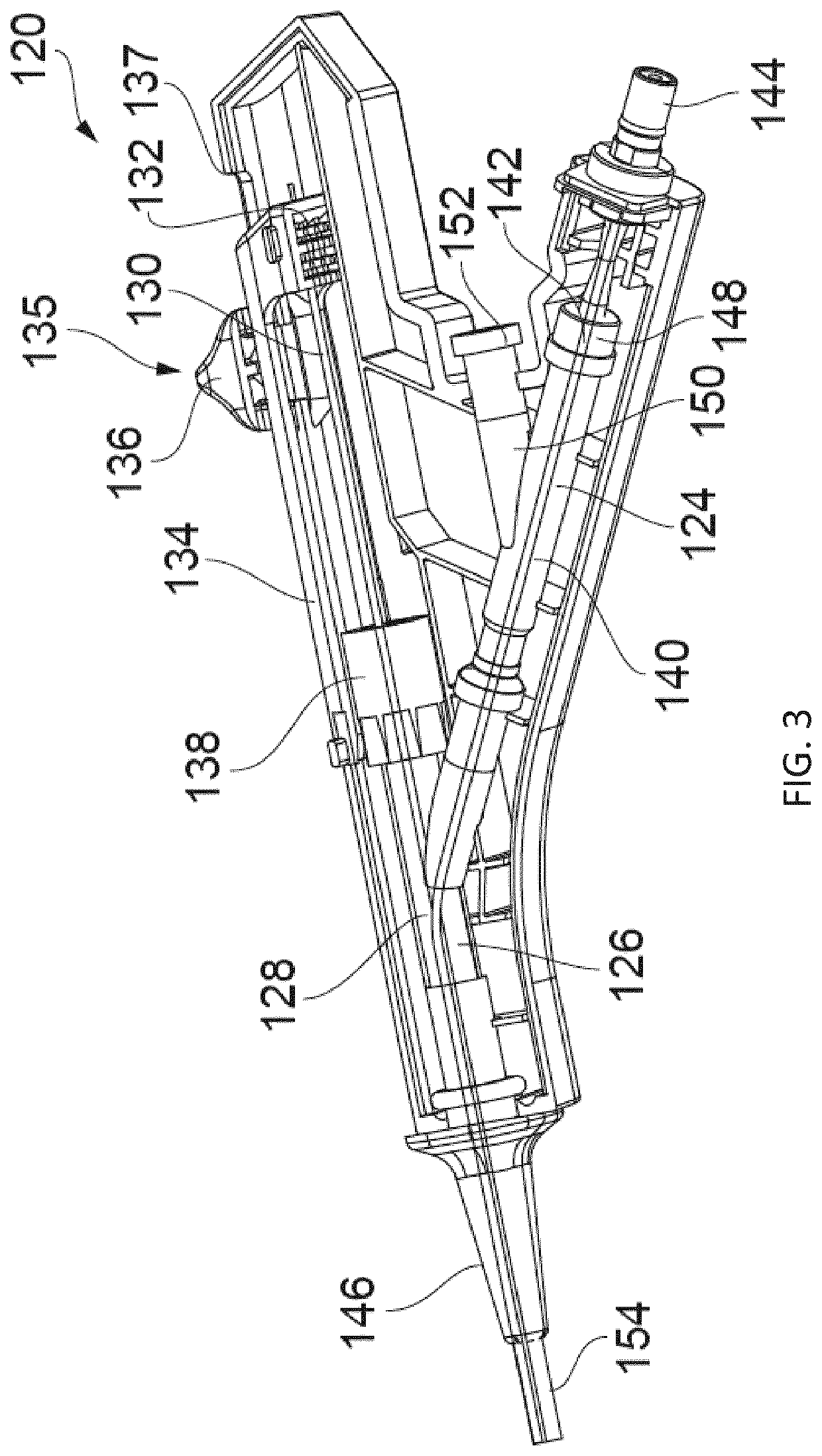

Interface joint for interconnecting an electrosurgical generator and an electrosurgical instrument

PendingUS20220000554A1Reduce harmChance of damageDiagnosticsInstrument handpiecesCoaxial cableControl theory

An interface joint for interconnecting an electrosurgical generator and an electrosurgical instrument, the interface joint comprising: a housing having: an inlet for receiving electromagnetic energy from the electrosurgical generator, and an outlet; a slidable trigger on the housing, the slidable trigger being attached to a push rod that extends out of the housing through the outlet; and a single cable assembly for connecting the outlet to the electrosurgical instrument, the single cable assembly comprising a flexible sleeve that conveys the push rod and a coaxial cable that is connected to the inlet. The interface joint may include a reinforcement element coupled to a first portion of the push rod so as to reinforce the first portion. Additionally or alternatively, the interface joint may include a slide limiting mechanism coupled to the push rod and configured to limit a maximum slide distance of an internal tube over the push rod.

Owner:CREO MEDICAL LTD

Nozzle arrangement of a cleaning device for cleaning a surface

ActiveUS10856715B2Reduce quality problemsIncrease flexibilityCarpet cleanersBrush bodiesEngineeringPaintbrush

The present invention relates to a nozzle arrangement (10) of a cleaning device (100) for cleaning a surface (20), comprising: —a nozzle housing (28); —a rotating brush (12) that is rotatable about a brush axis (14) and comprises a substantially cylindrical core element (52) with flexible brush elements (16) that are arranged on a circumferential surface (56) of the core element (52), wherein said brush elements (16) are configured to contact the surface to be cleaned (20) and pick up dirt and liquid particles (22, 24) from the surface to be cleaned (20) during a rotation of the rotating brush (12); —a drive for driving the rotating brush (12); —a liquid supplying arrangement (58) for supplying a cleansing liquid (68) to the rotating brush (12); —a wiping element (32) for wiping dirt and liquid particles (22, 24) across or off the surface to be cleaned (20), wherein said wiping element (32) extends along a longitudinal direction (48), which is arranged substantially parallel to the brush axis (14), and wherein said wiping element (32) is arranged on a first longitudinal side (27) of the rotating brush (12) where the brush elements (16) enter the nozzle housing (28) during the rotation of the rotating brush (12); and—at least one side sealing element (62a, b) for sealing a lateral side (82a, b) of the nozzle housing (28), wherein the at least one side sealing element (62a, b) is spaced apart from a transverse side (80a, b) of the core element (52) that is transverse to the circumferential surface (56) of the core element (52), such that a gap (84a, b) is defined between said transverse side (80a, b) of the core element (52) and the at least one side sealing element (62a, b); wherein the liquid supplying arrangement (58) is configured to also supply cleaning liquid (68) to said gap (84a, b).

Owner:VERSUNI HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com