Three-axle parallel mainshaft head structure for implemonting multidirection verticel-horizontal processing

A spindle head and multi-directional technology, applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problem that vertical and horizontal processing cannot be realized, and the operating range of rotary motion is small, only about 30°~60° And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

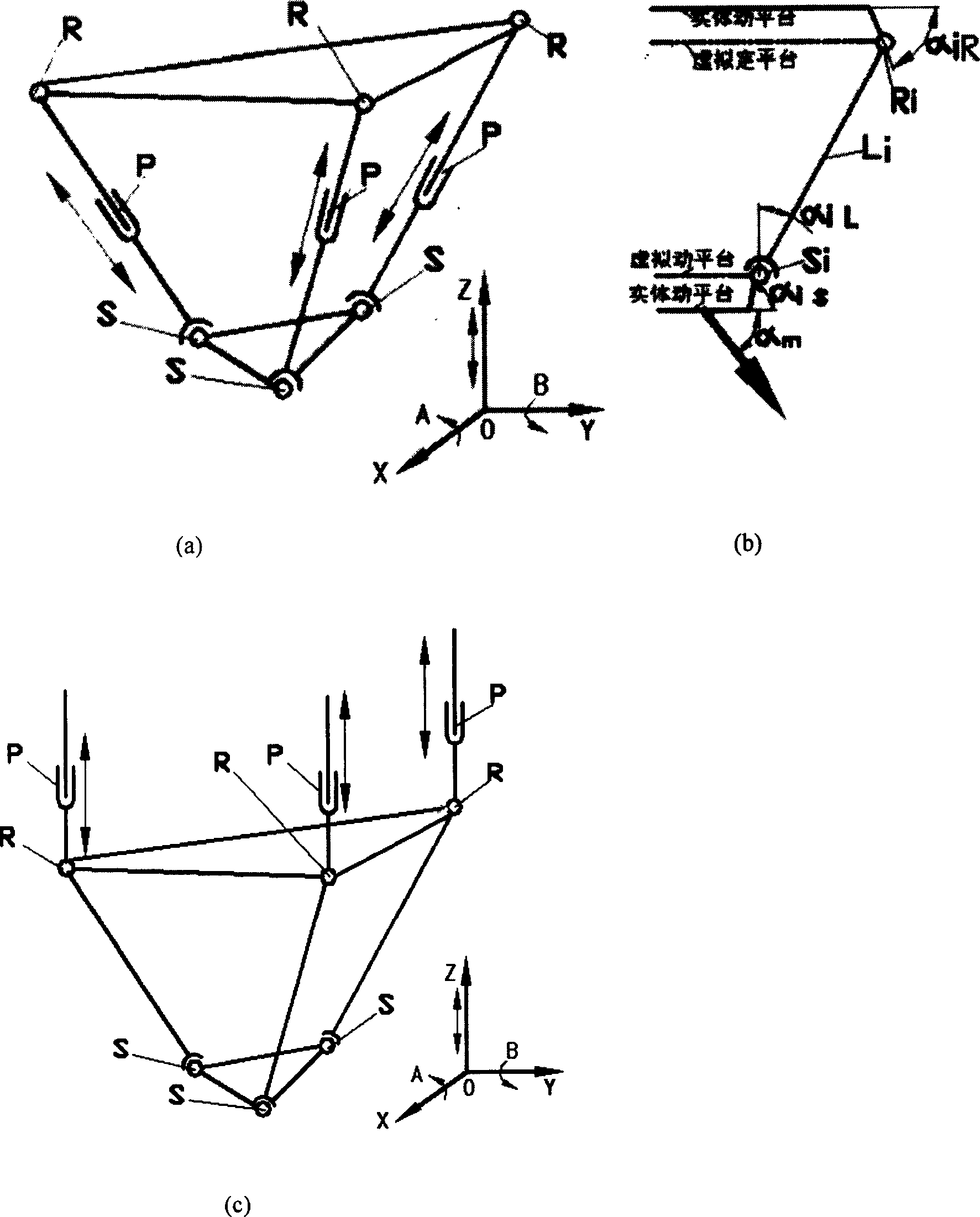

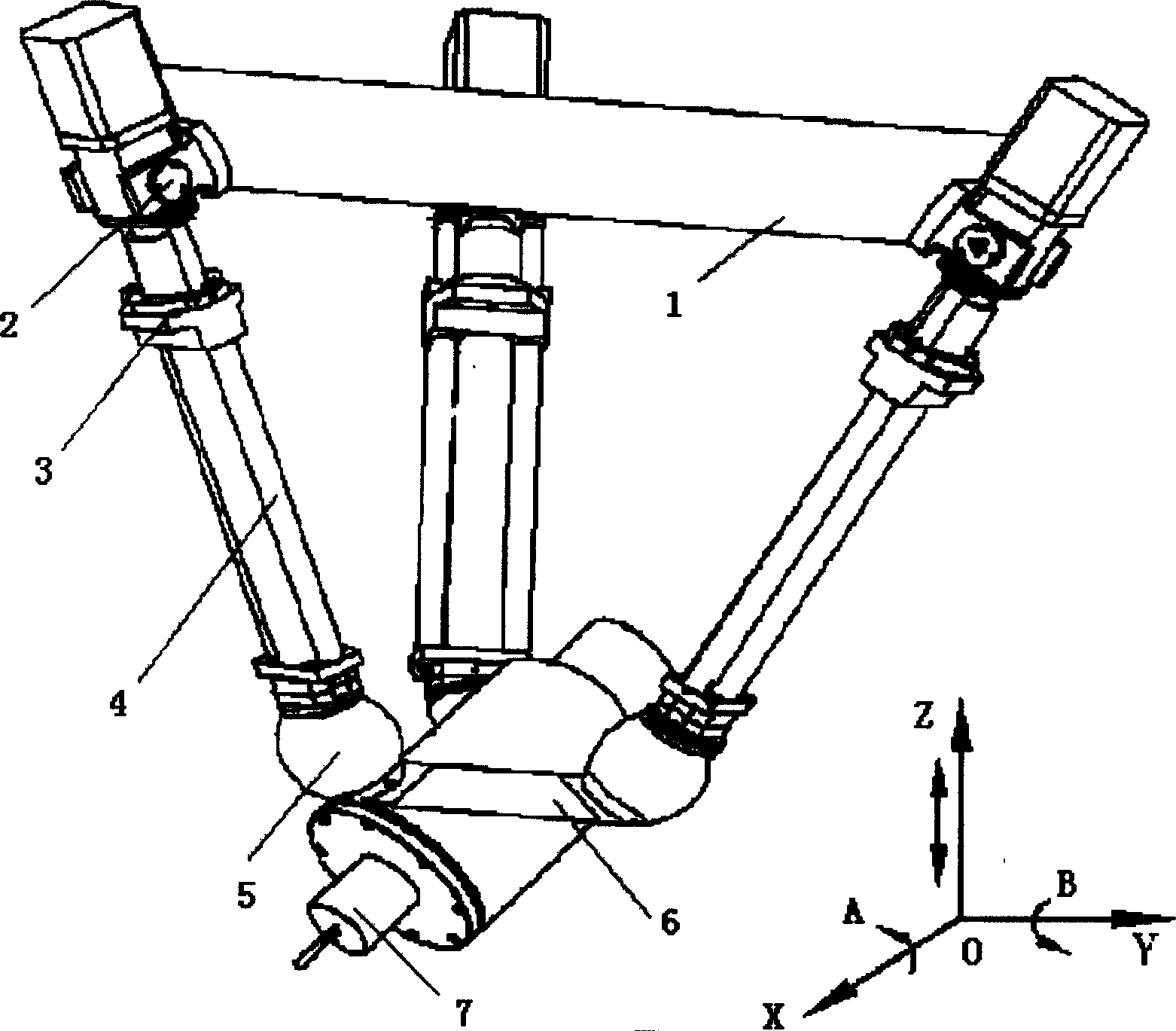

[0023] figure 2 It is a structural diagram of a 3-RPS type three-axis parallel spindle mechanism. The fixed platform 1 in the figure is connected to three rotary subassemblies 2 distributed at 120°, and the three rotary subassemblies 2 are respectively connected to three moving subassemblies 3. The three moving subassemblies 3 are respectively connected with the three rod assemblies 4, and the three rod assemblies 4 are respectively connected with the three spherical subassemblies 5, and the three spherical subassemblies 5 are connected with the moving platform 6 in 120° distribution, and the moving platform 6 is connected with the moving platform 6. The main shaft part 7 is connected. The three moving pairs are active motion pairs, which are respectively driven by servo motors, or can be driven by hydraulic pressure. The main shaft components are AC servo electric spindles, or variable frequency electric spindles.

Embodiment 2

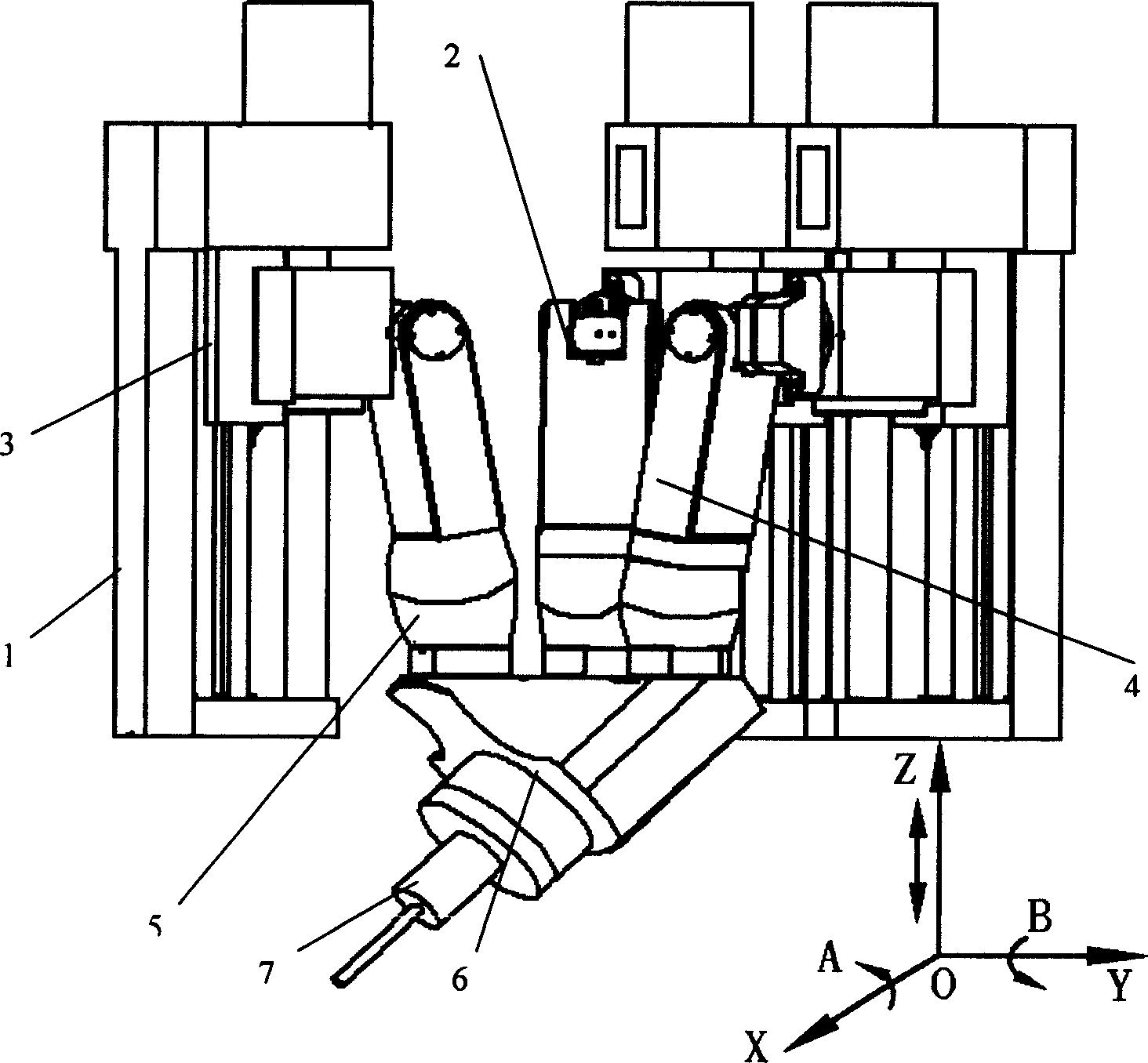

[0025] image 3 It is the structural diagram of the 3-PRS type three-axis parallel spindle mechanism, and its implementation method is the same as figure 2 Similar, but the difference is that the linear movement pair of the parallel spindle head mechanism is in the front, and the rotary pair is behind. The A-axis and B-axis of the mechanism also exceed 90°, which can realize vertical and horizontal machining.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com